Machining method of high-quality large-diameter thin-wall metal barrel body

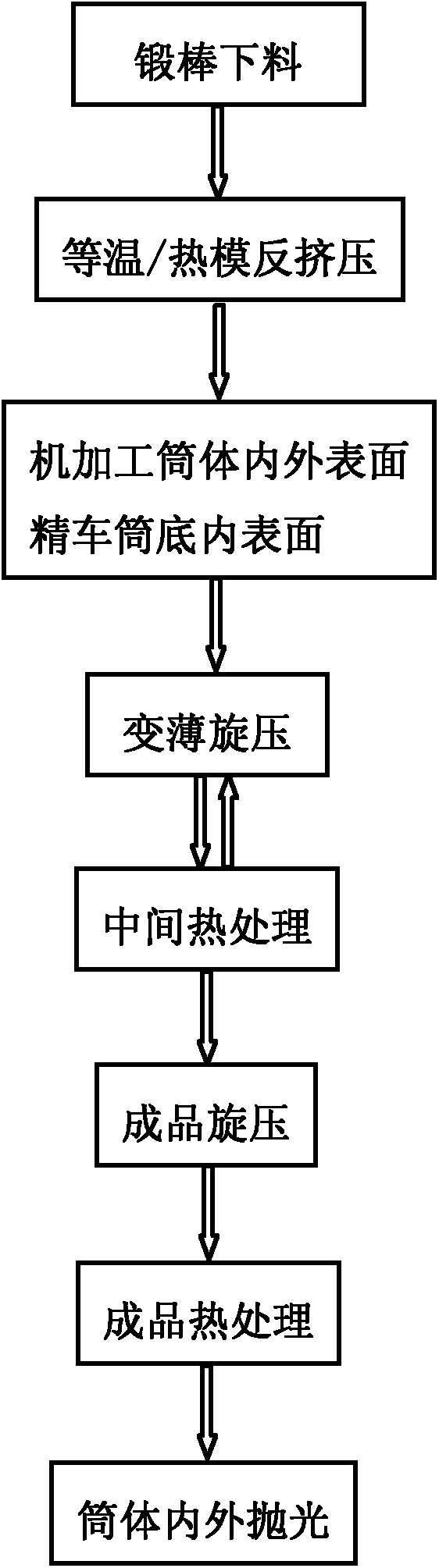

A processing method and large-diameter technology, applied in the field of metal processing, can solve the problems of short preparation process, difficult processing and forming, long processing process, etc., and achieve the effect of good application prospect, high product added value, and low material deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The processing object is the Hastelloy C alloy cylinder. A forged rod with a diameter of 300mm is blanked. After machining, it is covered with a normal carbon steel ladle with a wall thickness of 10mm. It is heated to 890°C and kept for 3 hours. Continue to heat up to 1220°C and hold for 4 hours. ; Then coated with glass lubricating powder, put into the extrusion barrel for hot die back extrusion, the extrusion speed is 1.5mm / s, the extrusion ratio is 3.5, and the temperature of the extrusion tool is 950°C. Remove the wrapping material, machine the inner and outer surfaces of the cylinder, and finish the inner surface of the bottom of the cylinder. The outer diameter of the spinning cylinder blank is 294mm, and the wall thickness is 10mm. Three-wheel powerful spinning machine is used for thinning and spinning, the wall reduction rate of the first pass is 20%, the thinning rate of subsequent passes is 26%, the feed ratio of the first two passes of the finished product is ...

Embodiment 2

[0040]The processing object is the GH4698 alloy cylinder, and the forged rod with a diameter of 260mm is blanked. After machining, it is covered with a normal carbon steel ladle with a wall thickness of 10mm, heated to 860°C, kept for 2h, and continued to heat up to 1220°C, and kept for 3h; Then it is coated with glass lubricating powder, put into the extrusion barrel for hot mold reverse extrusion, the extrusion speed is 1.5mm / s, the extrusion ratio is 3.1, and the extrusion die temperature is 950°C. Remove the sheath material, machine the inner and outer surfaces of the cylinder, and finish the inner surface of the bottom of the cylinder. The outer diameter of the spinning cylinder blank is 255mm, and the wall thickness is 10mm. Using a three-wheel powerful spinning machine for thinning and spinning, the wall reduction rate of the first pass is 21%, the thinning rate of subsequent passes is 27%, and the feed ratio of the first two passes of the finished product is 0.6mm / n, T...

Embodiment 3

[0042] The processing object is an Inconel718 alloy cylinder. A forged rod with a diameter of 300mm is blanked. After machining, it is preheated to 260°C and sprayed with a high-temperature anti-oxidation glass lubricant, then heated to 850°C, kept for 2 hours, and continued to heat up to 1050°C. Keep warm for 4 hours; then coat with glass lubricating powder, put it into the extrusion cylinder for isothermal back extrusion, the extrusion speed is 1mm / s, and the extrusion ratio is 4. The inner and outer surfaces of the cylinder are machined, and the inner surface of the bottom of the cylinder is finished. After machining, the outer diameter of the cylinder is 295mm, and the wall thickness is 15mm. A three-wheel powerful spinning machine is used for thinning and spinning. The thinning rate of the first pass is 18%, the thinning rate of the subsequent pass is 25%, and the feed ratio of the first two passes of the finished product is 0.7mm / n. The feed ratio of other passes is 1.2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com