Method for preparing powder metallurgy titanium alloy bar

A technology of powder metallurgy and titanium alloy, which is applied in the field of preparation of high-performance powder metallurgy titanium alloy rods, can solve problems such as difficulty in preparing large-size titanium alloy rods, failure to meet fastener requirements, performance impact, etc., and achieve fine structure , there is no composition segregation, and the effect of meeting the size and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

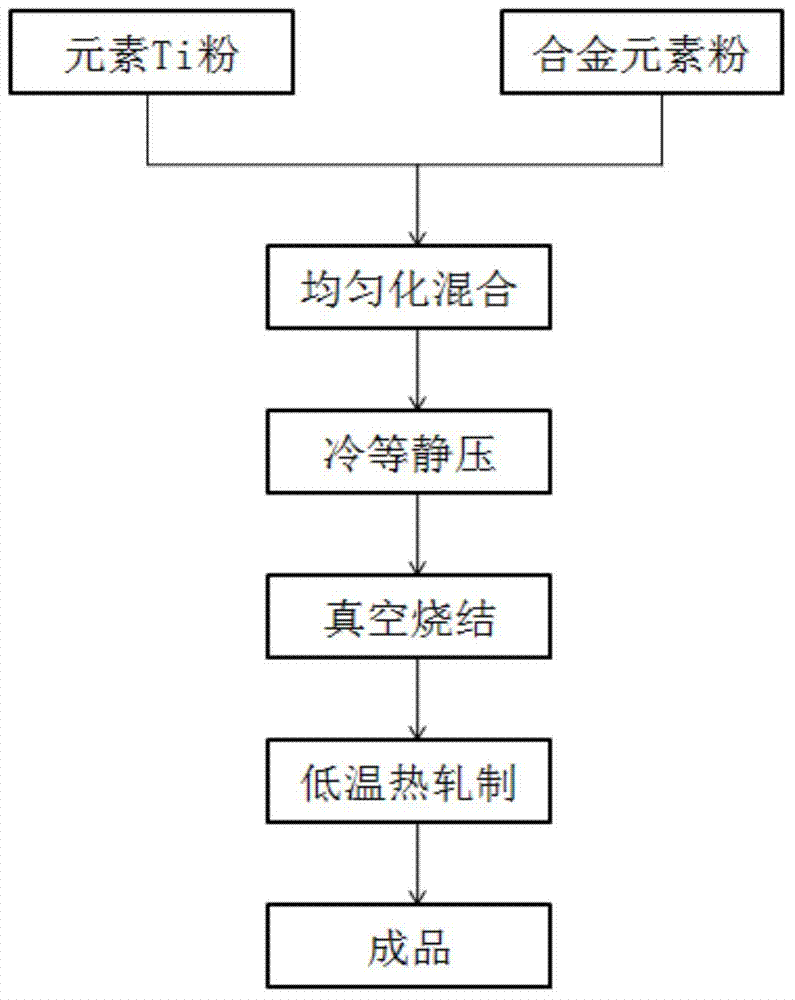

[0038] a kind of like figure 1 Shown the preparation method of powder metallurgy titanium alloy bar material for fastener of the present invention, comprises the following steps:

[0039] (1) With particle size being -325 mesh Ti powder (oxygen content is 0.35%) and particle size being -250 mesh Al-V master alloy powder (oxygen content is 0.47%) as raw material, except a small amount of unavoidable impurity oxygen element, raw material It does not contain other elements except Ti powder and Al-V master alloy powder; weigh Ti powder and Al-V master alloy powder according to the mass ratio of 9:1, and the Al and V in Al-V master alloy powder The mass ratio is controlled at 6:4, and the weighed raw material powder is mixed evenly with a V-shaped mixer, and the mixing time is 8 hours. The mixing process is protected by an inert gas argon;

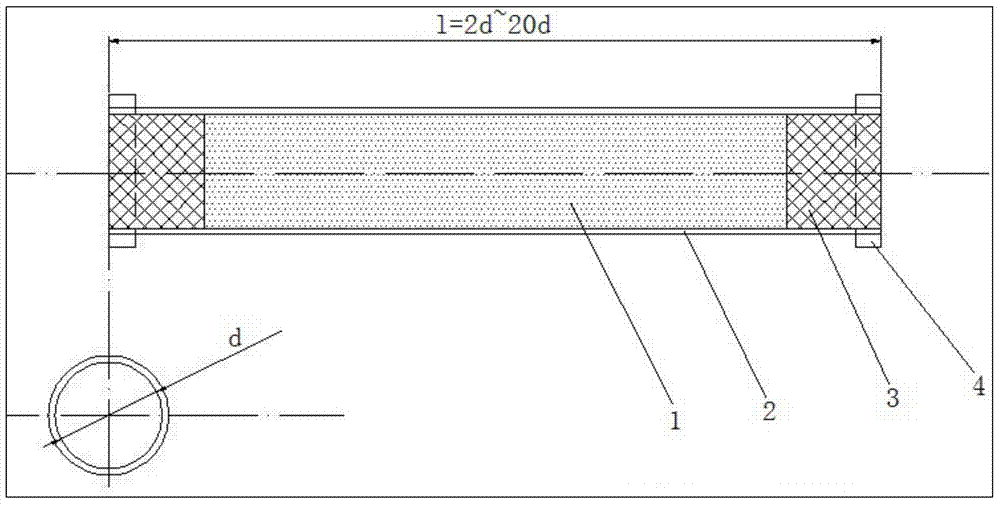

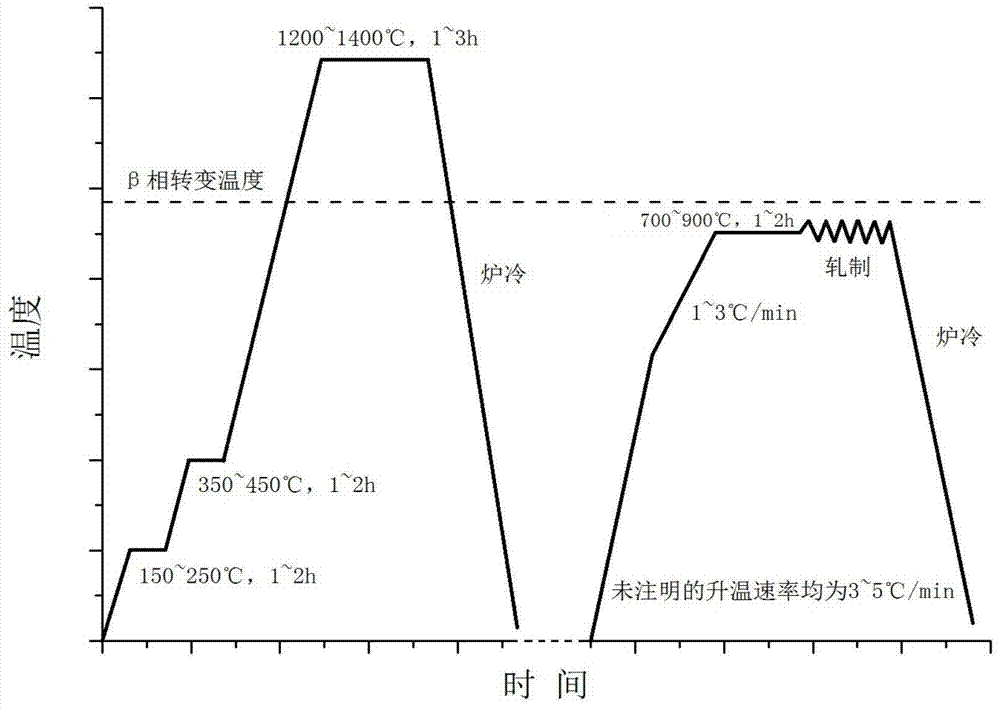

[0040] (2) Put the powder 1 fully mixed in step (1) into the cold isostatic pressing sleeve 2, which is a Ф40×250mm rubber circular sleeve (...

Embodiment 2

[0046] a kind of like figure 1 Shown the preparation method of powder metallurgy titanium alloy bar material for fastener of the present invention, comprises the following steps:

[0047] (1) With particle size being -325 mesh Ti powder (oxygen content is 0.35%) and particle size being -250 mesh Al-V master alloy powder (oxygen content is 0.47%) as raw material, except a small amount of unavoidable impurity oxygen element, raw material It does not contain other elements except Ti powder and Al-V master alloy powder; weigh Ti powder and Al-V master alloy powder according to the mass ratio of 9:1, and the Al and V in Al-V master alloy powder The mass ratio is controlled at 6:4, and the weighed raw material powder is mixed evenly with a V-shaped mixer, and the mixing time is 8 hours. The mixing process is protected by an inert gas argon;

[0048] (2) Put the powder 1 fully mixed in step (1) into the cold isostatic pressing sleeve 2, the cold isostatic pressing sleeve 2 is a Ф50...

Embodiment 3

[0054] a kind of like figure 1 Shown the preparation method of powder metallurgy titanium alloy bar material for fastener of the present invention, comprises the following steps:

[0055] (1) With a particle size of -200 mesh Ti powder (oxygen content is 0.20%), a particle size of -250 mesh Mo powder (oxygen content is 0.22%) and a particle size of -250 mesh Al-V master alloy powder (oxygen content is 0.47%) %) as the raw material, except for a small amount of unavoidable impurity oxygen element, the raw material does not contain other elemental components except Ti powder, Mo powder, Al-V master alloy powder; Ti powder, Mo powder and Al-V master alloy powder According to the mass ratio of 35:2:3, the mass ratio of Al and V in the Al-V master alloy powder is controlled at 6:4, and the weighed raw material powder is mixed evenly with a V-shaped mixer, and the mixing time is 8h , the mixing process is protected by inert gas argon;

[0056] (2) Put the powder 1 fully mixed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com