Production method for flattening and slicing bamboo veneer

A production method and planing technology, which is applied in the jointing of wooden veneers, reed/straw treatment, wood compression, etc., can solve the problems of difficult continuous production, high quality of bamboo chips, and high manufacturing cost, and achieve the benefits of water Effect of heat conduction, simplification of preparation process and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

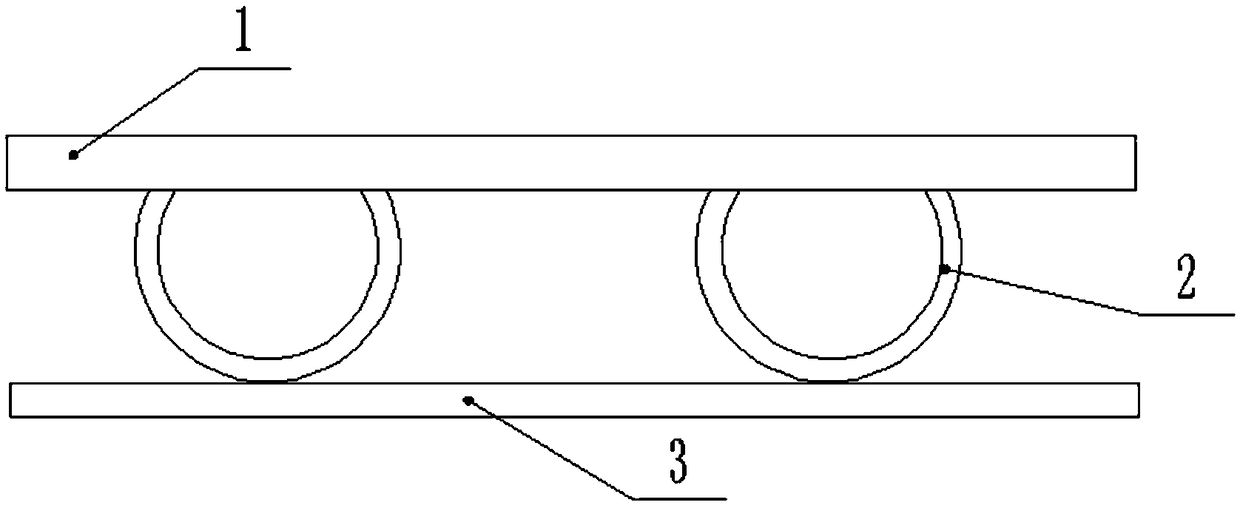

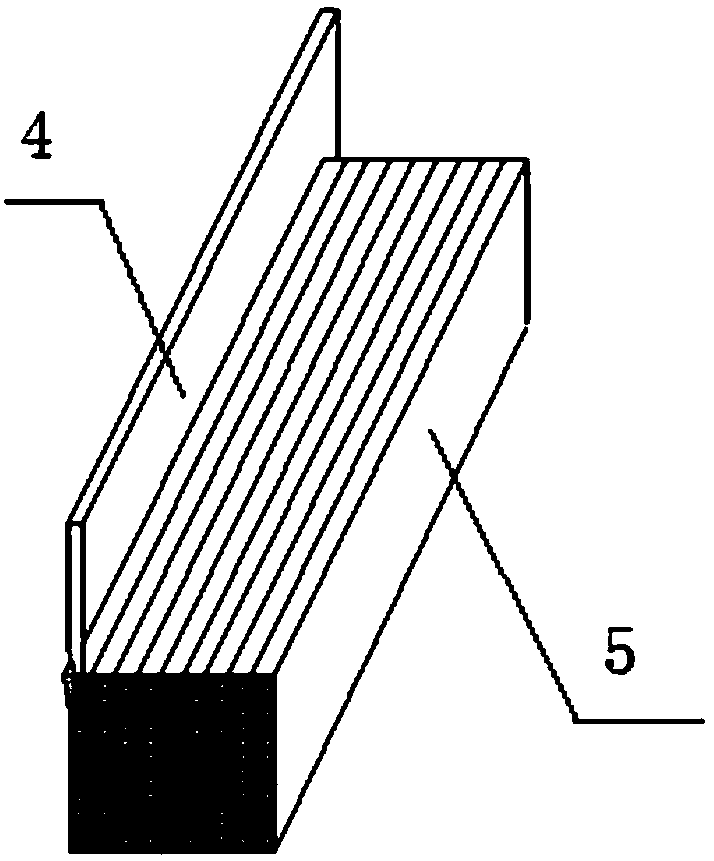

[0028] Example 1, the production specification is 2100×250×0.4mm chordwise flattened and sliced bamboo veneer, contrast figure 1 with figure 2 , The manufacturing method is as follows:

[0029] (1) Cut the bamboo with a moisture content of 25% into 2250mm long bamboo; through a device equipped with an inner milling cutter and an outer planer, the inner section, outer section, bamboo green and bamboo of the bamboo with an inner diameter of 90mm or more Remove the yellow at the same time, and use a circular saw to make a longitudinal straight seam along the bamboo axis.

[0030] (2) Fix the bamboo material 2 described in step (1) on the stainless steel backing plate 3 with a thickness of 4 mm, so that the straight slot of the bamboo material 2 faces upward. When the backing plate 3 is filled with the bamboo material 2, the backing plate 3 containing the bamboo material 2 is pushed onto the pressure plate of the built-in compressor of the high-temperature steam pressure tank, and t...

example 2

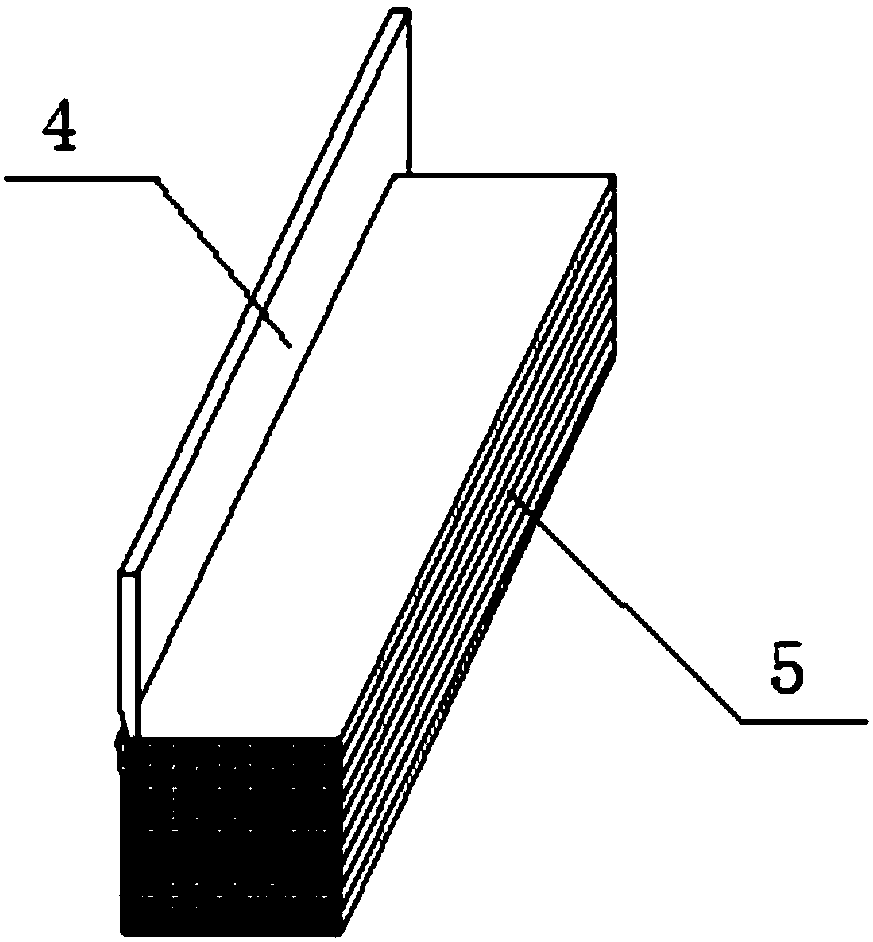

[0036] Example 2, the production specification is 2100×500×1.0mm radially flattened and sliced bamboo veneer, contrast figure 1 with image 3 , The manufacturing method is as follows:

[0037] (1) Cut the bamboo with a moisture content of 25% into 2250mm long bamboo; through a device equipped with an inner milling cutter and an outer planer, the inner section, outer section, bamboo green and bamboo of the bamboo with an inner diameter of 80mm or more The yellow is removed at the same time, and a longitudinal straight through seam is made along the axis of the bamboo.

[0038] (2) Fix the bamboo material 2 described in step (1) on the stainless steel backing plate 3 with a thickness of 4 mm, with the straight slot of the bamboo material 2 facing upward. Push the backing plate 3 containing the bamboo material 2 onto the pressure plate of the press in the high-temperature steam pressure tank, and close the pressure tank cover. Fill the tank with high temperature steam at a tempera...

example 3

[0044] Example 3, the production specification is 2100×500×0.8mm radially flattened and sliced bamboo veneer, contrast image 3 , The manufacturing method is as follows:

[0045] (1) Cut the bamboo with a moisture content of 20% into 2300mm long bamboo; through a device equipped with an inner milling cutter and an outer planing knife, the inner section, outer section, bamboo green and bamboo of the bamboo with an inner diameter of 80mm or more The yellow is removed at the same time, and a longitudinal straight through seam is made along the axis of the bamboo.

[0046] (2) Fix the bamboo material 2 described in step (1) on the stainless steel backing plate 3 with a thickness of 3 mm, with the straight slit of the bamboo material 2 facing downward. Push the backing plate 3 containing the bamboo material 2 onto the pressure plate of the press in the high-temperature steam pressure tank, and close the pressure tank cover. Fill the tank with high-temperature steam at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com