Automatic aluminum foil wrapping equipment for refrigerator air return pipe

A technology of air return pipe and aluminum foil, which is applied in the directions of wrapping objects, packaging, transportation and packaging, etc., can solve the problems of manual wrapping aluminum foil positioning difference, high labor intensity, and difficulty in ensuring the consistency of aluminum foil wrapping length and position, saving manpower, The effect of improving production efficiency and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

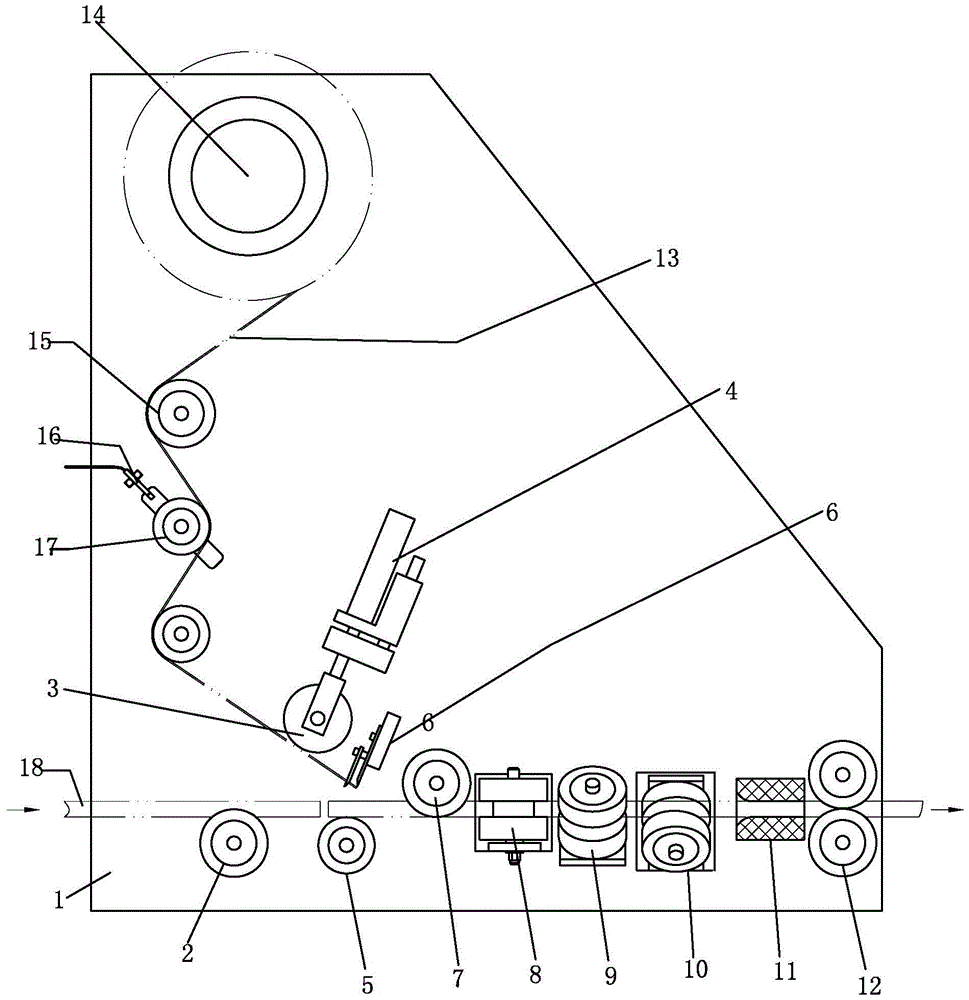

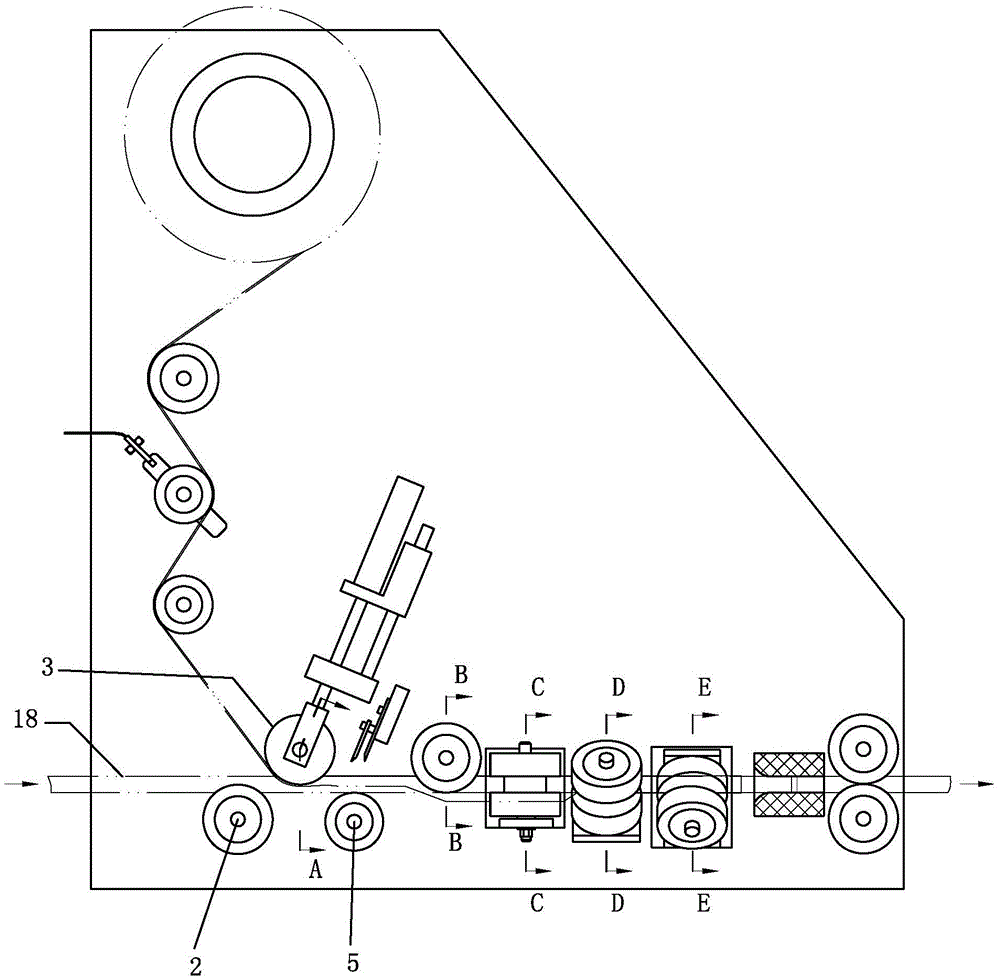

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

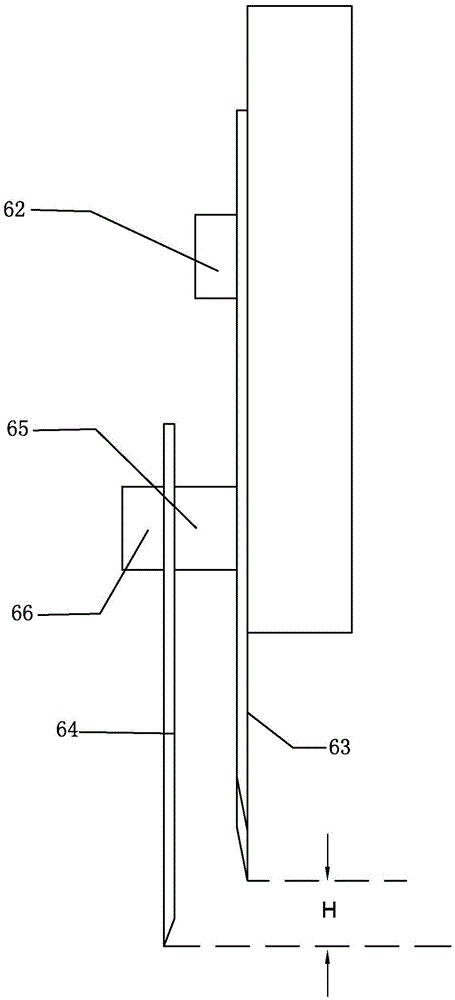

[0028] In the figure: 1, base plate; 2, front guide wheel; 3, pressure wheel; 4, cylinder; 5, support wheel; 6, blade; 61, mounting seat; 62, locking screw; 63, cutter; 64, hanging knife ;65, pad cover; 66, adjusting screw; 7, upper forming wheel; 8, side forming wheel; 9, outer inclined forming wheel; 10, inner inclined forming wheel; 11, guide connecting cylinder; 12, rear guide wheel; 13 , aluminum foil; 14, material roller; 15, positioning roller; 16, sensor; 17, rotary vane roller; 18, return air pipe.

[0029] Such as figure 1 , figure 2 As shown, the present invention discloses a processing equipment for automatic wrapping of refrigerator air return pipe aluminum foil, including a base plate 1, a front guide wheel 2, a pressure wheel 3, a cylinder 4, a support wheel 5, a blade 6, an upper forming wheel 7, and a side forming wheel 8 , Outer inclined forming w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com