Automatic cooling machine for PPR products

A technology of automatic cooling and automatic cooling device, which is applied in the field of cooling and shaping of PPR formed products, to achieve the effect of improving cooling efficiency, reducing the number of personnel used, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

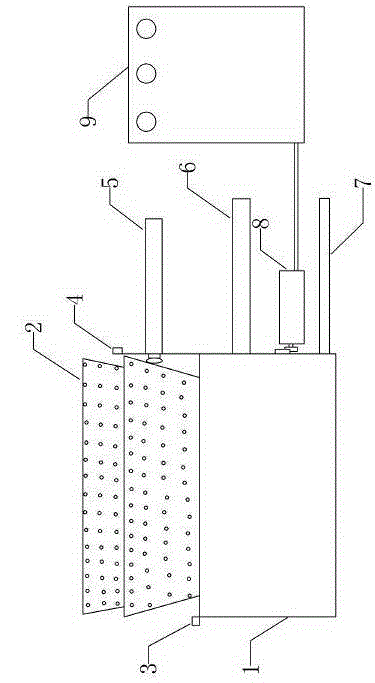

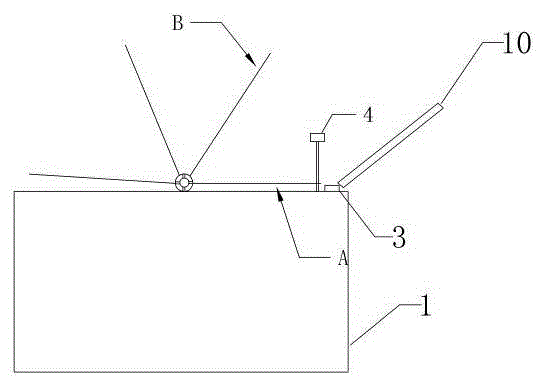

[0022] Such as figure 1 and figure 2 As shown, the PPR product automatic cooling machine includes a main water tank 1, and a circuit control device 9 is installed on the side of the main water tank 1 for controlling the transmission motor 8; Inducting the falling of the product, the induction switch 4 is used to sense the turning of the blade, and transmit the signal to the circuit control device 9 to control the operation or stop of the transmission motor 8; A water outlet pipe 6 is arranged at the upper end, and the position of the water outlet pipe 6 is two-thirds of the height of the main water tank 1 for circulating cooling water; a rotating shaft 2 with blades is installed in the middle of the main water tank 1, and the blades are drilled 4mm full The filter hole is used to filter water to prevent the water from overflowing the water tank 1 when rotating; and a push-out cylinder 5 is installed on the side wall of the main water tank 1, and the position of the push-out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com