Wood softening agent and preparation method, wood softening method and wood slice manufacturing method

A softener and wood technology, applied in the field of wood anatomy, can solve the problems of time-consuming and low efficiency, and achieve the effects of reducing energy consumption, reducing stiffness, and shortening softening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

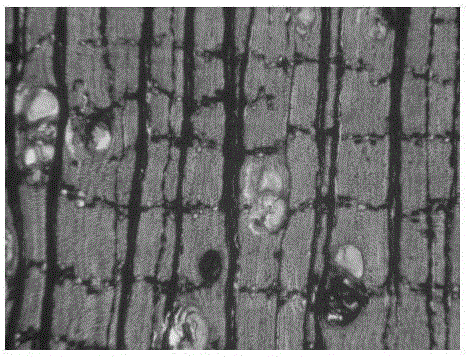

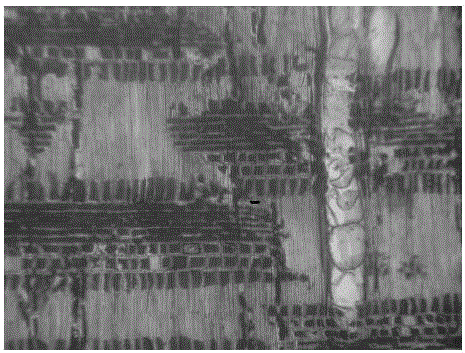

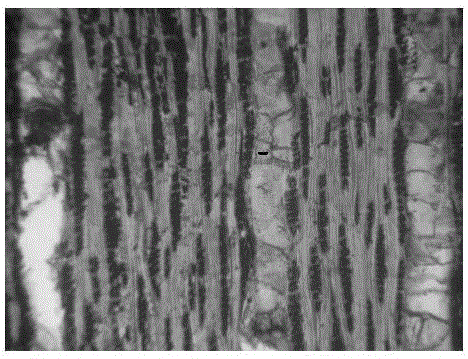

Image

Examples

Embodiment 1

[0046] This embodiment provides a wood softener, which includes lithium chloride, N,N-dimethylacetamide and water, and the ratio of the three substances is 1:4:18.

[0047] This embodiment provides the preparation method of the above-mentioned wood softener. When making the above-mentioned wood softener, lithium chloride and water are mixed. After the lithium chloride is completely dissolved, N,N-dimethylacetamide is added and stirred evenly.

[0048] The present embodiment provides a kind of wood softening method, uses the above-mentioned wood softening agent to soften the sweet stone fruit wood, comprises the steps:

[0049] Step 1: Saw the drupe wood into wood samples of 15mm × 15mm × 15mm. It is required that the three cross-sections of the wood, the diameter and the string, are clearly visible to form a cross-section sample of the drupe wood, a radial section sample of the drupe wood and Pimento wood string section sample;

[0050] Step 2: Put the above-mentioned sample ...

Embodiment 2

[0061]This embodiment provides a wood softener, which includes lithium chloride, N,N-dimethylacetamide and water, and the ratio of the three substances is 1:4:18.

[0062] This embodiment provides the preparation method of the above-mentioned wood softener. When making the above-mentioned wood softener, lithium chloride and water are mixed. After the lithium chloride is completely dissolved, N,N-dimethylacetamide is added and stirred evenly.

[0063] The present embodiment provides a kind of wood softening method, uses the above-mentioned wood softener to soften red ironwood, comprises the steps:

[0064] Step 1: Saw the red iron wood into a wood sample of 15mm×15mm×15mm. It is required that the three cross-sections of the wood, the diameter and the string, are clearly visible to form the cross-section sample of the red iron wood and the radial cut surface of the red iron wood. Samples and wing red iron wood string section samples;

[0065] Step 2: Put the above-mentioned sam...

Embodiment 3

[0074] This embodiment provides a wood softener, which includes lithium chloride, N,N-dimethylacetamide and water, and the ratio of the three substances is 1:4:18.

[0075] This embodiment provides the preparation method of the above-mentioned wood softener. When making the above-mentioned wood softener, lithium chloride and water are mixed. After the lithium chloride is completely dissolved, N,N-dimethylacetamide is added and stirred evenly.

[0076] The present embodiment provides a kind of wood softening method, uses the above-mentioned wood softener to soften double-column hematoxylin, comprises the steps:

[0077] Step 1: Saw the double-column hematoxylin into a wood sample of 15mm×15mm×15mm. It is required that the three cross-sections of the wood, the diameter and the chord, are clearly visible to form a double-column hematoxylin cross-section sample and a double-column hematoxylin radial section. Samples and double-column hematoxylin string section samples;

[0078] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com