Four-wheel synchronous rail change welding material transfer trolley

A transfer vehicle and material technology, applied in the direction of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of limited carrying capacity, high production cost, complex structure, etc., and achieve improved production efficiency, large load tonnage, and compact structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be further completely and clearly described below in conjunction with the accompanying drawings. Other scheme drawings can be obtained under the premise of creative improvement.

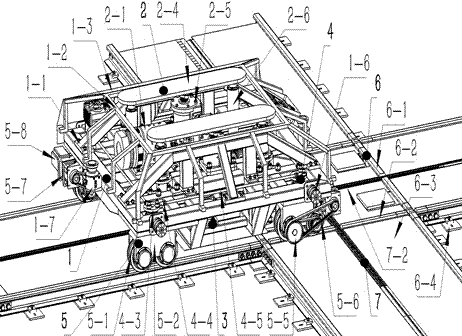

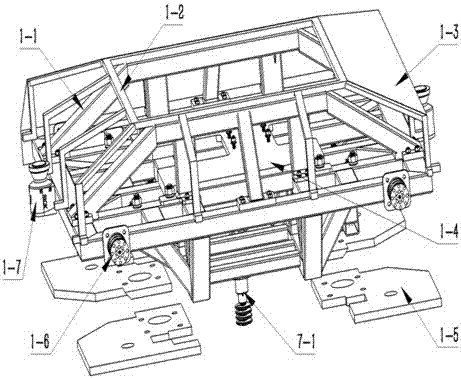

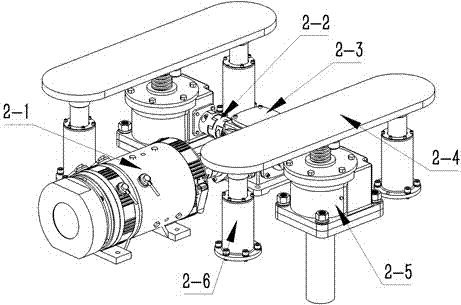

[0021] refer to Figure 1 to Figure 5 As shown, a four-wheel synchronous track-changing welding material transfer vehicle includes a vehicle body 1, a workpiece lifting mechanism 2, a vehicle body lifting mechanism 3, a reversing mechanism 4, a traveling mechanism 5, a track 6 and a sliding electric pick-up 7. The workpiece lifting mechanism 2 is fixed on the lifting and fixing steel plate 1-4 of the body 1 by bolts, the body lifting mechanism 3 is installed in the square steel pipe welding frame 1-1 of the body 1, and the traveling mechanism 5 is fixed on the body 1 by four bolts. On the load-bearing steel plate 1-5 at the corner, the reversing mechanism 4 is connected with the traveling mechanism 5 through the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com