High-efficiency shock-absorbing permanent magnet motor

A permanent magnet motor, high-efficiency technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of inconvenient disassembly and maintenance of permanent magnet motors, reduce the service life of the motor, reduce work efficiency, etc., and achieve simple structure, extended The effect of ensuring service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

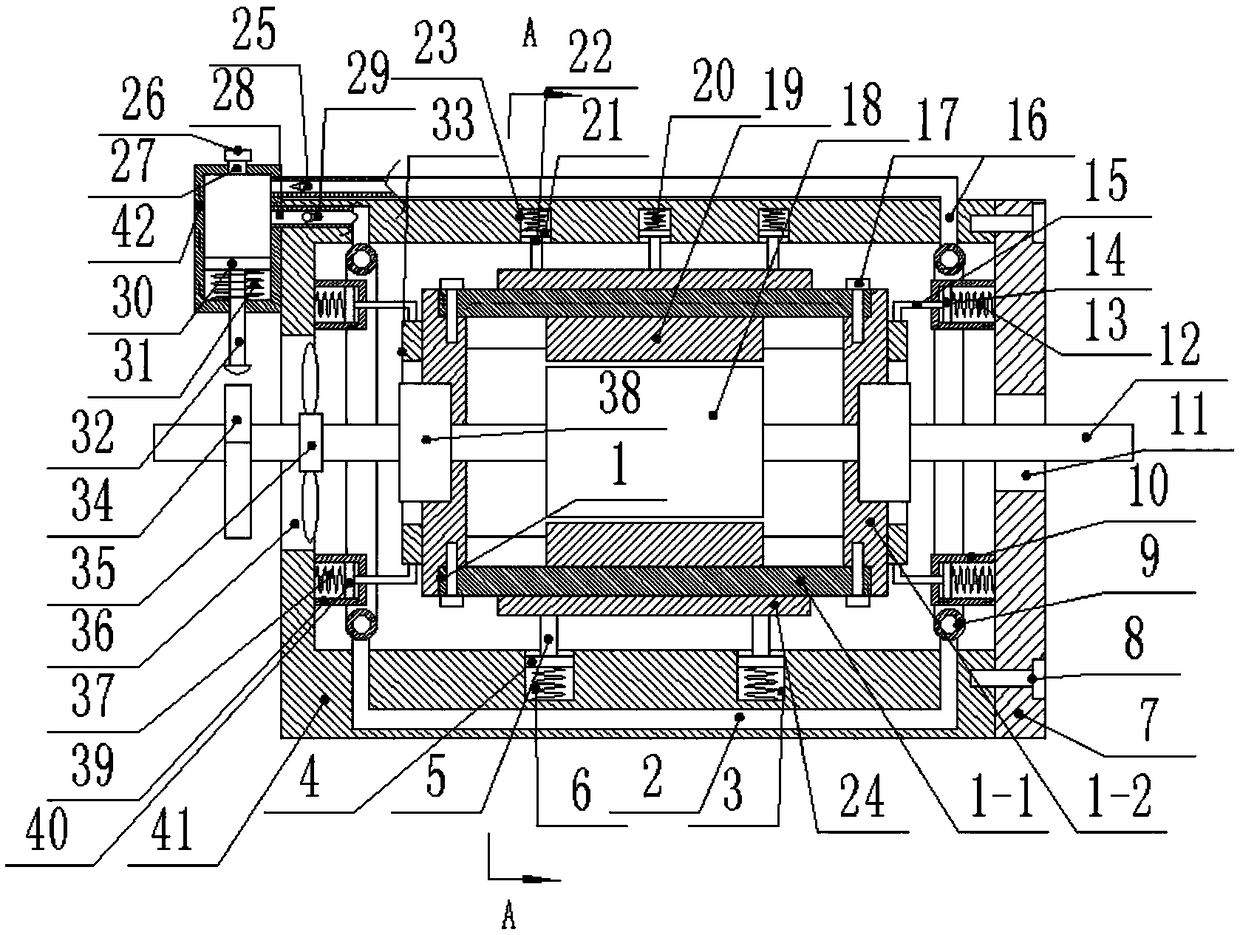

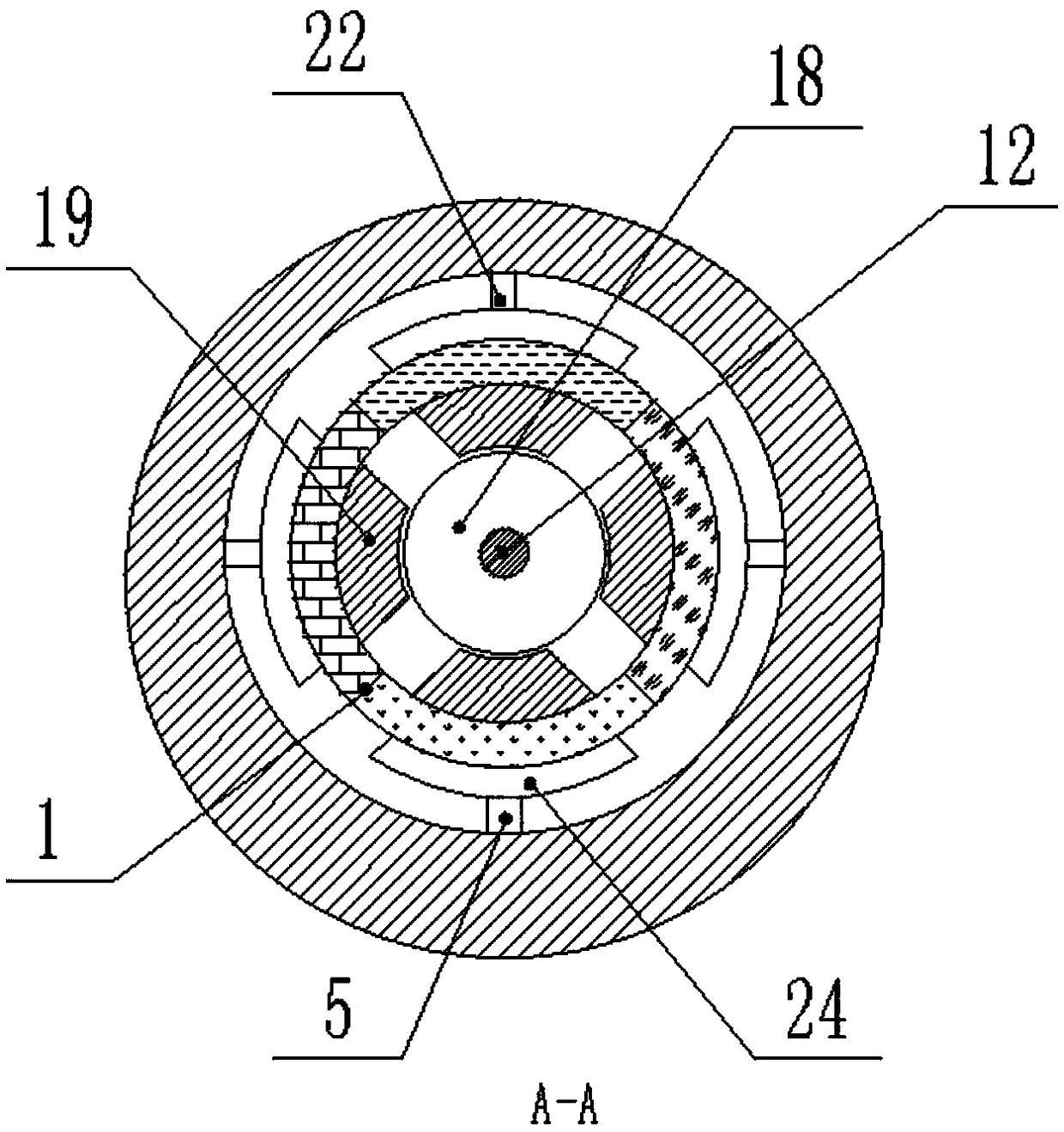

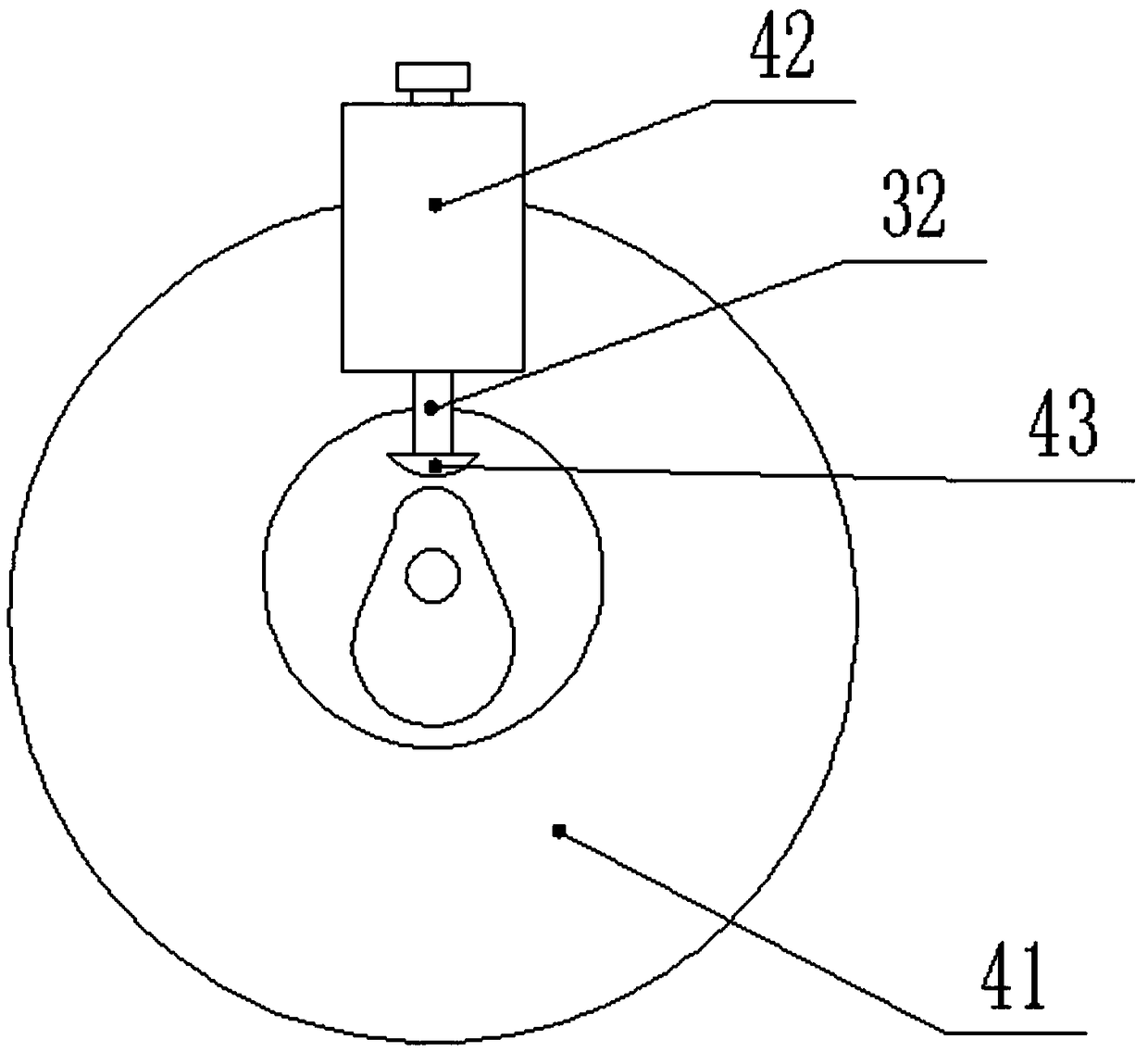

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a high-efficiency shock-absorbing permanent magnet motor includes a motor base shell 1, and the motor base shell 1 is composed of four arc-shaped plates 1-1 and two circular plates 1-2, and the four arc-shaped plates 1 The side walls of -1 are sequentially connected and distributed in a ring shape. The two ends of the four arc-shaped plates 1-1 are respectively embedded in the two circular plates 1-2, and the upper four corners of each arc-shaped plate 1-1 pass through the second round plate. The bolts 17 are fixedly connected to the circular plates 1-2 at both ends, the outer middle of each arc-shaped plate 1-1 is fitted with an arc-shaped splint 24, and the inner side of each arc-shaped plate 1-1 is fixedly connected with a stator 19, The center of the four arc-shaped plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com