Patents

Literature

41results about How to "No cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

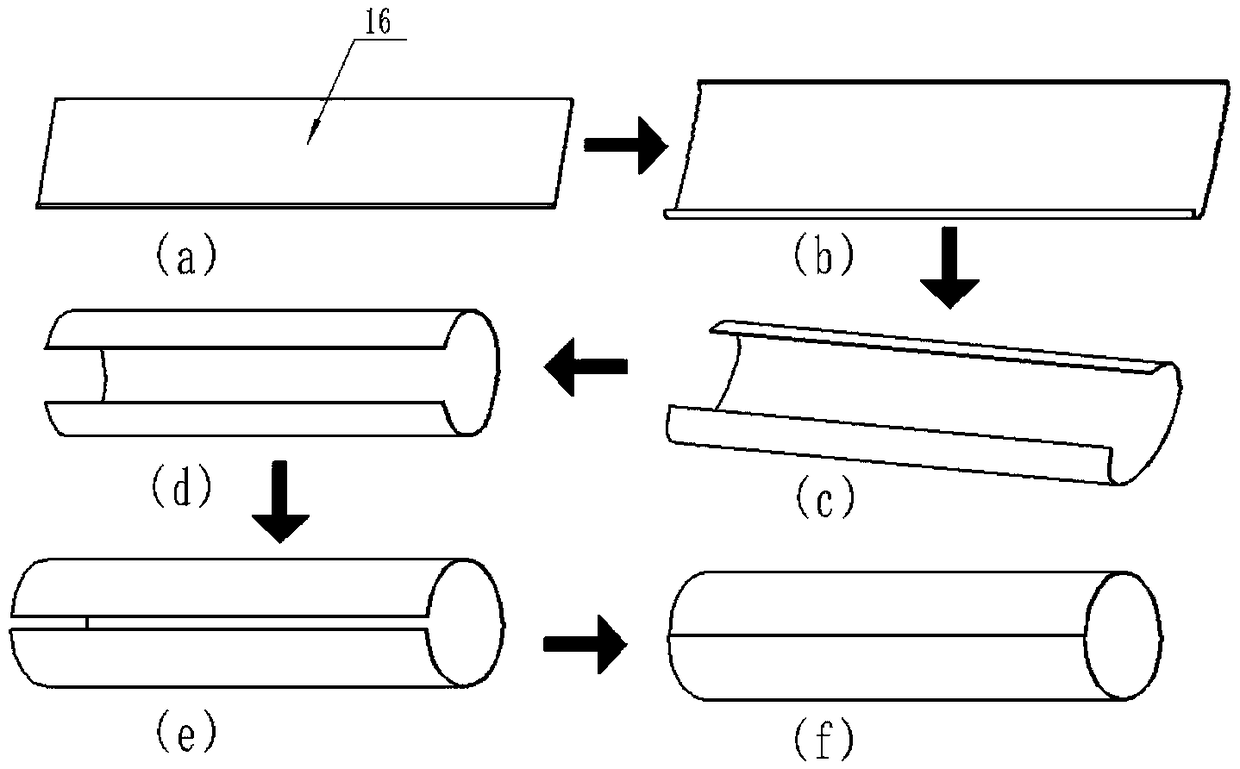

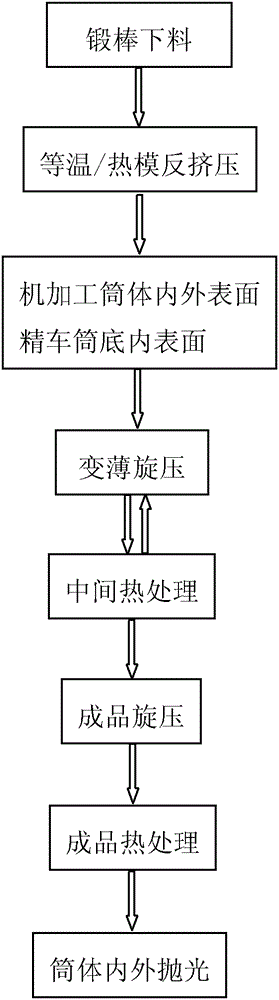

Machining method of high-quality large-diameter thin-wall metal barrel body

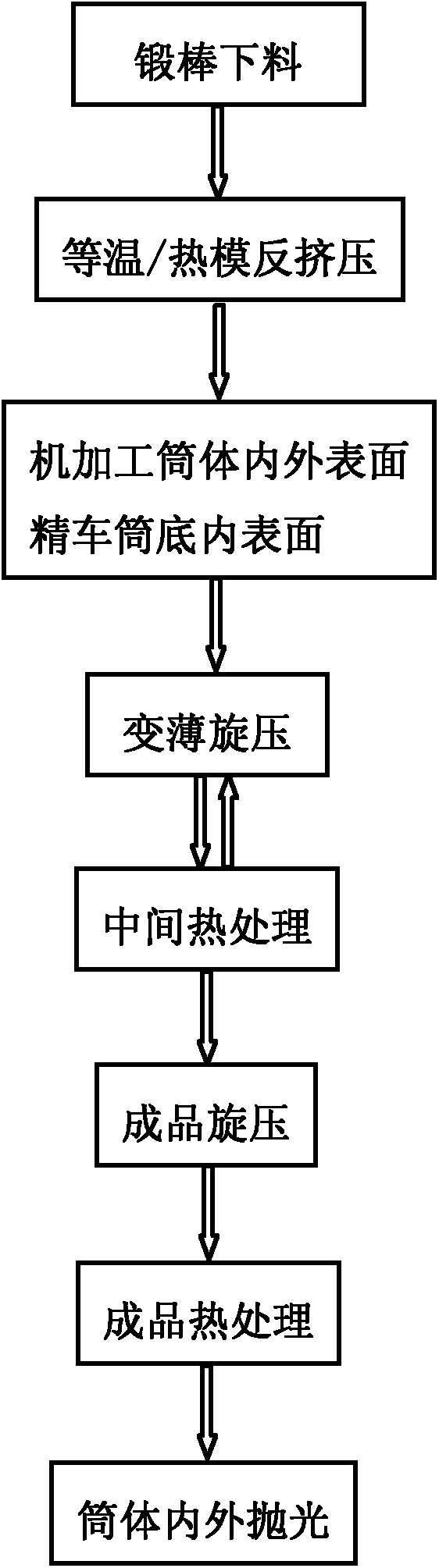

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

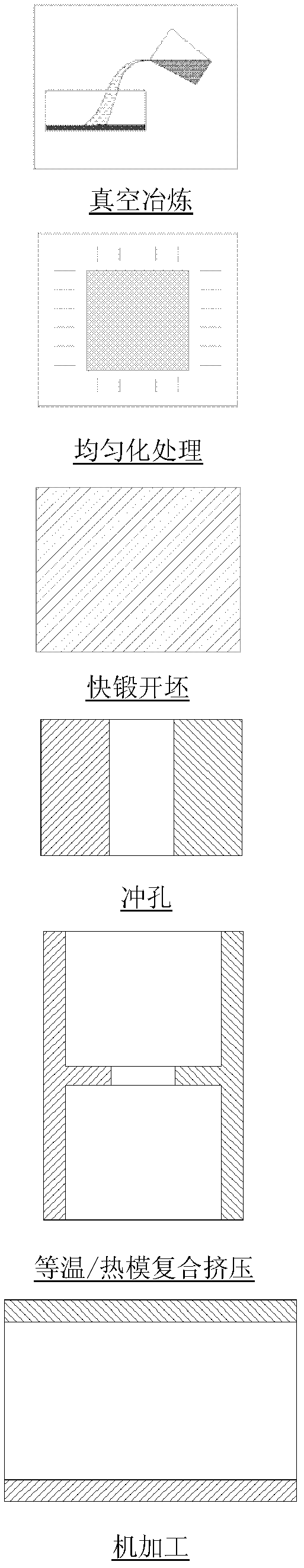

Compound extrusion preparation method of large-diameter high-quality tube blank or annular blank

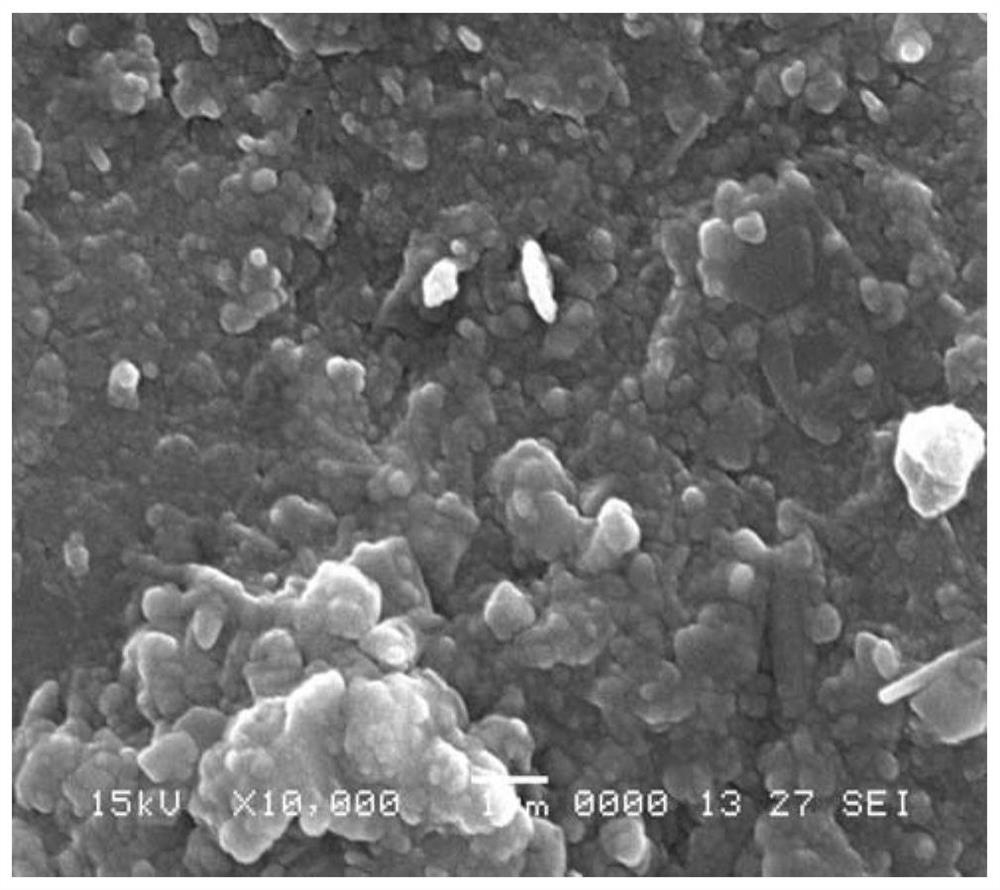

ActiveCN103170797AUniform and fine tissueForming labor-savingMetal-working apparatusHeat processingUtilization rate

The invention relates to a compound extrusion preparation method of a large-diameter high-quality tube blank or an annular blank. The compound extrusion preparation method is mainly aimed at materials which are large in deformation resistance, narrow in heat processing temperature range, difficult in heat processing, and difficult to deform. The compound extrusion preparation method comprises the following steps: (1) a high-quality ingot blank with high purity is prepared through a vacuum melting process; (2) homogenization treatment is carried out alternatively, multi-pass pier drawing fast forging cogging-down is carried out, an organization is refined, and the homogeneity of the organization is improved; (3) hollow blank material is prefabricated in a punch mode; (4) isothermality / heat molding compound extrusion is carried out on the prefabricated hollow blank material, the tube blank with the uniform and thin organization is prepared; and (5) subsequent machining is carried out, and a finished tube (ring) and the high-quality ingot blank are obtained. The novel preparation method is used for preparing the large-diameter tube (ring) blank with the uniform and thin organization. The preparation method is labor-saving in shaping, energy-saving, high in material utilization rate, high in product quality, and capable of resolving the problems that a tube (ring) blank prepared through a traditional process is thick in organization, poor in uniformity, large in shaping force and the like.

Owner:GRIMAT ENG INST CO LTD

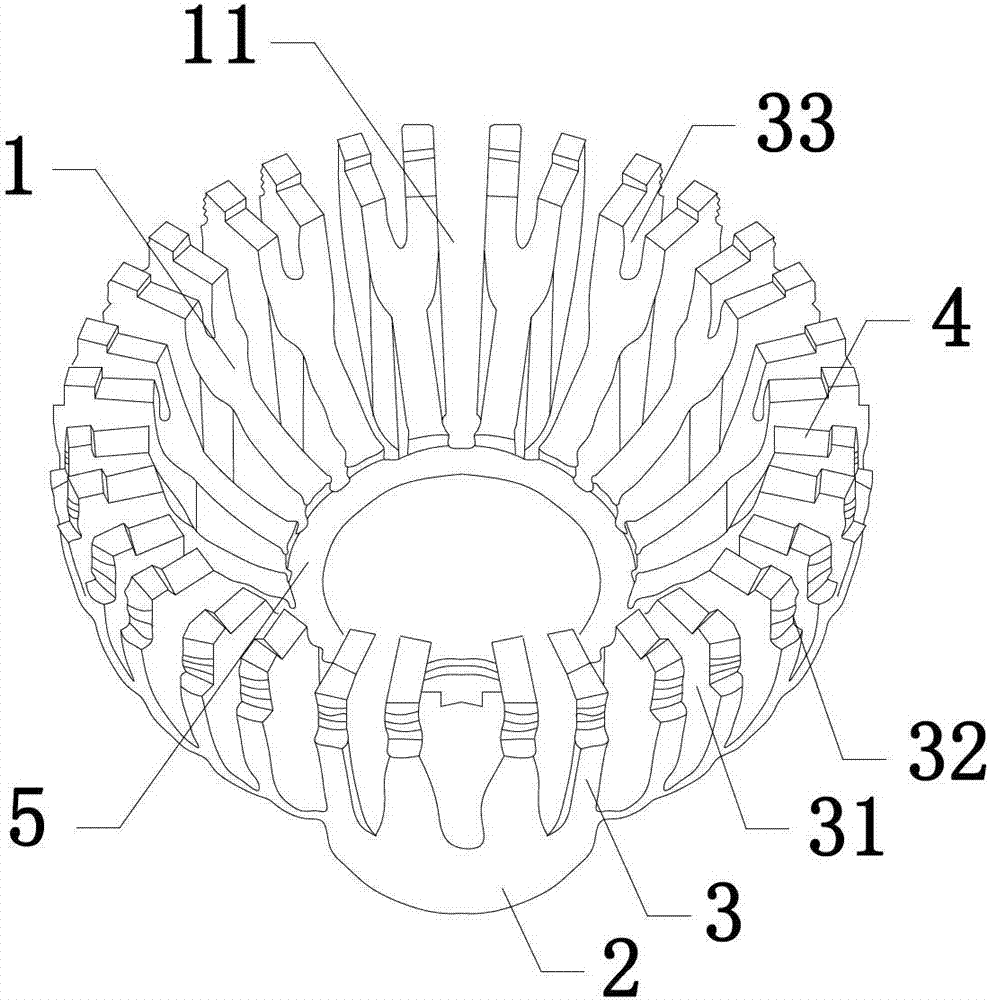

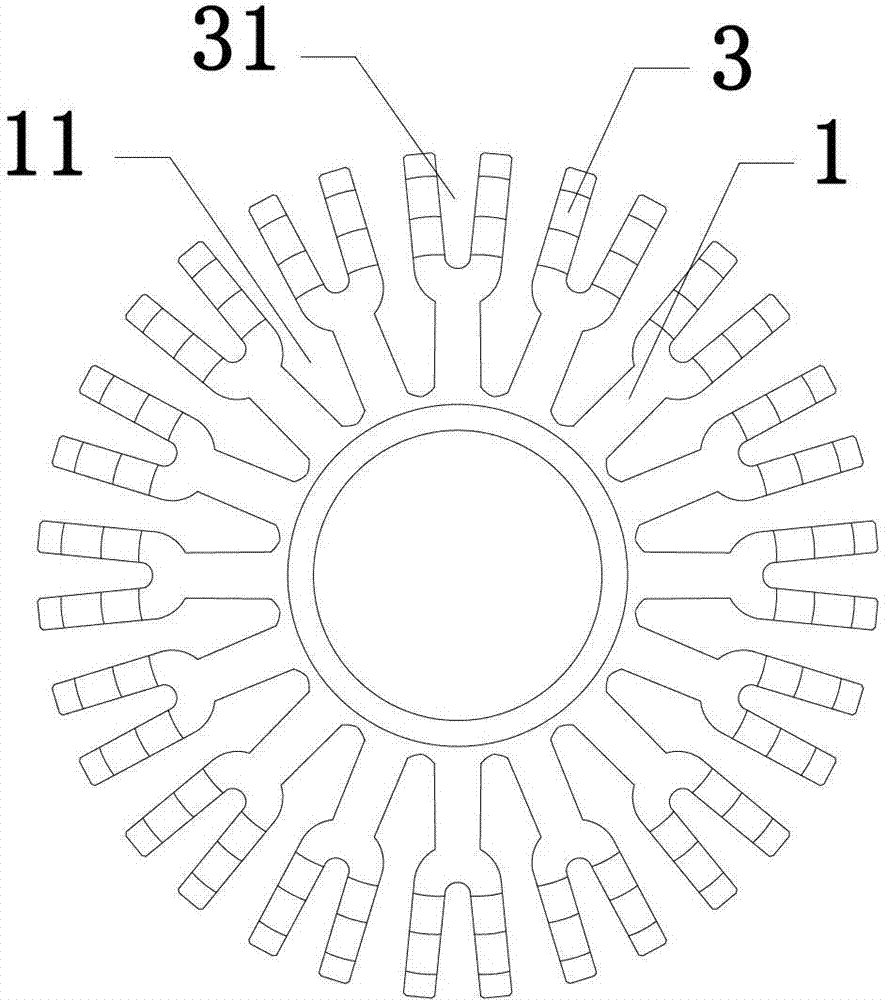

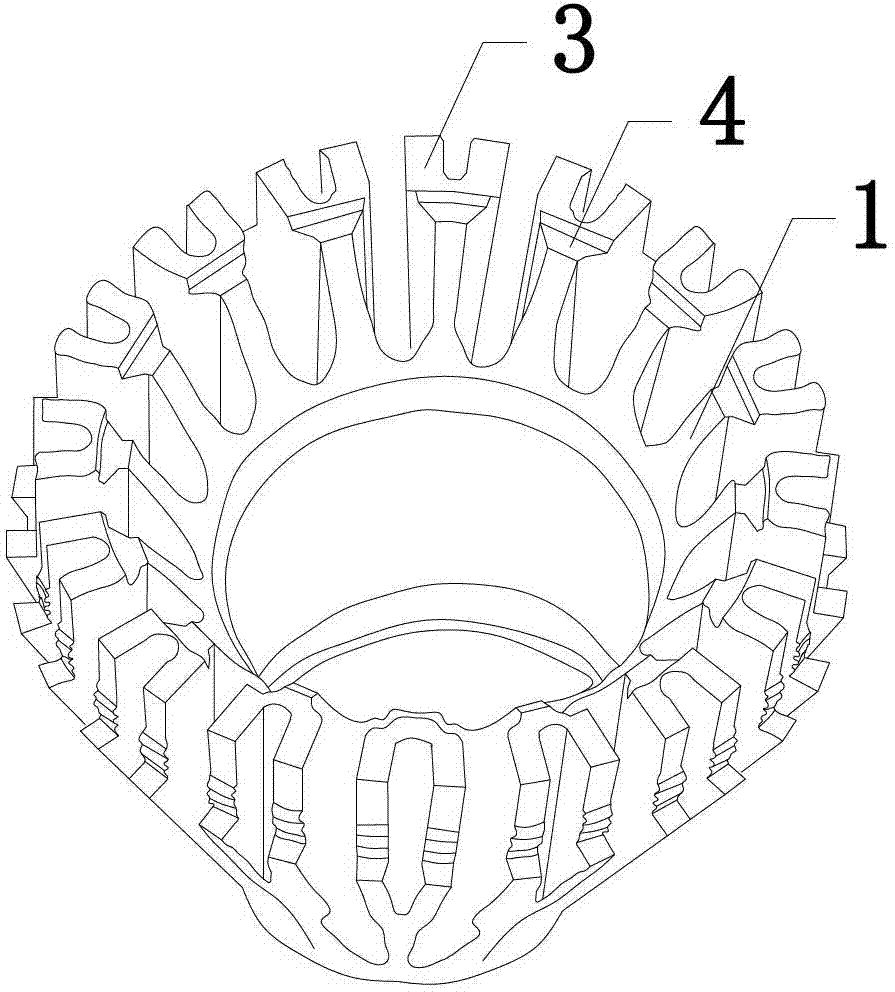

Radiating shell of LED lamp

InactiveCN103206695AIncrease cooling areaImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

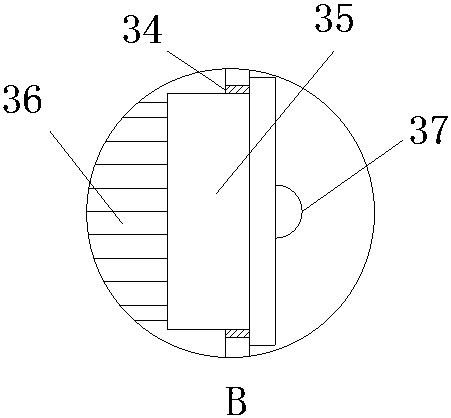

The invention aims at providing a radiating shell for improving radiating efficiency of an LED lamp. The radiating shell comprises a tubular heat absorbing core and multiple radiating fins radially arranged around the heat absorbing core, a main ventilation groove is formed between each two adjacent radiating fins, the multiple radiating fins extend towards a same end of the heat absorbing core and form a cavity used for holding devices by surrounding at the end, the cavity and the main ventilation grooves are communicated, the outside of each radiating fin is at least provided with two radially-arranged fins, and auxiliary ventilation grooves are formed among the fins on a same radiating fin. The structure of the radiating shell is improved by additionally arranging the fins on the radiating fins, so that radiating effect of the radiating shell is greatly improved.

Owner:GUANGDONG ECORISING TECH

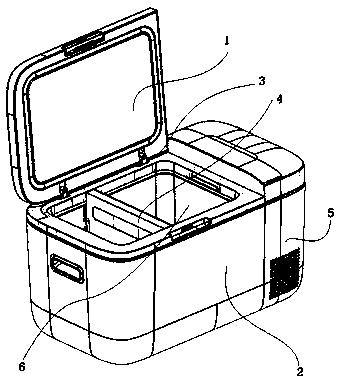

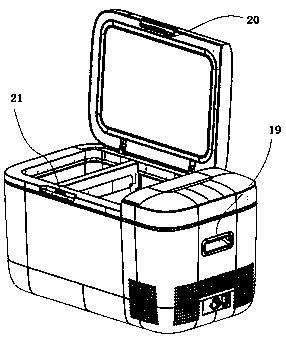

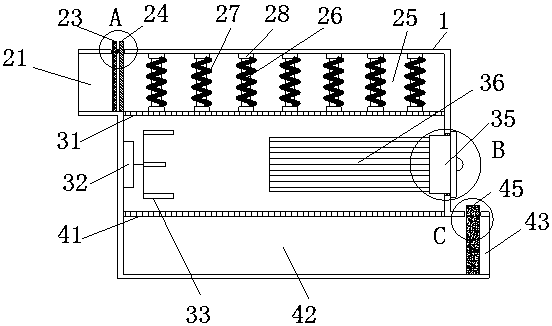

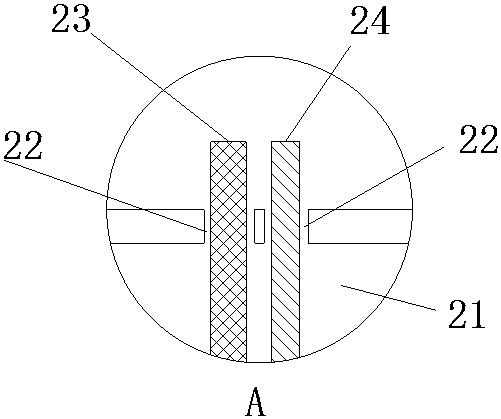

Novel car refrigerator

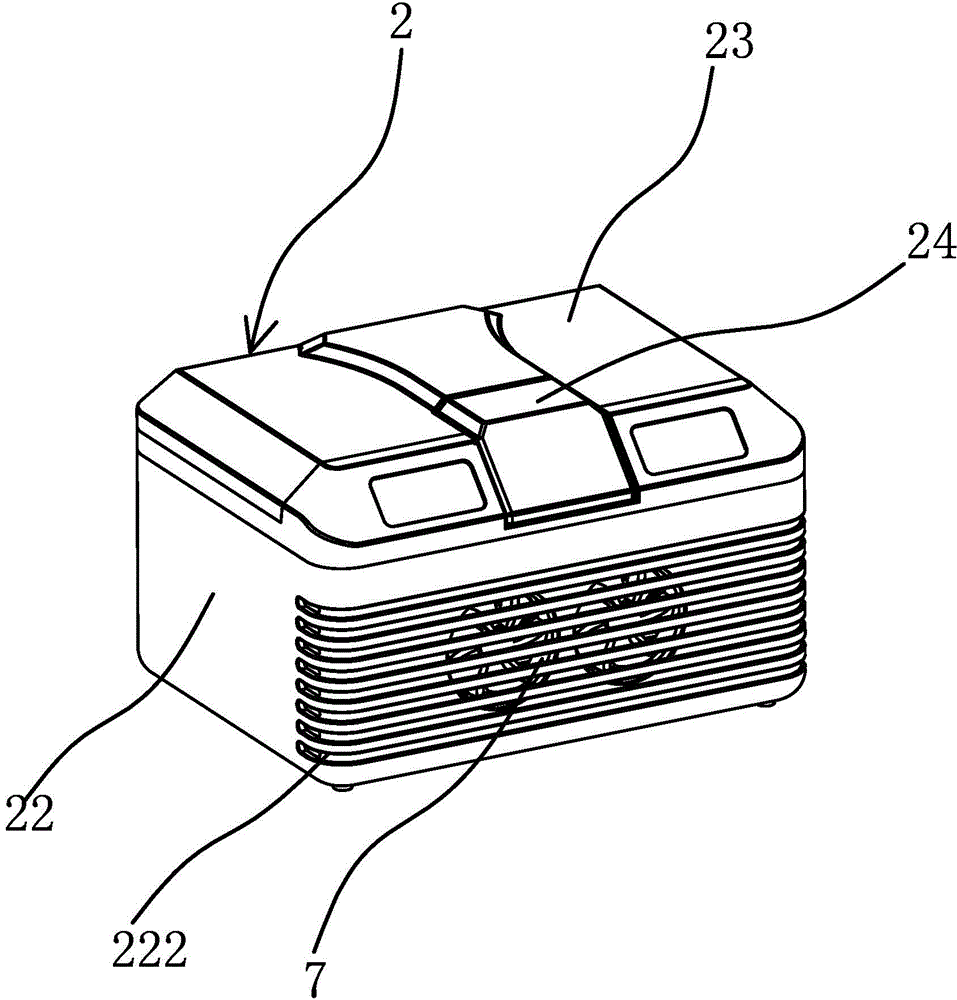

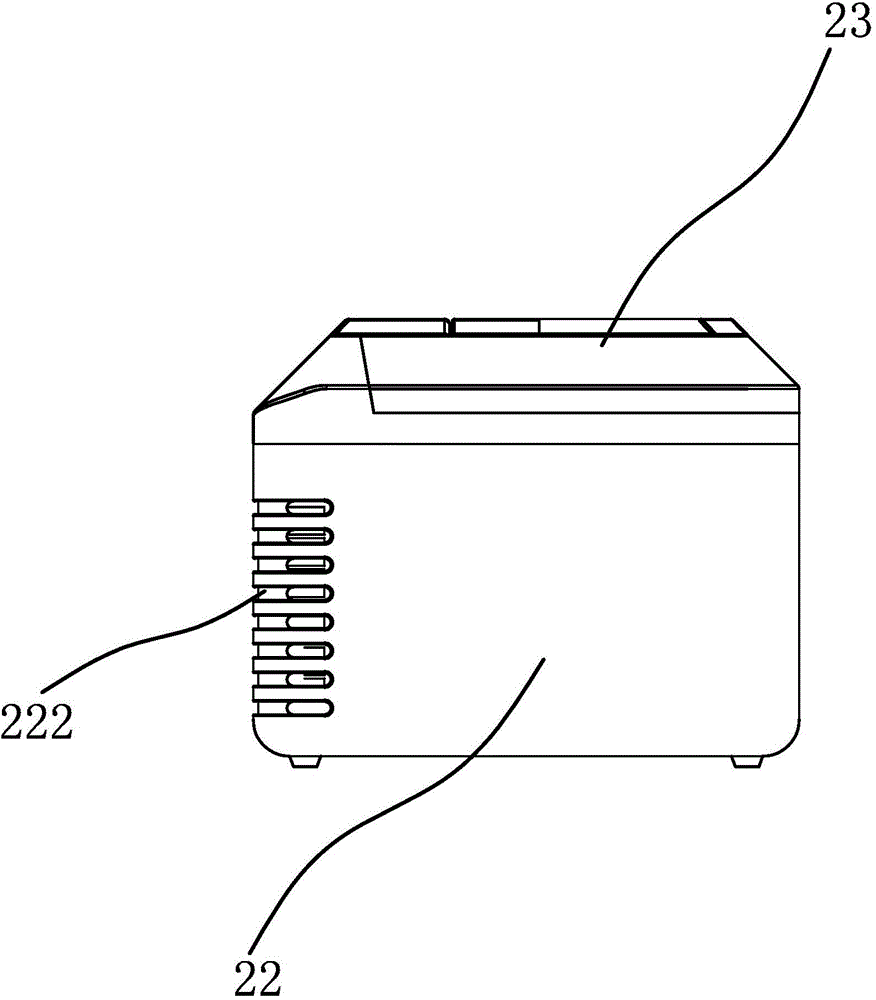

PendingCN108253683AAffects the inner cavity volumeChange the inner volumeLighting and heating apparatusDomestic refrigeratorsEngineeringReed switch

The invention relates to a novel car refrigerator. The novel car refrigerator comprises a refrigerator box body and an upper box cover. A refrigerator inner chamber is installed in the refrigerator box body, and one side of the upper end of the refrigerator inner chamber is rotatably connected to the upper box cover by a limit rotation seat. One side of the refrigerator box body is provided with amounting inner chamber, and a middle part of the refrigerator inner chamber is vertically inserted with a partition plate, and a compressor is centrally installed in the mounting inner chamber. A condenser and a controller are correspondingly mounted on both sides of the compressor, and a fan is mounted on the outside of the condenser. The lower end, below the partition plate of the refrigeratorinner chamber is provided with a reed switch, and the lower end of the partition plate is provided with a reed switch magnet corresponding to the reed switch, and an evaporator is arranged on both side walls of the refrigerator inner chamber. The controller, the partition plate and the reed switch cooperate to control the automatic switching of single and double boxes, energy can be greatly saved.The upper box cover is provided with a limit structure and a damping structure to prevent unnecessary impact and the use effect is good.

Owner:GUANGDONG INDELB ENTERPRISE CO LTD

Novel vehicle-mounted air conditioner

InactiveCN107650624AReduce the temperatureNo cooling effectAir-treating devicesVehicle heating/cooling devicesEngineeringWaste management

The invention discloses a novel vehicle-mounted air conditioner. The novel vehicle-mounted air conditioner comprises a condenser, condenser pipelines, a compressor, a liquid storage dryer, a compressor pipeline, a dryer pipeline, expansion valves, an evaporator, a blower, a purifying dust removal device and an air conditioner air duct. The condenser is provided with the two condenser pipelines. One of the condenser pipelines is connected with the compressor, and the other condenser pipeline is connected with the liquid storage dryer. The compressor is provided with the compressor pipeline. Theliquid storage dryer is provided with the dryer pipeline. The compressor pipeline and the dryer pipeline are provided with the expansion valves. The tail ends of the compressor pipeline and the dryerpipeline are fixedly connected with the evaporator. The evaporator is provided with the blower. The evaporator is provided with the purifying dust removal device. The outer wall of one side of the purifying dust removal device is provided with the air conditioner air duct. The novel vehicle-mounted air conditioner has the characteristics of being capable of regulating temperature and humidity ina car and purifying, dusting and sterilizing air in the car, and convenient to disassemble and clean up.

Owner:安徽汇泰车轮有限公司

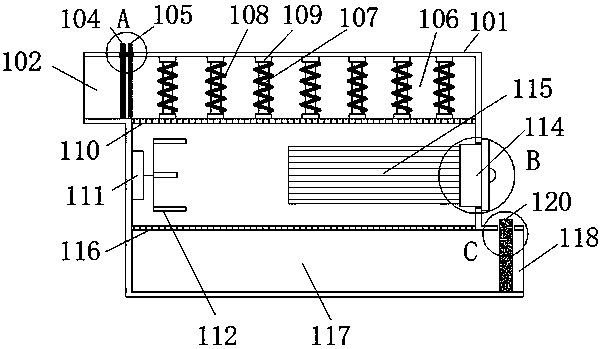

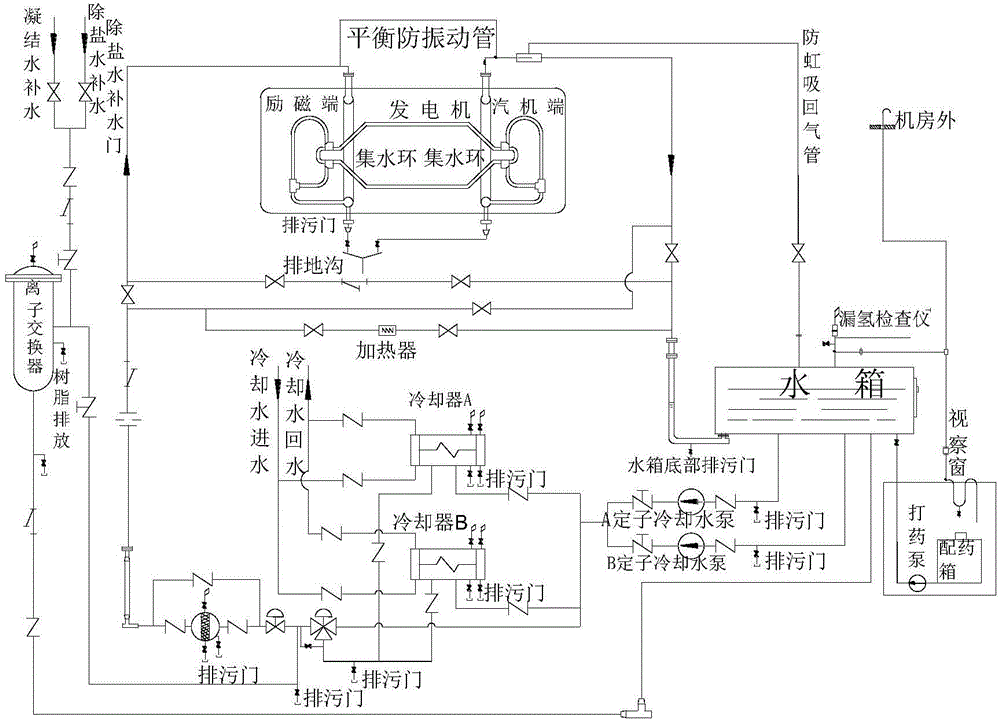

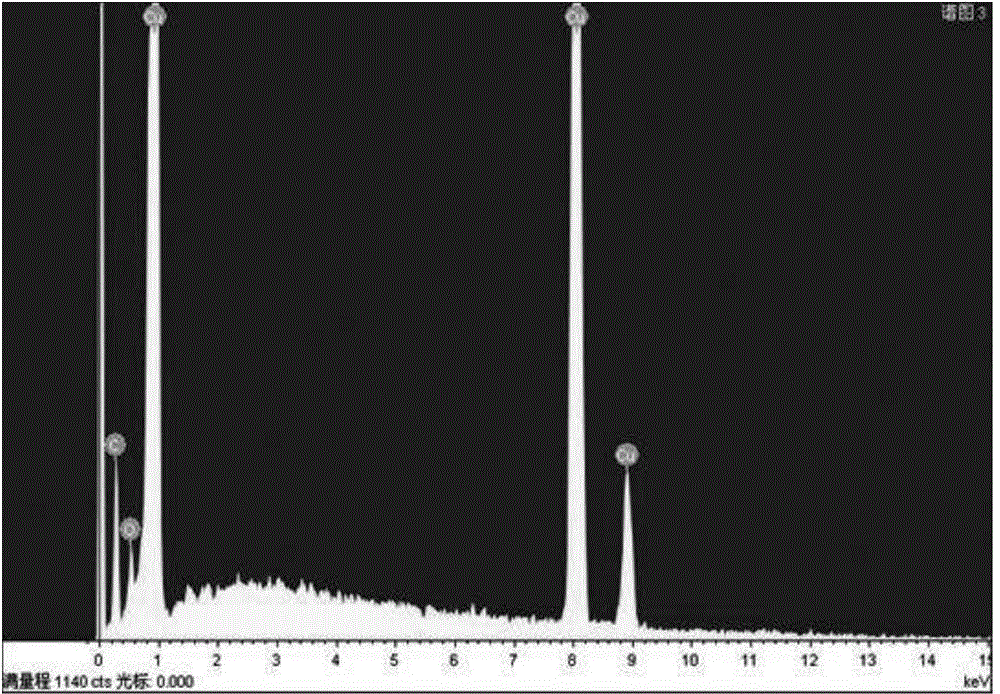

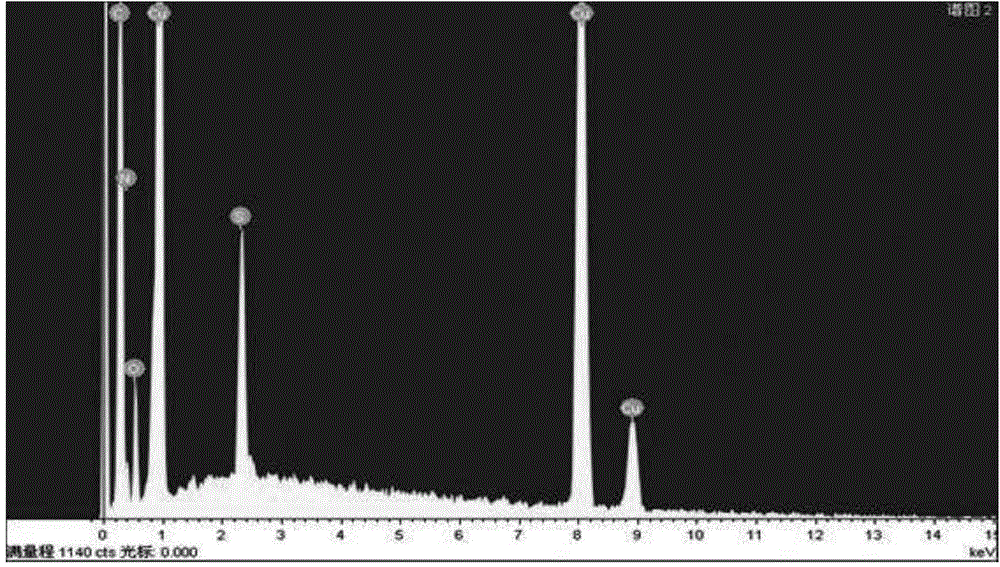

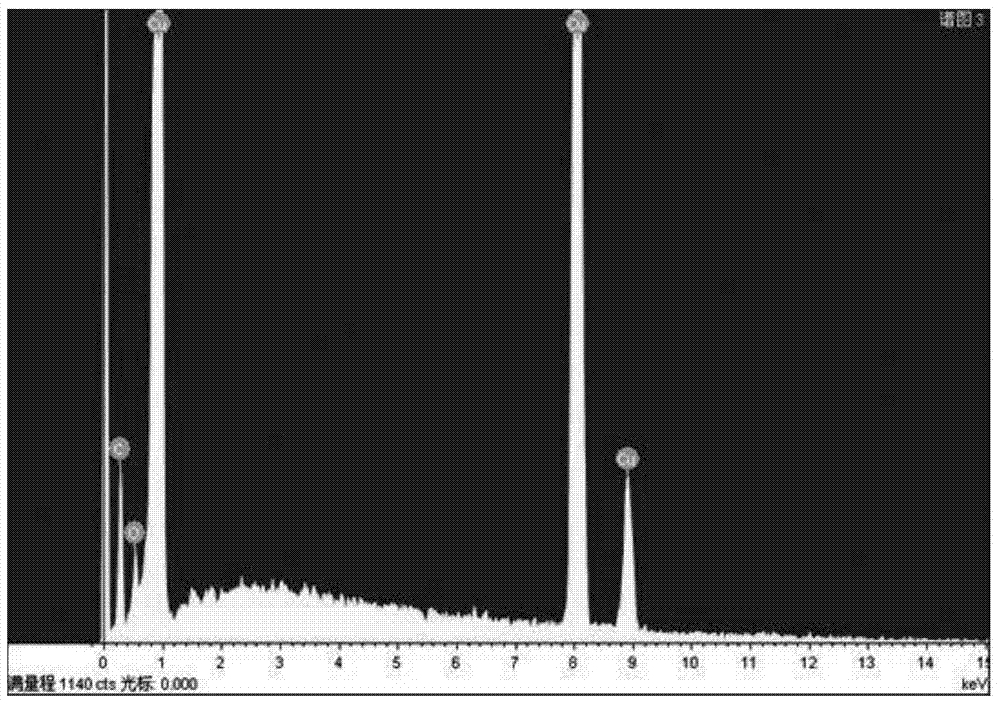

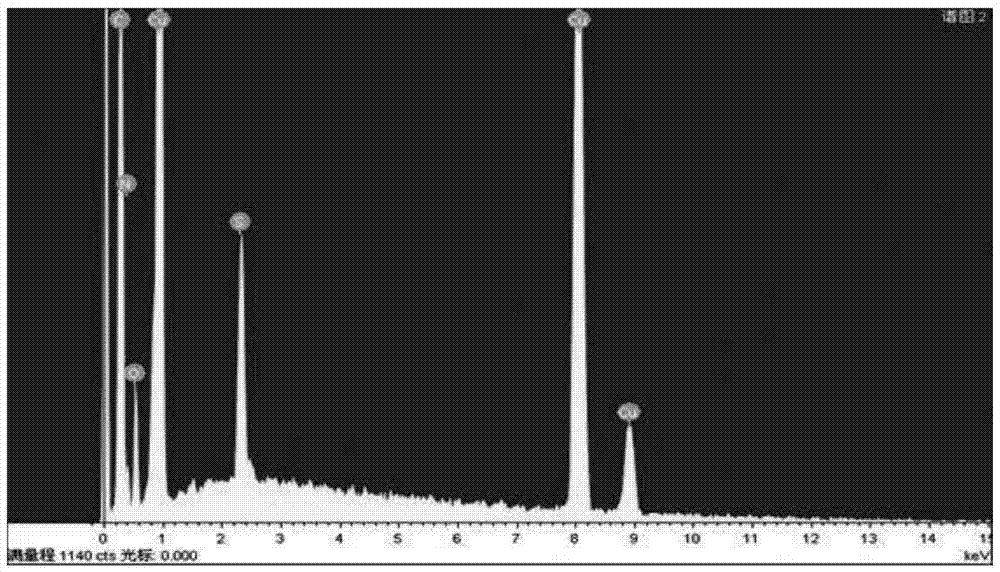

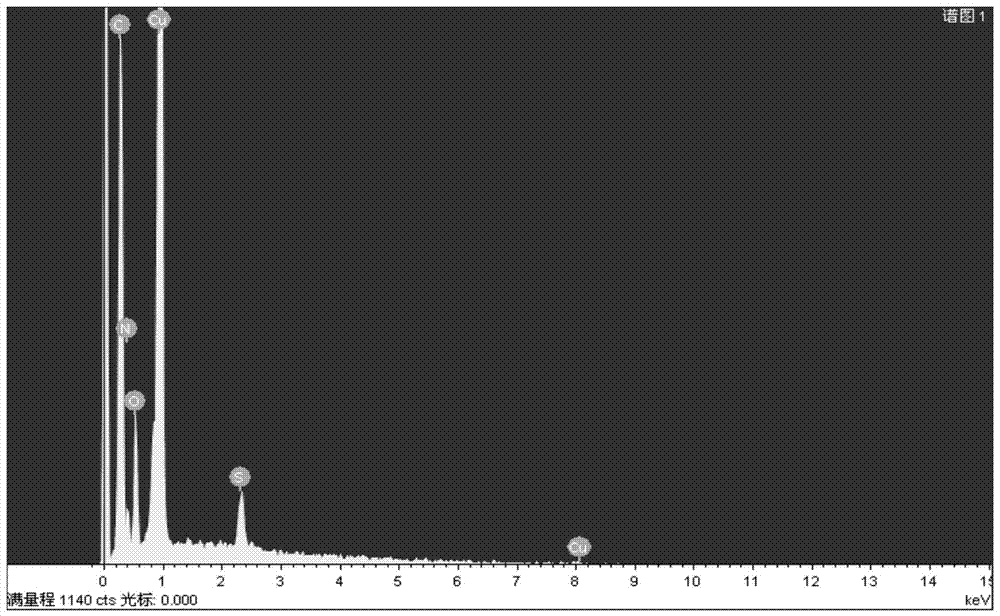

Method for solving obstruction of hollow lead of generator stator bar and inhibiting corrosion of hollow lead

The invention discloses a method for solving the obstruction of a hollow lead of a generator stator bar and inhibiting the corrosion of the hollow lead. The method comprises the following steps: pickling for descaling, activating, and prefilming, wherein a composite acid used in the pickling step comprises, by weight, 65-92 parts of aminosulfonic acid and 8-35 parts of hydrofluoric acid, and a prefilming agent used in the prefilming step comprises, by weight, 35-45 parts of tolyltriazole, 40-44 parts of 2-mercaptobenzothiazole, 10-25 parts of benzotriazole and 10-15 parts of hydroxypropyl methyl cellulose. The method can realize the thorough solving of copper corrosion deposits adhered in the hollow lead and the formation of a firm molecular film in the hollow lead without corroding other metal materials in the cooling water system of the generator stator, effectively prevents the direct contact of copper atoms with cooling water, and substantially inhibits the electrochemical corrosion of copper in the cooling water with a low pH value.

Owner:SHANDONG ZHONGSHI YITONG GRP

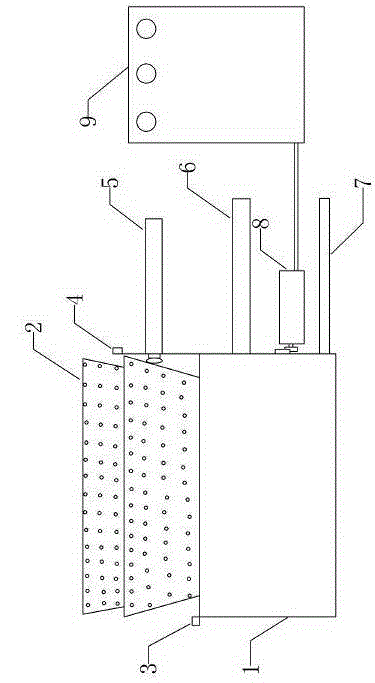

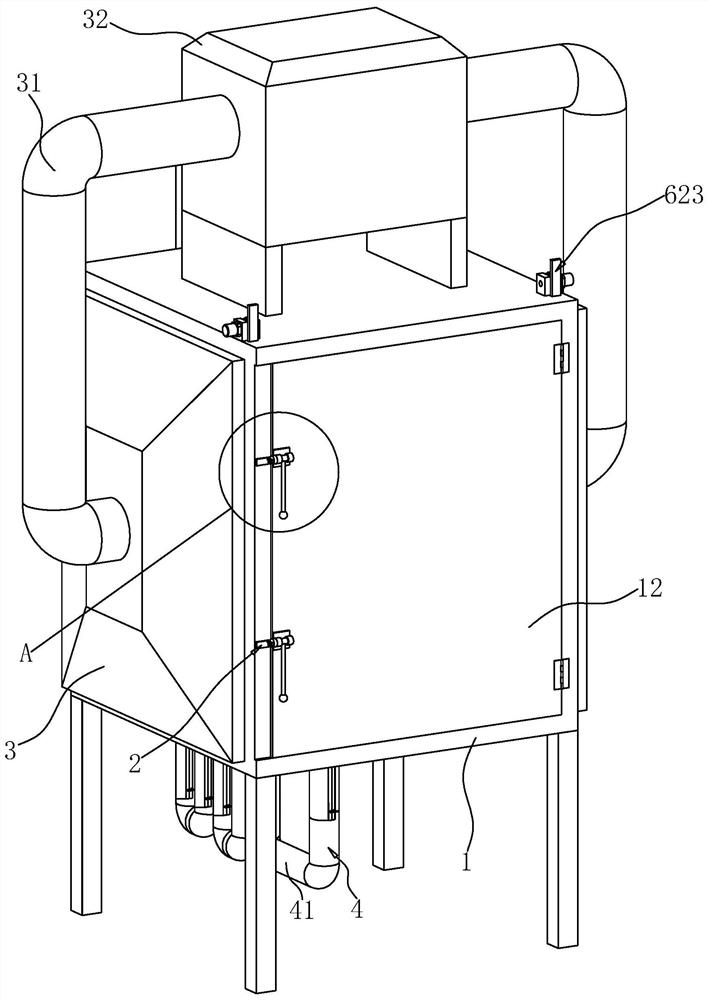

Purifying and dust-removing apparatus

InactiveCN107696830AReduce the temperatureNo cooling effectAir-treating devicesVehicle heating/cooling devicesActivated carbonElectricity

The invention discloses a purifying and dust-removing apparatus comprising a housing, a first-stage dust removing device, a second-stage dust removing device and a third-stage dust removing device. The housing is in a cubic cavity structure; the first-stage dust removing device is arranged on the upper section mounted on the housing and comprises an air inlet, an air inlet insertion port, a filterplate, a disinfecting plate, a dust removing cabin, negative electricity aluminum plates, positive electricity copper filaments and power supplies; the second-stage dust removing device is arranged in the middle section of the housing and comprises an upper layer ventilating plate, a motor, fans, screw holes, a filter core pedestal, a filter core and a pull ring; and the third-stage dust removingdevice is arranged on the lower end of the housing and has a lower layer ventilating plate, an air discharging cabin, an air outlet, an air outlet insertion port and an activated carbon absorbing plate. The purifying and dust-removing apparatus can adjust vehicle inside temperature and humidity, can purify air, remove dust and disinfect for the vehicle, and is characterized by convenient detachment and cleaning.

Owner:安徽汇泰车轮有限公司

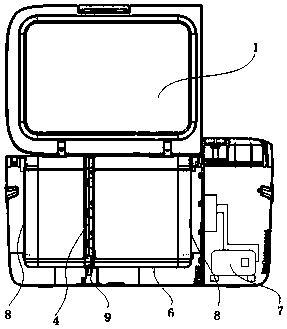

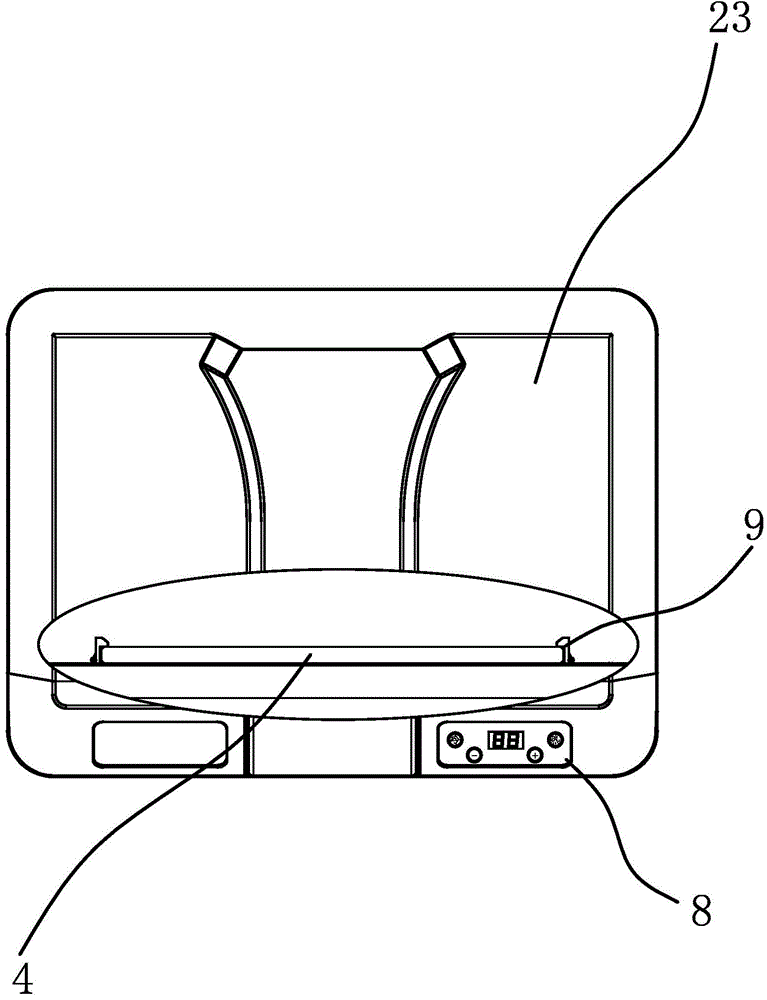

Refrigerator

InactiveCN104677005ANo cooling effectGuaranteed cooling effectLighting and heating apparatusDomestic refrigeratorsThermal energyInsulation layer

The invention belongs to the technical field of refrigerator equipment, provides a refrigerator and solves the technical problem that existing mobile refrigerators fail to keep the temperature for a long time after power cutoff. The refrigerator comprises a refrigerator body, an inner container with a cavity is arranged in the refrigerator body, the refrigerator body is provided with a heat insulation layer which is capable of peripherally coating the inner container, and a heat accumulation medium layer is detachably connected onto the inner wall of the inner container. A refrigeration sheet is arranged on the refrigerator body, the heat accumulation medium layer and the refrigeration sheet are positioned on inner and outer sides of the heat insulation layer respectively, the inner side of the refrigeration sheet is connected with the heat accumulation medium layer through a conduction medium capable of transferring thermal energy, and the outer side of the refrigeration sheet is fixedly connected with a heat radiation device communicated with the outside. The refrigerator has the advantage that refrigeration effects can be kept constantly for a long time owing to slowness in cold quantity release of the heat accumulation medium layer of the refrigerator.

Owner:吴海荣

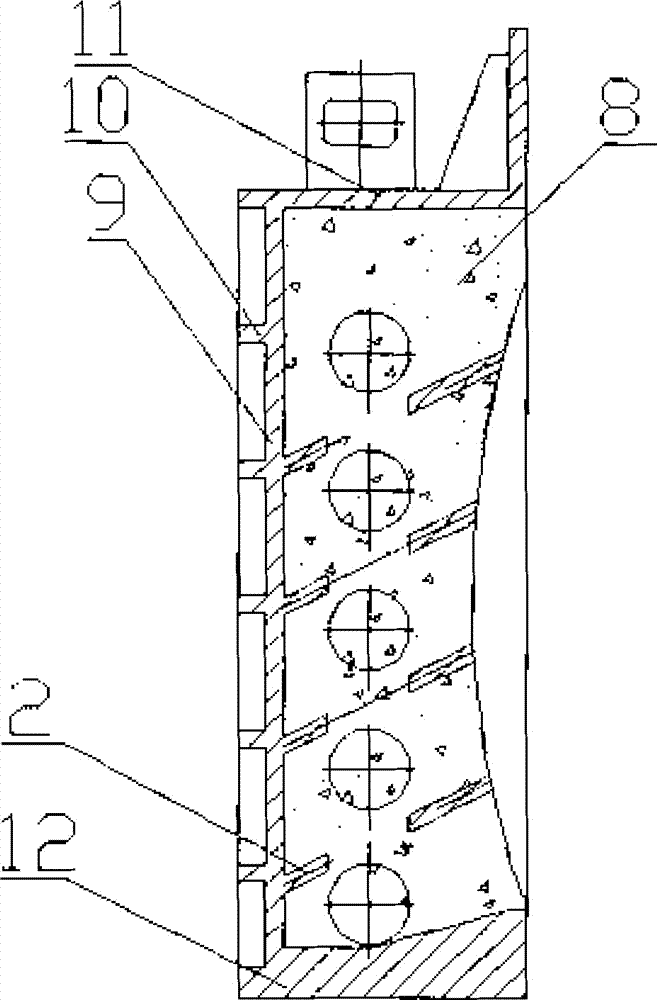

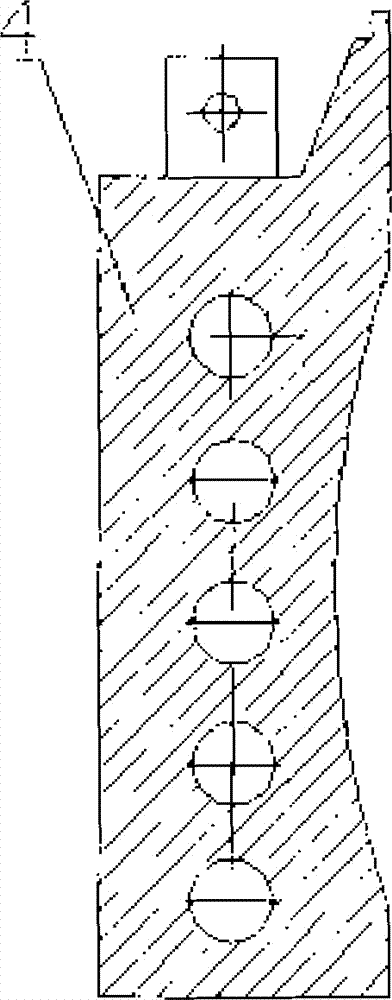

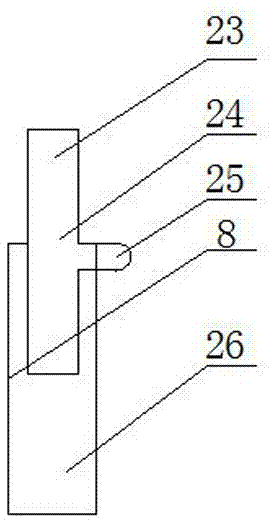

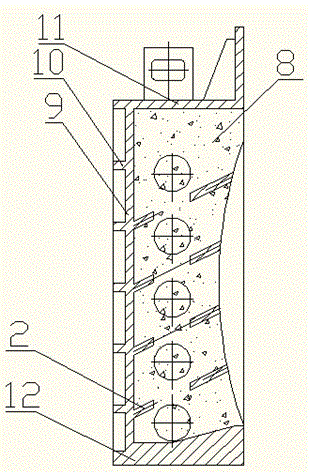

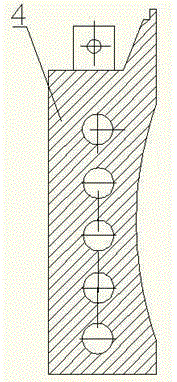

Non-water-cooling furnace door of slab heating furnace

ActiveCN103884185AImprove reliabilityExtended service lifeFurnace componentsThermal insulationEngineering

The invention belongs to the field of thick slab rolling and hot working, and particularly relates to a non-water-cooling furnace door of a slab heating furnace. The furnace door comprises side plates, and further comprises a plurality of sets of transverse rib plates and a plurality of sets of longitudinal rib plates, wherein the transverse rib plates and the longitudinal rib plates are located between the side plates. Each transverse rib plate comprises an inner transverse rib plate body and an outer transverse rib plate body, wherein the inner transverse rib plate body is perpendicular to the side plates and inclines upwards, an angle of inclination is formed between the inner transverse rib plate body and the horizontal plane, the lower end of the inner transverse rib plate body is connected with one side of a front face plate, the other side of the front face plate is fixedly connected with the outer transverse rib plate body, the outer transverse rib plate body is respectively perpendicular to the front face plate and the side plates, and the inner transverse rib plate body is provided with a plurality of inner transverse rib plate body holes. The longitudinal rib plates are provided with a plurality of longitudinal rib plate holes. According to the non-water-cooling furnace door, thermal insulation materials cannot fall off when the furnace door is frequently opened and closed at the high temperature, the high-temperature resisting performance is good, the service life is long, the production and operation cost is low, the furnace door does not need water cooling through the transverse rib plates, the longitudinal rib plates and the rib plate body holes, and the overall deformation is very small when the furnace door is used at the high temperature for a long time.

Owner:JIGANG GRP

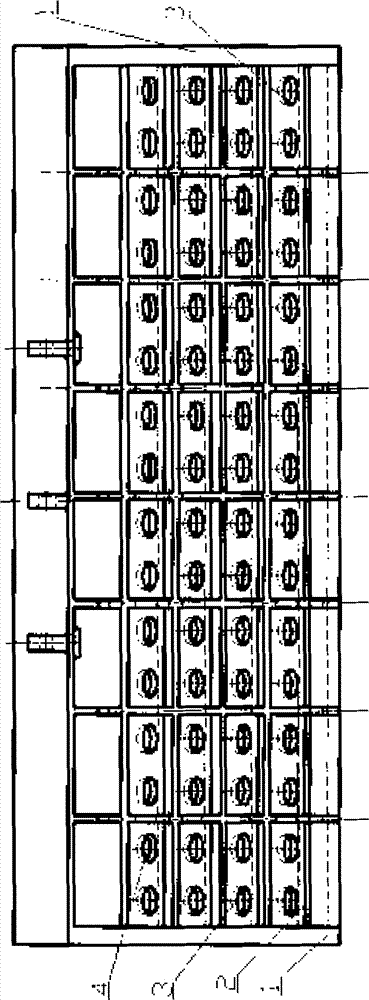

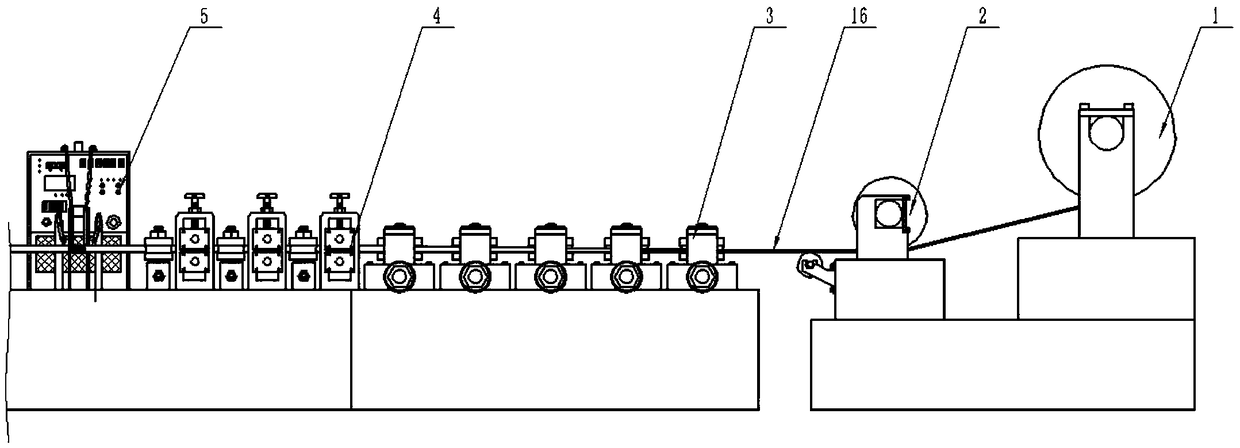

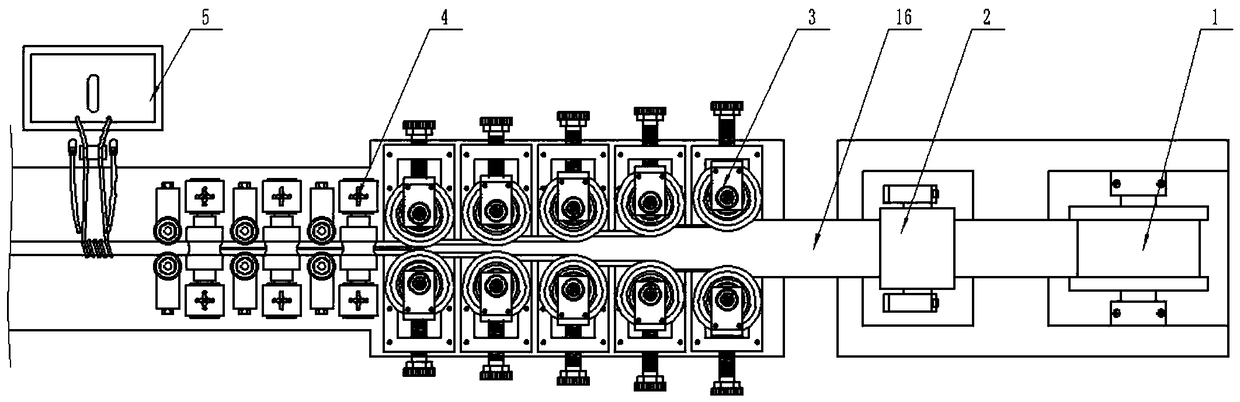

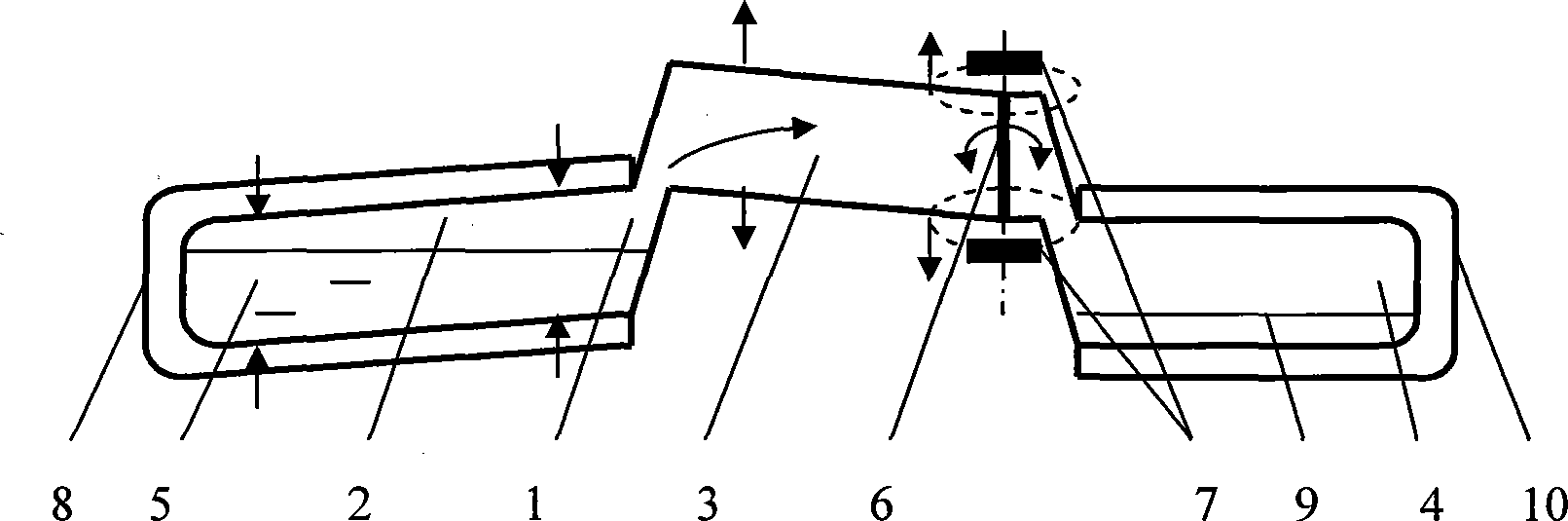

Flat tea pressing machine

ActiveCN106739098ASuppression efficientReduce brittlenessPre-extraction tea treatmentShaping pressAgricultural engineeringTea leaf

The invention discloses a flat tea pressing machine. The flat tea pressing machine comprises a drying machine, a cooling device and a pressing device. The cooling device comprises a cooling frame and a lifting machine. The lifting machine is provided with a conveying belt used for conveying tea leaves. The pressing device comprises a plurality of vibration grooves arrayed in a stepped manned, a roller couple is arranged between the adjacent upper and low vibration grooves and supported by an inlet of the lower vibration groove, an upper vibration groove outlet is formed over a pressing seam in the middle of the corresponding roller couple, each roller couple and the corresponding lower vibration groove are connected through a rotating rod, and each lower vibration groove is connected with a tea outlet hopper. The stir-frying machine carries out drying and pressing independently, dried tea leaves become lower in brittleness after being cooled through the cooling frame, and tea dust is not prone to appearing. Each roller couple is composed of two rollers, wherein one roller rotates clockwise, the other roller rotates anticlockwise, when cooled tea leaves are put into the seam between the two rollers, the two rollers will produce pressure for the tea leaves, two kinds of pressure press the tea leaves, and the tea leaves can be shaped more quickly and durably.

Owner:GUIZHOU MEITAN LINSHENG TEA

Production method of high-quality diesel oil with low condensation point

ActiveCN103805260AQuality assuranceGuaranteed yieldTreatment with hydrotreatment processesFractionationRaw material

The invention discloses a production method of high-quality diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading isodewaxing catalyst bed layer, and a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

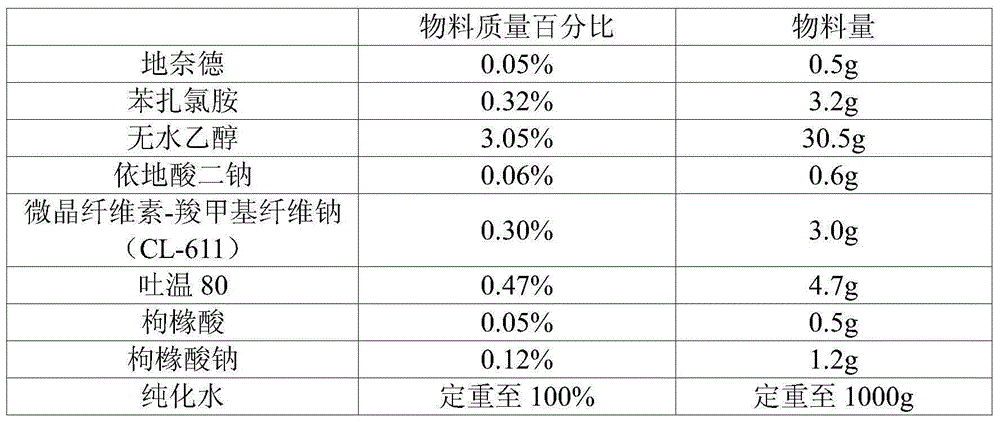

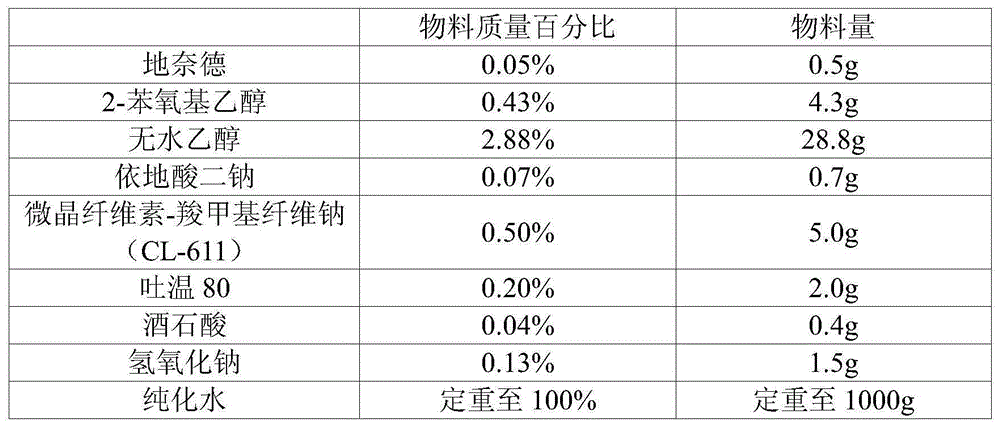

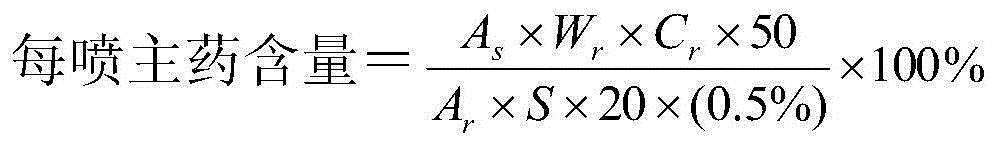

Topical spraying agent containing desonide

InactiveCN106474062AImprove complianceExpand the spraying areaOrganic active ingredientsAerosol deliveryMedicineTopical spray

The invention belongs to the field of pharmaceutical preparations, relates to a pharmaceutical preparation containing desonide, and specifically relates to a topical spraying agent containing the desonide. A drug contained in the topical desonide spraying agent is a stable-quality desonide drug containing desonide micro powder, and the desonide drug comprises, by weight, 0.05%-0.2% of the desonide micro powder and balance of pharmaceutically acceptable excipients. The topical desonide spraying agent is sprayed directly on a site of action, and is uniform to distribute, the effect is fast to take, in addition, by use of a direct spray method, contact with microorganism is reduced, by use of a closed dark storage container, contact with water and oxygen in the air can be avoided, and the drug stability can be improved.

Owner:CHONGQING HUAPONT PHARMA

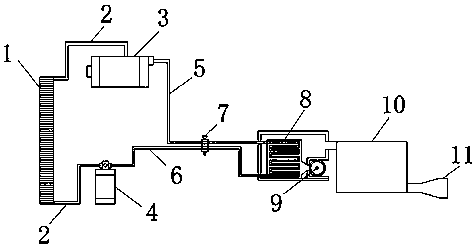

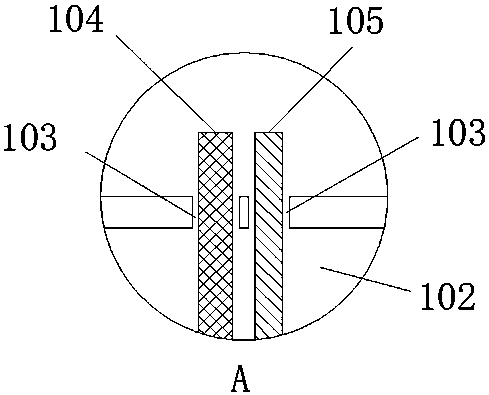

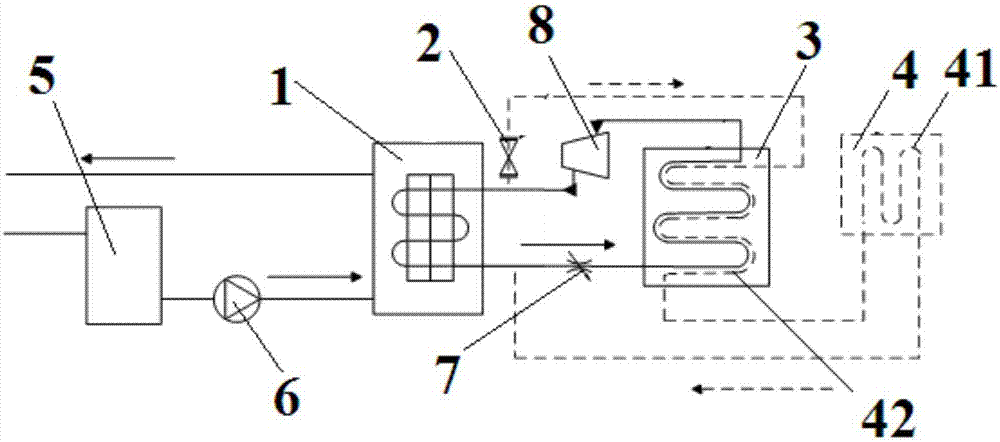

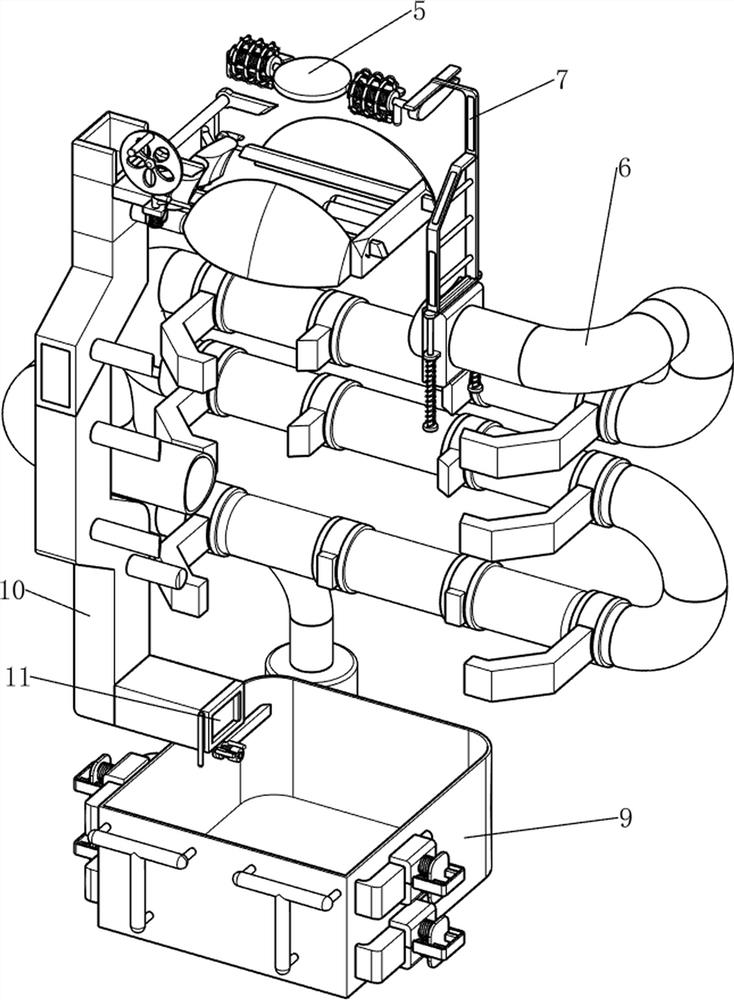

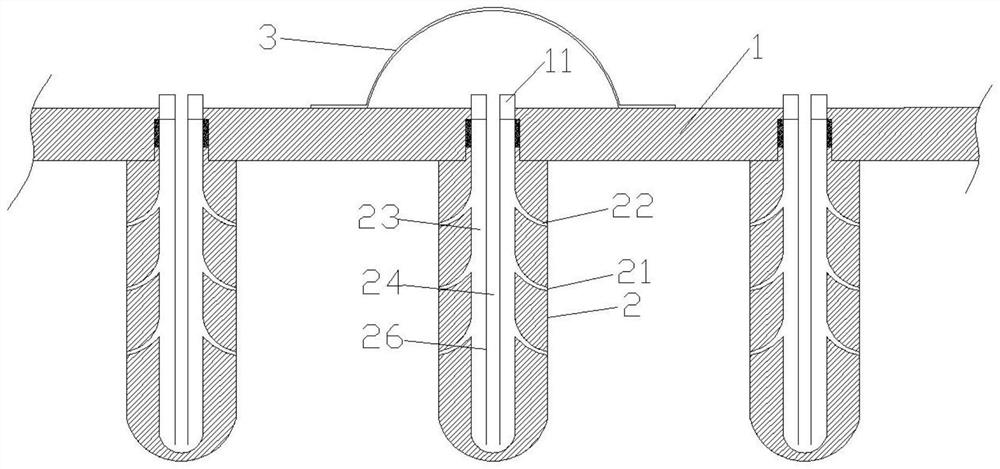

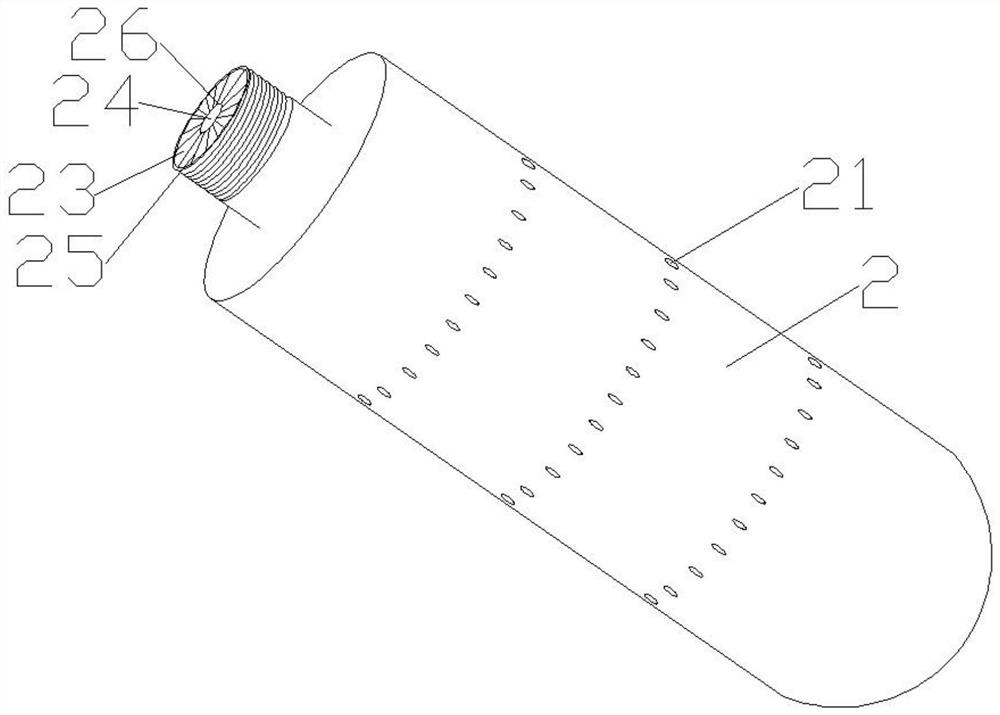

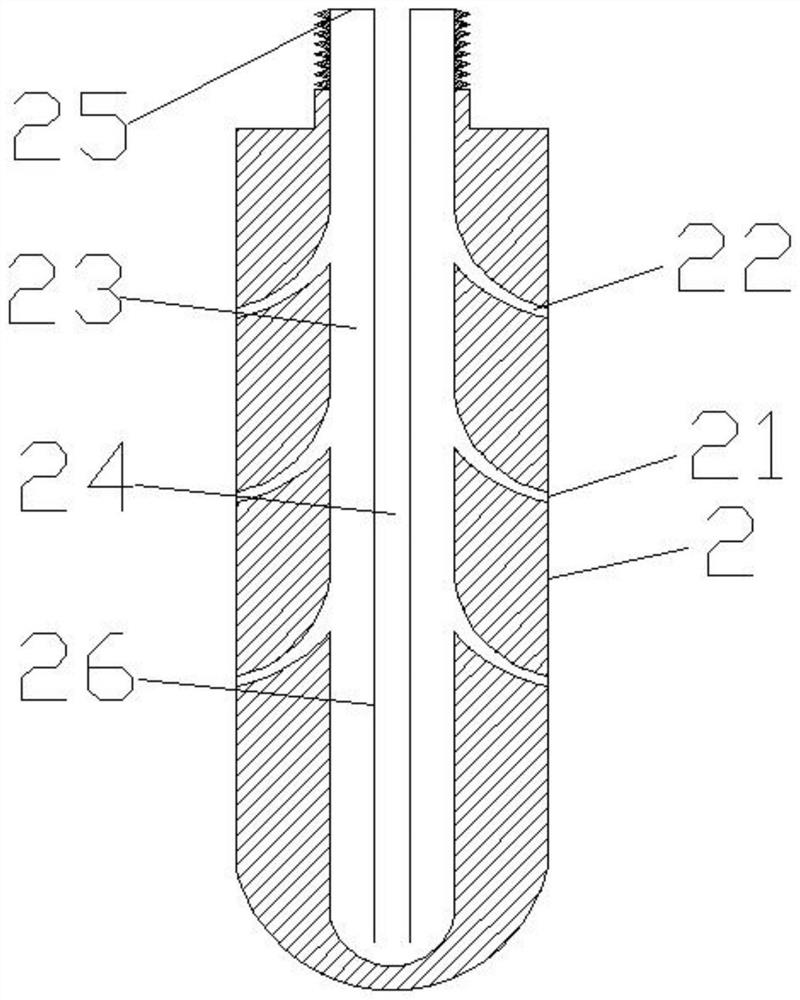

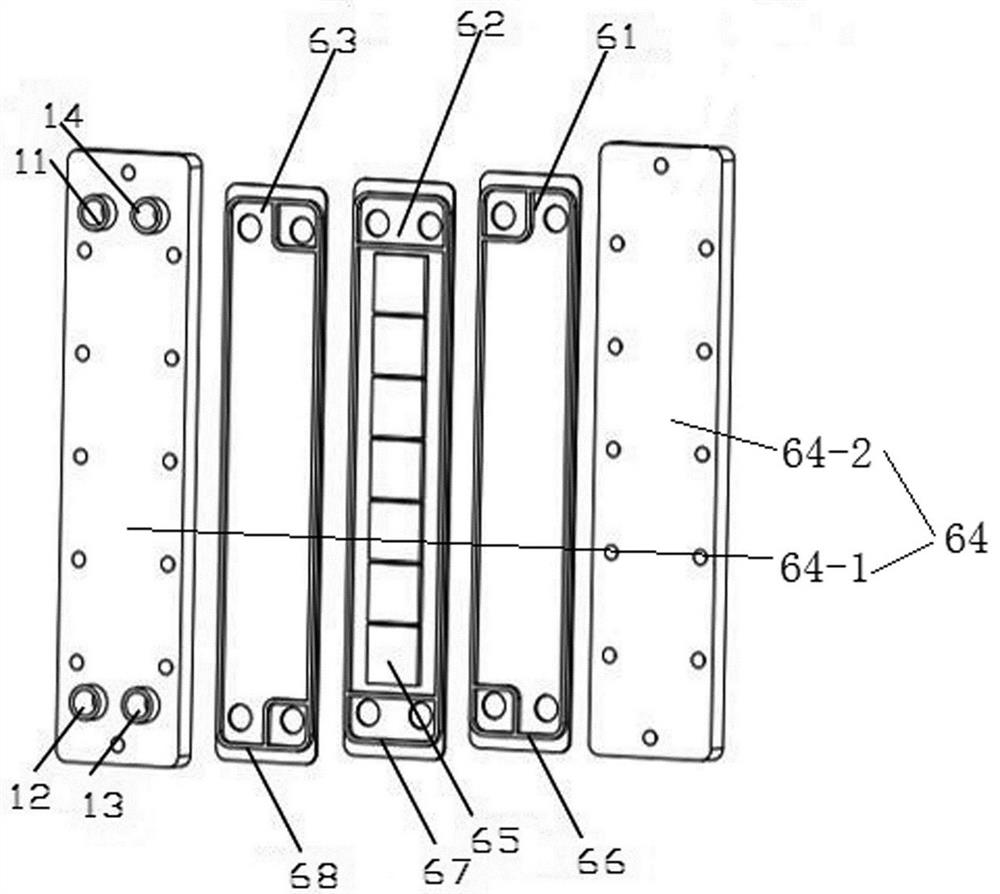

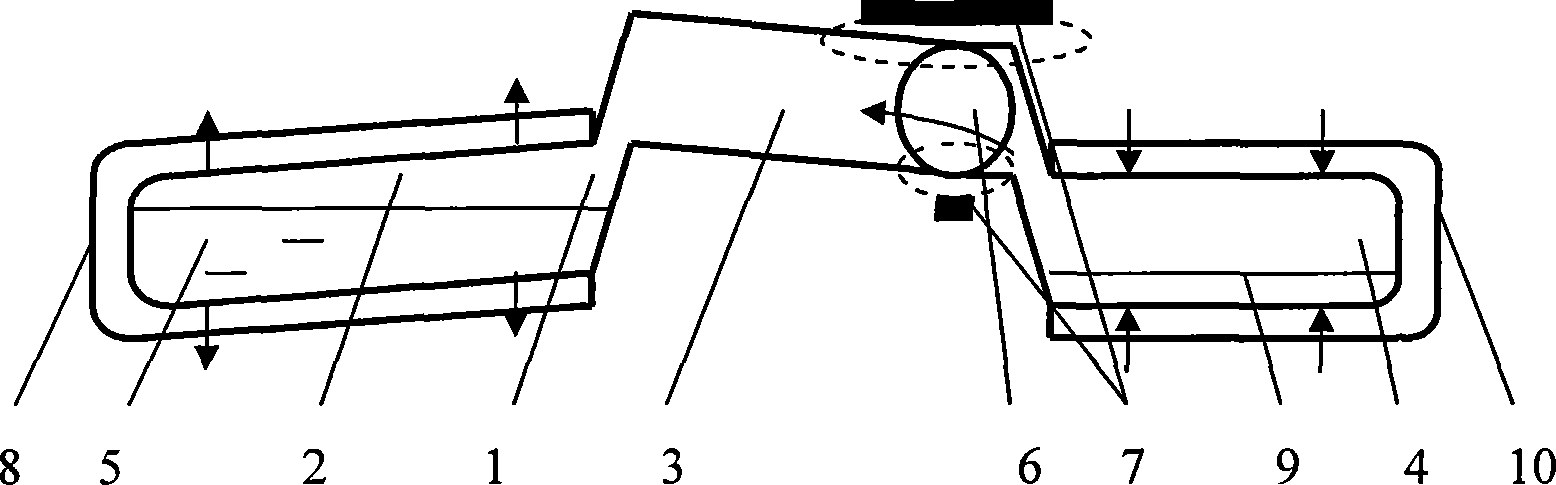

Air source heat pump anti-frosting system combined with photovoltaic system

PendingCN107270587AIncrease air temperatureAvoid frostHeat pumpsPV power plantsEvaporatorEngineering

The invention discloses an air source heat pump anti-frosting system combined with a photovoltaic system. The air source heat pump anti-frosting system comprises a condenser (1), an evaporator (3), a water pump (6), a water tank (5), an expansion valve (7) and a compressor (8), wherein a heat exchange coiled tube (41) is arranged in a photovoltaic system generation device (4); an outlet end of the heat exchange coiled tube (41) communicates with a connecting pipeline between a condensing channel and the expansion valve (7); an inlet end of the heat exchange coiled tube (41) is connected with one end of a heating pipeline (42) in the evaporator (3); the other end of the heating pipeline (42) is connected with one end of a switch valve (2); and the other end of the switch valve (2) communicates with a connecting pipeline between the condensing channel and the compressor (8). The air source heat pump anti-frosting system combined with photovoltaic system disclosed by the invention can increase the temperature of air around the heat pump evaporator, prevents frosting, and can improve power generation efficiency of the photovoltaic system.

Owner:武汉协鑫新能源电力设计有限公司

Automatic cooling machine for PPR products

The invention specifically relates to an automatic cooling machine for PPR products, which belongs to the field of PPR cooling. The automatic cooling machine for PPR products comprises a cooling water tank filled with cooling water, wherein a rotating shaft with blades is mounted in the middle part of the water tank; and the automatic cooling machine further comprises an induction switch and a circuit control device which are arranged on the sidewall of the water tank. According to the invention, mechanical operation replaces manual operation, so the automatic cooling machine overcomes the disadvantages that a worker has to take a product by hand and cooling the product by pressing with a board and that a PPR product undergoes great shrinkage and fast deformation in the prior art; and the purpose of operating a plurality of the automatic cooling machine by only one work is realized, so work efficiency of workers is improved.

Owner:ERA PIPELINE (CHONGQING) CO LTD

Novel heat radiation device for computer circuits

InactiveCN107291196APlay a cooling effectSolve the inconvenienceDigital data processing detailsCooling effectWater flow

The invention discloses a novel heat radiation device for computer circuits. The device comprises suckers, a small water pump, telescopic rods, a hollow board A, a hollow board B, a graphene heat radiation film, a fan and a working power supply. Four corners of the hollow board A are installed with the telescopic rods. Upper ends of the telescopic rods are provided with the suckers. The novel heat radiation device for computer circuits has the following beneficial effects: by adding water to the interior of the hollow board A, heat dispersed by the bottom of a computer can be absorbed when water flows; by absorbing heat at the bottom of the computer, the effect of radiating heat of the computer circuits is exerted; when the fan works, heat of the surface of a computer keyboard is radiated; due to the fact that a liquid discharge pipe is installed on the hollow board A and the hollow board B can be retracted by the telescopic rods, water in the hollow board A can be discharged so that weight is reduced and the device is convenient to carry; through the graphene heat radiation film installed on a water hose A, water temperature can be rapidly reduced; therefore, the cooling effect can be exerted when higher temperature is caused because a large quantity of heat is absorbed by water; and the novel heat radiation device for computer circuits is practical and suitable for broad promotion and application.

Owner:合肥锦和信息技术有限公司

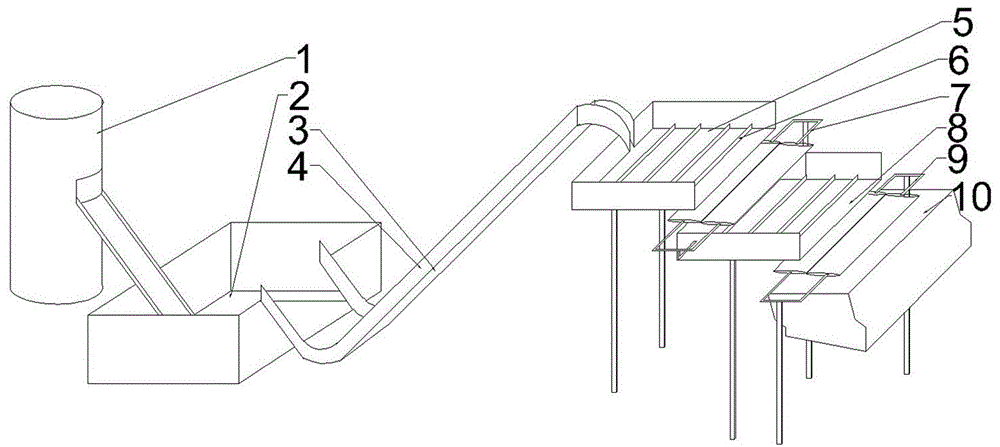

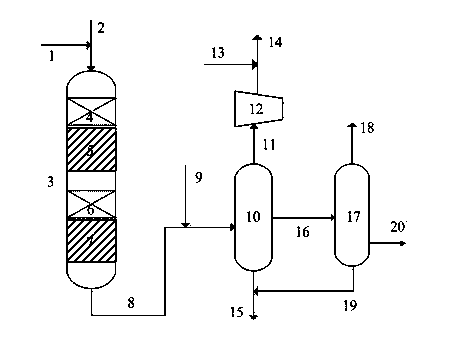

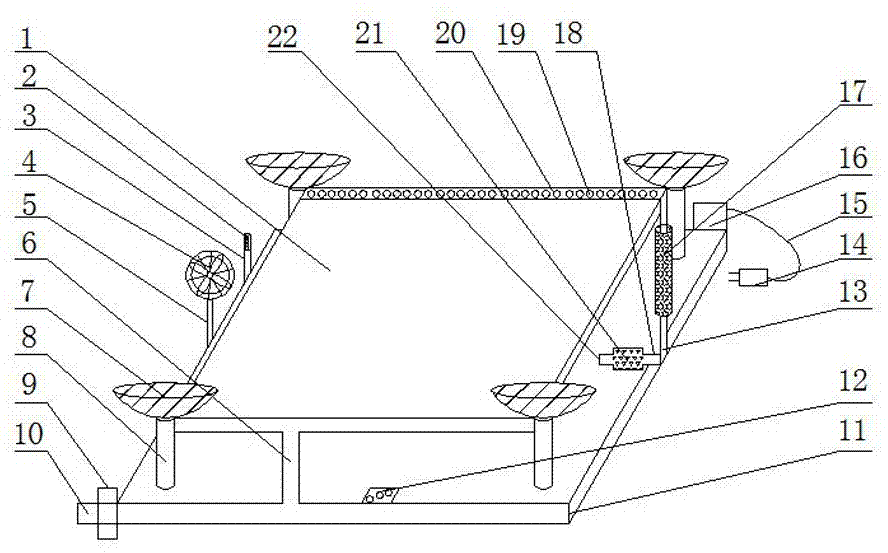

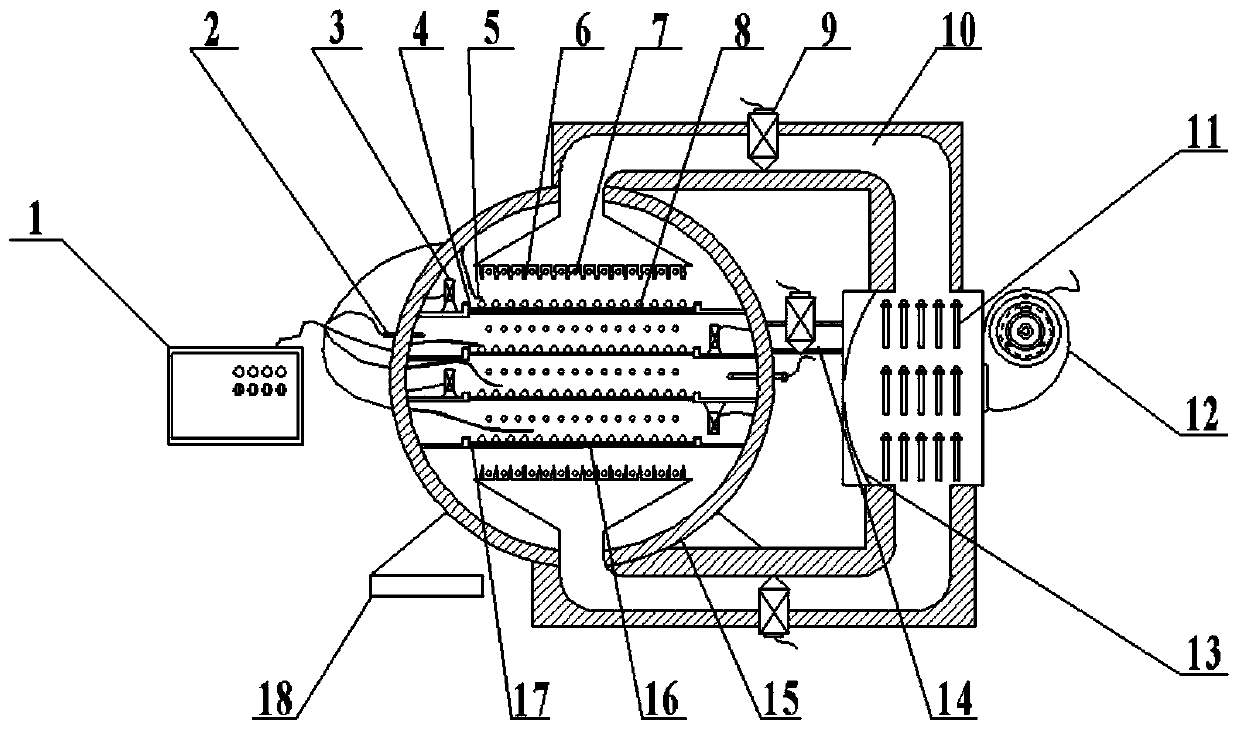

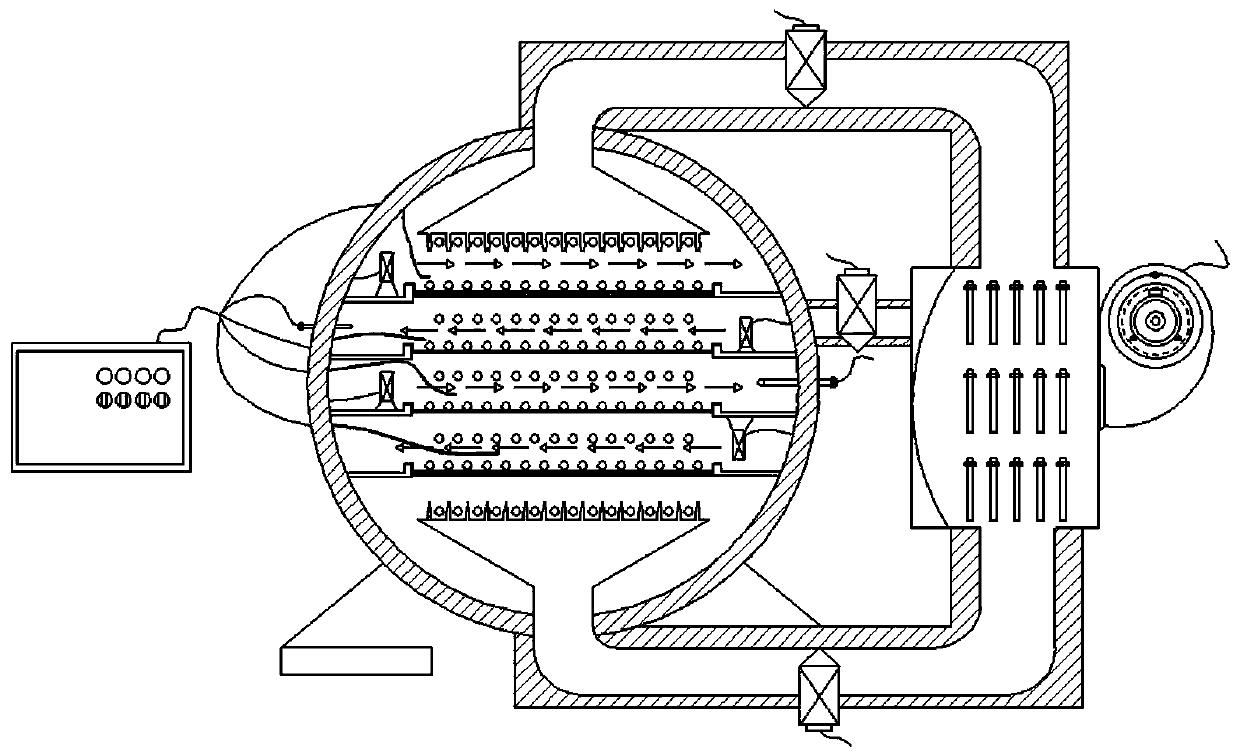

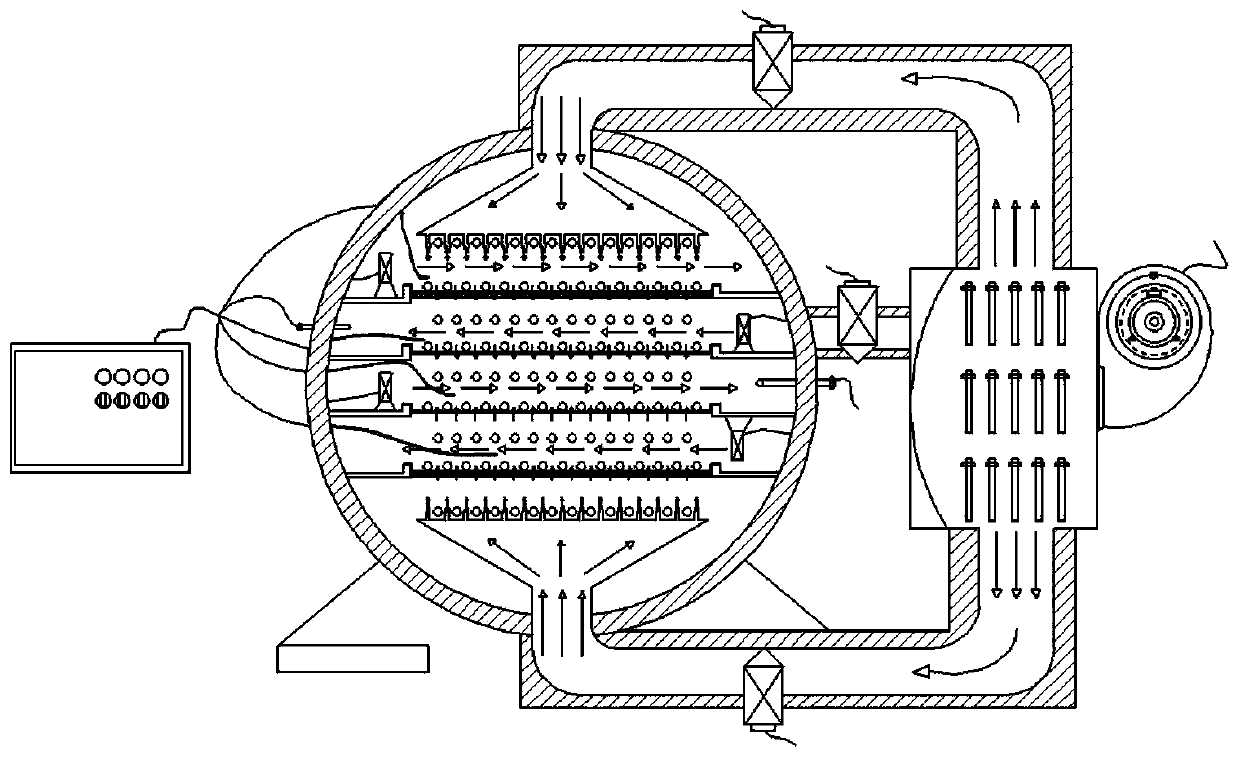

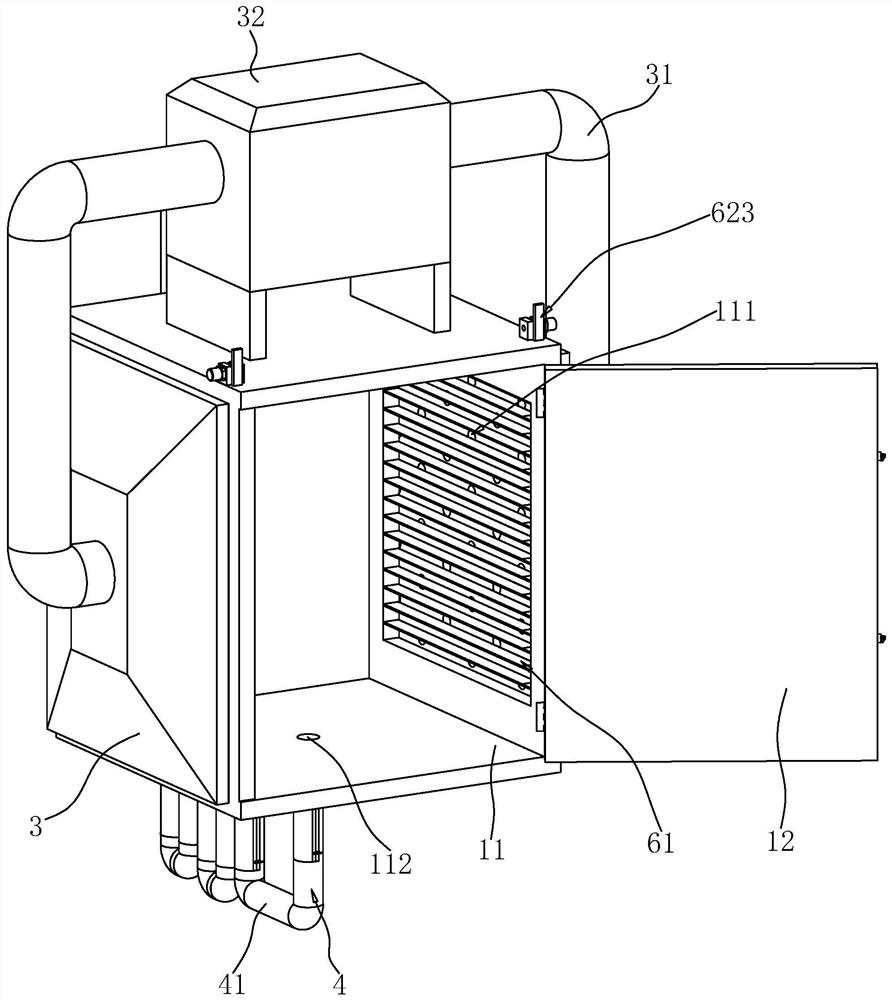

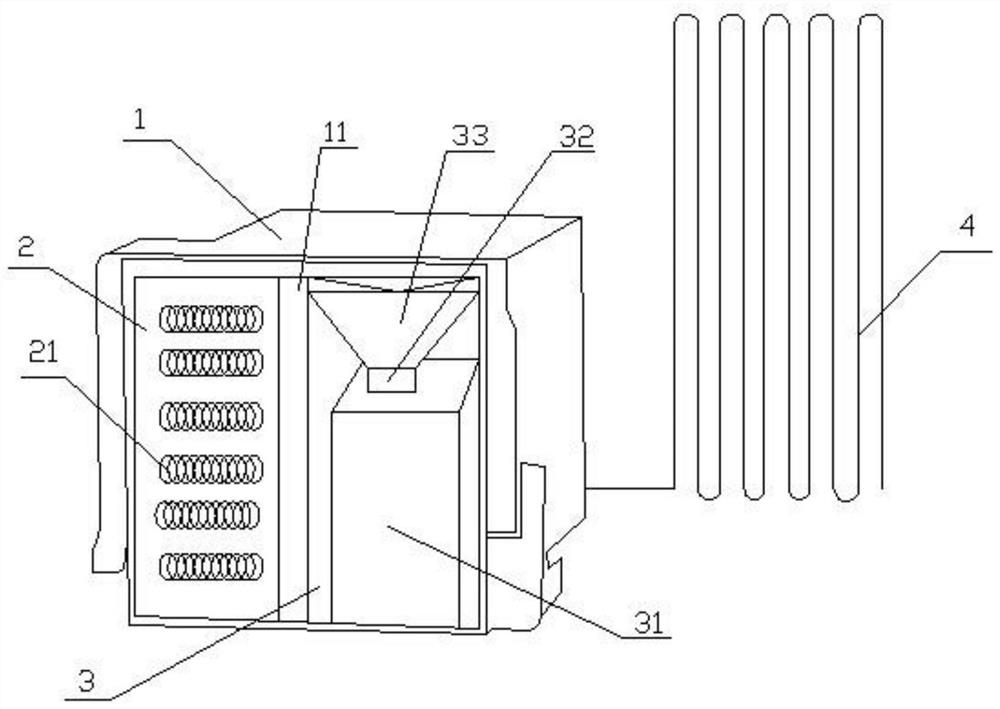

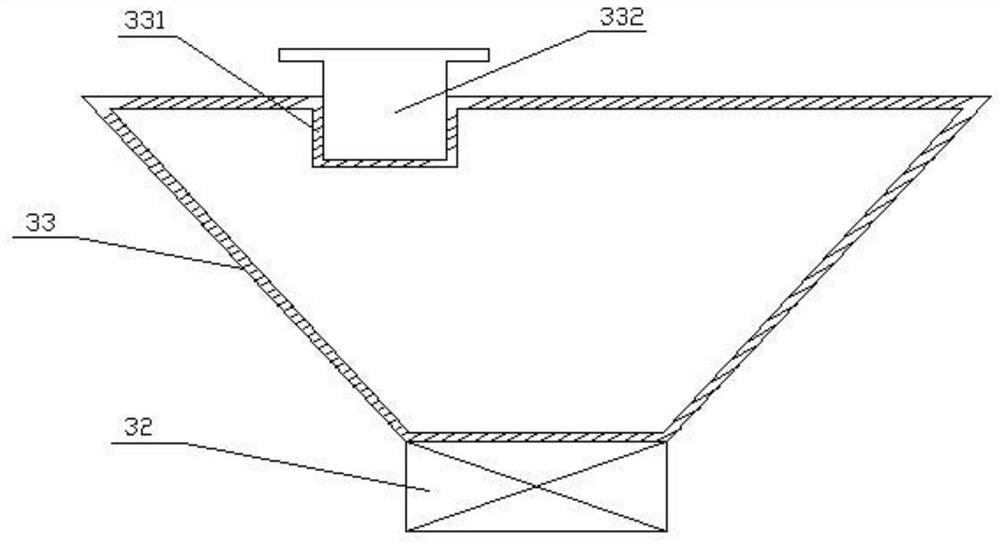

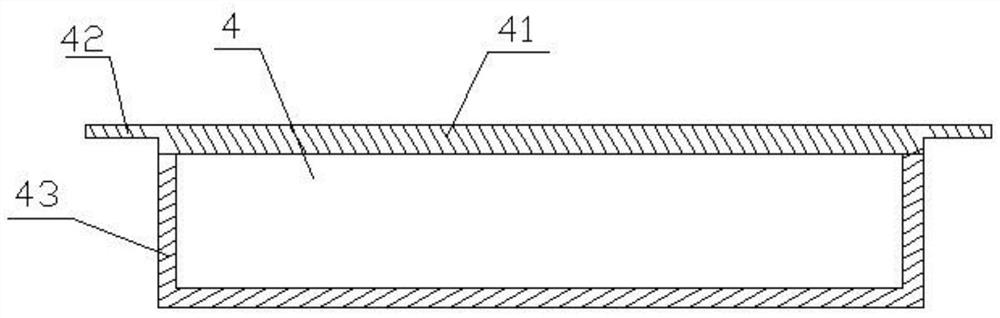

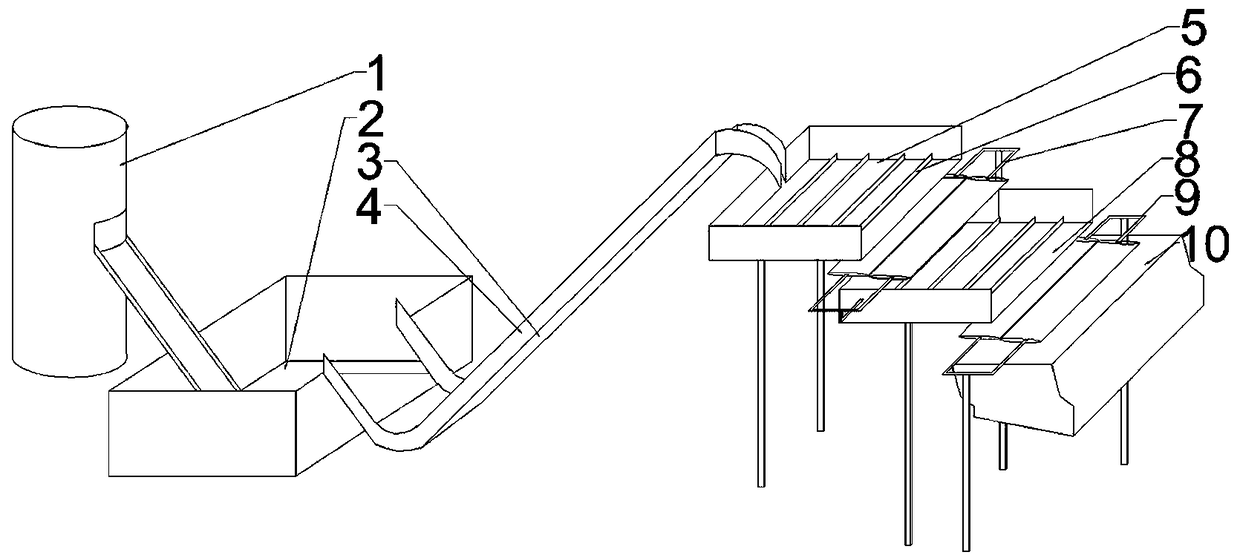

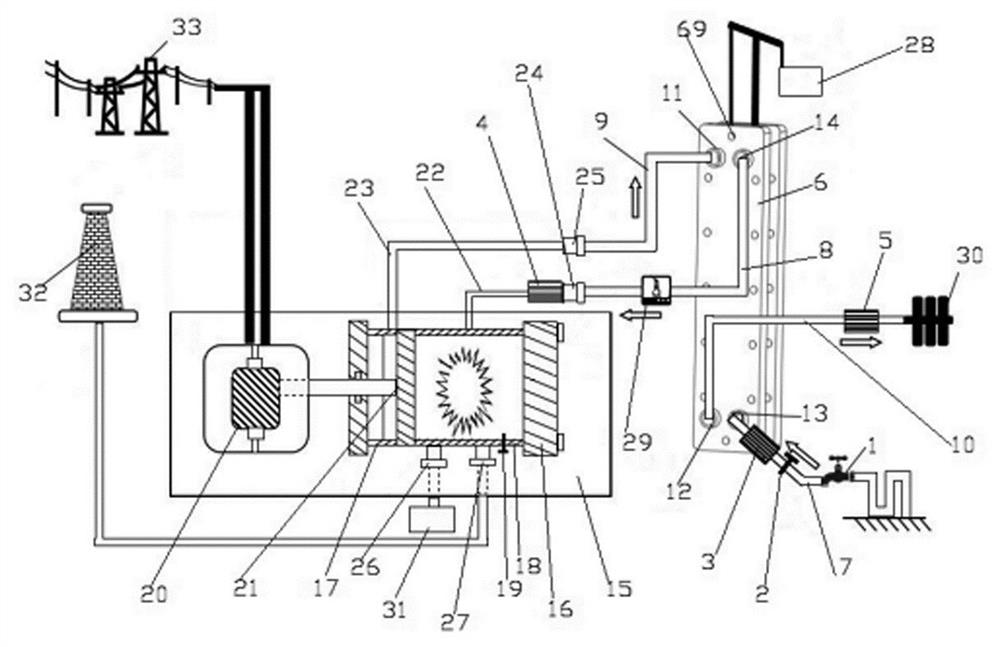

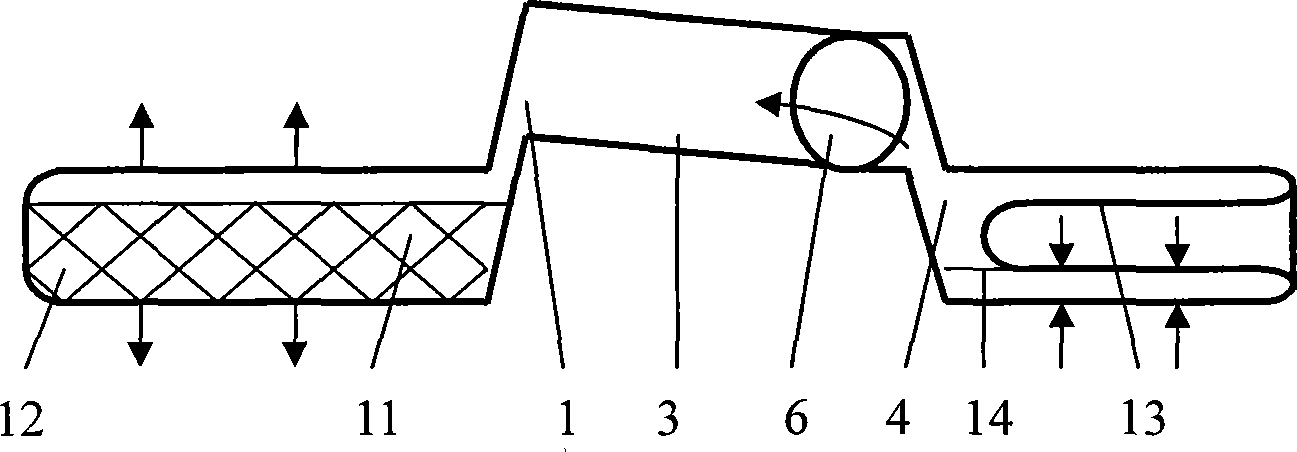

Gas jet impact drying and infrared radiation drying combined method and device

ActiveCN110671897AHigh degree of automationReduce labor intensityDrying solid materials with heatDrying gas arrangementsSpray nozzleAir blower

The invention belongs to the technical field of agricultural product machining, and particularly relates to a gas jet impact drying and infrared radiation drying combined method and device. The devicecomprises a material plate (4), a material (8), a box body (15), a box body support (18), an industrial control touch integrated machine (1), a temperature and humidity sensor (2), a cross flow fan (3), a temperature sensor PT100 (5), a spraying nozzle (6), an infrared heating pipe (7), a one-way electromagnetic valve (9), an air inlet pipeline (10), an electric heating pipe (11), an air blower (12), an arc-shaped flow guide plate (13), an air return pipeline (14), a patch type temperature sensor (16), a sensor support (17) and a dehumidifying draught fan (19). The industrial control touch integrated machine obtains the central temperature of the material through the patch type temperature sensor (16), obtains the temperature and relative humidity data in the box body through the temperature and humidity sensor, compares the data with set values and controls corresponding hardware to make an adjustment, and the whole device has the advantages of being high in automation degree, low inlabor intensity and the like.

Owner:CHINA AGRI UNIV

Drainage device used for smoke water treatment and capable of preventing smoke from being mixed with sewage

InactiveCN113289450AEasy to cleanAvoid heatGas treatmentDispersed particle separationCooling effectSewage

The invention relates to a drainage device, in particular to a drainage device used for smoke water treatment and capable of preventing smoke from being mixed with sewage. The invention aims to provide the drainage device used for smoke water treatment and capable of preventing smoke from being mixed with sewage, which can improve the working efficiency and reduce energy waste. According to the technical scheme, the drainage device for smoke and water treatment and capable of preventing smoke and sewage from being mixed comprises a main cylinder, an air inlet, a base, a lower frame, an air inlet control mechanism, a water circulation mechanism and a water opening mechanism, the air inlet is formed in the top of the main cylinder, the base is arranged on the main cylinder, and the lower frame is arranged between the top of the base and the bottom of the main cylinder. By arranging the water circulation mechanism, the situation that water becomes hot after cooling the main cylinder, and the cooling effect cannot be achieved is avoided; and by arranging the filtering mechanism, after sewage is filtered by a filtering circular plate, people can conveniently clean particles on the filtering circular plate.

Owner:杨菲菲

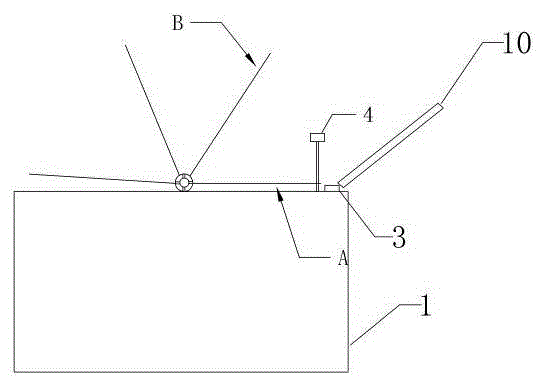

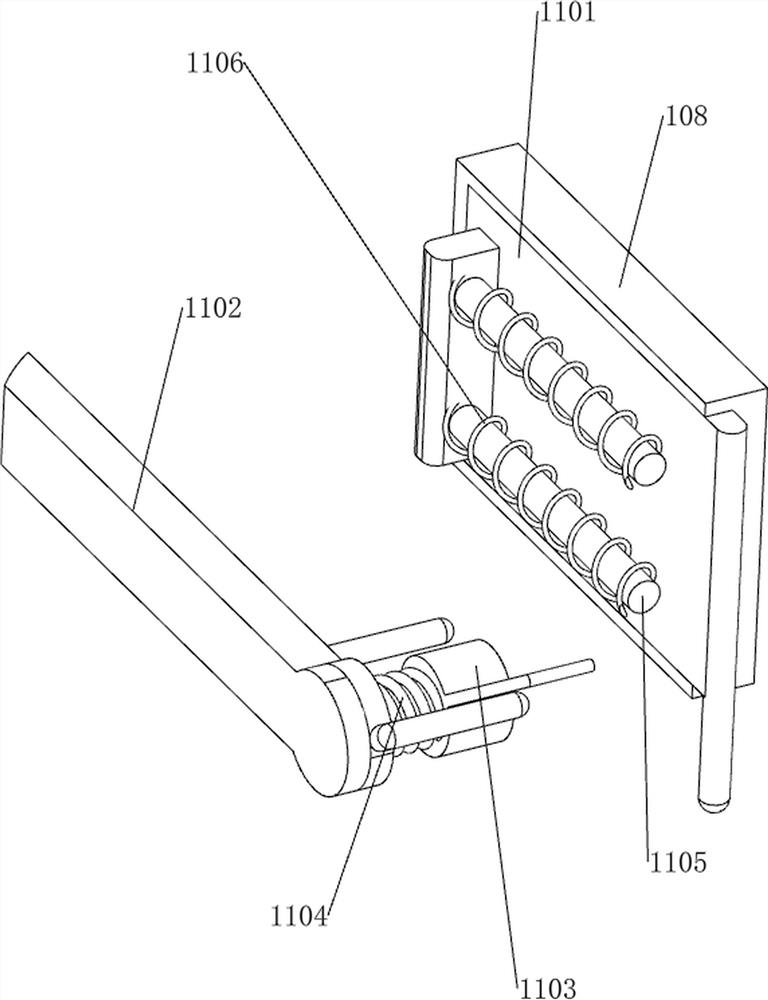

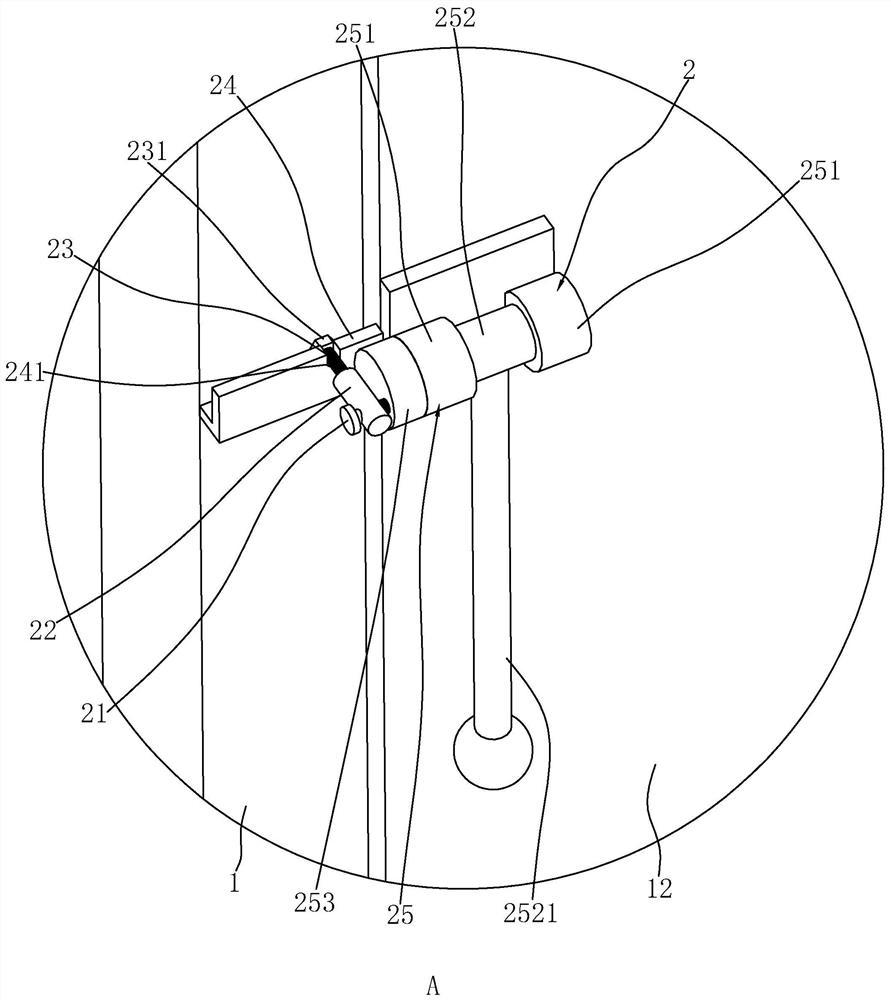

Pipe inner wall positioning and cooling device and method

PendingCN109365978ANo cooling effectAvoid meltingWelding/cutting auxillary devicesHigh frequency current welding apparatusThermal stateSprayer

The invention discloses a pipe inner wall positioning and cooling device and relates to the technical field of pipe inner wall cooling. The pipe inner wall positioning and cooling device comprises a liquid supply pipe, a liquid storage box, a liquid conveying pipe, a water pump, a bracket, a self-rotation sprayer, a temperature sensor, a temperature controller and a relay. The pipe inner wall positioning and cooling device adopts the temperature sensor to position a thermal-state steel pipe to prevent a steel pipe forming machine tool from reassembling and adjustment when a component is repaired or replaced or prevent the steel pipe forming machine tool from component position adjustment during the cleaning process to avoid reassembling and adjustment, so that the thermal-state steel pipeis cooled. The pipe inner wall positioning and cooling device adopts the self-rotation sprayer to cool the inner wall of the steel pipe, so that the situation that high-frequency welding does not coolthe inner surface of the steel pipe to cause a crack and to melt the oxide scale of the steel pipe is prevented.

Owner:江苏宏宝优特管业制造有限公司

Hot air circulating oven

InactiveCN112146373ASlow lossAchieve high efficiency and energy savingDrying gas arrangementsDrying solid materialsEngineeringLaboratory oven

The invention relates to a hot air circulation oven which comprises an oven body, a drying chamber is formed in the oven body, an opening mechanism is arranged on one side of the drying chamber, a sealing door plate is arranged at the opening of the drying chamber, air inlets allowing hot air to enter are formed in the two opposite sides of the drying chamber, a moisture discharging opening is formed in the lower side of the drying chamber and communicates with dehumidifying pipes through an exhaust fan, the dehumidifying pipes are perpendicular to the horizontal plane, every two adjacent dehumidifying pipes communicate with each other through a communicating pipe, the two communicating pipes located on the same dehumidifying pipe are located on the upper side and the lower side of the dehumidifying pipe respectively, the multiple dehumidifying pipes and the communicating pipes are arranged in an arch shape, the dehumidifying pipe located at the tail end is connected with an air heater, the other end of the air heater is connected with a hot air blower, the other side of the hot air blower communicates with a hot air cover, and the hot air cover is attached to the side wall of thebox body and communicates with the air inlets. The hot air circulation oven has the effect of reducing the energy consumption.

Owner:北京春风药业有限公司

A controller for limiting the temperature inside the switch cabinet

ActiveCN110134159BEnsure safetyAvoid lostTemperatue controlSubstation/switching arrangement cooling/ventilationTemperature controlChemical reaction

The invention discloses a controller for limiting inside temperature of a switch cabinet, and the controller comprises a controller outer box, and further comprises a heat control box, a cold controlbox and a heat absorption tube, wherein the heat control box and the cold control box are arranged inside the controller outer box, the heat absorbing tube is installed outside the controller outer box, the heat control box and the cold control box are separated by a heat insulating layer, a plurality of resistance coils are installed inside the heat control box, a water tank is installed inside the cold control box, a sealed box is installed above the water tank, and one end of the water tank is installed with one end of the heat absorbing tube. The controller of the invention, from the pointof view of the temperature controller itself regulating the internal temperature of the circuit box, provides a temperature to guarantee the normal operation of the circuit box when exceeding the normal working temperature in an extremely cold environment, and delays the burning temperature inside the circuit box through the heat absorption of chemical reaction in an extremely hot environment, sothat the circuit box can be safely used to delay the occurrence of danger.

Owner:HUAINAN WANTAI RONGBO LIGHTING TECH

The method of solving the blockage of the hollow wire of the stator bar of the generator and inhibiting the corrosion

The invention discloses a method for solving the obstruction of a hollow lead of a generator stator bar and inhibiting the corrosion of the hollow lead. The method comprises the following steps: pickling for descaling, activating, and prefilming, wherein a composite acid used in the pickling step comprises, by weight, 65-92 parts of aminosulfonic acid and 8-35 parts of hydrofluoric acid, and a prefilming agent used in the prefilming step comprises, by weight, 35-45 parts of tolyltriazole, 40-44 parts of 2-mercaptobenzothiazole, 10-25 parts of benzotriazole and 10-15 parts of hydroxypropyl methyl cellulose. The method can realize the thorough solving of copper corrosion deposits adhered in the hollow lead and the formation of a firm molecular film in the hollow lead without corroding other metal materials in the cooling water system of the generator stator, effectively prevents the direct contact of copper atoms with cooling water, and substantially inhibits the electrochemical corrosion of copper in the cooling water with a low pH value.

Owner:SHANDONG ZHONGSHI YITONG GRP

A flat tea press machine

ActiveCN106739098BSuppression efficientReduce brittlenessPre-extraction tea treatmentShaping pressAgricultural engineeringBrittleness

The invention discloses a flat tea pressing machine. The flat tea pressing machine comprises a drying machine, a cooling device and a pressing device. The cooling device comprises a cooling frame and a lifting machine. The lifting machine is provided with a conveying belt used for conveying tea leaves. The pressing device comprises a plurality of vibration grooves arrayed in a stepped manned, a roller couple is arranged between the adjacent upper and low vibration grooves and supported by an inlet of the lower vibration groove, an upper vibration groove outlet is formed over a pressing seam in the middle of the corresponding roller couple, each roller couple and the corresponding lower vibration groove are connected through a rotating rod, and each lower vibration groove is connected with a tea outlet hopper. The stir-frying machine carries out drying and pressing independently, dried tea leaves become lower in brittleness after being cooled through the cooling frame, and tea dust is not prone to appearing. Each roller couple is composed of two rollers, wherein one roller rotates clockwise, the other roller rotates anticlockwise, when cooled tea leaves are put into the seam between the two rollers, the two rollers will produce pressure for the tea leaves, two kinds of pressure press the tea leaves, and the tea leaves can be shaped more quickly and durably.

Owner:GUIZHOU MEITAN LINSHENG TEA

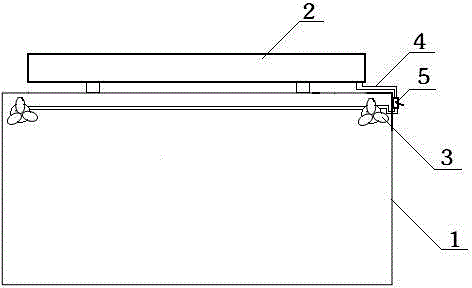

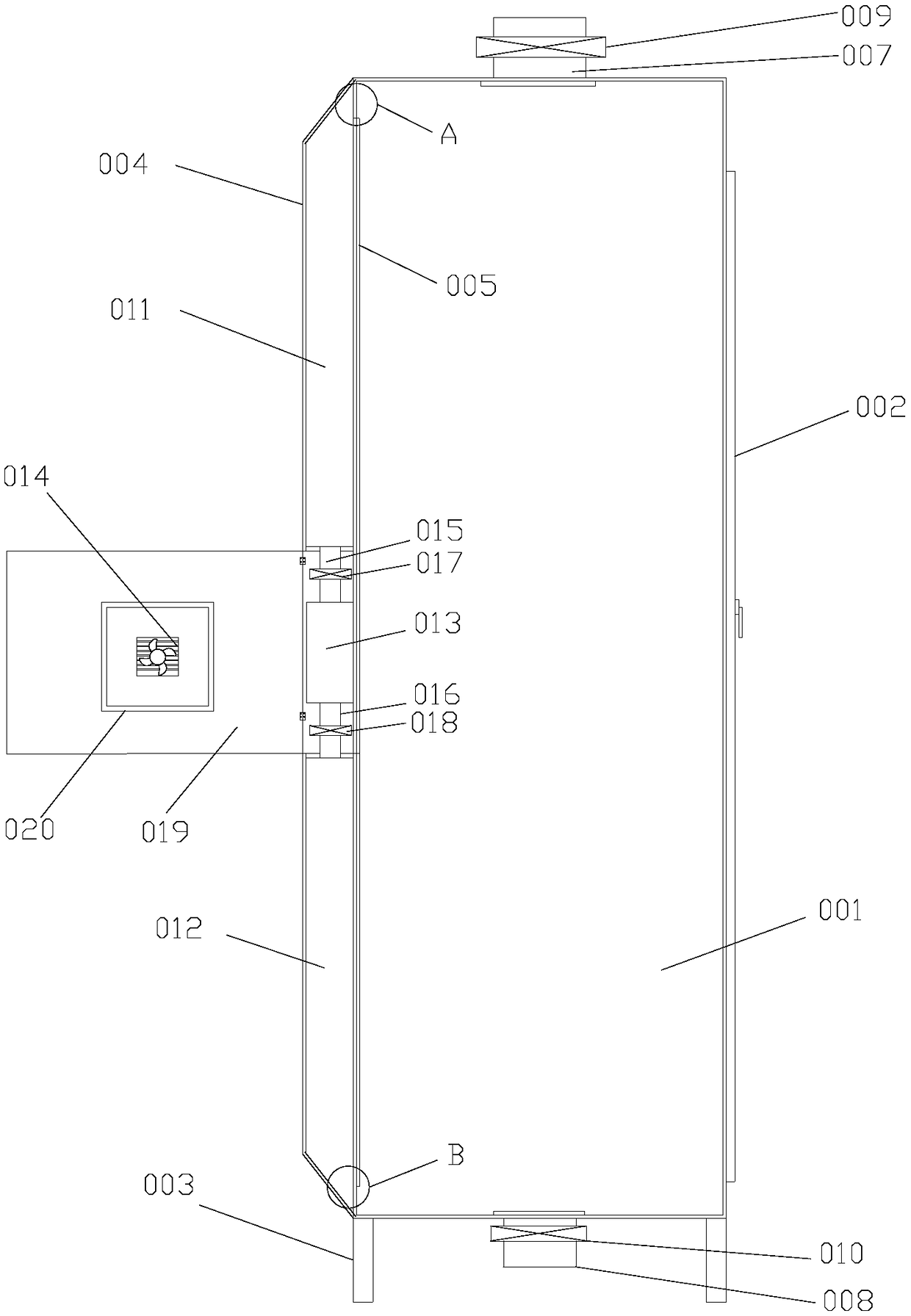

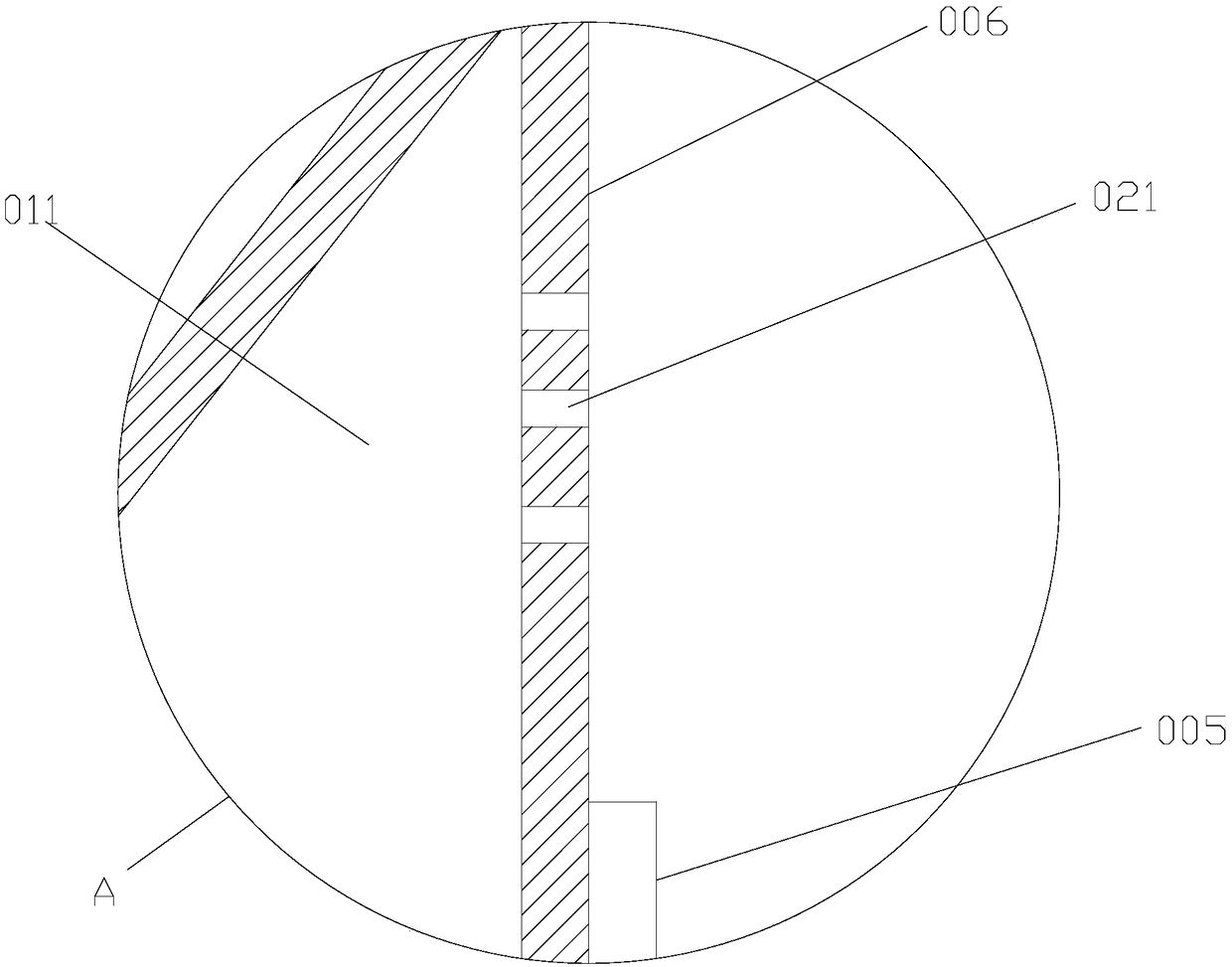

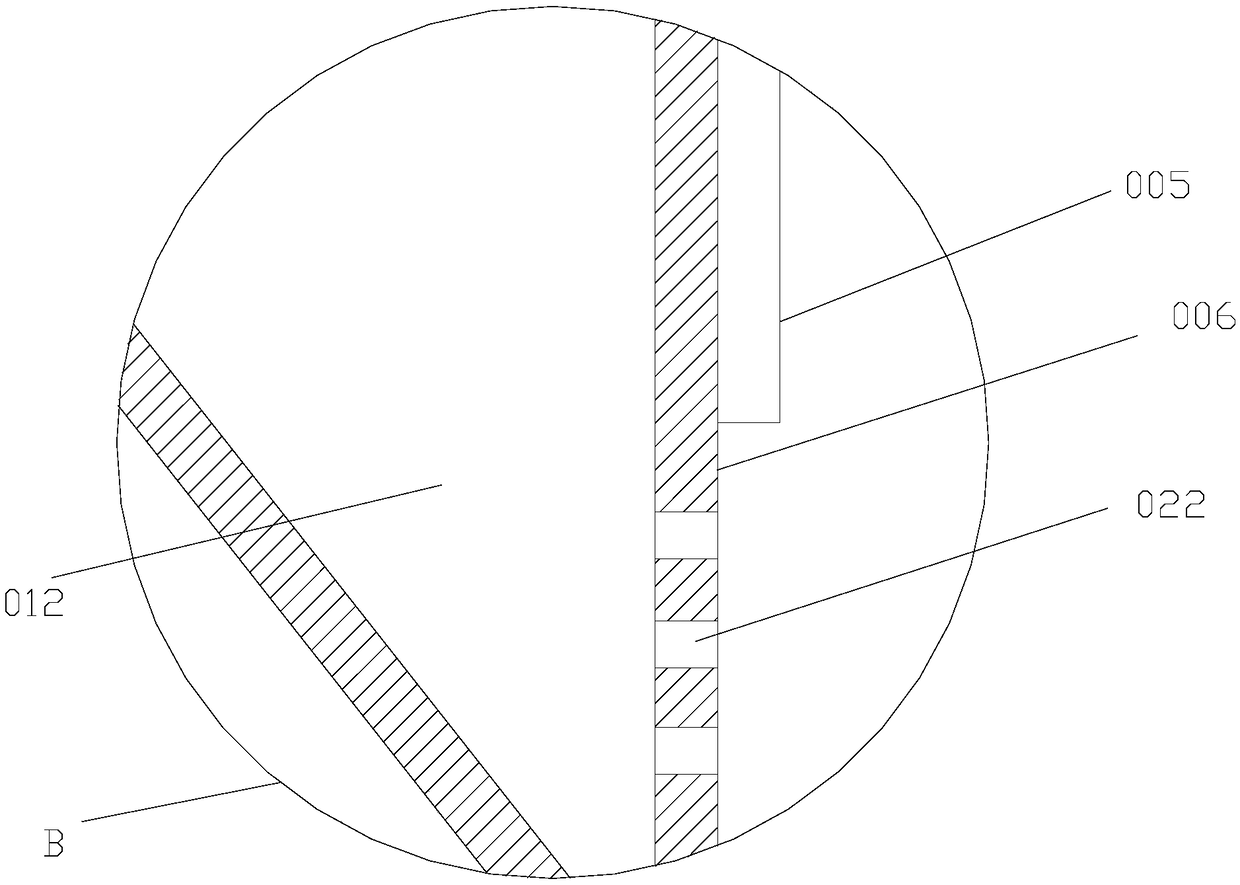

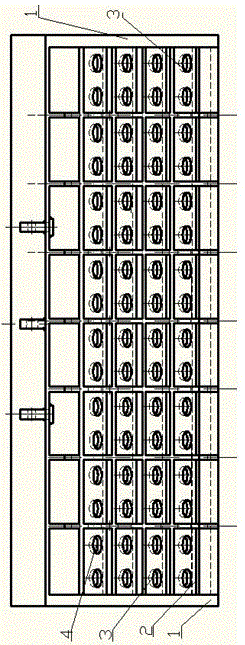

Outdoor box-type equipment with solar self-ventilation devices

InactiveCN105226527ANo pollution in the processNo cooling effectSubstation/switching arrangement cooling/ventilationFree energiesCooling effect

The invnetion relates to outdoor box-type equipment with solar self-ventilation devices. The outdoor box-type equipment comprises a box body (1). The outdoor box-type equipment is characterized in that the box body (1) is provided with a solar cell panel (2), one or more exhaust fans (3) are disposed in corners in the box body (1) and face equipment, and power supply output lines (4) of the solar cell panel (2) are connected to the exhaust fans (3) in parallel through a power supply switch (5). The outdoor box-type equipment has the advantages of less investment, convenient refits and the obvious cooling effect; and the solar cell panel can provide a new environmental-friendly, safe and pollution-free energy. Through the outdoor box-type equipment, a cooling function of box-type equipment can be achieved, a solar resource can also be used, and resource waste is reduced.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO QIHE POWER SUPPLY CO +1

A control method for a cooling system of an electrical cabinet

InactiveCN106786045BReduce the temperatureIncrease temperatureSubstation/switching arrangement cooling/ventilationBasementEngineering

The invention discloses an electrical cabinet. An upper ventilation pipe and a lower ventilation pipe are arranged on a cabinet body, an upper air chamber is arranged at an upper part of a back package cavity of the cabinet body, a lower air chamber is arranged at a lower part of the back package cavity, an air outlet chamber is arranged at the center of the back package cavity, an air outlet door is hinged with the middle part of the back package cavity, an exhaust fan is arranged on the air outlet door, and an upper ventilation hole and a lower ventilation hole are formed in a back plate. The invention also discloses a heat dissipation system of the electrical cabinet. A basement is arranged below a ground plate of a power distribution room, an air duct is arranged above the electrical cabinet, an exhaust pipe is connected with the top of the air duct, an air blower is arranged outside the power distribution room, a hot air cabinet is fixedly arranged on a side surface of the air duct, upper air holes are formed in a bottom surface of the air duct and are in one-to-one correspondence to the electrical cabinets, and lower air holes are formed in the ground plate of a power distribution cabinet and are in one-to-one correspondence to the electrical cabinets. The electrical cabinet has the advantages that hot air can be borrowed from the electrical cabinet aside to increase the temperature of the electrical cabinet when the temperature of the electrical cabinet is excessively low, the condensation-preventing cost is lower, meanwhile, independent or centralized heat dissipation can be achieved, and the heat dissipation effect is good.

Owner:浙江科源电器有限公司

A mold for producing Longlu capsules

The invention discloses a mold for producing Longlu capsules, comprising a steel plate, a mold column and a handle; the main body of the mold column is a cylinder, and the bottom end is a semicircle; Air inlet and outlet; the air passage is an arc-shaped flared structure; the smaller end of the vertical section of the air passage is fixedly connected with the air hole, and the other end is fixedly connected with the air inlet; the main body of the air inlet is a cylinder The bottom end is semi-circular or semi-elliptical; the cross section of the main body of the air inlet is annular; the annular center of the air inlet is provided with an air outlet; the cross section of the air outlet is circular, and the circular edge and the air inlet The edges of the annular inner ring are overlapped; an annular wall is arranged at the overlap of the air outlet and the air inlet; the steel plate and the die column are detachably connected with threads; The mold for producing Longlu capsules of the invention has the advantages of rapid exhaust, rapid cooling, easy demoulding, easy disassembly, and high productivity.

Owner:TIANJIN HEZHI PHARMA CO LTD

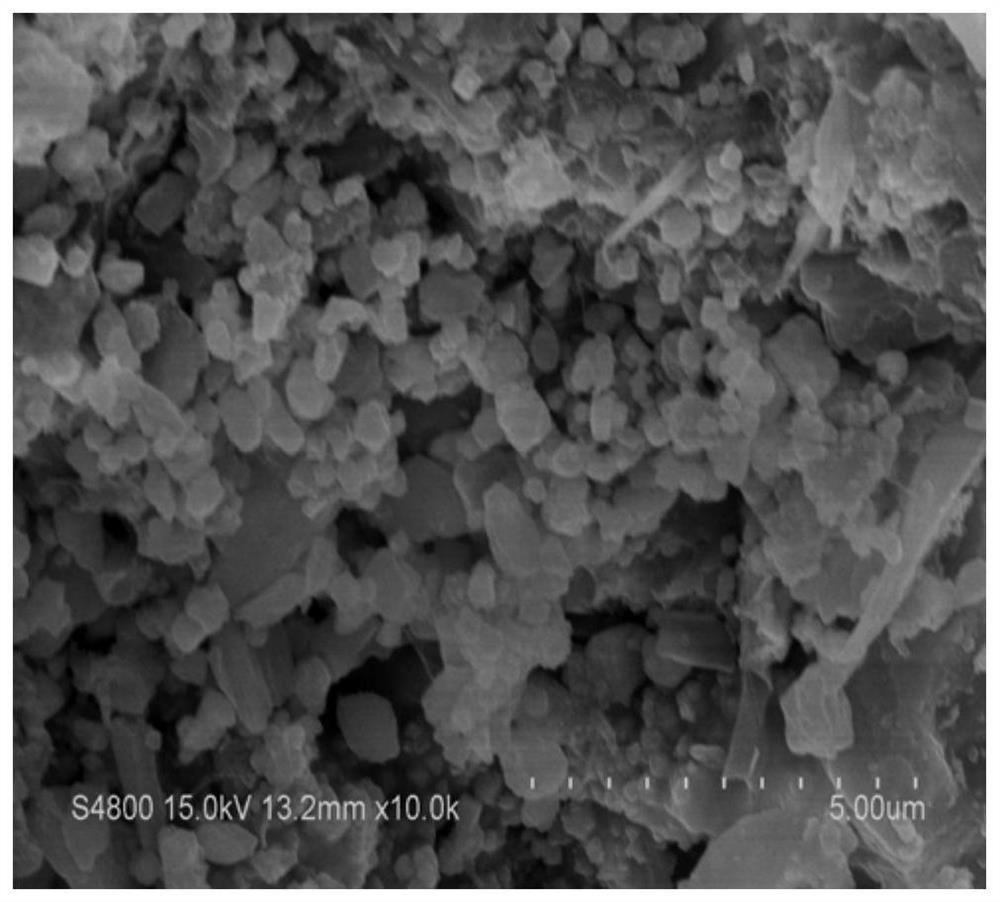

A 160km/h express truck brake pad for preventing thermal cracking of brake disc and manufacturing method thereof

ActiveCN109667865BImprove defects such as thermal crackingReduce wearOther chemical processesFriction liningButyl rubberTruck

The invention relates to a 160km / h express freight car brake pad for preventing thermal cracking of the brake disc and a manufacturing method thereof. The 160km / h express truck brake pads for preventing heat cracking of the brake discs include the following components and weight percentages: boron modified phenolic resin 20%-40%, butyl rubber 10%-18%, reinforcing fiber 6% ‑10%, carbon fiber 10%‑18%, sepiolite fiber 1%‑5%, vermiculite 1%‑8%, fluorite 2%‑8%, magnesium oxide 2%‑9%, clay 2%‑8 %, dispersant 0.2%‑3%. Compared with the prior art, the brake disc of the invention has a lower density, is more convenient to use, and can reduce vehicle quality. The brake pad of the present invention has a microporous structure, and the micropores play the role of heat dissipation, which can effectively reduce the friction temperature, the friction coefficient does not decline at a high temperature of 600°C, and the brake disc has no hot spots and cracks, effectively protecting the couple. The wear of the brake pads is low and the service life is longer than that of similar products.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

Heat exchangeable thermovoltaic power generation system

PendingCN111663997ATake advantage ofEfficient use ofLiquid coolingInternal combustion piston enginesWater sourceWater flow

The invention relates to the technical field of energy utilization, more in particular to a heat exchangeable thermovoltaic power generation system. The heat exchangeable thermovoltaic power generation system comprises a water source, a thermovoltaic power generation unit and a gas generator unit. After the water source is started, a water flow passing through a cold end of the thermovoltaic powergeneration unit enters a cooling water channel of an air cylinder through a water inlet pipe to cool the air cylinder, the water with raised temperature after heat exchange flows into a hot end of the thermovoltaic power generation unit through a water outlet pipe, the thermovoltaic power generation unit can carry out thermovoltaic power generation by means of a water flow temperature difference,and finally, the hot water after thermovoltaic power generation flows into a heating system through a fourth water pipe to achieved gradient utilization of energy sources. The system not only can guarantee a cooling purpose of original cylinder sleeve water, but also can be used for power generation and heating and lowering the improvement cost to the maximum extent. The heat exchangeable thermovoltaic power generation system is primarily applied to the field of the thermovoltaic power generation system with a heat exchange function.

Owner:江苏芷泉能源科技有限公司

A processing method of high-quality large-diameter thin-walled metal cylinder

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

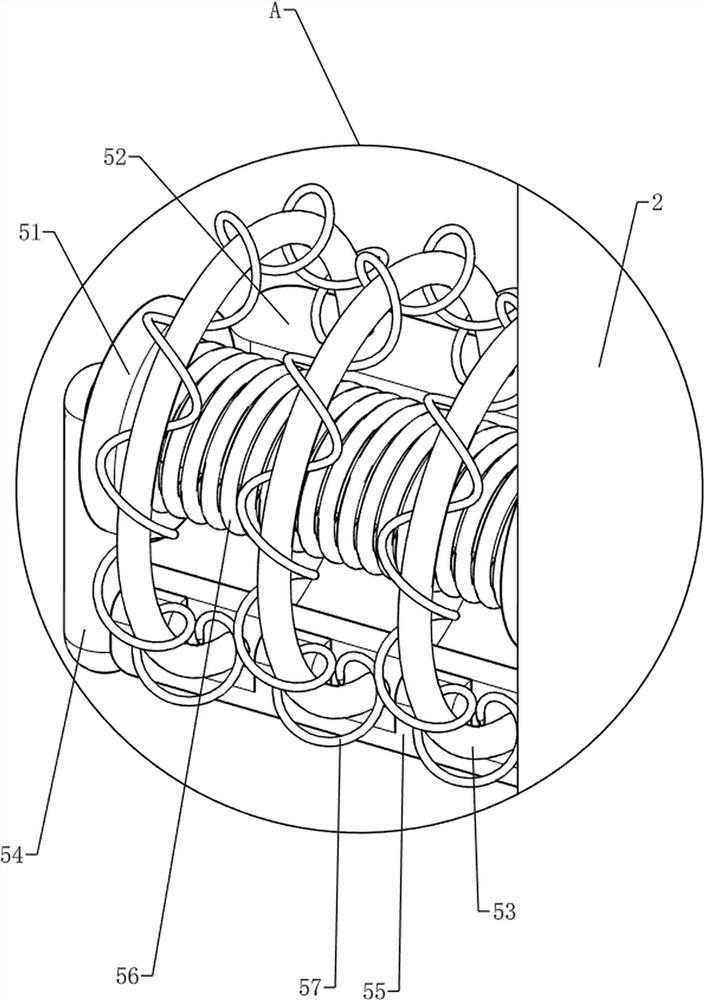

Glass shell absorption type adsorption refrigeration element manufacturing method equipment and products

InactiveCN102401505BLow priceHigh strengthClimate change adaptationEnergy efficient heating/coolingLinear motionAdsorption refrigeration

The invention relates to a method for manufacturing an absorptive type or adsorptive type refrigeration element for glass shell. In the method, glass is used as a container for the absorptive type or adsorptive type refrigeration element. In the absorptive type or adsorptive type refrigeration element manufactured according to the method, the closed container is vacuumized and filled with an absorbent solution or an absorbent material working medium pair, and a valve also can be arranged in the refrigeration element; and the refrigeration element comprises three function parts, namely an absorption chamber / regeneration chamber or an adsorption chamber / desorption chamber, a condensation section and an evaporation chamber, and is characterized by comprising the glass closed container. The glass tube bending equipment special for the glass shell absorptive type or adsorptive type refrigeration element is characterized in that an intermediate clamp can made vertical motion relative to an axis of a glass tube, clamps at two ends can make linear motion along the axis of the glass tube and make rotary motion relative to the axis of the glass tube. The method has the advantages that the glass container does not generate noncondensable gas, is less in deflation, resistant to corrosion and high in tightness, and the manufactured element which is in a shape like a Chinese character 'pin' can be formed at one time by hot drawing. Four embodiments are provided in the figure.

Owner:赵钦基

Slab heating furnace without water-cooled furnace door

ActiveCN103884185BImprove cooling effectHigh strengthFurnace componentsThermal insulationEngineering

Owner:JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com