Flexible material filling and pointing machine, and concrete deck joint method

A technology for concrete panels and flexible fillers, applied in ceramic molding machines, dams, sea area projects, etc., can solve the problems of difficult embedding and filling, difficult operation, low efficiency, etc., and achieve the effect of easy embedding and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

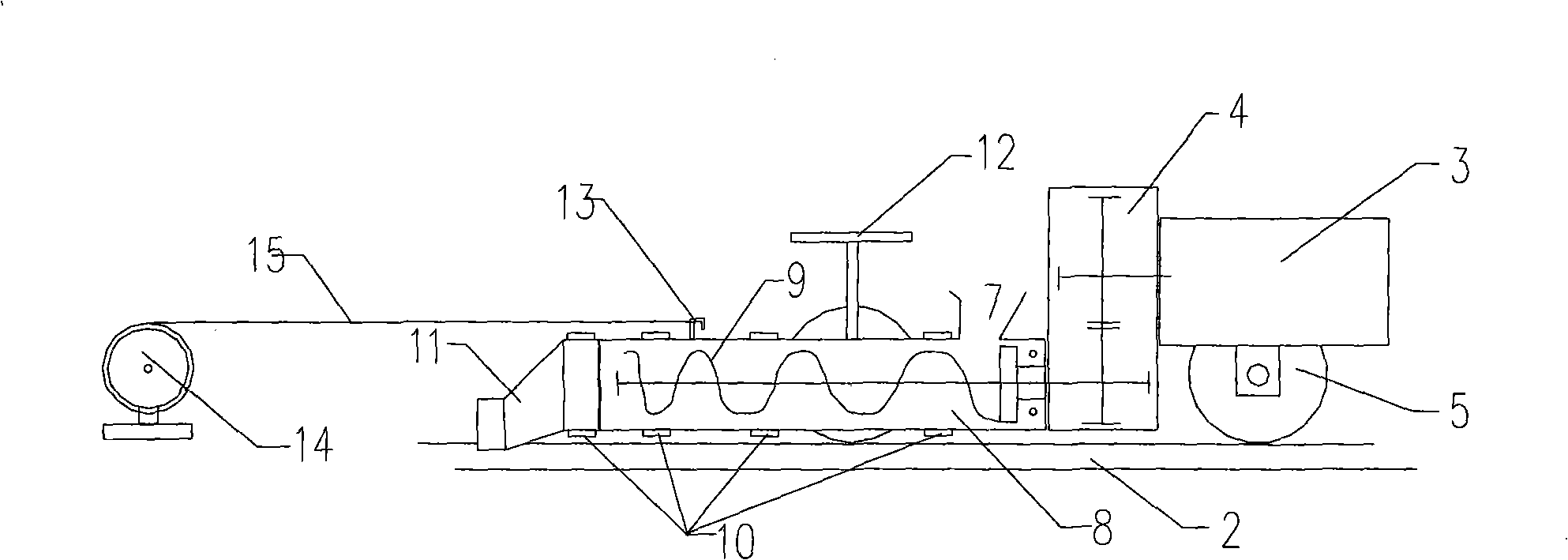

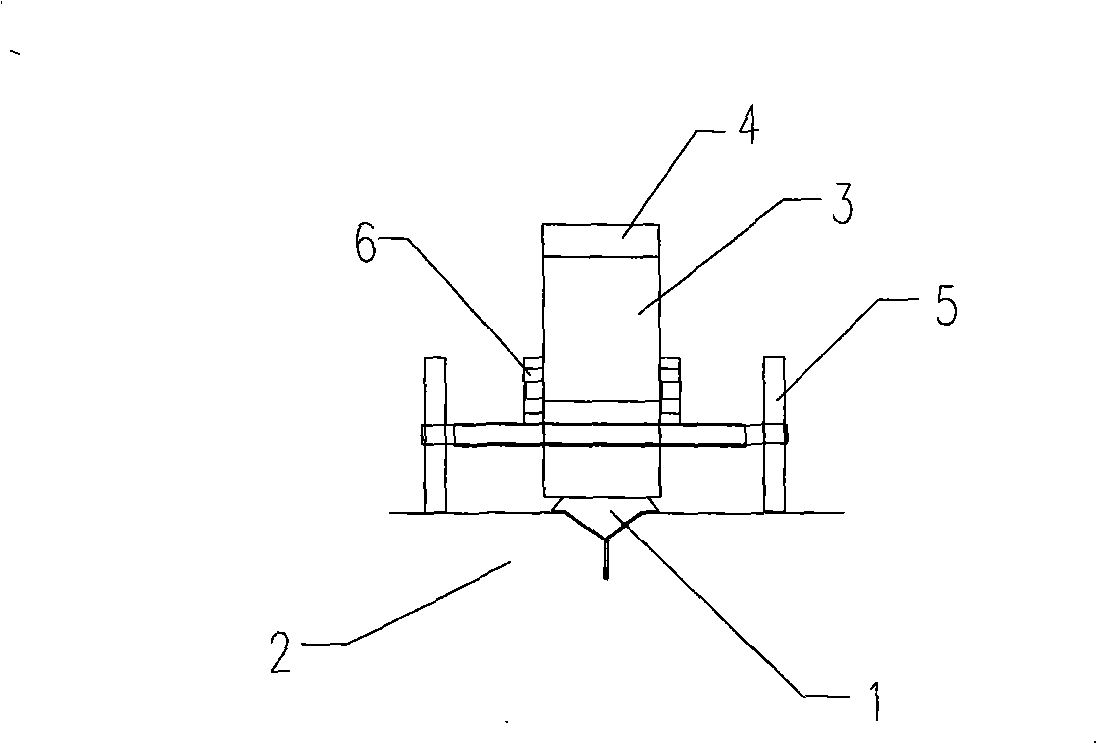

[0033] Such as figure 1 with figure 2 As shown, the flexible filler 1 is filled into the stuffing chamber 8 from the feed port 7, the power machine 3 drives the extruding screw 9 to rotate after passing through the governor 4, the heater 10 raises the temperature of the stuffing in the stuffing chamber 8, and is extruded The role of the pressure screw 9 is to extrude from the die opening of the die head 11; the walking part of the filling machine includes support wheels 5, the steering device 12 and the height adjustment device 6 of the fuselage, and the traction part of the filling machine includes a hoist 14, a hook 13 and Wire rope 15.

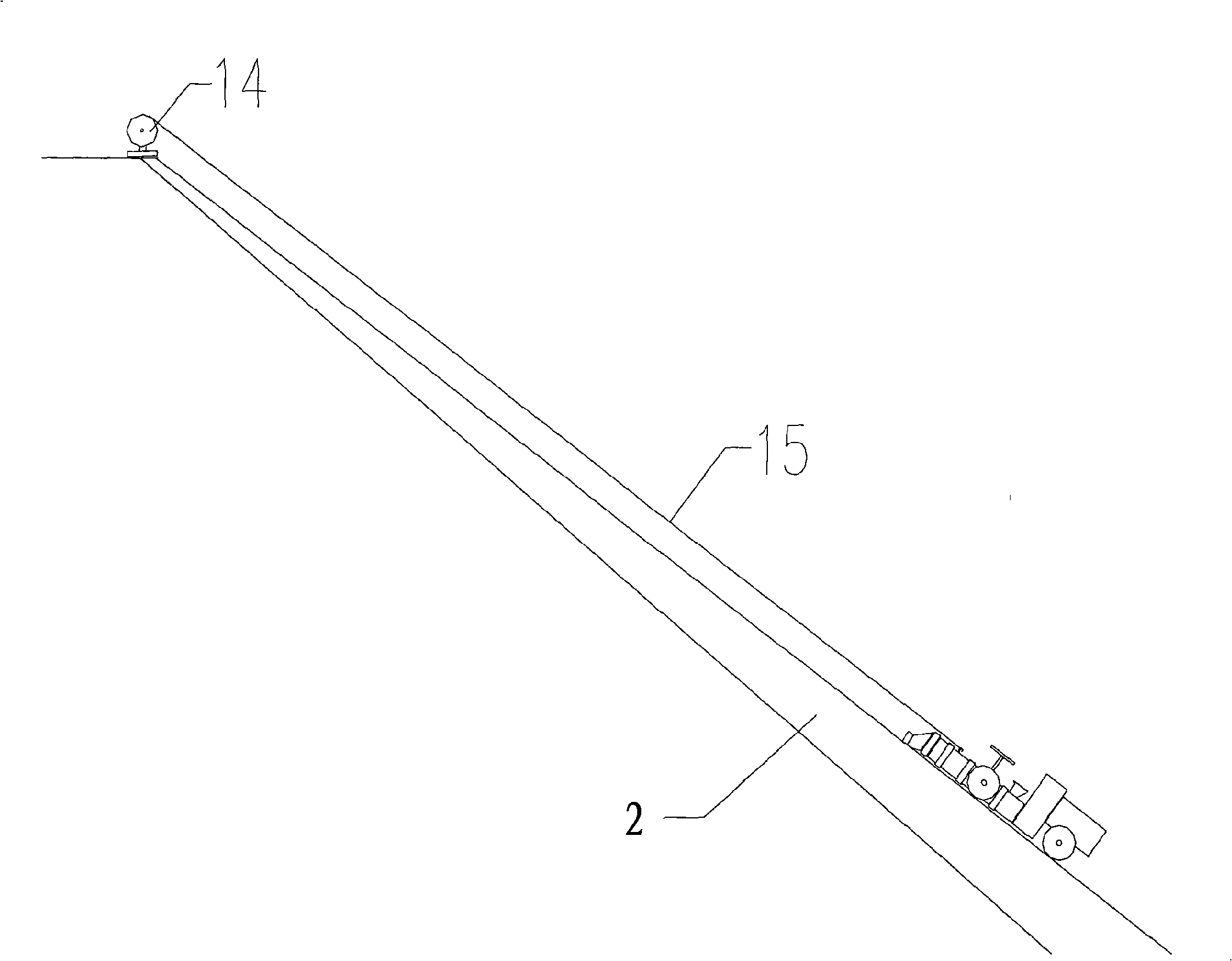

[0034] The filling machine operates as image 3 As shown, the hoist 14 fixed on the top of the dam pulls the main machine across the gap on the concrete panel 2 through the wire rope 15; At the place, the embedded filling machine can better realize the embedded filling that is not directly up and down along the dam surface through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com