Metal pipeline welding device for water conservancy construction

A technology for metal pipes and welding devices, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor adjustment of pipes and welding angles, and the inability to achieve high-quality welding effects of pipes, and achieve high welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

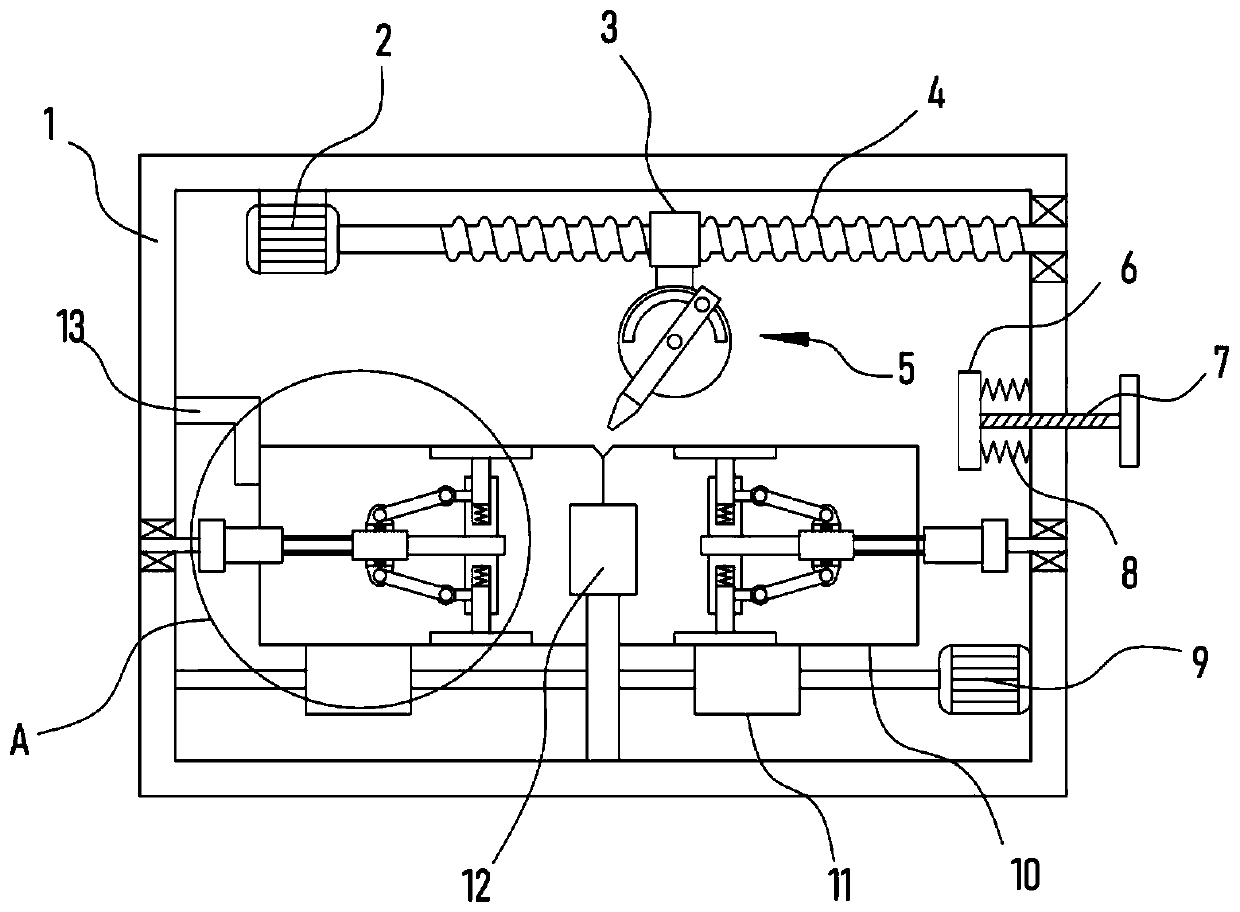

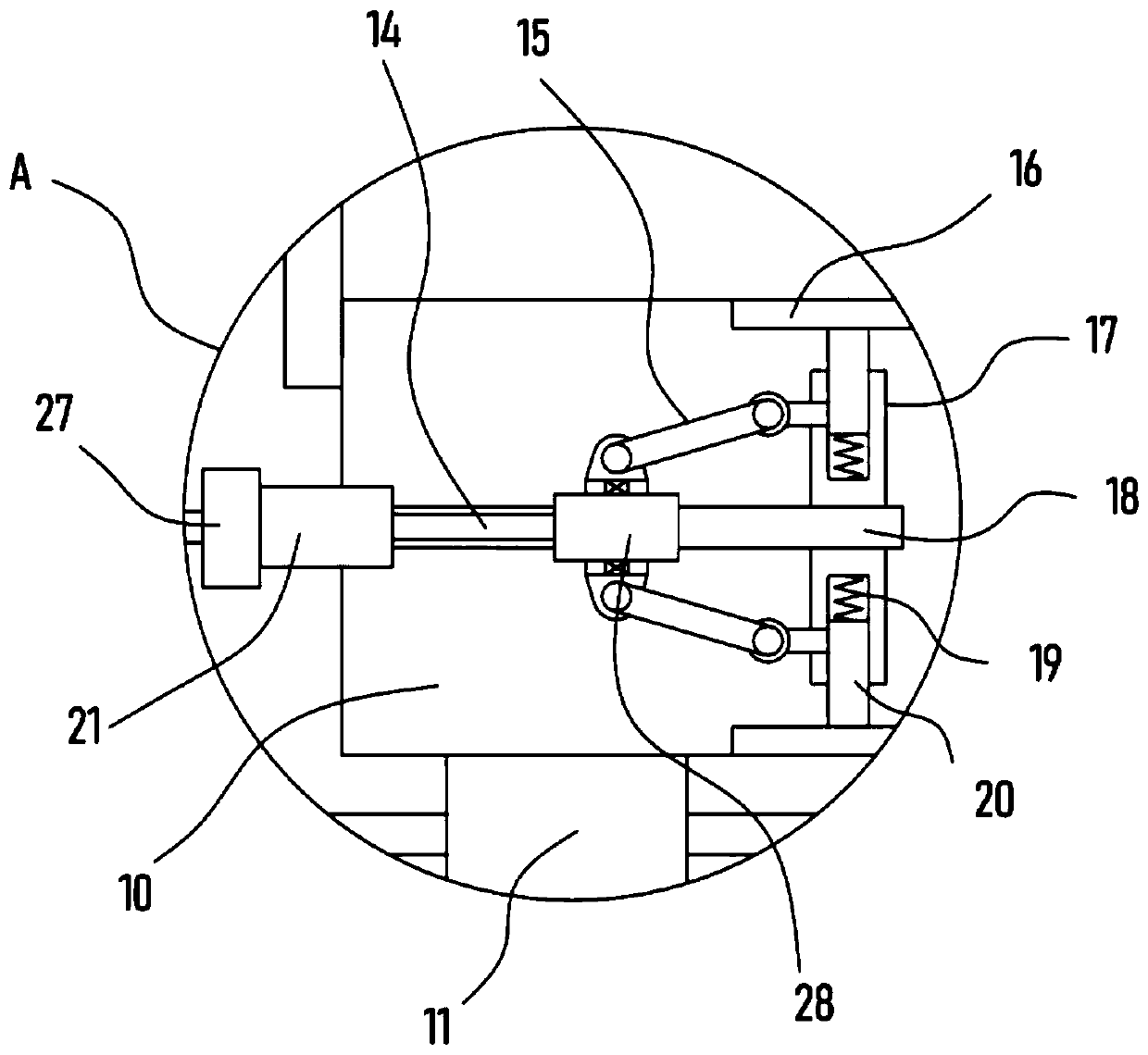

[0023] See Figure 1-5 , A metal pipe welding device for water conservancy construction, comprising a support frame 1, a servo motor 2 is fixedly installed on the top of the support frame 1, and two support limit mechanisms for supporting the pipeline 10 are provided in the support frame 1. The frame 1 is driven by a rotating motor 9 with a roller 11 for driving the pipe 10 to rotate. The pipe 10 is provided with a welding assembly 5 which is driven and connected by a translation mechanism. The welding assembly 5 includes a connecting plate 24. The welding gun 25 connected to the steering mechanism.

[0024] Before welding, after the two pipes 10 are connected, they are supported and fixed from the inside of the pipe 10 through the set supporting and limiting mechanism, and the welding assembly 5 used for welding is driven by the translation mechanism to move to the vicinity of the joint of the pipe 10 and adjusted by the steering mechanism The welding torch 25 faces the butt jo...

Embodiment 2

[0029] On the basis of embodiment 1, in order to facilitate the movement of the welding assembly 5 to the welding position, the translation mechanism provided in the device includes a screw rod 4 coaxially fixed with the output shaft of the servo motor 2, and a threaded sleeve is threaded on the screw rod 4 Block 3, the threaded sleeve block 3 and the welding assembly 5 are fixedly connected. The servo motor 2 is used to drive and rotate the screw rod 4. The screw rod 4 drives the threaded block 3 to move laterally, and then drives the welding assembly 5 to move to the position where the two pipes 10 are connected. The position of the welding assembly 5 is adjusted smoothly and accurately .

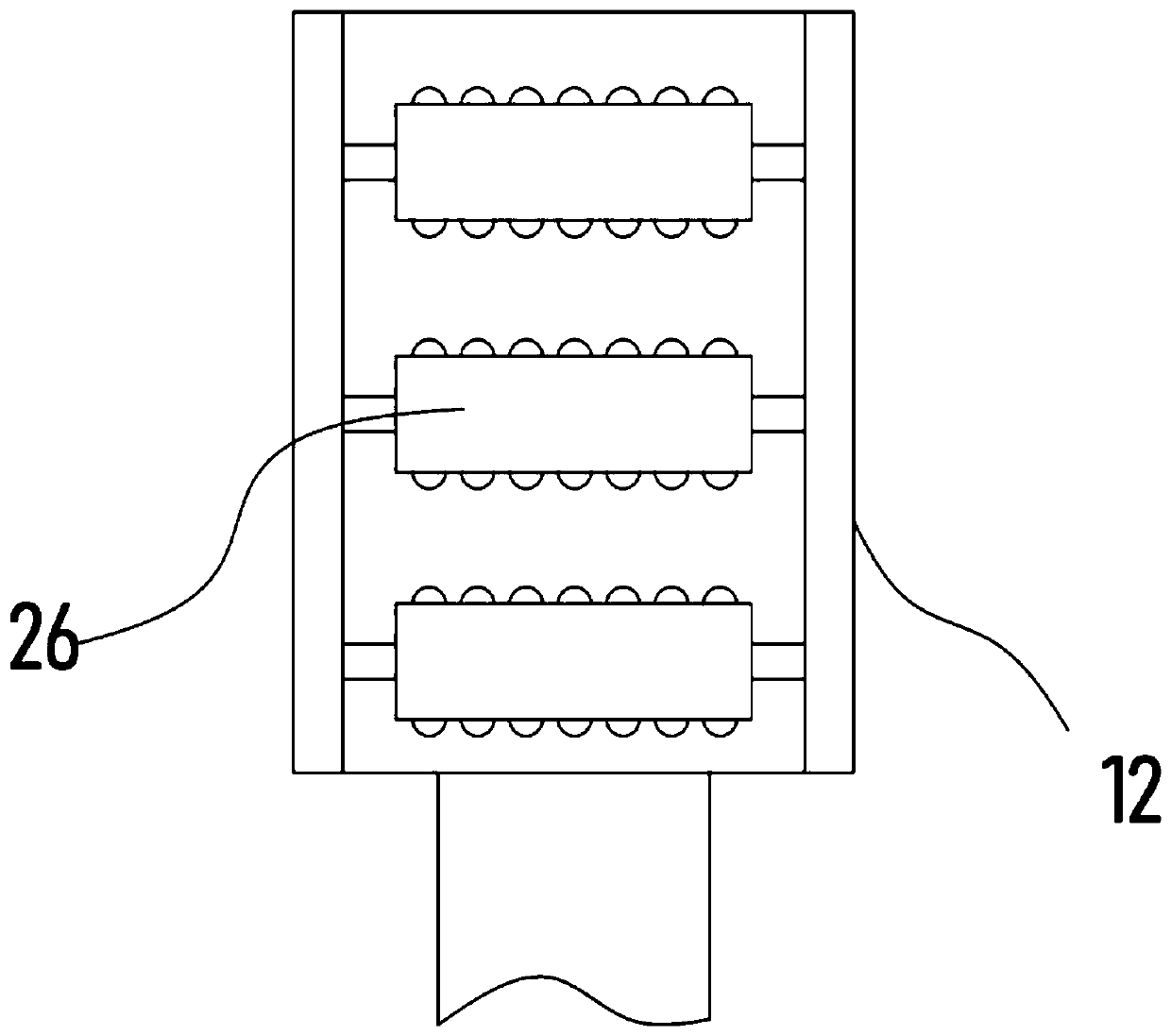

[0030] Due to the different welding processes when welding different pipes 10, the welding angle needs to be adjusted adaptively. For this reason, the connecting plate 24 is fixed at the bottom of the threaded block 3, and the steering mechanism includes a locking stud threaded through the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com