Packaging carton handle flexible automatic mounting production line

A technology of automatic installation and carton handles, applied in the field of automatic production lines and packaging machinery design, can solve the problems of time-consuming, laborious and high installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

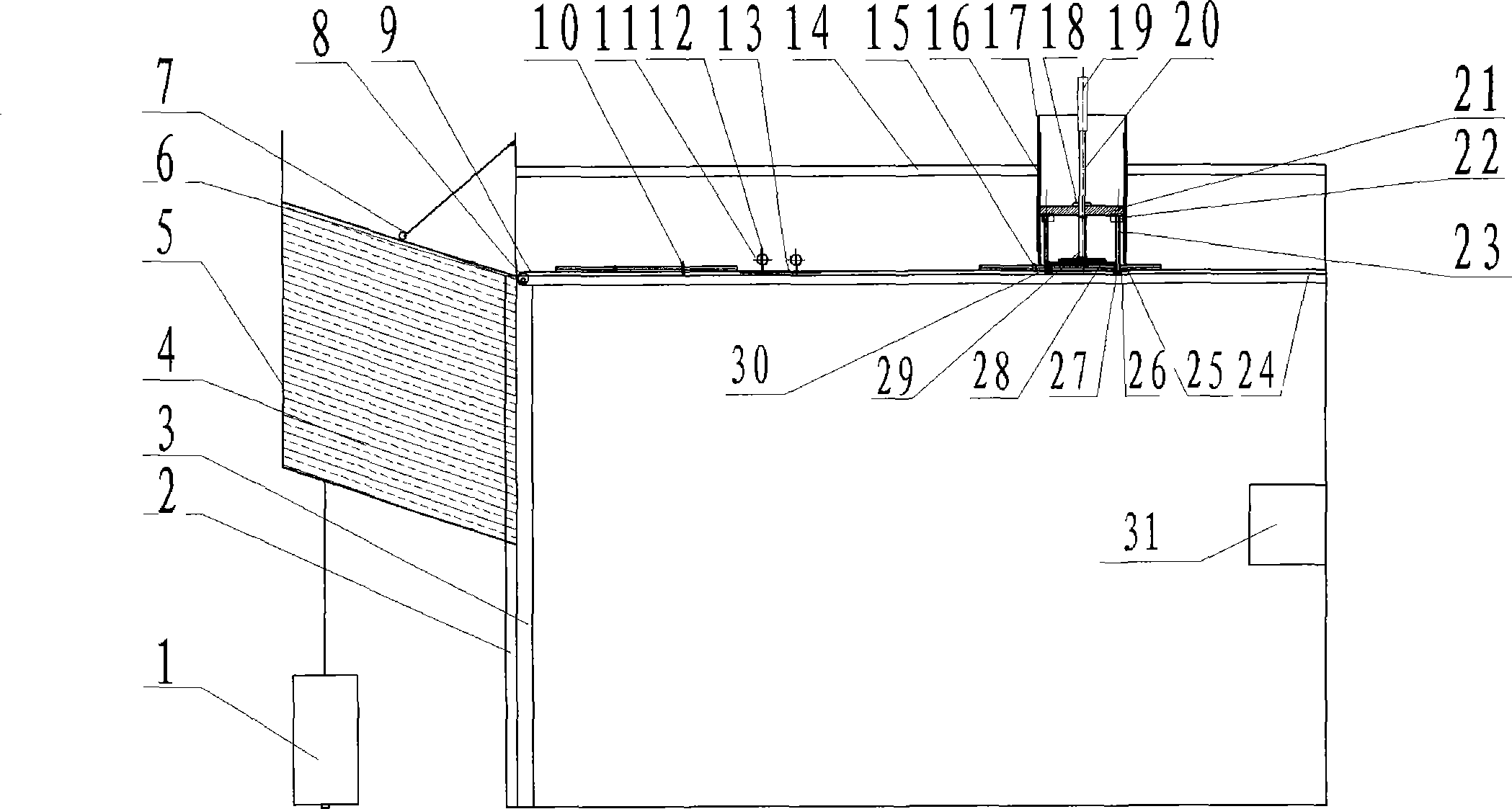

[0017] The present invention will be described in detail below in conjunction with the drawings.

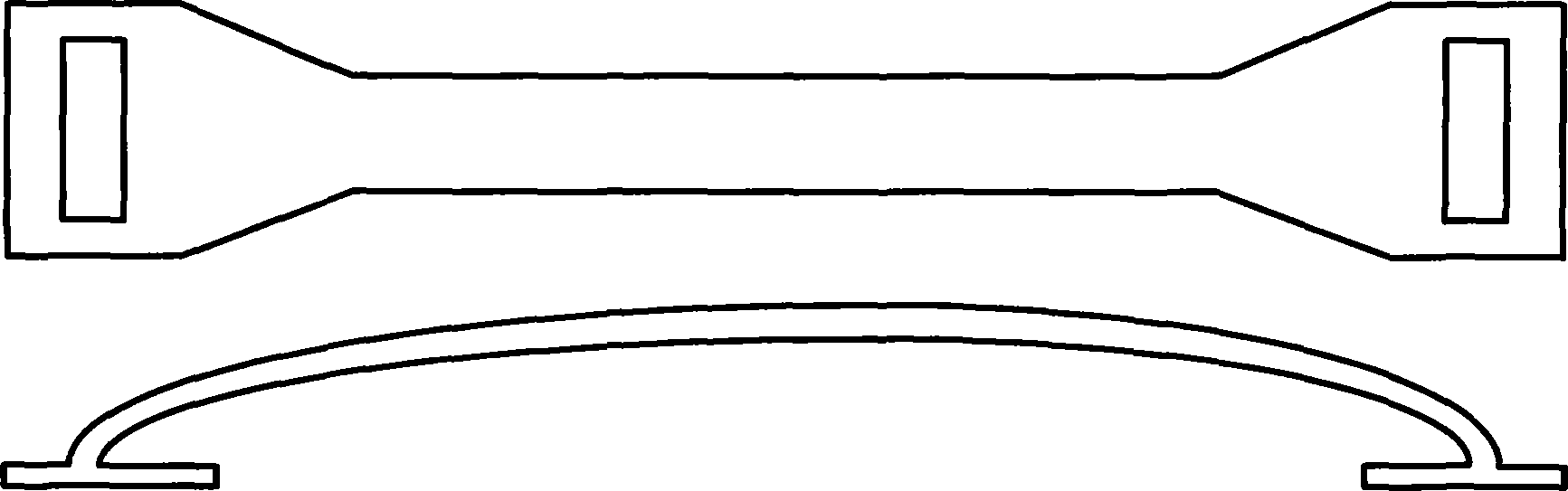

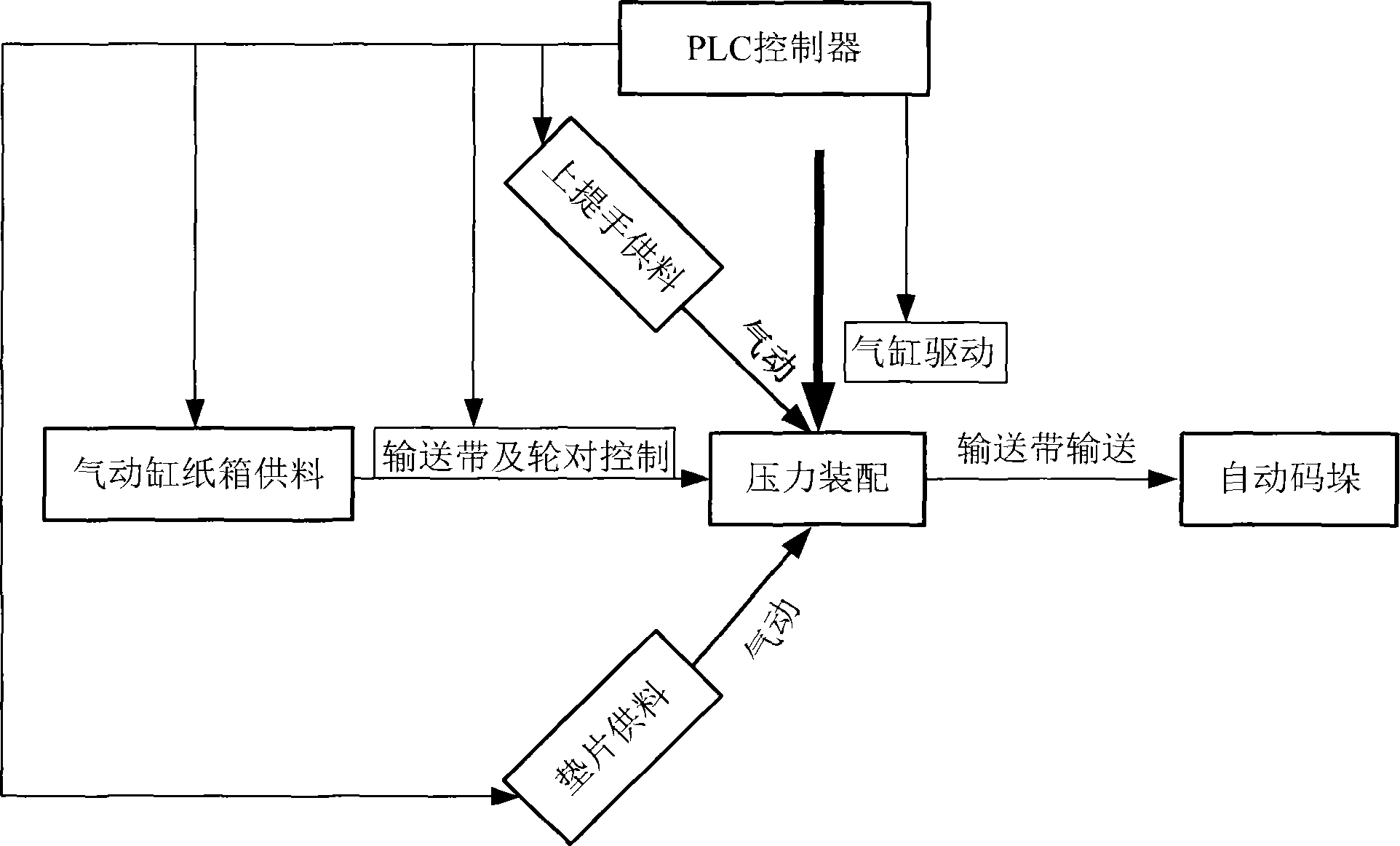

[0018] The packaging carton handle flexible automatic installation production line of the present invention is a device that automatically transports the carton and the carton installation handle and gasket to a designated position and can realize automatic compression and automatic installation of the handle. The automatic production line transfers the carton by The conveyor belt is conveyed to the set station, and the automatic installation part of the handle automatically completes the feeding and assembly operations of the upper handle and the gasket.

[0019] The specific workflow is as figure 2 As shown, the pneumatic cylinder feeds the cartons onto the conveyor belt, and the conveyor belt drives the cartons forward, and is rolled by the wheels during the forward movement, so that the cartons are flattened and the cartons move within the set width range. After the carton reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com