Coated sandwich cake and production process and production line thereof

A production process and production line technology, which is applied in the field of coated layer cake and its production process and production line, can solve the problems such as poor taste of the cake, and achieve the effects of maintaining and strengthening nutrients, high production efficiency, and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

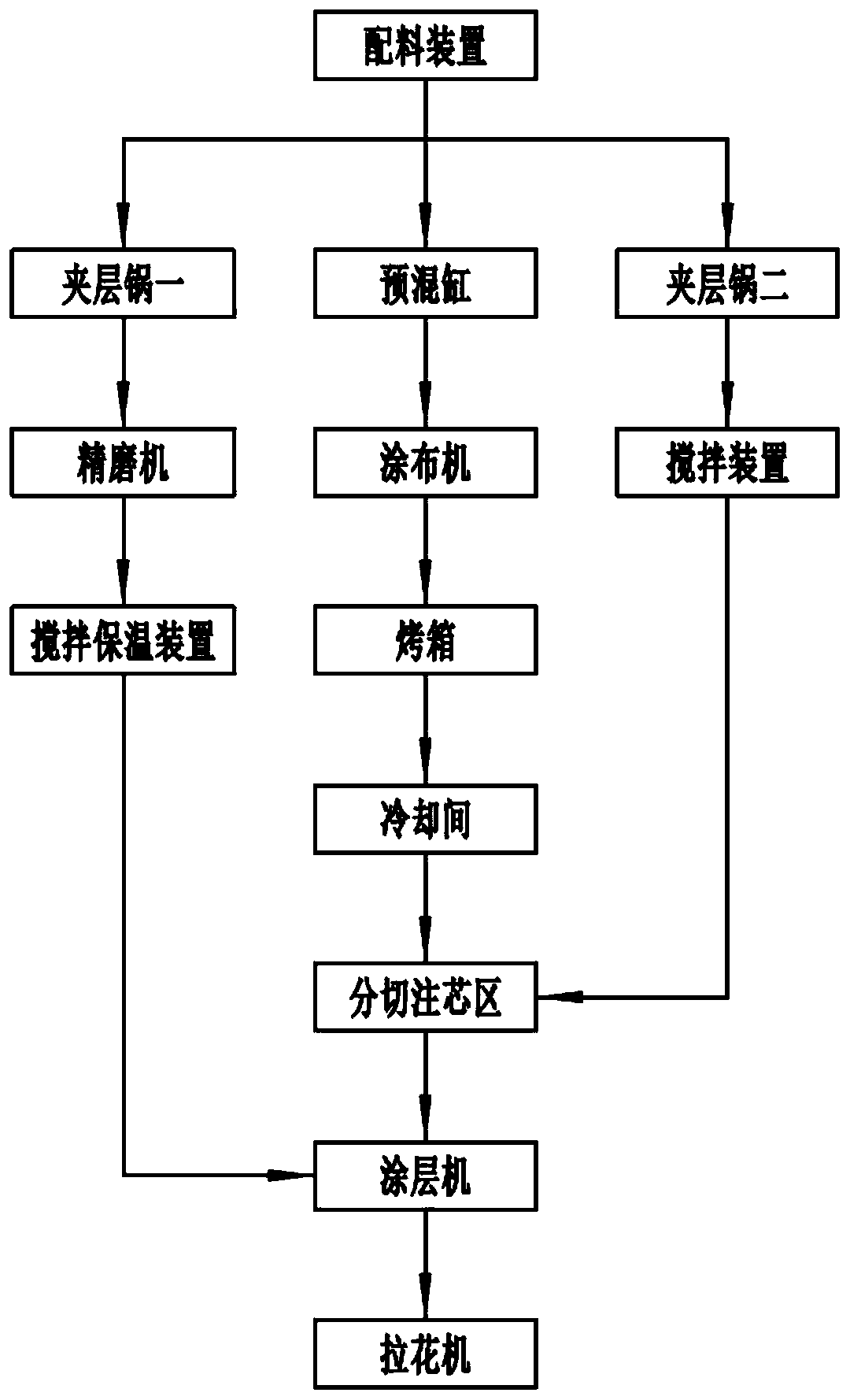

[0042] A kind of coated layer cake and its production process

[0043] Coated layer cake, produced by the following process:

[0044] Step S10, ingredients: weighing the raw materials for preparing the coated layer cake;

[0045] Step S20, refining and keeping the slurry warm: Melt 0.35kg of anhydrous cream and 8kg of cocoa butter substitute in a clamping pot, then transfer them to the refining machine, start the refining machine, and add 0.2kg of glucose, 9kg of sugar, 3kg of whey powder, 1.2kg of lactose, 1.5kg of whole milk powder, grind for 10 hours, add 0.09kg of soybean lecithin after the fineness of the slurry reaches below 50 microns, continue grinding for 1 hour, and stir at 58°C Insulation to obtain coating slurry;

[0046] Step S30, boil the syrup: pour 4kg of water into the jacketed pot and boil, add 0.35kg of glucose, boil until boiling, then add citric acid, boil for 8 minutes, then add 6kg of maltose powder, boil until boiling, then add 0.75g of sorbic acid P...

Embodiment 2

[0054] A kind of coated layer cake and its production process

[0055] Coated layer cake, produced by the following process:

[0056] Step S10, ingredients: weighing the raw materials for preparing the coated layer cake;

[0057] Step S20, refining and keeping the slurry warm: Melt 0.25kg of anhydrous butter and 7kg of cocoa butter substitute in a clamping pot, then transfer to the refining machine, start the refining machine, and add 0.15kg of glucose, 6kg of The white sugar of 2kg, the whey powder of 2kg, the lactose of 0.8kg, the whole milk powder of 1kg are ground, grind for 8 hours, add the soybean lecithin of 0.06kg after the fineness of the slurry reaches below 50 microns, continue to grind for 1 hour, get coated Layer the slurry, and put it under stirring at 55°C for heat preservation;

[0058] Step S30, boiling syrup: pour water into a jacketed pot and boil, add 0.3kg of glucose, boil until boiling, then add citric acid, cook for 5-10 minutes, then add 5kg of maltos...

Embodiment 3

[0066] A kind of coated layer cake and its production process

[0067] Coated layer cake, produced by:

[0068] Step S10, ingredients: weighing the raw materials for preparing the coated layer cake;

[0069] Step S20, refining and keeping the slurry warm: Melt 0.45kg of anhydrous butter and 9kg of cocoa butter substitute in a chuck, then transfer to the refining machine, start the refining machine, and add 0.25kg of glucose, 12kg of The white sugar of 4kg, the whey powder of 1.6kg, the lactose of 1.6kg, the whole milk powder of 2kg are ground, grind for 12 hours, add the soybean lecithin of 0.12kg after the fineness of the slurry reaches below 50 microns, continue to grind for 1 hour, get coated Layer the slurry, and place it at 60°C with stirring and heat preservation;

[0070] Step S30, boil the syrup: pour water into the jacketed pot and boil, add 0.4kg of glucose, boil until boiling, then add citric acid, boil for 10 minutes, then add 7kg of maltose powder, boil until bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com