Novel transverse elasticity positioning method of side-rolling resistant torsion bar for railway vehicle and device of method

An anti-roll torsion bar and elastic positioning technology, which is applied to bogies, transportation and packaging, railway car body parts, etc., can solve the problem that the anti-roll torsion bar system cannot effectively perform lateral positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

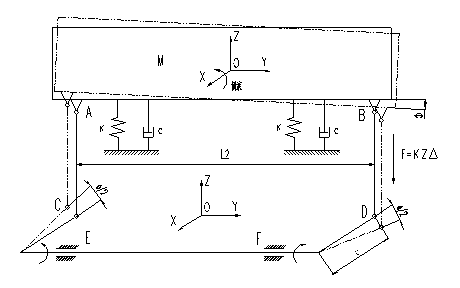

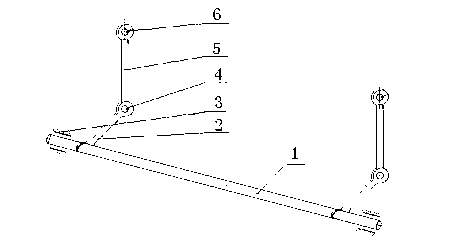

[0031] In order to explain the technical solutions of the embodiments of the present invention more clearly, the following will briefly introduce the drawings used in the description of the embodiments. Obviously, the drawings in the following description are only some embodiments of the present invention. A person of ordinary skill in the art can obtain other drawings based on these drawings without creative work.

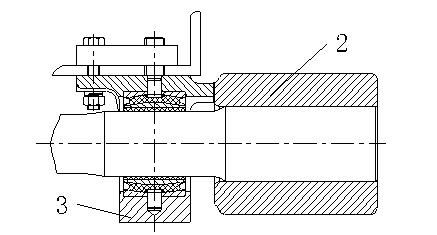

[0032] As attached Figure 7 As shown in the first embodiment, the present invention provides a new type of lateral elastic positioning method for anti-rolling torsion rods for rail vehicles. Firstly, a groove is opened at the opposite assembly end of the supporting seat 3 and the torsion arm 2; An elastic thrust pad 12 is provided between the torsion arm 2 and the elastic thrust pad 12 is a two-half structure, which facilitates the assembly and use of the elastic thrust pad 12, including the left end cover 7, the right end cover 10, the rubber 8 and the partition 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com