Method for solving obstruction of hollow lead of generator stator bar and inhibiting corrosion of hollow lead

A generator stator and hollow wire technology is applied in the field of solving the blockage of the hollow wire of the generator stator bar and inhibiting corrosion, and can solve the problems of complex structure, blockage of the hollow wire, and shortening the service time of the hollow wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

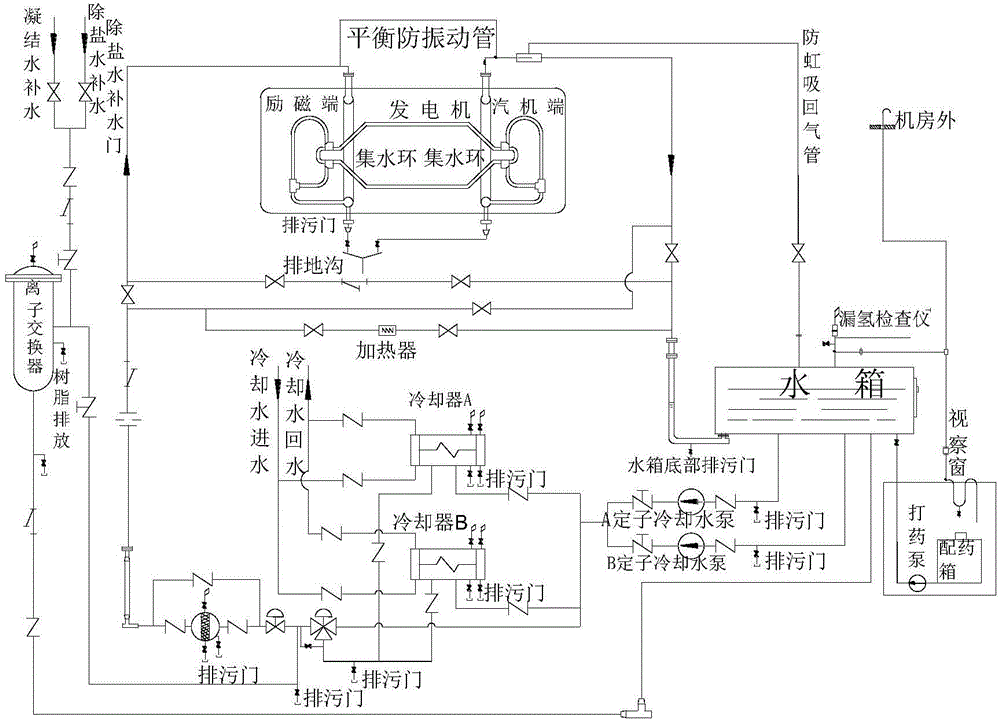

[0043] The method of the present invention is used to deal with the clogging problem of the internal cooling water system of the 650MW nuclear power steam turbine generator #1 unit of Qinshan Nuclear Power Phase II of China National Nuclear Corporation in October 2011.

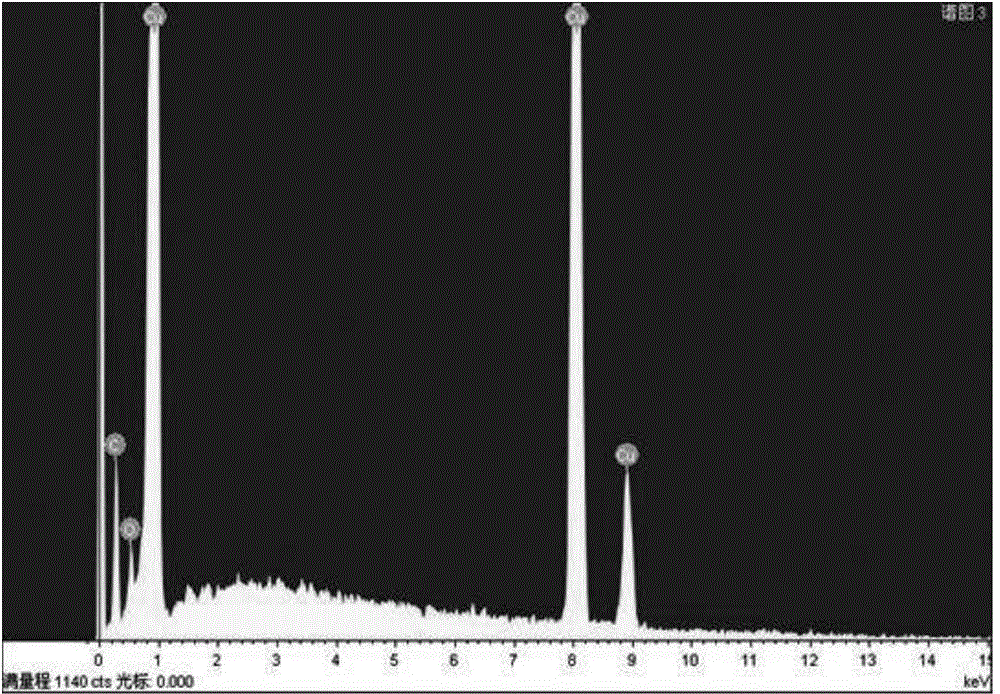

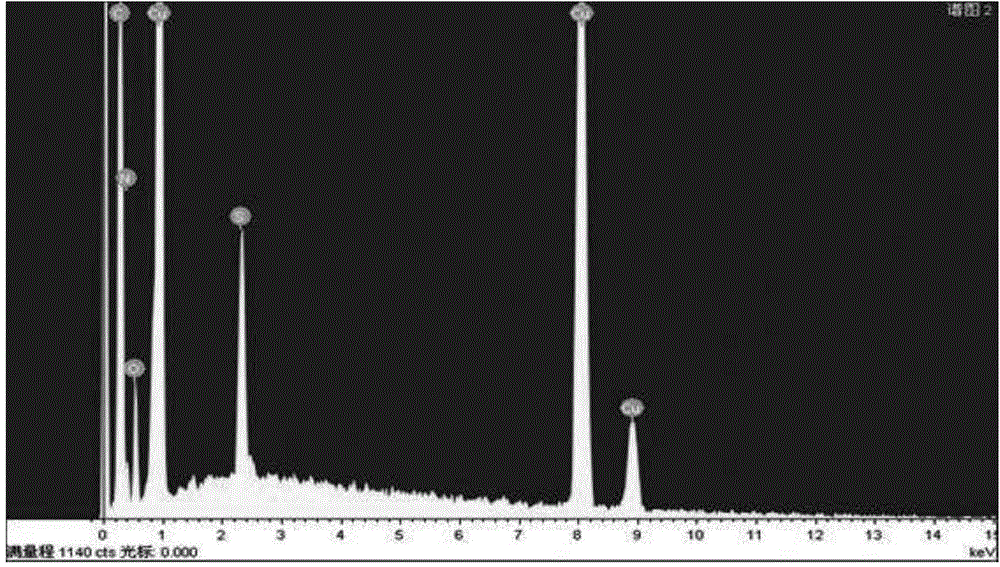

[0044]China National Nuclear Corporation Qinshan Nuclear Power Co., Ltd. #1 unit generator is the first domestically produced nuclear energy steam turbine generator set manufactured by Harbin Electric Machinery Factory. The model is QFSN-650-2. Cooling method, the unit was put into operation in 2002. With the increase of the operating life of the unit, the internal cooling water flow rate began to decrease, the internal cooling water pressure began to increase, and the temperature difference between the wire rod layers became larger. In order to ensure the generator In October 2011, the shutdown inspection was carried out. After the shutdown, the air-water two-phase method was used to flush the hollow wires and...

Embodiment 2

[0065] Using the method of the present invention to deal with the blockage of the inner cooling water system of the 1000MW generator of Huaneng Haimen Power Plant #2 unit in February 2014.

[0066] Huaneng Haimen Power Plant #2 unit generator is manufactured by Dongfang Electric Machinery Factory, the model is QFSN-1000-2-27, its rated capacity is 1000MW, the machine terminal voltage is 27KV, and it adopts water-hydrogen-hydrogen cooling method. The unit was put into operation for power generation in 2009. With the increase of the operating life of the unit, it was found that the flow rate of the internal cooling water of the generator began to decrease during the operation, and the internal cooling water pressure began to rise. In October 2013, the pressure of the internal cooling water at the inlet of the stator bar rose to 0.330Mpa. The flow rate is 118t / h, and the temperature difference between the layers of the No. 36 wire rod is as high as 17°C, which seriously affects th...

Embodiment 3

[0086] Using the method of the present invention to deal with, in October 2013, Zhengzhou Yuzhong Energy Co., Ltd. #3 unit 1000MW generator internal cooling water system blockage problem.

[0087] The #3 unit generator of Zhengzhou Yuzhong Energy Co., Ltd. is a turbogenerator set manufactured by Dongfang Electric Machinery Factory. During the operation in August 2013, the inlet pressure of the stator cooling water was set at 0.30MPa. Gradually decreased from 131t to 125t, and the maximum temperature difference of the wire rod reached 23°C, which seriously affected the safe and stable operation of the unit. After shutting down in September, it was washed with nitrogen-water two-phase flow, and some black powder and flakes were washed out. Judgment Copper oxide deposits appeared on the surface of the hollow wire of the generator stator bar, and the two-phase flow flushing failed to completely solve the problem of hollow wire blockage.

[0088] The specific steps of the method ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com