Patents

Literature

39results about How to "Inhibits galvanic corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface antiseptic treating agent for cable bridge frame

InactiveCN101085889ARaise the ratioOvercome the problem of poor scratch resistanceCellulose coatingsAnti-corrosive paintsWear resistantRare earth

The invention relates to a kind of corrosion-resistant and erosion resistant coating material, which in detail is a corrosion-resistant material for cable bridge surface. The invention adds flaky zinc powder concentration for traditional dacromet coating formulation, adds penetrating agent, surface active agent, hardening agent and rare earth material. The coating layer on the surface is characterized by high adhesion power, good wearing resistant performance, good antiweatherability and stable chemically-resistant property, and suitability for wild environment utilization for a long time, which as long as 30 years.

Owner:孔繁明

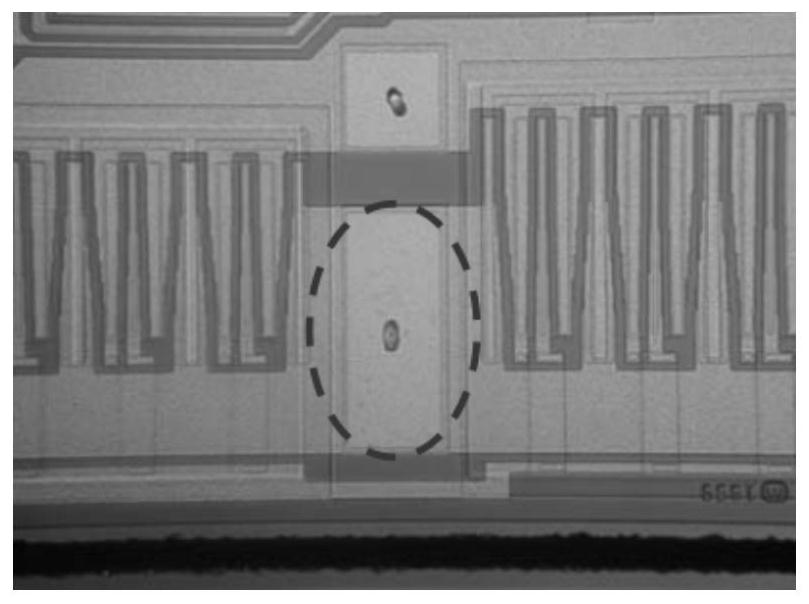

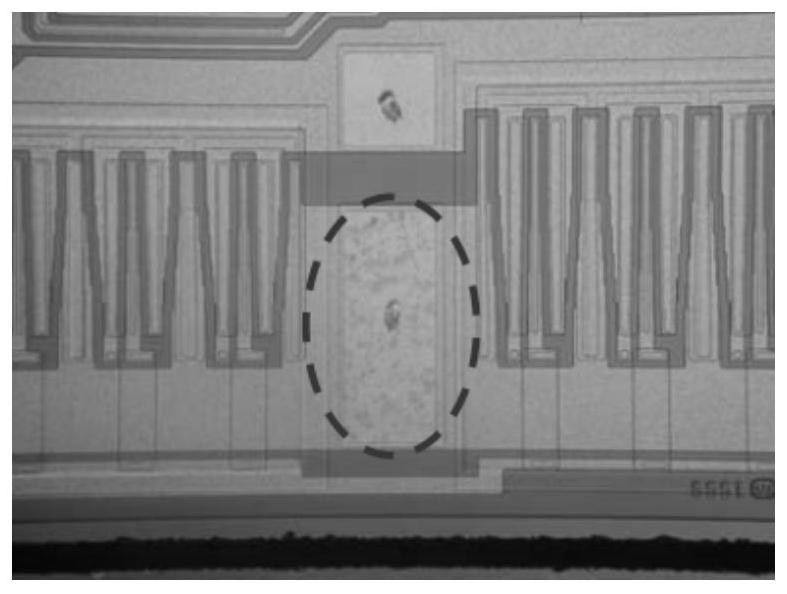

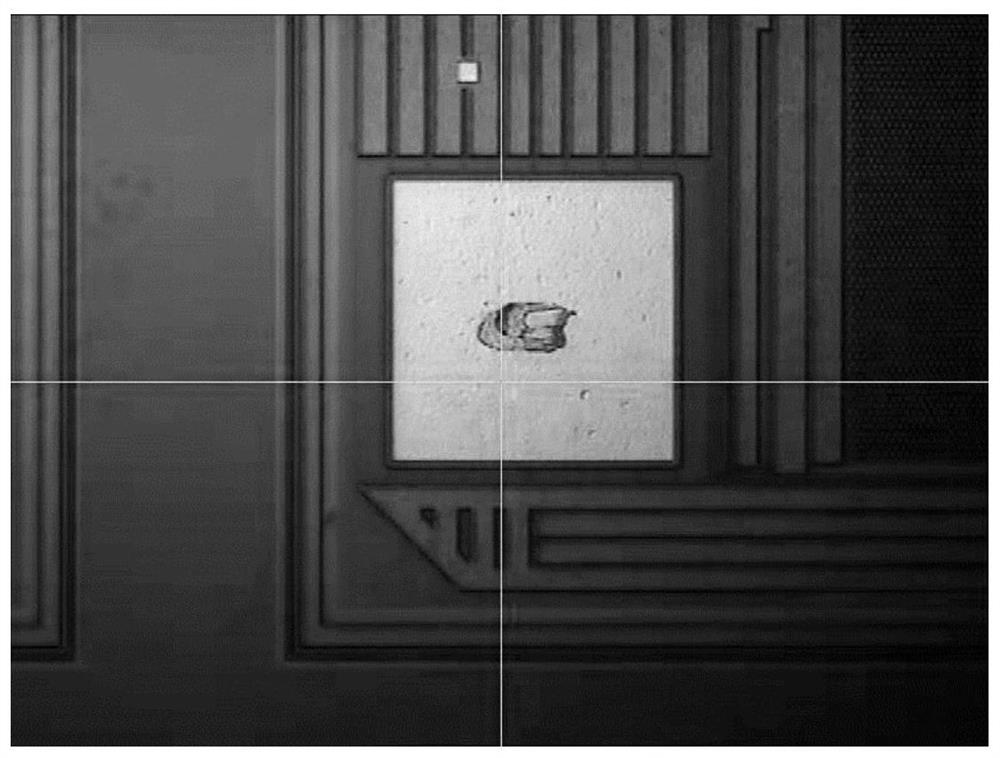

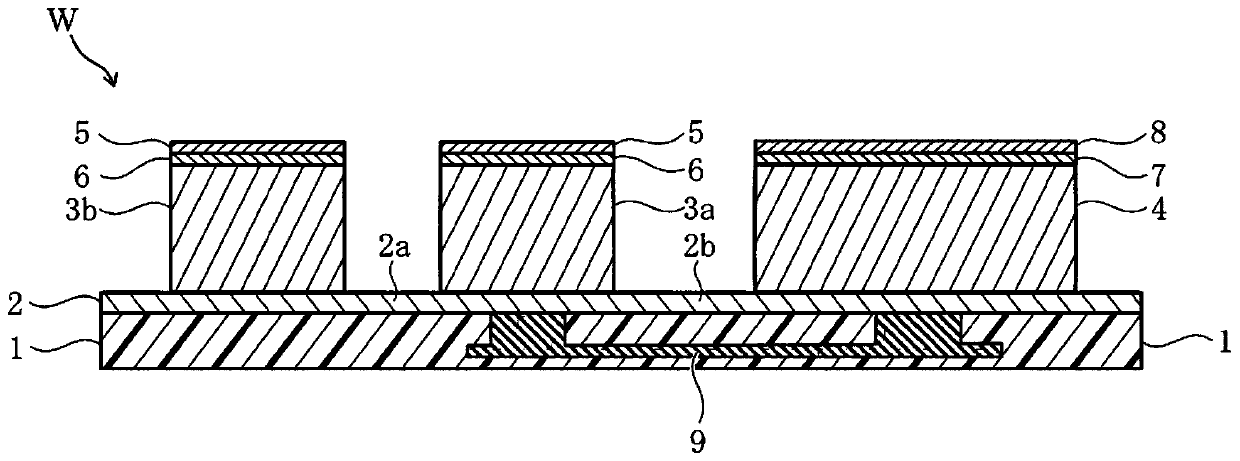

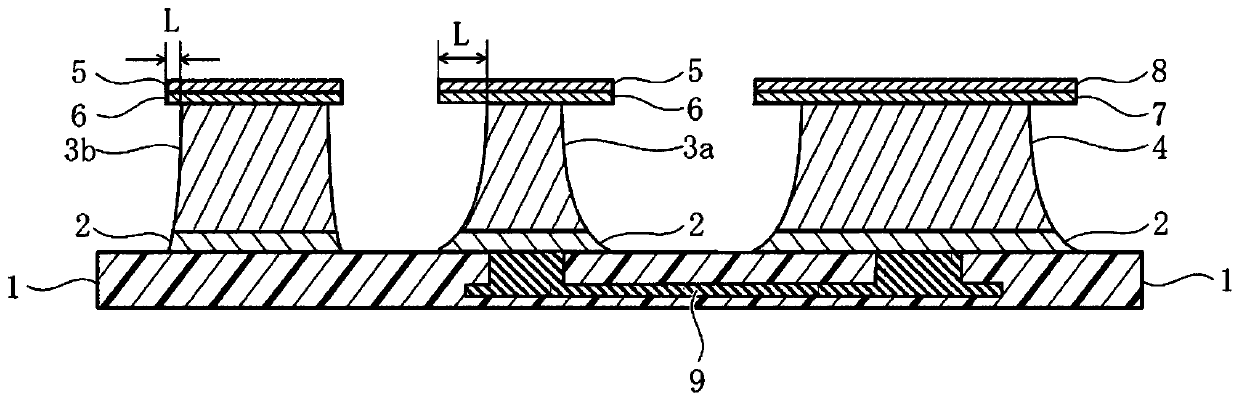

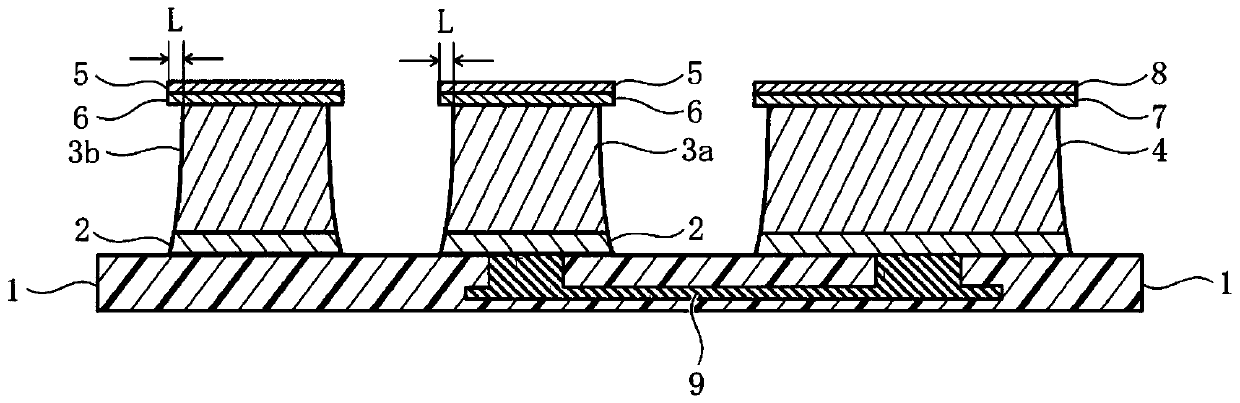

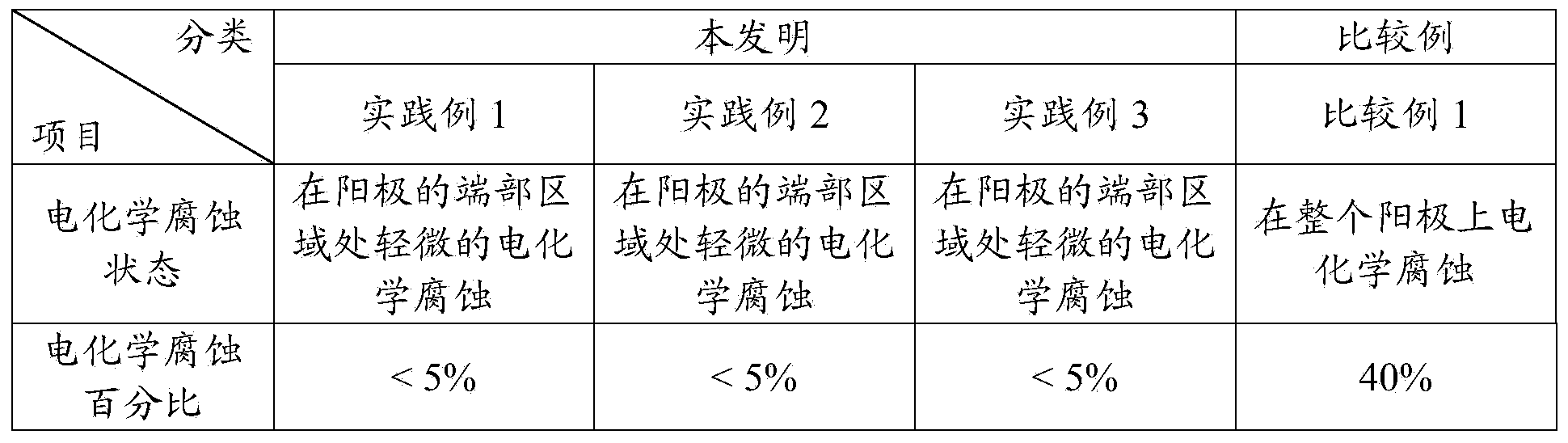

Polishing solution for inhibiting electrochemical corrosion of phase change material

InactiveCN102516879AInhibits galvanic corrosionImproving the Chemical Mechanical Polishing ProcessElectrical apparatusPolishing compositions with abrasivesPhase-change memoryAqueous medium

The invention provides a polishing solution for inhibiting electrochemical corrosion of a phase change material, which comprises polishing particles, an electrochemical corrosion inhibitor and an aqueous medium; by referring the total weight of the polishing solution, the content of the polishing particles is 0.1-30wt% and the content of the electrochemical corrosion inhibitor is 0.0001-10wt%. The provided polishing solution is capable of carrying out polishing treatment to a phase change memory member, substantially inhibiting the electrochemical corrosion of the phase change material during a chemically mechanical polishing process, and substantially improving the chemically mechanical polishing process of a phase change material figure chip.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

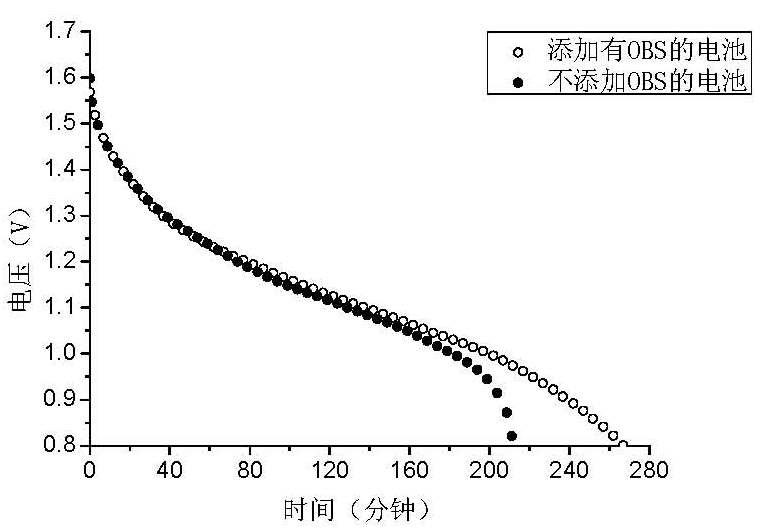

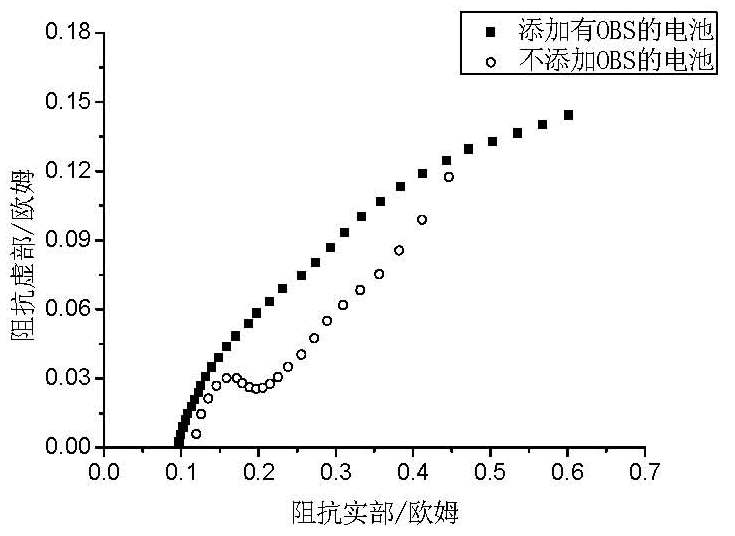

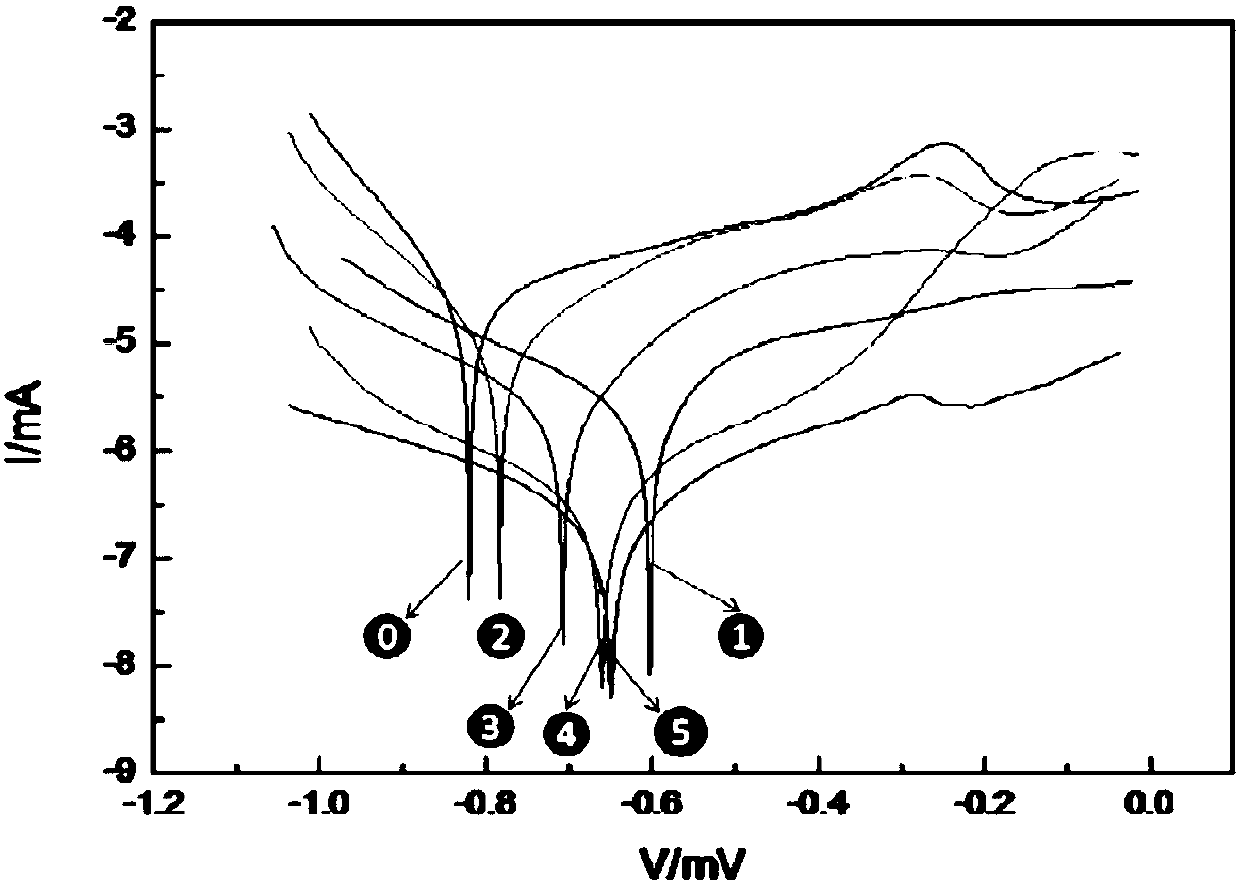

Alkaline zinc-manganese dioxide cell and preparation method thereof

ActiveCN101894952AImprove discharge capacityReduce interfacial tensionPrimary cell electrodesDry cellsHigh rateAdhesive

The invention belongs to the field of electrochemistry and relates to an alkaline zinc-manganese dioxide cell and a preparation method thereof. In the alkaline zinc-manganese dioxide cell, cathode and anode materials of the cell are modified by an organofluorine compound, polytetrafluoroethylene wax particles are doped in the anode to serve as an adhesive of electrolytic manganese and graphite powder, so that the stability of a cathode ring of the cell is greatly enhanced through high chemical stability of the node. Sodium p-perfluorous nonenoxybenzenesulfonate-containing electrolyte solution is dispersed in cathode zinc powder to form a protective film, electrochemical corrosion reaction of the zinc powder can be suppressed, and the zinc powder corrosion is avoided under the condition that the cell does not discharge. Therefore, the self discharge and gas evolution volume of the cell are effectively reduced. The alkaline zinc-manganese dioxide cell has the characteristics of stable heavy-current discharge, long storage period, and low gas evolution volume, and solves the problems that the conventional alkaline zinc-manganese dioxide cell has poor high-rate discharge performance, severe self discharge phenomenon of a zinc-nickel cell, short storage period, and the like.

Owner:ZHENGJIANG MUSTANG BATTERY CO LTD

Highly-color-change-resistant golden brass alloy and preparation method

The invention discloses a highly-color-change-resistant golden brass alloy and preparation method. The highly-color-change-resistant golden brass alloy comprises the following components of Mn, Sn, Ni, Zn, Sr, Ce, B, Si and the balance Cu and inevitable impurities. The preparation process comprises the following steps of casting, hot rolling, cold rolling, intermediate annealing, cold finish roughrolling, cold finish rolling and finished product annealing. The alloy produced by the method is high in golden degree, good in color-change resistance, excellent in hot and cold machining performance, small in deformation resistance, free of precious metal elements and relatively low in cost; the alloy produced by the method is reasonable in component, the golden degree of the alloy is improvedthrough reasonable matching of cheap manganese, nickel, zinc and tin, the zinc content is lower than 20% so that dezincification corrosion can be avoided, through the reasonable combination strontium,cerium, boron and silicon, the process performance can be improved, and the color-change resistance can be improved; according to the alloy, the production process is simple, the production cost is low, the machining performance is good, the golden degree is high, the color-change resistance is excellent in the environment of salt mist, high humidity, synthetic perspiration and the like, and thealloy is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

High discoloration resistance and low-cost gold bronze alloy and preparation method thereof

The invention provides a high discoloration resistance and low-cost gold bronze alloy and a preparation method thereof. The high discoloration resistance and low-cost gold bronze alloy comprises the following components of Mn, Al, Ni, Si, Ce, Sr, P and B, and the balance Cu and inevitable impurities. The preparation method comprises the steps of smelting, semi-continuous casting, hot rolling, surface milling, cold rolling, intermediate annealing, cold finish rough rolling, cold finish rolling and finished product annealing. The alloy produced by the method has high gold color, good discoloration resistance performance, excellent hot and cold working properties and small deformation resistance, and does not contain noble metal elements, so that the alloy is relatively low in cost. The alloyhas reasonable components, and the gold degree of the alloy is improved through reasonable matching of cheap manganese, aluminum, nickel and silicon. The reasonable collocation of strontium, cerium,phosphorus and silicon can improve the technological performance and the discoloration resistance. The alloy is low in price of raw materials, simple in production process, environment-friendly, low in production cost, good in processing performance, high in the gold degree, excellent in discoloration resistance performance in environments such as salt mist, high-humidity and artificial sweat, andsuitable for industrial production.

Owner:CENT SOUTH UNIV

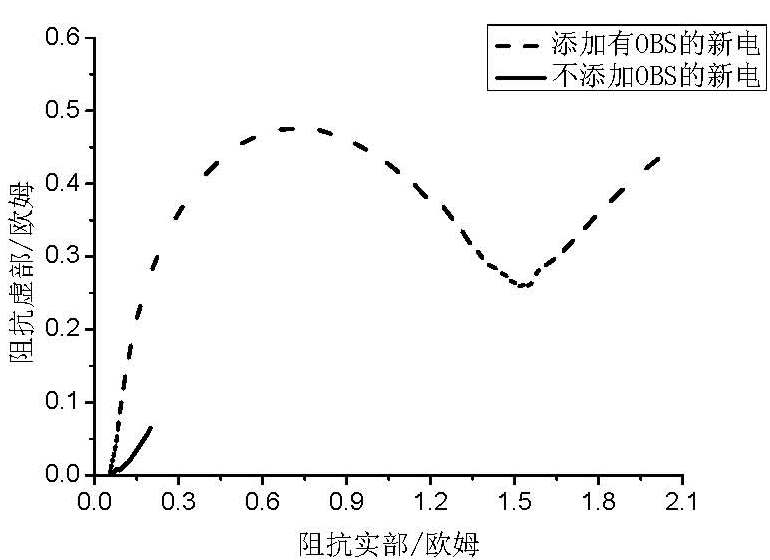

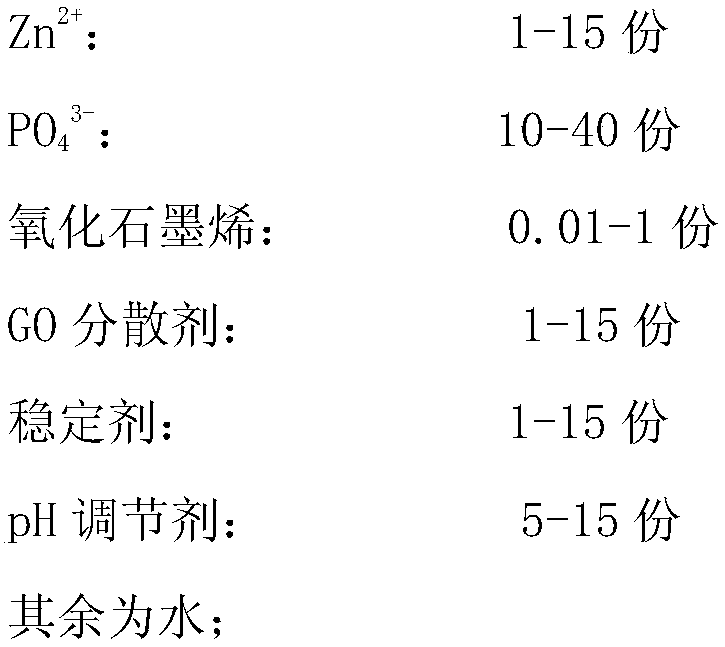

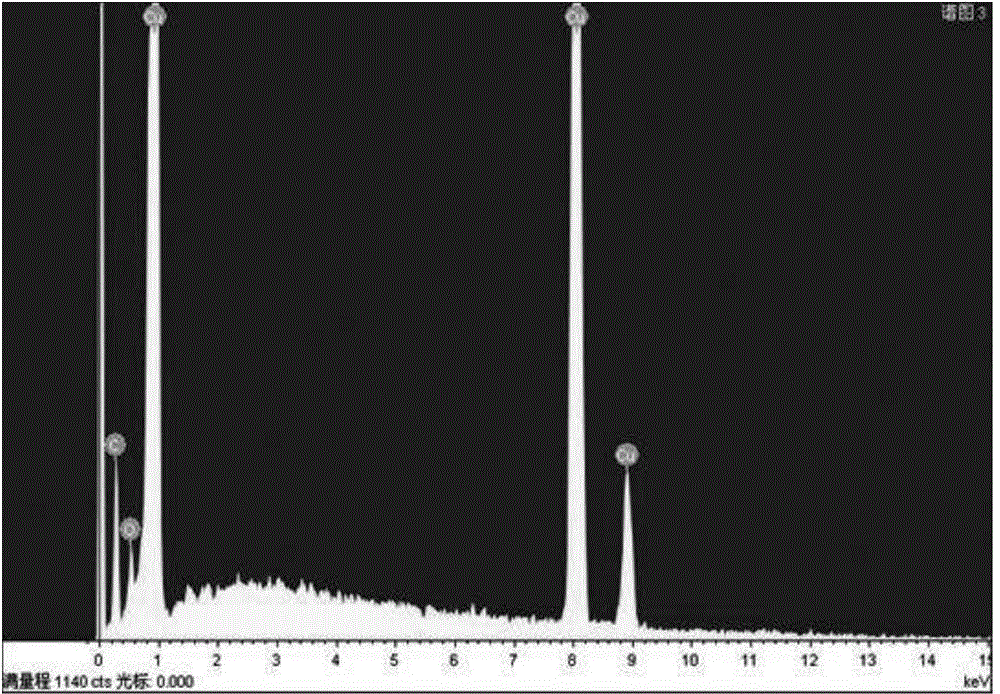

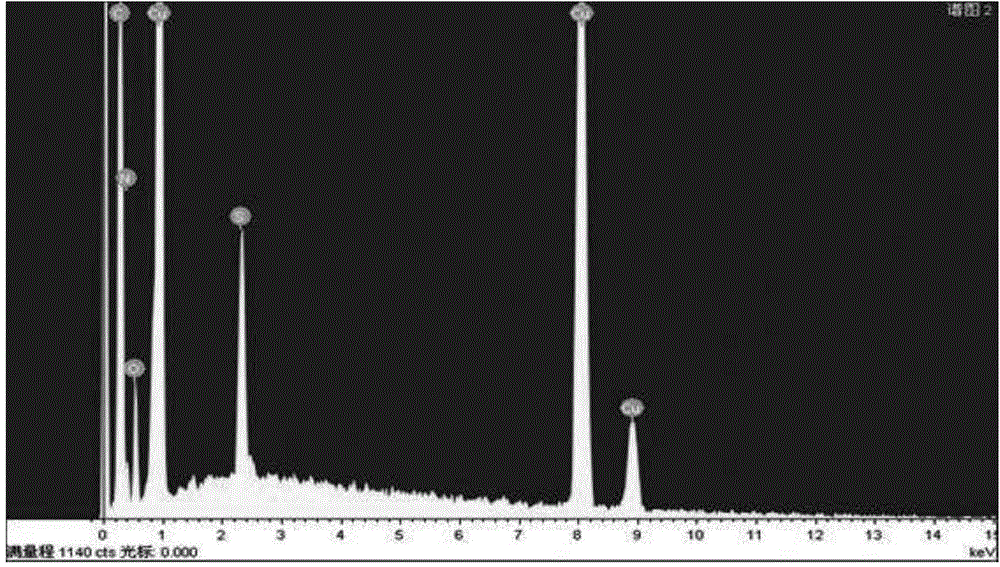

Efficient anticorrosion zinc-type phosphating solution and preparation method thereof

InactiveCN107740168AFast preparationEfficient preparationPhosphatisationElectrochemical corrosionElectrolyte

The invention discloses an efficient anticorrosion zinc-type phosphating solution and a preparation method thereof. The zinc-type phosphating solution comprises the raw material formula components of,by weight, 1-15 parts of Zn<2+>, 10-40 parts of PO4<3->, 0.01-1 part of oxidized graphene, 1-15 parts of a GO dispersing agent, 1-15 parts of a stabilizer, 5-15 parts of a pH modifier and 1000 partsof water. According to the prepared phosphating electrolyte, the safe and non-toxic effects are achieved, a phosphating film can be quickly and efficiently prepared, and especially when a metal workpiece serves as a cathode in the phosphating solution for electrolytic phosphating, the workpiece can have a smooth surface and multiple excellent properties such as scratch resistance and aging resistance. The oxidized graphene can be evenly distributed in a coating of the phosphating film, micro-holes in the surface of a phosphate film are effectively filled with the oxidized graphene, thus an isolation layer is formed, the physical shielding effect is achieved, a way through which a corrosive medium directly makes contact with the metal workpiece is blocked, occurrence of electrochemical corrosion is further inhibited, and the corrosion rate is decreased to a large extent.

Owner:SOUTH CHINA UNIV OF TECH

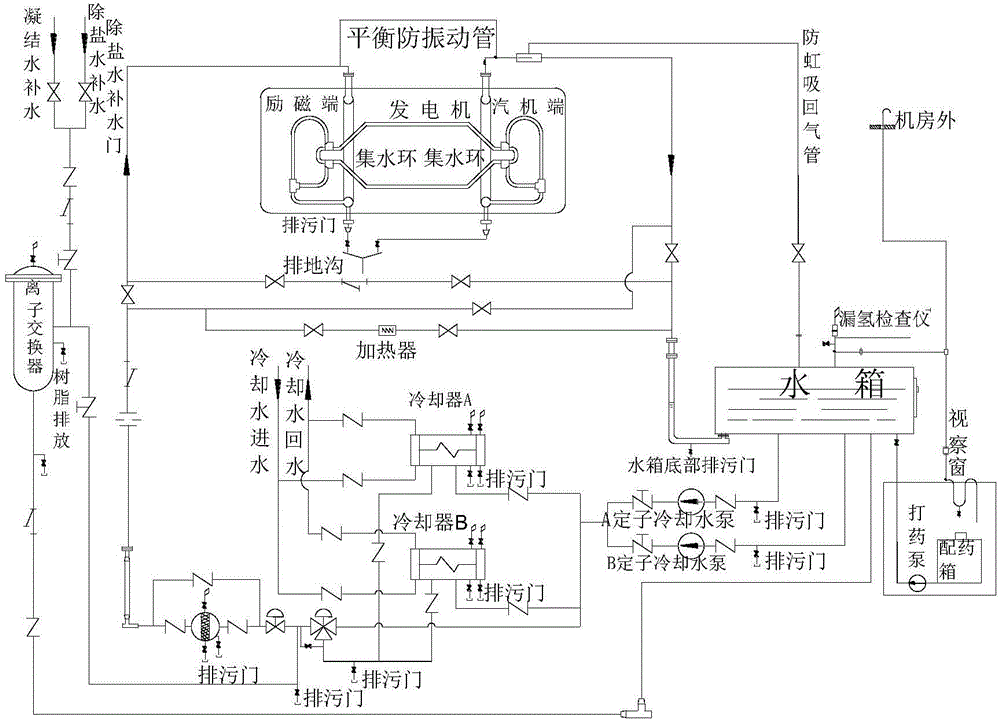

Method for solving obstruction of hollow lead of generator stator bar and inhibiting corrosion of hollow lead

The invention discloses a method for solving the obstruction of a hollow lead of a generator stator bar and inhibiting the corrosion of the hollow lead. The method comprises the following steps: pickling for descaling, activating, and prefilming, wherein a composite acid used in the pickling step comprises, by weight, 65-92 parts of aminosulfonic acid and 8-35 parts of hydrofluoric acid, and a prefilming agent used in the prefilming step comprises, by weight, 35-45 parts of tolyltriazole, 40-44 parts of 2-mercaptobenzothiazole, 10-25 parts of benzotriazole and 10-15 parts of hydroxypropyl methyl cellulose. The method can realize the thorough solving of copper corrosion deposits adhered in the hollow lead and the formation of a firm molecular film in the hollow lead without corroding other metal materials in the cooling water system of the generator stator, effectively prevents the direct contact of copper atoms with cooling water, and substantially inhibits the electrochemical corrosion of copper in the cooling water with a low pH value.

Owner:SHANDONG ZHONGSHI YITONG GRP

Wafer cutting fluid

ActiveCN112708500AIncrease electron densityInhibits galvanic corrosionLubricant compositionActive agentWafer

The invention discloses wafer cutting fluid, belonging to the field of surface precision machining of photoelectronic devices. An oligomeric soap compound in the cutting fluid is ionized in a solution to form a negative charge group, and also has an amphiphilic structure similar to a surfactant, so the oligomeric soap compound can form a directionally arranged adsorption layer on the surface of a wafer, the negative charge group faces outwards and form a repulsive force with silicon chips having negative charges; and therefore, direct contact between the silicon chips and the surface of the wafer is prevented, and pollution of the silicon chips to the wafer is avoided. Meanwhile, a natural plant extract adopted in the cutting fluid is a compound with a heterocyclic structure having one or more N atoms or S atoms, electrons on a metal surface can be bonded more easily through the N or S atoms in the heterocyclic structure, so a protective film is formed, and electrochemical corrosion of a bonding pad on the surface of the semiconductor wafer is inhibited.

Owner:江苏奥首材料科技有限公司

Copper etching liquid

PendingCN110997981AInhibits galvanic corrosionEasy Bath ManagementPrinted circuit manufactureCarboxylic acidSaturated fatty acid

The purpose of the present invention is to provide a copper etching liquid which is capable of reliably suppressing galvanic corrosion, while achieving easy bath control and excellent etching rate. Inorder to achieve the above-described purpose, the present invention provides a copper etching liquid which is composed of an alkaline aqueous solution, and which is characterized by containing 1-70 g / L of copper, 10-500 g / L of ammonia water in terms of 25% ammonia water and 5-500g / L of an ammonium salt. This copper etching liquid is also characterized in that the ammonium salt is composed of oneor more ammonium salts that are selected from the group consisting of an ammonium salt of an inorganic acid, an ammonium salt of a sulfonic acid, an ammonium salt of a saturated fatty acid, an ammonium salt of an aromatic carboxylic acid, an ammonium salt of a hydroxy acid and an ammonium salt of a dicarboxylic acid.

Owner:MELTEX

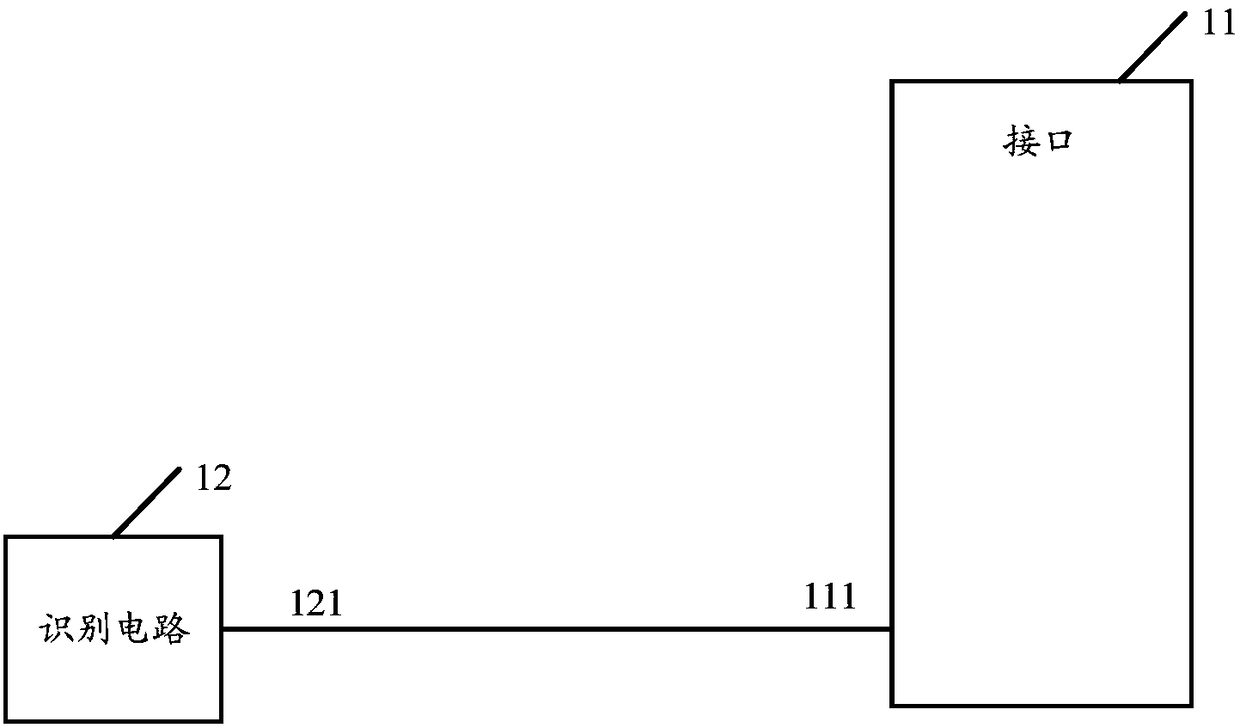

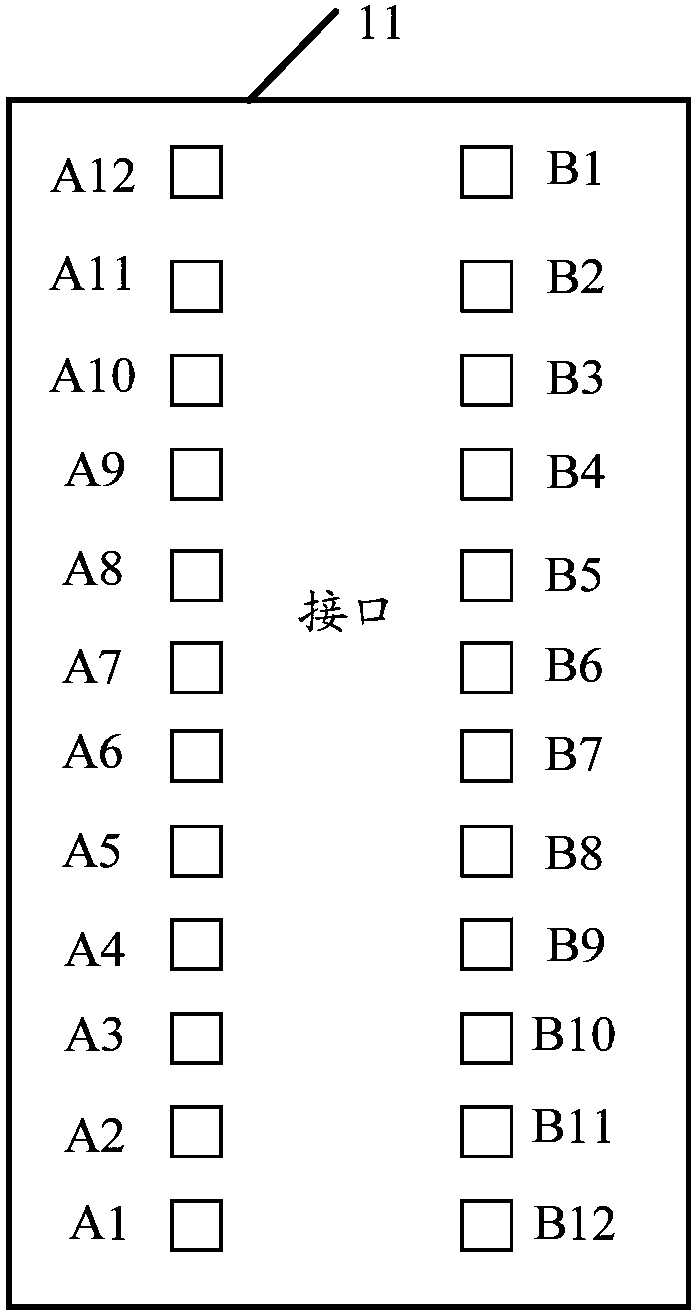

Interface circuit and electronic device

ActiveCN108411310AInhibits galvanic corrosionGalvanic corrosion does not occurElectrochemical corrosionComputer science

The invention discloses an interface circuit and an electronic device. The interface circuit comprises an interface and an identifying circuit; the interface comprises a first detecting pin; the identifying circuit comprises a detecting end; the detecting end is connected with the first detecting pin; the identifying circuit inputs detecting signals to the first detecting pin through the detectingend; and the detecting signals are used for inhibiting electrochemical corrosion of the first detecting pin and electric conducting liquid when the first detecting pin is contacted with the electricconducting liquid. The electrochemical corrosion of the interface is inhibited when the electric conducting liquid enters the first detecting pin of the interface.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

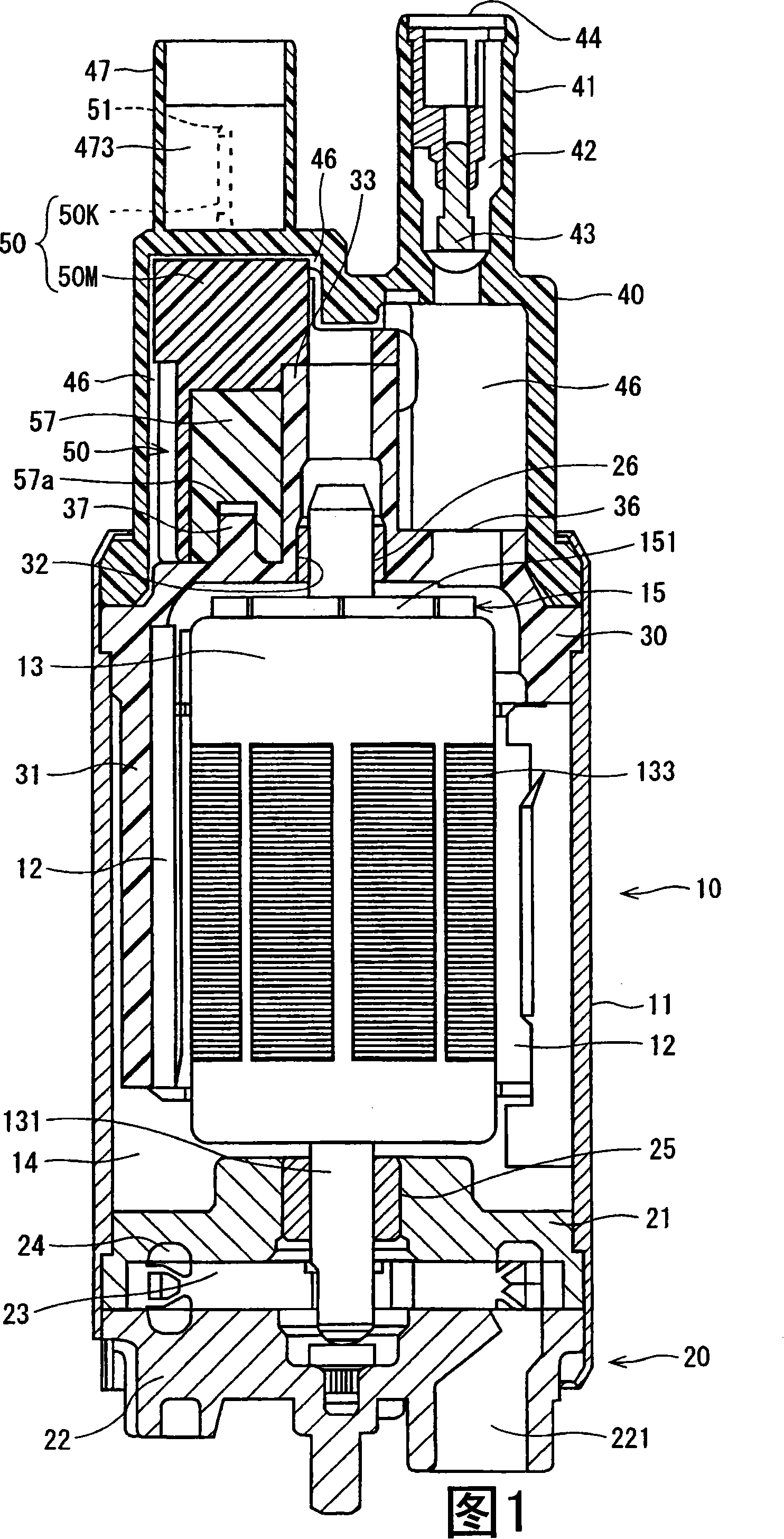

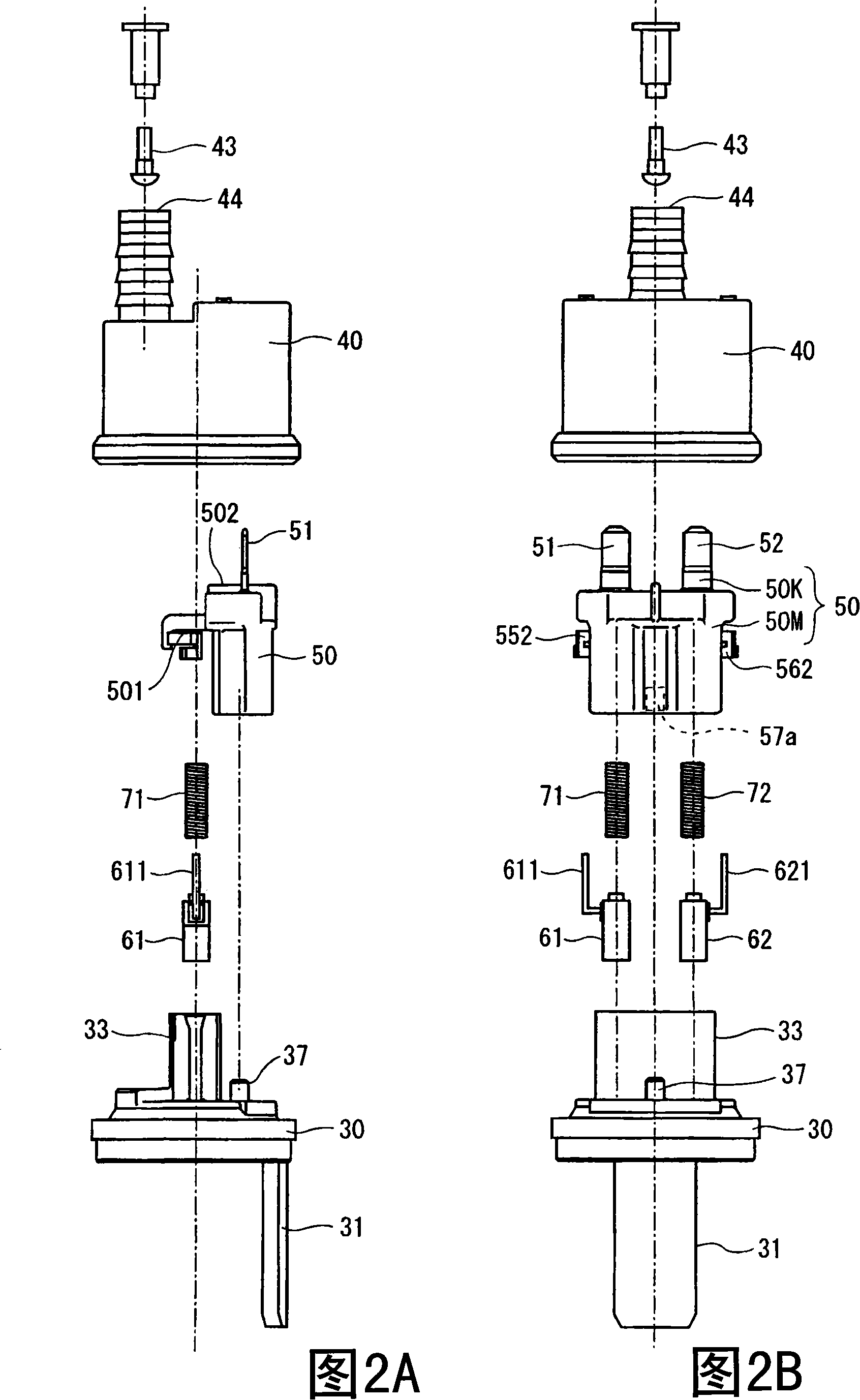

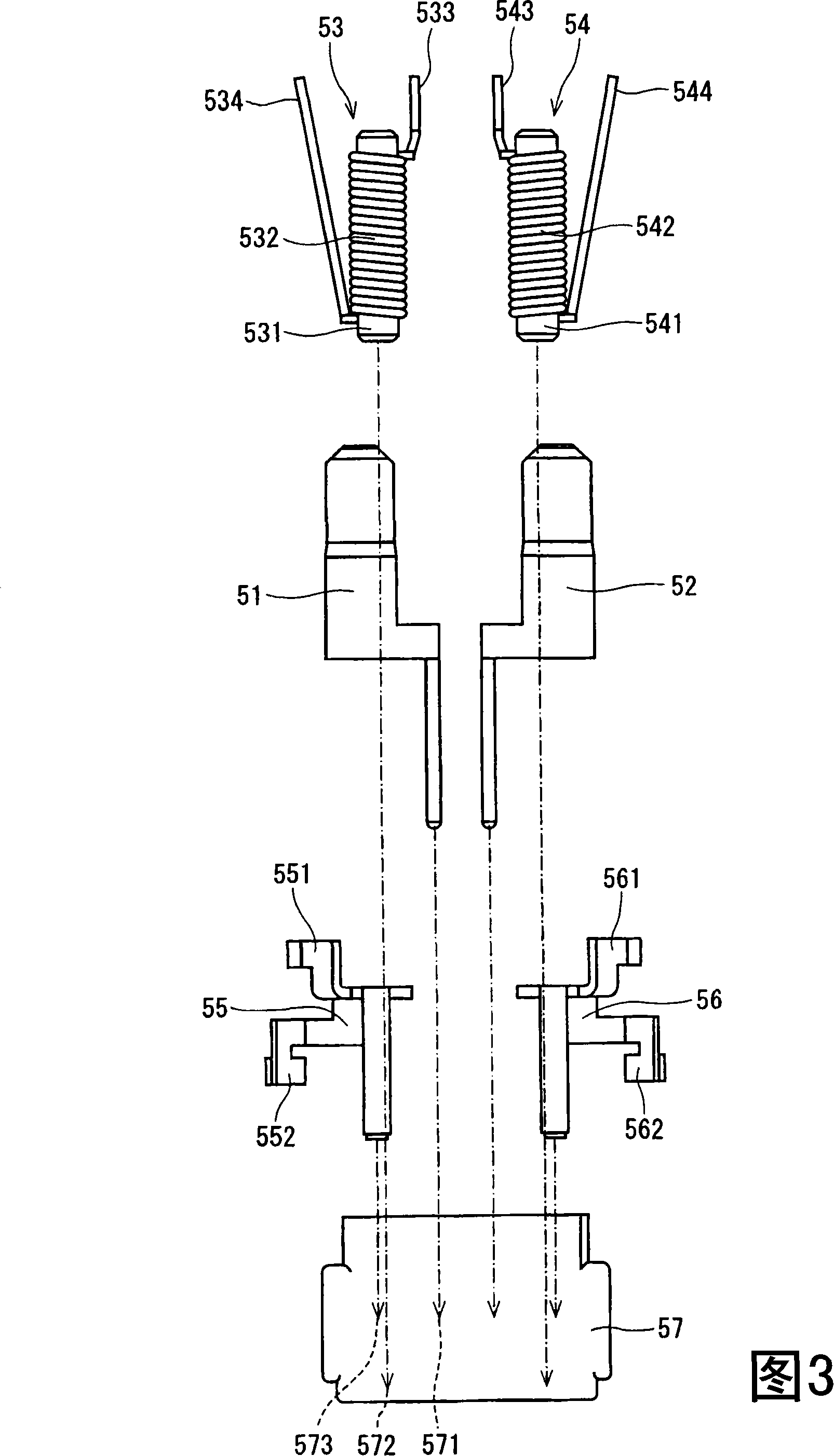

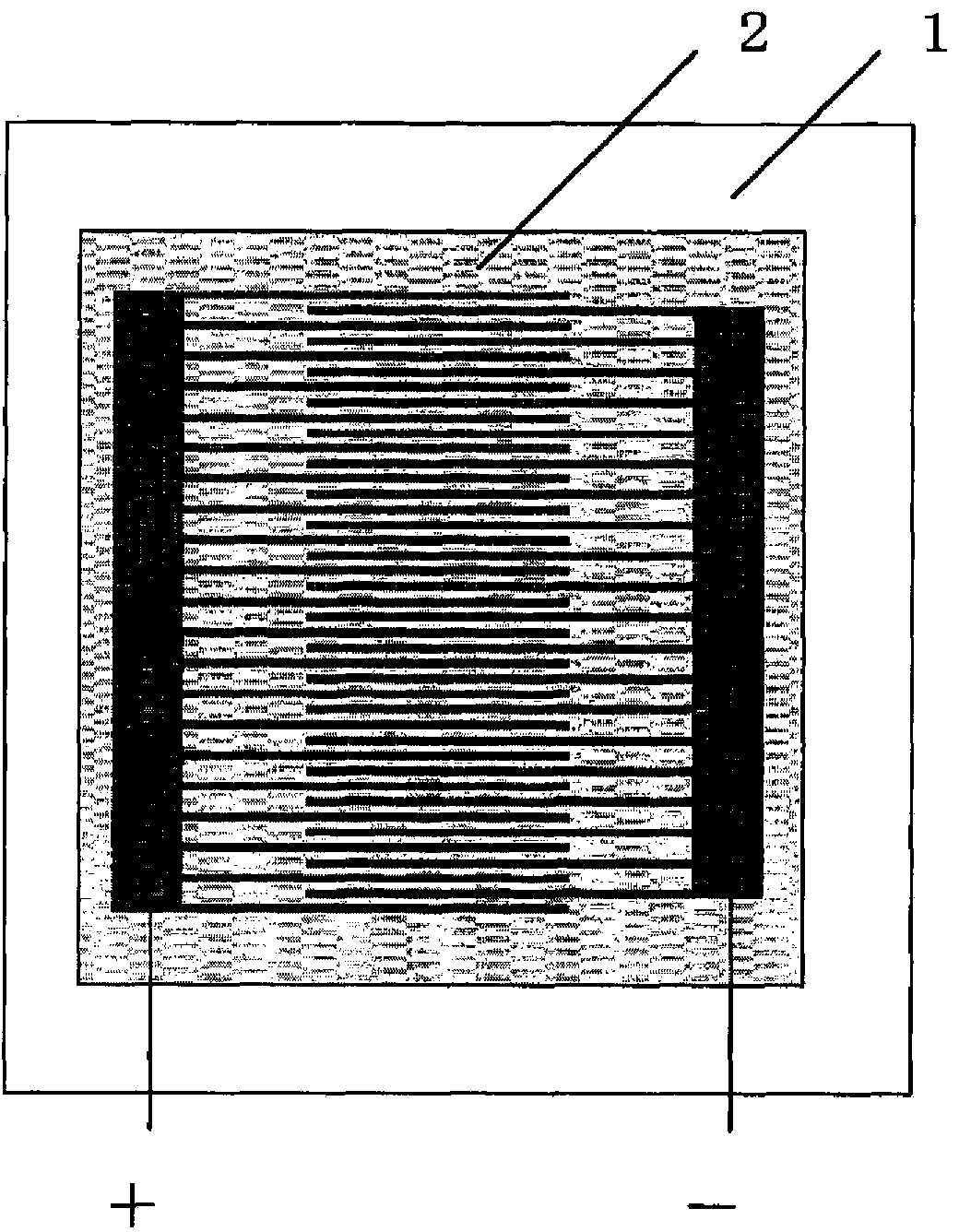

Electric fuel pump and method for manufacturing the same

ActiveCN101139965AInhibits galvanic corrosionInternal combustion piston enginesFuel injection apparatusElectricityEngineering

A fuel pump includes a case member defining a fuel passage, an inlet, and an outlet. A pump portion is provided in the fuel passage for pumping fuel from the inlet to the outlet. A motor portion is provided in the case member for driving the pump portion. A positive electrode terminal and a negative electrode terminal are provided for conducting electricity to the motor portion. A holder being insulative is provided inside the case member. The holder is mounted with the positive electrode terminal and the negative electrode terminal. The positive electrode terminal and the negative electrode terminal are resin-molded.

Owner:DENSO CORP

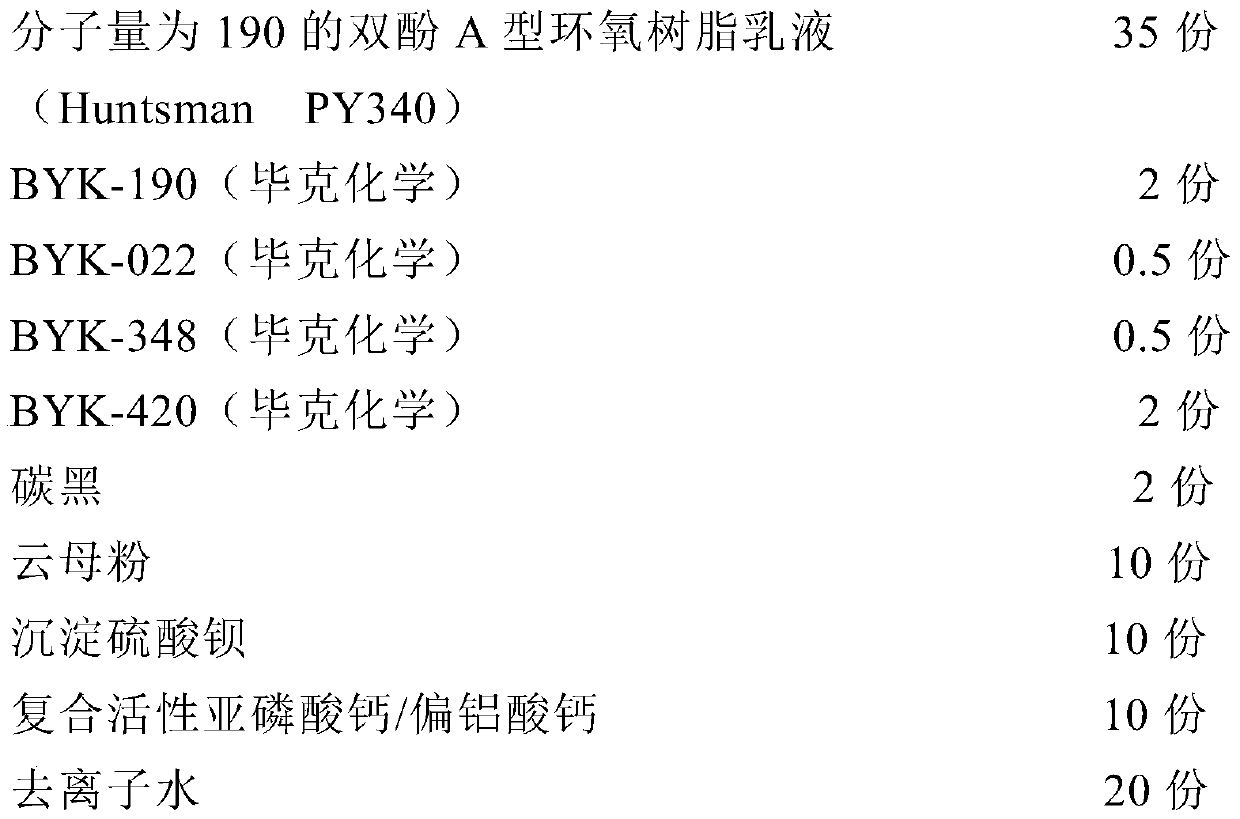

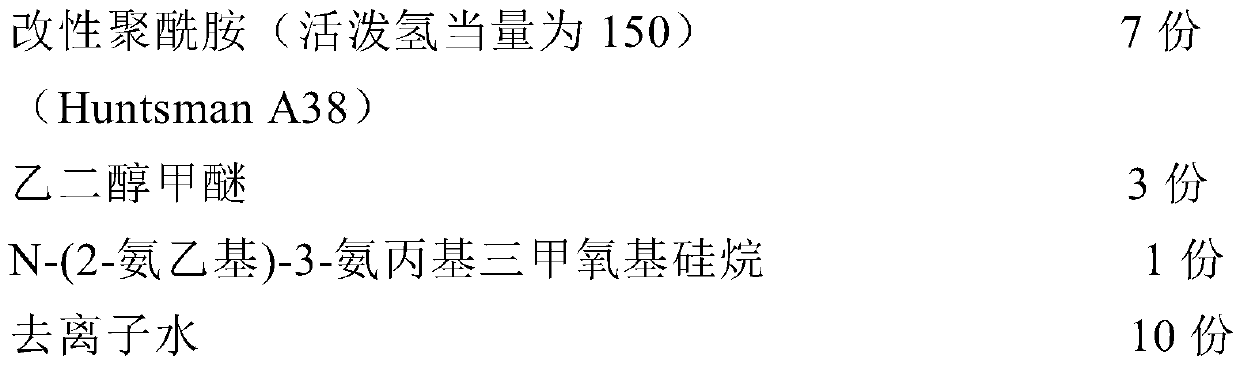

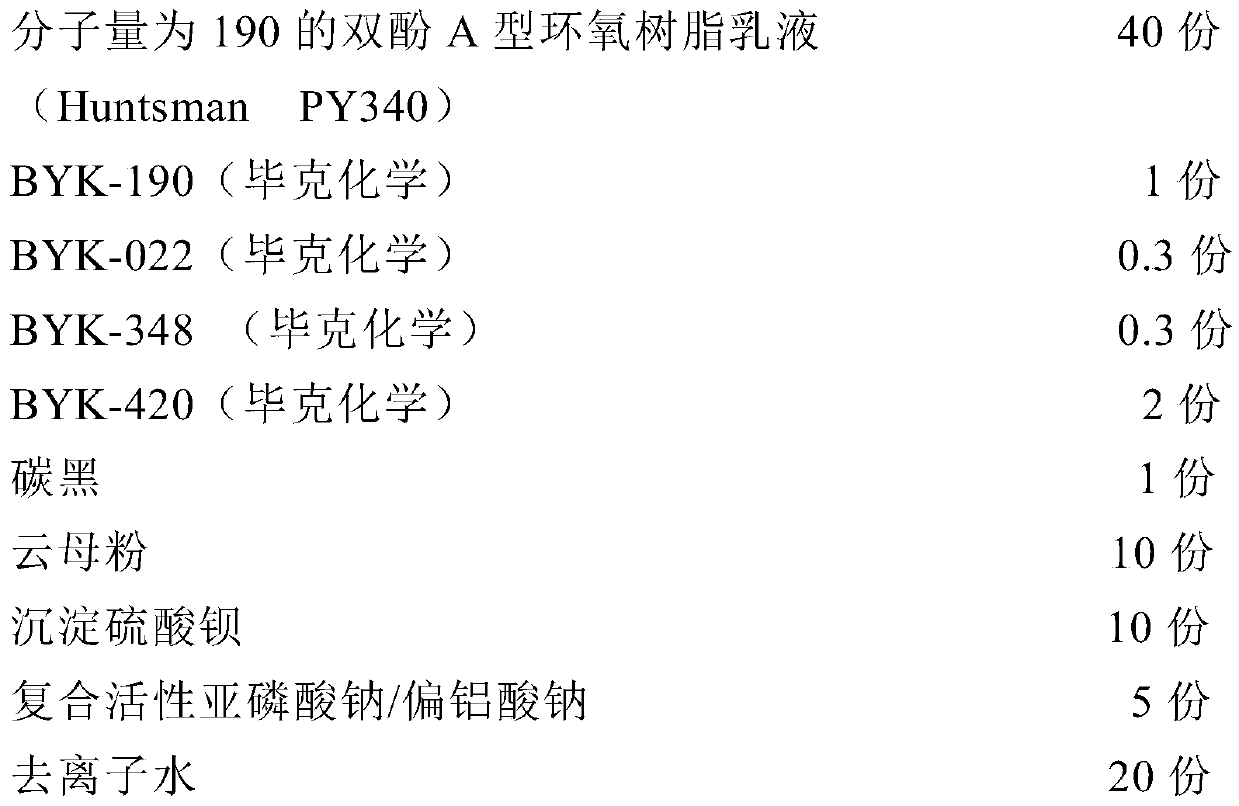

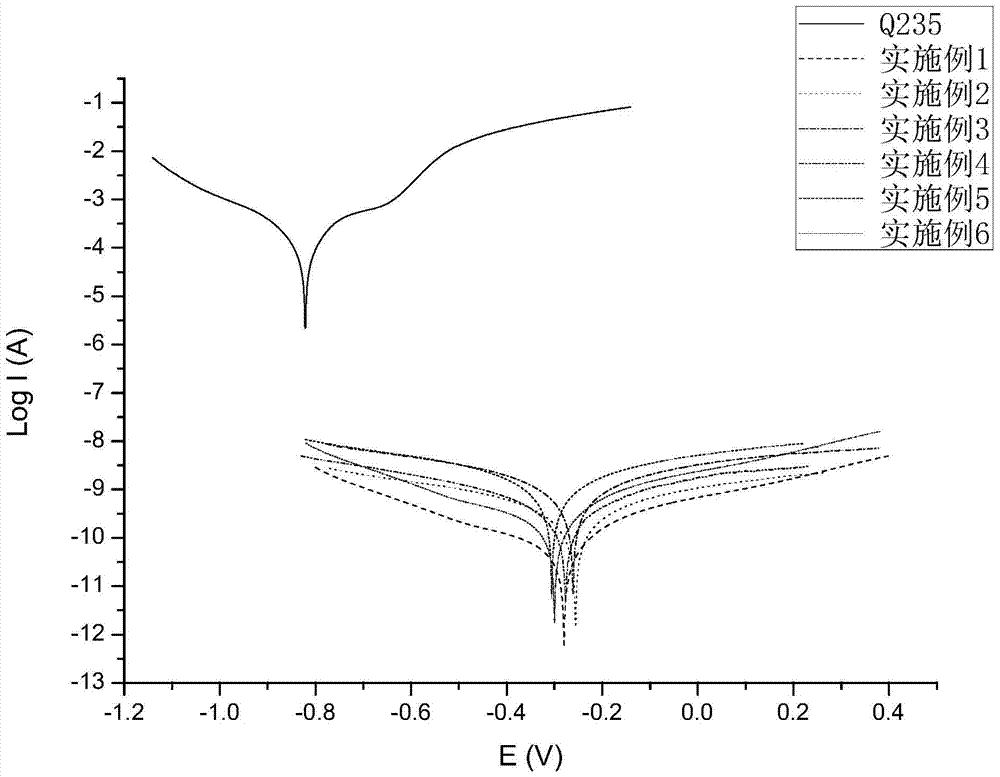

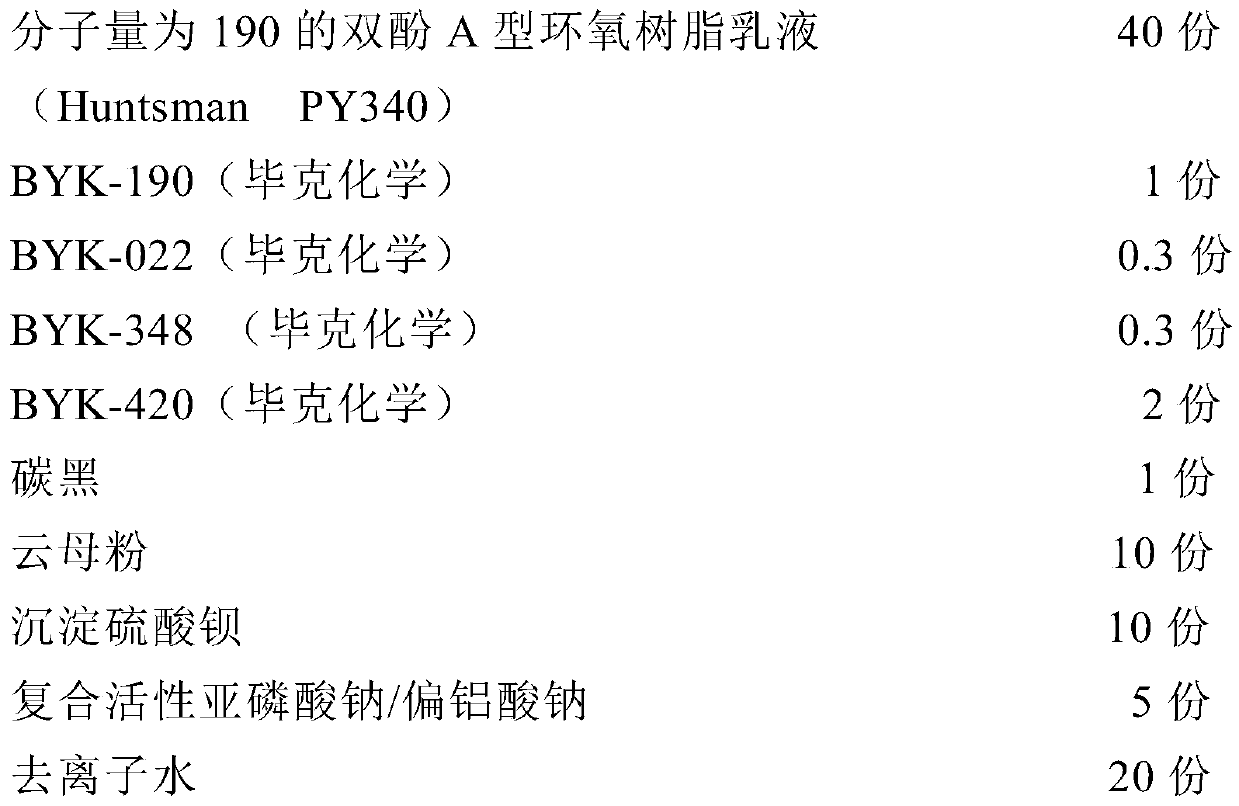

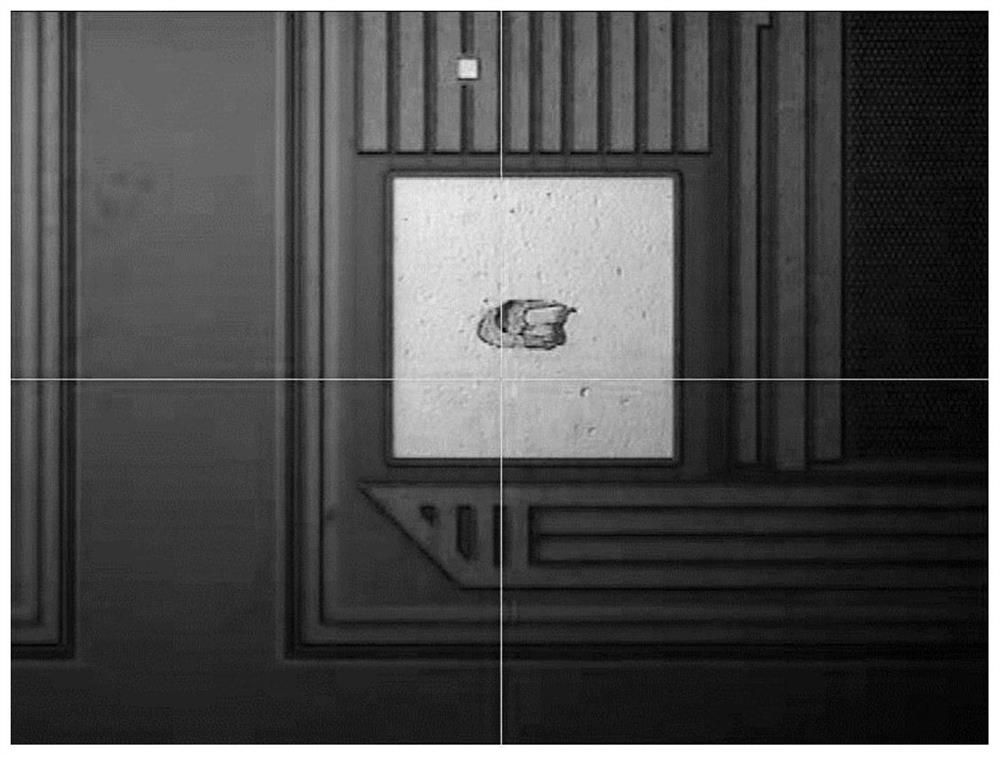

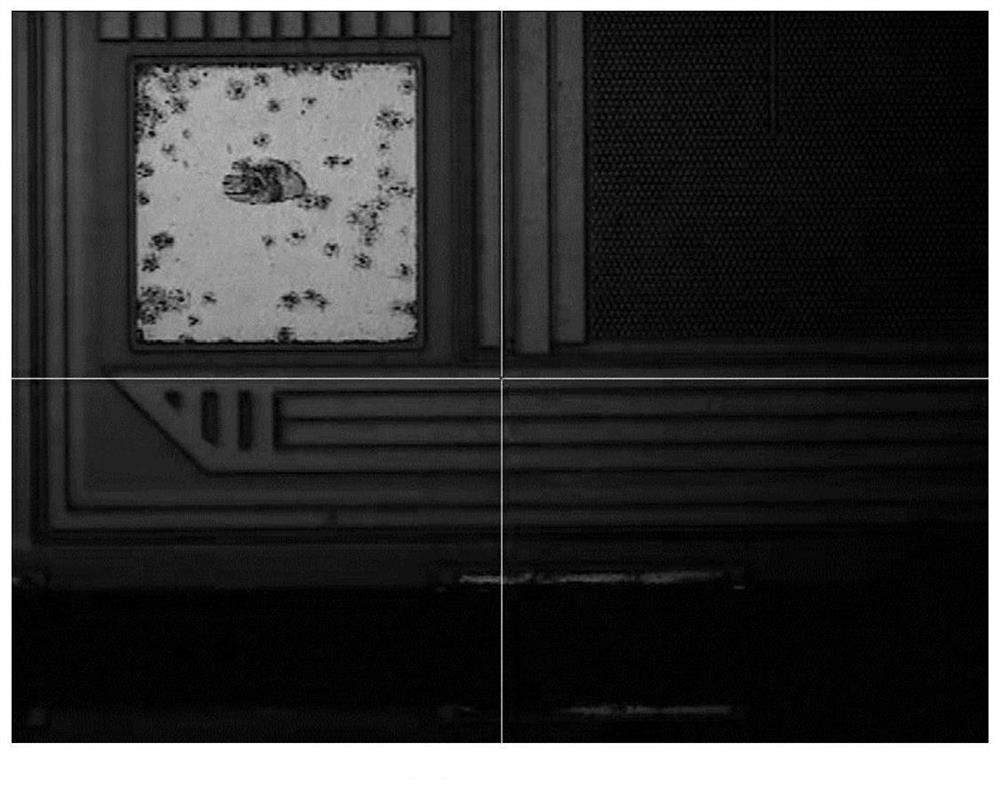

Waterborne epoxy anticorrosive coating containing composite active salt and preparation method of coating

ActiveCN110183932AImprove adhesionImprove performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater immersion

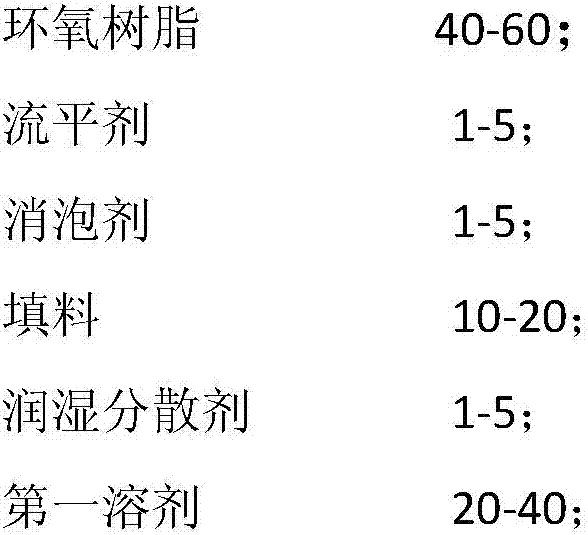

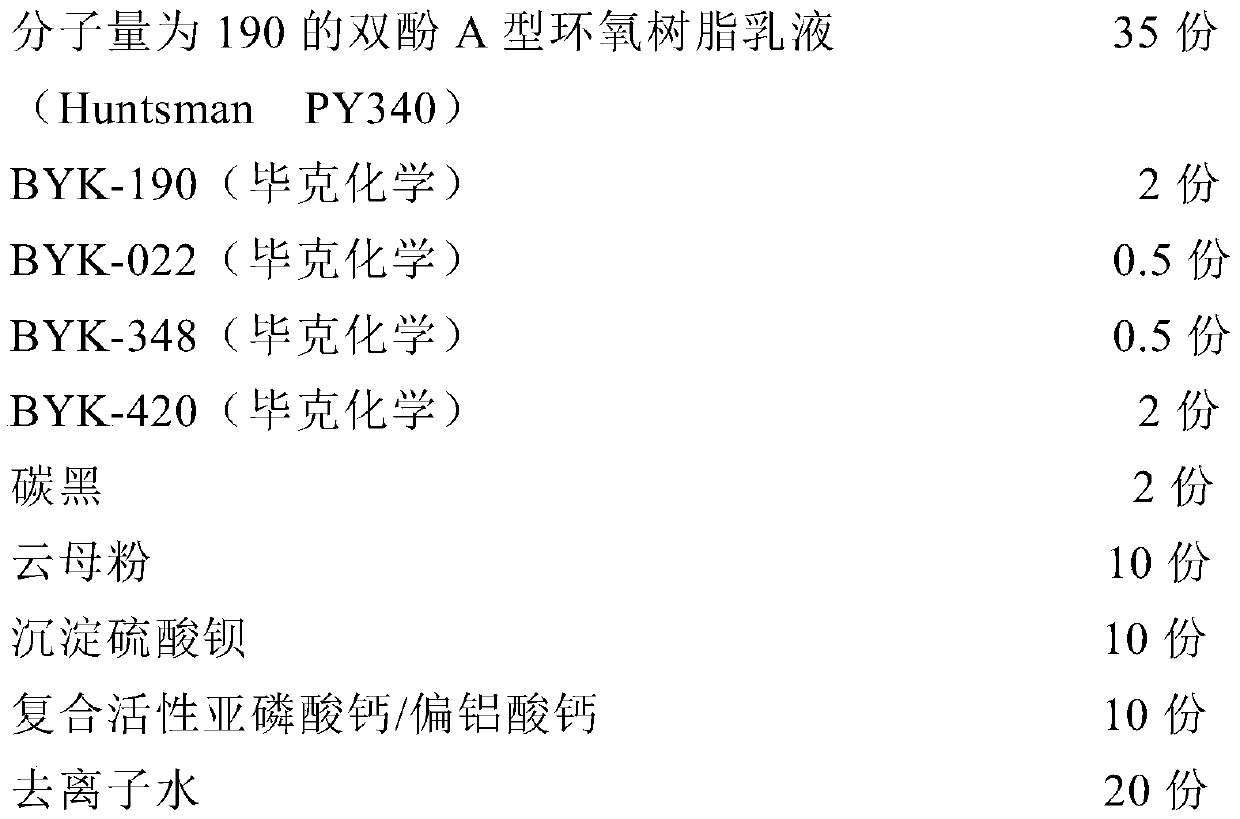

The invention discloses a waterborne epoxy anticorrosive coating containing a composite active salt and a preparation method of the coating. The coating comprises a component A and a component B, andthe mass ratio of the component A to the component B is (3-5):1. The component A comprises: 35-40 parts of a waterborne epoxy emulsion, 1-2 parts of carbon black, 10-15 parts of mica powder, 10-15 parts of precipitated barium sulfate, 10-20 parts of a composite active salt phosphite / metaaluminate, 1-2 parts of a wetting and dispersing agent, 0.3-0.5 part of an antifoaming agent, 0.3-0.5 part of aleveling agent, 2-3 parts of a thixotropic agent, and 20-30 parts of deionized water. The component B comprises: 7-10 parts of a waterborne epoxy curing agent, 3-5 parts of a co-solvent, 10-15 parts of deionized water, and 1-3 parts of an amino group-containing organosilicon monomer. The phosphite / metaluminate composite active filler is selected as an anticorrosive filler, a cured film is formed by combining with a resin, and a coating layer formed by the prepared waterborne epoxy composition coating has excellent corrosion resistance to salt spray, cathode peeling, seawater immersion and deionized water immersion, and has excellent adhesion.

Owner:MARINE CHEM RES INST +1

A kind of polyaniline graphene nanocomposite anticorrosion coating and preparation method thereof

ActiveCN104910752BEvenly dispersedDoes not affect appearanceAnti-corrosive paintsEpoxy resin coatingsEpoxyMolecular level

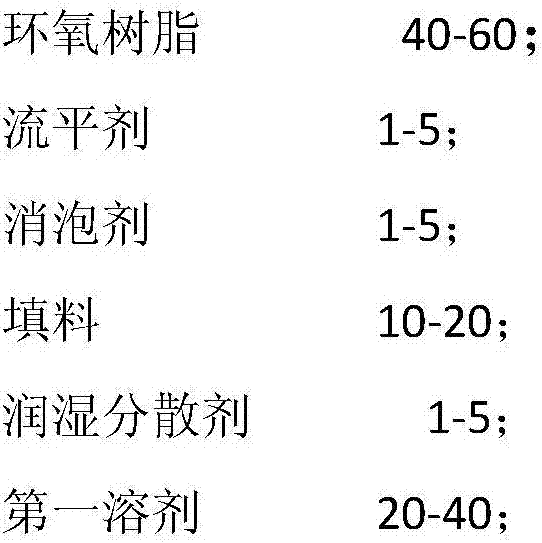

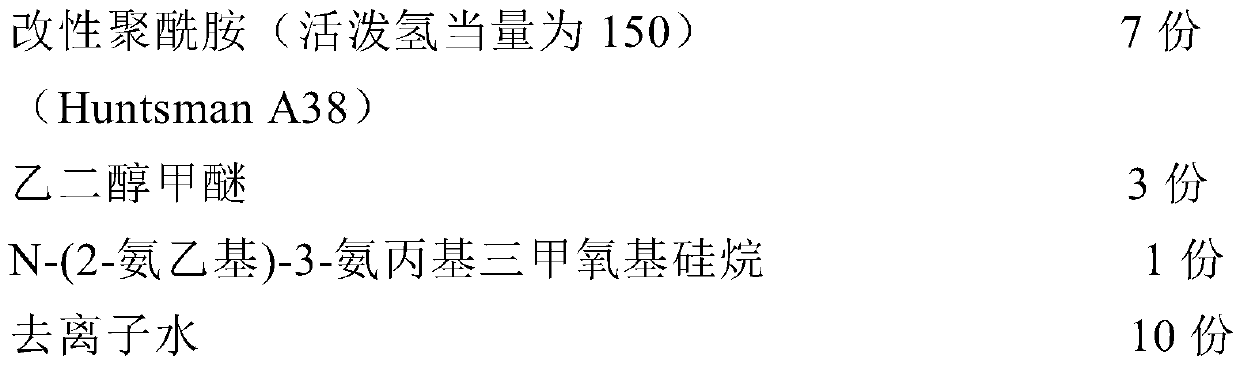

The invention discloses polyaniline graphene nano composite anticorrosion paint and a preparation method thereof. The polyaniline graphene nano composite anticorrosion paint is prepared by uniformly stirring a component A and a component B in a weight ratio of 1: 0.25 to 1: 0.5; the component A comprises 40 to 60 parts by weight of epoxy resin, 1 to 5 parts by weight of flatting agent, 1 to 5 parts by weight of defoaming agent, 10 to 20 parts by weight of filler, 1 to 5 parts by weight of wetting dispersing agent and 20 to 40 parts by weight of first solvent; the component B comprises 30 to 50 parts of curing agent, 10 to 30 parts of eigenstate polyaniline graphene composite material and 30 to 50 parts of second solvent. The eigenstate polyaniline and metal form a passivation film, the dispersion of a single layer or fewer layers of graphene is guaranteed on the aspect of the molecular level, the formation of a graphene conducting network is prevented, and the electrochemical corrosion is inhibited; meanwhile, a physical shielding and chemical anticorrosion effect is provided, so that the paint is excellent in anticorrosion performance, resistant to high temperature and high in hardness; and moreover, the preparation method is simple, controllable, low in production cost and suitable for industrialized production.

Owner:天津昊图环保科技有限公司

A kind of waterborne epoxy anticorrosion coating containing composite active salt and preparation method thereof

ActiveCN110183932BOsmotic blockInhibits galvanic corrosionAnti-corrosive paintsEpoxy resin coatingsPhosphite saltFirming agent

The invention discloses a waterborne epoxy anticorrosive coating containing a composite active salt and a preparation method of the coating. The coating comprises a component A and a component B, andthe mass ratio of the component A to the component B is (3-5):1. The component A comprises: 35-40 parts of a waterborne epoxy emulsion, 1-2 parts of carbon black, 10-15 parts of mica powder, 10-15 parts of precipitated barium sulfate, 10-20 parts of a composite active salt phosphite / metaaluminate, 1-2 parts of a wetting and dispersing agent, 0.3-0.5 part of an antifoaming agent, 0.3-0.5 part of aleveling agent, 2-3 parts of a thixotropic agent, and 20-30 parts of deionized water. The component B comprises: 7-10 parts of a waterborne epoxy curing agent, 3-5 parts of a co-solvent, 10-15 parts of deionized water, and 1-3 parts of an amino group-containing organosilicon monomer. The phosphite / metaluminate composite active filler is selected as an anticorrosive filler, a cured film is formed by combining with a resin, and a coating layer formed by the prepared waterborne epoxy composition coating has excellent corrosion resistance to salt spray, cathode peeling, seawater immersion and deionized water immersion, and has excellent adhesion.

Owner:MARINE CHEM RES INST CO LTD +1

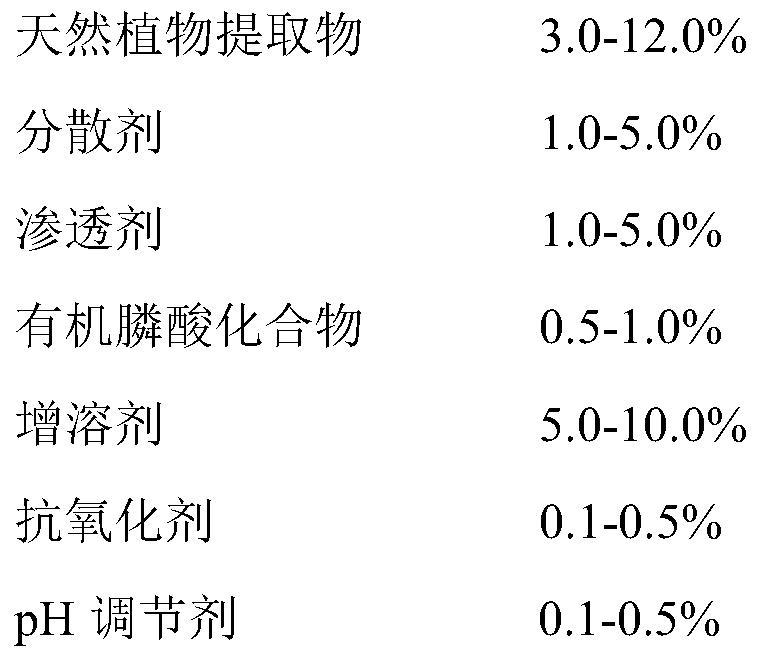

Wafer cutting fluid containing natural plant extracts

InactiveCN112662460AIncrease electron densityInhibits galvanic corrosionLubricant compositionWaferElectron density

The invention discloses a wafer cutting fluid containing natural plant extracts, and belongs to the field of surface precision machining of photoelectronic devices. The cutting fluid contains natural plant extracts and is a compound with a heterocyclic structure in a series of molecular structures. Wherein the heterocyclic structure has one or more N atoms or S atoms, and in addition, the H atom on at least one C in the heterocyclic structure is substituted by an -NH2, -NO2, -CHO or -COOH functional group, and therefore the electron density of the N or S atoms in the heterocyclic structure can be improved; therefore, electrons on the metal surface can be combined into bonds more easily, a protective film is formed, and electrochemical corrosion of a bonding pad on the surface of a semiconductor wafer is inhibited.

Owner:江苏奥首材料科技有限公司

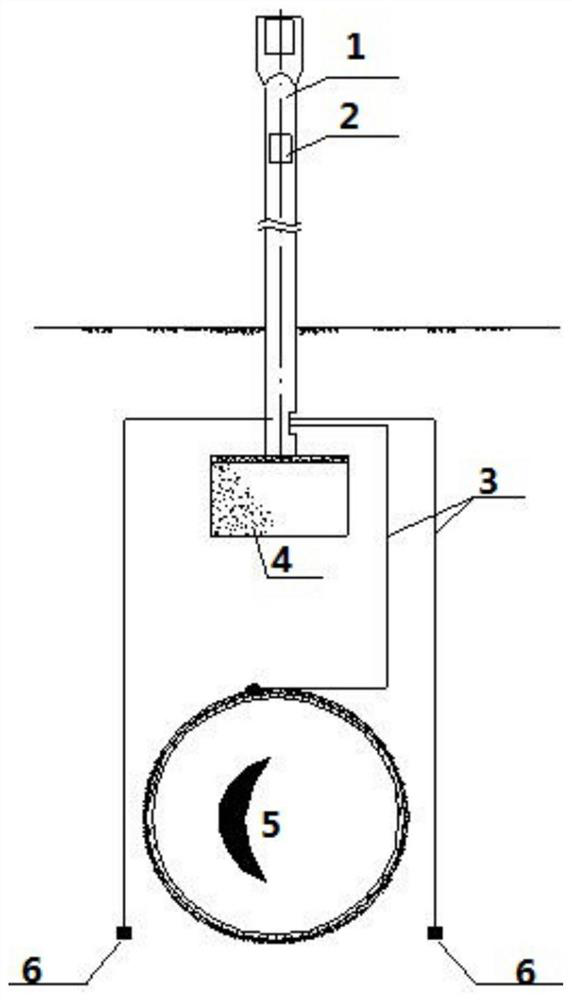

A Drainage Method for Buried Metal Pipes Near DC Grounding Electrode

The invention discloses a drainage method aiming at a buried metal pipeline near a direct-current grounding electrode, and relates to the field of corrosion prevention of buried metal pipelines, especially the field of corrosion prevention of the buried metal pipelines in a direct-current stray current environment. The drainage method comprises the following steps that the strength and direction of stray current borne by the metal pipeline near the direct-current grounding electrode are tested; the resistance rate of a soil medium where the metal pipeline near the direct-current grounding electrode is located is tested; drained current protection parameters are calculated; and field installation and parameter monitoring are carried out. The drainage efficiency can be improved, the engineering cost and the corrosion risks can be reduced, the anti-corrosion effect of the buried metal pipeline is guaranteed, and the service life of the buried metal pipeline is prolonged.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +2

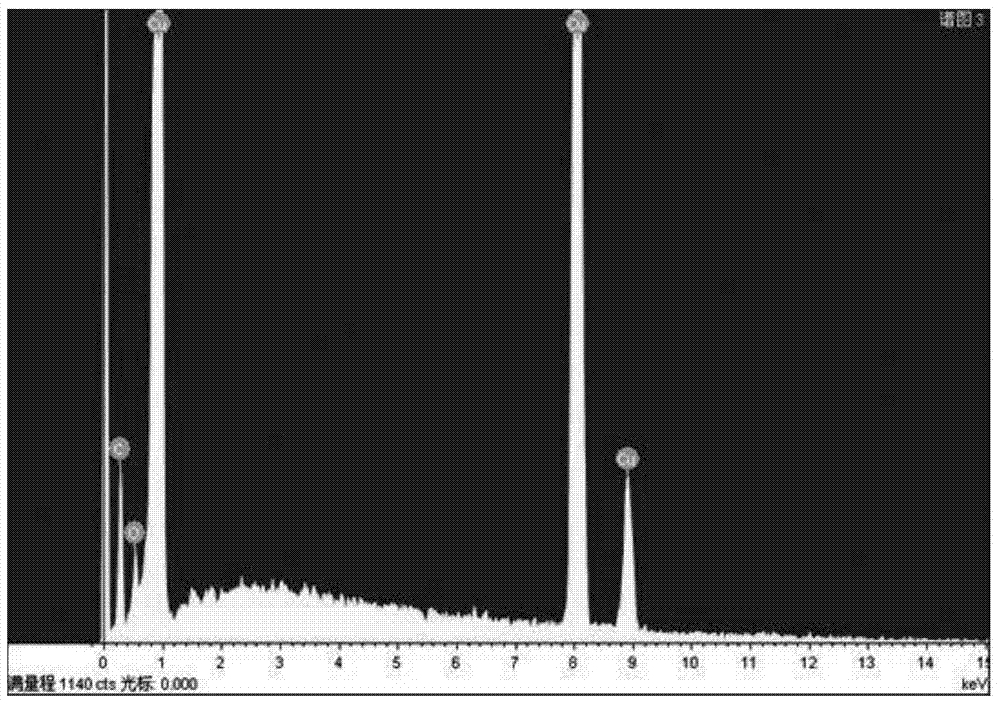

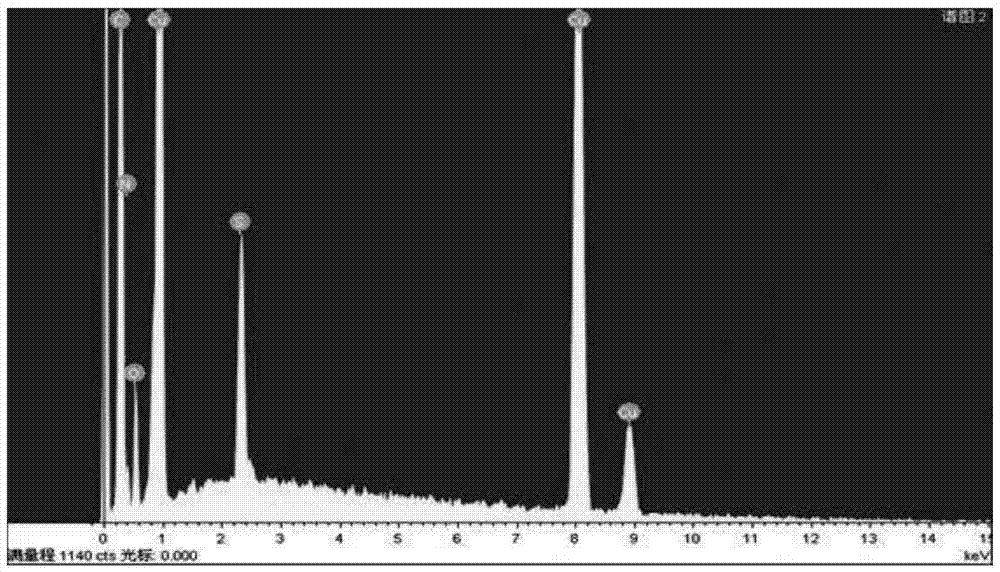

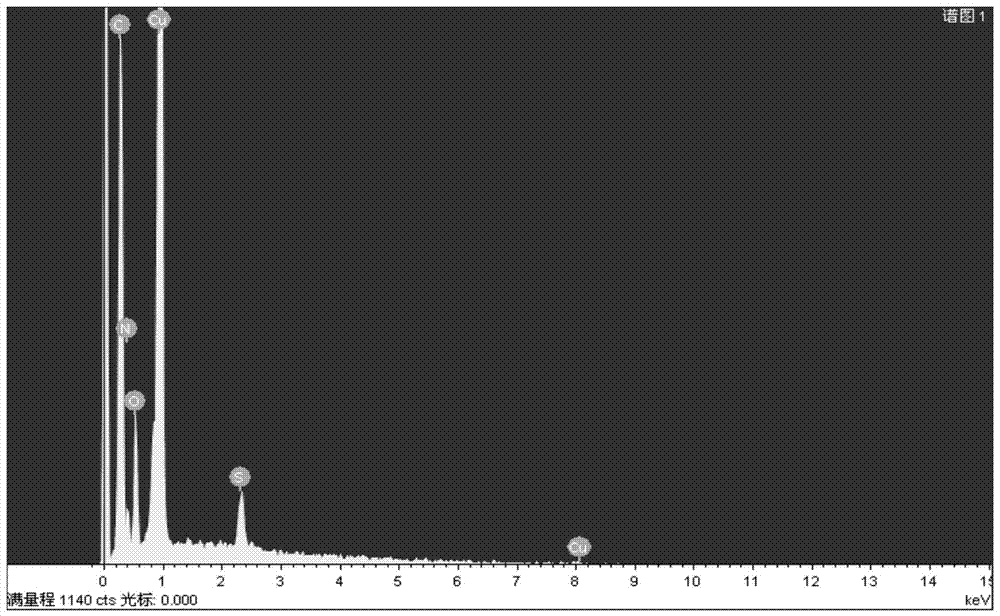

The method of solving the blockage of the hollow wire of the stator bar of the generator and inhibiting the corrosion

The invention discloses a method for solving the obstruction of a hollow lead of a generator stator bar and inhibiting the corrosion of the hollow lead. The method comprises the following steps: pickling for descaling, activating, and prefilming, wherein a composite acid used in the pickling step comprises, by weight, 65-92 parts of aminosulfonic acid and 8-35 parts of hydrofluoric acid, and a prefilming agent used in the prefilming step comprises, by weight, 35-45 parts of tolyltriazole, 40-44 parts of 2-mercaptobenzothiazole, 10-25 parts of benzotriazole and 10-15 parts of hydroxypropyl methyl cellulose. The method can realize the thorough solving of copper corrosion deposits adhered in the hollow lead and the formation of a firm molecular film in the hollow lead without corroding other metal materials in the cooling water system of the generator stator, effectively prevents the direct contact of copper atoms with cooling water, and substantially inhibits the electrochemical corrosion of copper in the cooling water with a low pH value.

Owner:SHANDONG ZHONGSHI YITONG GRP

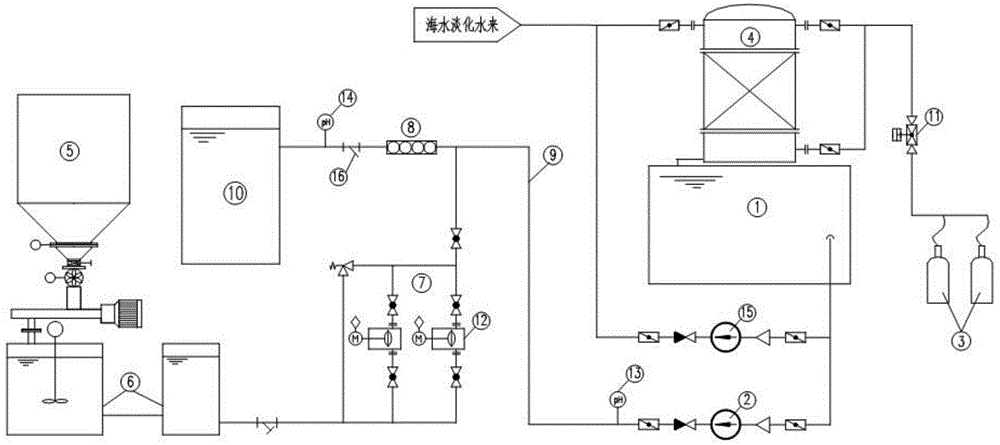

A set of seawater desalination resource conditioning device

ActiveCN104211224BMaintain safe operationGood for healthSeawater treatmentMultistage water/sewage treatmentCo2 absorptionEngineering

The invention provides a set of seawater desalination and reclamation conditioning devices. A seawater desalination water inlet pipeline is connected to a water inlet of a carbon dioxide absorbing tower; a water outlet of the carbon dioxide absorbing tower is connected to a water inlet of a seawater desalination water tank; one end of a main pipeline is connected to a water outlet of the seawater desalination water tank while the other end of the main pipeline is connected to a water inlet of a lime milk pipeline mixer; a seawater desalination water pump and a first online PH meter which is interlocked with a carbon dioxide gas regulating valve are arranged on the main pipeline; an outlet pipeline of the lime milk pipeline mixer is connected to a conditioning water tank, and a second online PH meter which is interlocked with a lime milk adding metering pump is arranged on a connecting pipeline. The whole set of system equipment is controlled by virtue of a PLC (Programmable Logic Controller) or a DCS (Distributed Control System), and is used for supplementing a certain quantity of mineralized materials into desalinated seawater in an accurate adding manner so as to guarantee residents in good health and simultaneously protecting the safe running of water supply networks.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

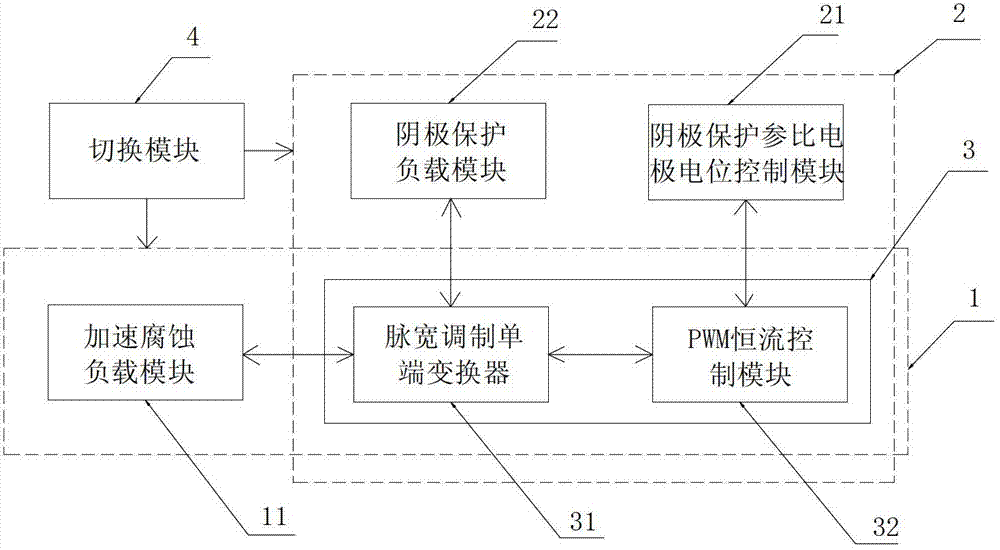

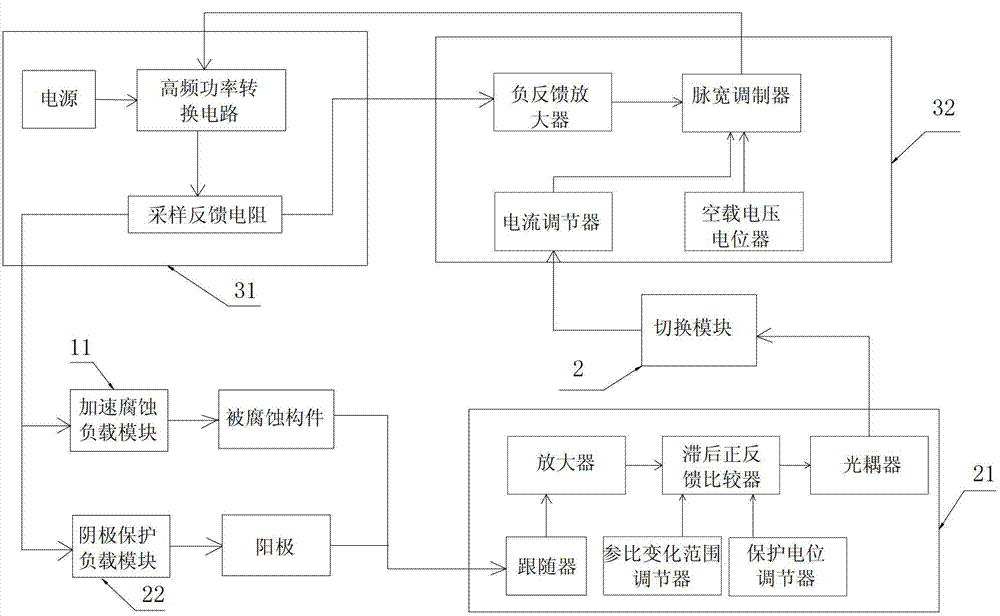

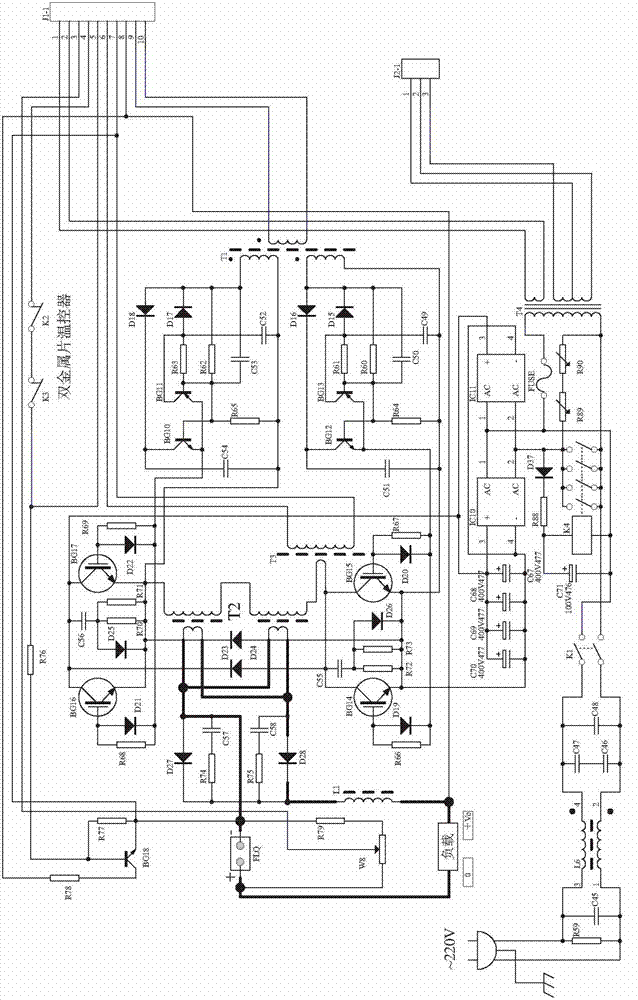

Constant-current intermittent cathodic protection and corrosion acceleration system and implementation method thereof

The invention relates to a constant-current rate intermittent cathodic protection and corrosion acceleration system and an implementation method thereof in the field of impressed current cathodic protection technologies and the experimental investigation thereof. The constant-current rate intermittent cathodic protection and corrosion acceleration system performs multiway constant-current output intermittent cathodic protection and corrosion acceleration functions, and a corrosion acceleration system and a cathodic protection system are provided with a common PWM (pulse-width modulation) constant-current control module and PWM single-ended converter. The constant-current rate intermittent cathodic protection and corrosion acceleration system conducts cathodic protection in a constant-current intermittent manner, so the cathodic protection cost is reduced; and meanwhile, the constant-current rate intermittent cathodic protection and corrosion acceleration system also performs a function of conducting corrosion acceleration at a constant-current rate, so the corrosion states of steel bars can be accurately predicted; the constant-current adjustable characteristic of the constant-current rate intermittent cathodic protection and corrosion acceleration system satisfies technological requirements of RC (reinforced concrete) structures with different numbers of steel bars and a impressed current cathodic protection and a common system module is used for providing the two functions, so the cost is saved.

Owner:CCCC FOURTH HARBOR ENG INST +4

A Method of Improving the Corrosion Resistance of Magnesium Alloy Valves

The invention relates to the technical field of new material processing, and discloses a method for improving the corrosion resistance of magnesium alloy valves. The prepared corrosion-resistant coating material is co-electrodeposited with zinc ions to the magnesium alloy valves to be plated by metal electrodeposition. On the workpiece, a dense layer with a thickness of 10.0-12.0 microns is formed to obtain a composite coating, which acts as an inert anti-corrosion barrier, prevents corrosion, remains stable in acidic media, can withstand the test of general high temperature, and reduces stress corrosion. Sensitivity, can inhibit the occurrence of electrochemical corrosion, the invention can significantly improve the corrosion resistance of magnesium alloy valves, solve the problems of high porosity and unstable protective properties of corrosion-resistant coatings for existing magnesium alloy valves, and have no pollution The waste liquid is produced without toxicity, and the economic and social benefits are significantly improved.

Owner:HEXIAN KEJIA VALVE CASTING

Method of protecting transparent nonmetallic electroconductive parts

ActiveCN103582678AInhibits galvanic corrosionCoatingsCable/conductor manufactureRoom temperatureBenzotriazole

A method of protecting a transparent nonmetallic electroconductive part formed by, e.g., ITO, on a transparent substrate, e.g., a glass substrate, from electrochemical corrosion, is characterized by coating the transparent nonmetallic electroconductive part with a room-temperature-curable silicone rubber composition that contains from 1 weight-ppm to 30 weight% of a triazole compound, e.g., a 1,2,4-triazole compound or a benzotriazole compound; and thereafter curing the composition.

Owner:DOW CORNING TORAY CO LTD

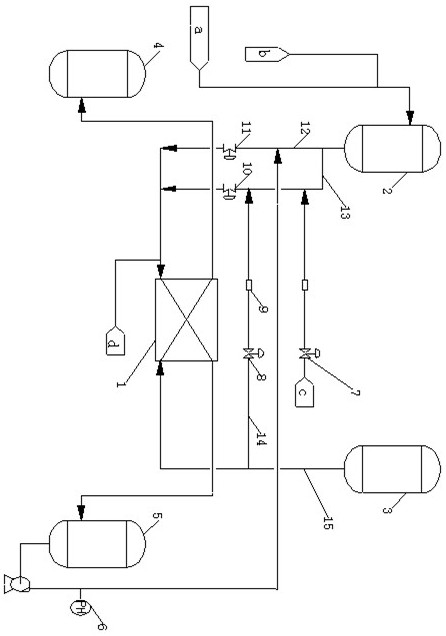

Process control method for reducing damage of electrolytic cell shutdown to cathode chamber

InactiveCN111647905AInhibits galvanic corrosionExtended service lifeElectrolysis componentsChemistryEngineering

The invention relates to a process control method for reducing damage of electrolytic cell shutdown to a cathode chamber. The system includes an electrolytic cell (1), a brine elevated tank (2), an alkali elevated tank (3), a cathode circulating tank (4) and an anode circulating tank (5). In the current reduction process of the electrolytic cell, the acid adding amount of saline water and 15% of returned saline water flow are gradually reduced, a proper amount of liquid caustic soda is added into saline water with the ratio of 2:1 after the electrolytic cell is stopped, so that hypochlorous chloride and chlorine with high oxidability in an anode chamber rapidly generate sodium hypochlorite with high stability and weak oxidability after the electrolytic cell is stopped; therefore, damage ofstopping to a cathode chamber is reduced. The method has the characteristics of low cost, safety, reliability and simple process.

Owner:TIANWEI CHEM +1

Manufacturing process of anti-electrochemical corrosion pipe pile

ActiveCN109795026BImprove corrosion resistanceInhibitionShaping reinforcementsCement mixing apparatusFiberSlag

The invention discloses a manufacturing process of an anti-electrochemical-corrosion pipe pile. The manufacturing process comprises the following steps that step 1, 420-480 kg / m<3> of cement, 200-230kg / m<3> of ground sand, 1700-1800 kg / m<3> of crushed stone, 70-120kg / m<3> of ground blast furnace slag, 90-110kg / m<3> of water, 4-6kg / m<3> of a water reducing agent, 0.5-1.5kg / m<3> of ultrafine aluminum powder with an average particle size of 7-15[mu]m and 0.3-0.6kg / m<3> of conductive fiber are made to fresh mixed concrete by a concrete forced mixer; step 2, insulating coating is applied on the inner surface of a centrifugal steel mold, and a prepared steel skeleton is placed in the centrifugal steel mold and connected with a prestressed steel anchor plate, a tension plate and a tension rod; and step 3, the lower half mold is filled with the fresh mixed concrete prepared in the step 2 is uniformly filled along the centrifugal steel mold, and the concrete is distributed more at the end which is preset to be subjected to tension. The pipe pile can internally form an anti-electrochemistry-corrosion structure and an ionic environment, and the anti-corrosion capacity of the pipe pile can beeffectively improved.

Owner:FUJIAN DADI CONCRETE PILE

Surface antiseptic treating agent for cable bridge frame

InactiveCN100532476CRaise the ratioOvercome the problem of poor scratch resistanceCellulose coatingsAnti-corrosive paintsResistWeather resistance

The invention relates to an anti-corrosion and anti-corrosion paint, in particular to a surface anti-corrosion treatment agent for cable bridges. It solves the problem that the traditional dacromet anti-corrosion coating in the prior art is difficult to meet the anti-corrosion problem of the cable tray. The present invention increases the proportion of scaly zinc powder on the basis of the traditional dacromet paint formula, increases penetrants, surfactants, hardening agents, and rare earth materials, and overcomes the poor anti-scratch effect of traditional dacromet paints Problems, so that the surface of the cable tray has a strong ability to resist scratches. Especially for cable trays, the coating formed on the surface of the present invention has high adhesion, high wear resistance, high weather resistance and high chemical resistance stability, and is very suitable for long-term use in harsh field environments. It can maintain the anti-rust effect for at least 30 years.

Owner:孔繁明

High anti-tarnish low-cost golden bronze alloy and preparation method

A gold bronze alloy with high discoloration resistance and low cost and a preparation method thereof. The alloy includes the following components Mn, Al, Ni, Si, Ce, Sr, P, B, and the balance is Cu and unavoidable impurities. The preparation process includes: smelting, semi-continuous casting; hot rolling; face milling, cold rolling, intermediate annealing; cold finish rough rolling, cold finish rolling, and finished product annealing. The alloy produced by the invention has high golden degree, good discoloration resistance, excellent heat and cold processing performance, small deformation resistance, no precious metal elements, and low cost. The composition of the alloy in the invention is reasonable, and the gold degree of the alloy is improved through reasonable matching of cheap manganese, aluminum, nickel and silicon. The reasonable combination of strontium, cerium, phosphorus and silicon can improve the process performance and anti-tarnish performance. The raw material of the alloy is cheap, the production process is simple, the environment is friendly, the production cost is low, the processing performance is good, the gold degree is high, and the anti-discoloration performance is excellent in salt spray, high humidity, artificial sweat and other environments, and it is suitable for industrial production.

Owner:CENT SOUTH UNIV

A kind of gold brass alloy with high resistance to discoloration and preparation method thereof

A gold brass alloy with high tarnish resistance and a preparation method thereof. The alloy includes the following components Mn, Sn, Ni, Zn, Sr, Ce, B, Si, the balance being Cu and unavoidable impurities. The preparation process includes: melting and casting; hot rolling; cold rolling, intermediate annealing; cold finish rough rolling, cold finish rolling, and finished annealing. The alloy produced by the invention has high golden degree, good discoloration resistance, excellent heat and cold processing performance, small deformation resistance, no precious metal elements, and low cost. The composition of the alloy in the present invention is reasonable, and the gold color of the alloy is improved through a reasonable combination of cheap manganese, nickel, zinc and tin. The zinc content is lower than 20%, which can avoid dezincification corrosion, and the reasonable combination of strontium, cerium, boron and silicon , can improve process performance and improve anti-tarnish performance. The alloy has simple production process, low production cost, good processing performance, high gold degree, excellent anti-discoloration performance in salt spray, high humidity, artificial sweat and other environments, and is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

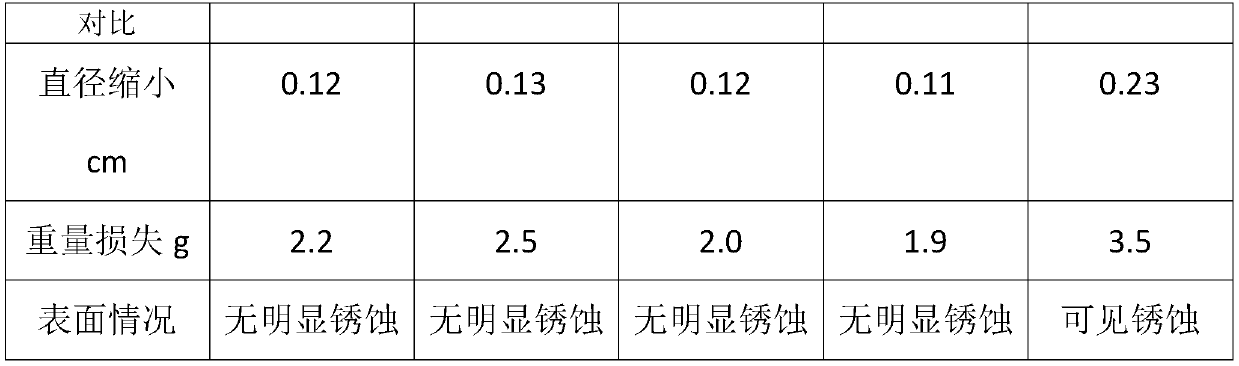

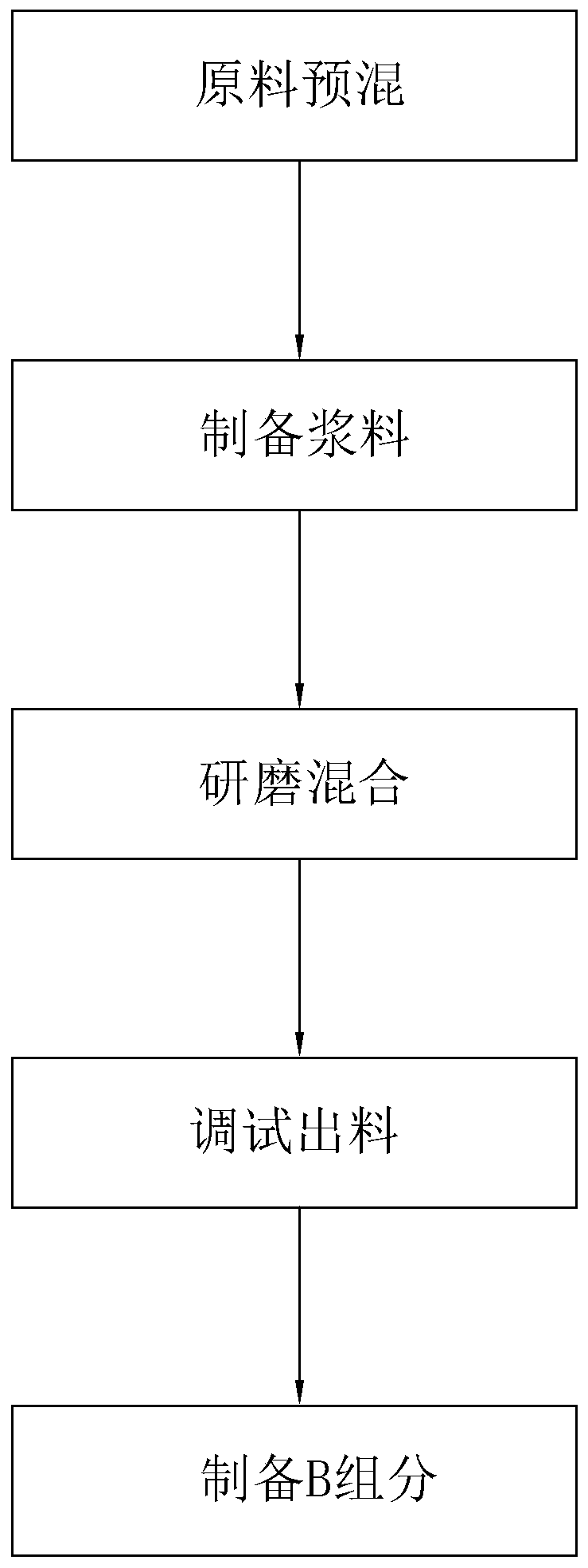

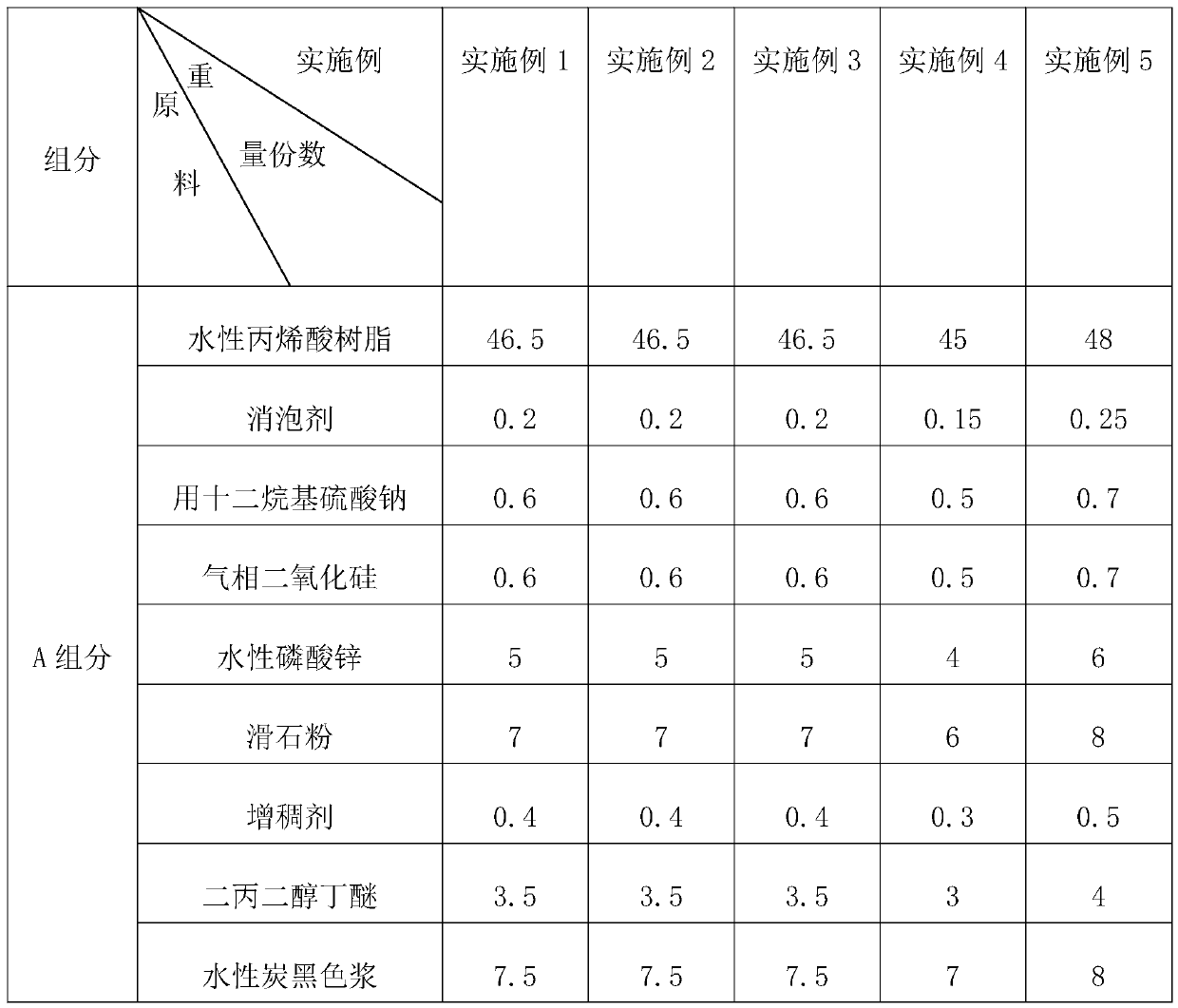

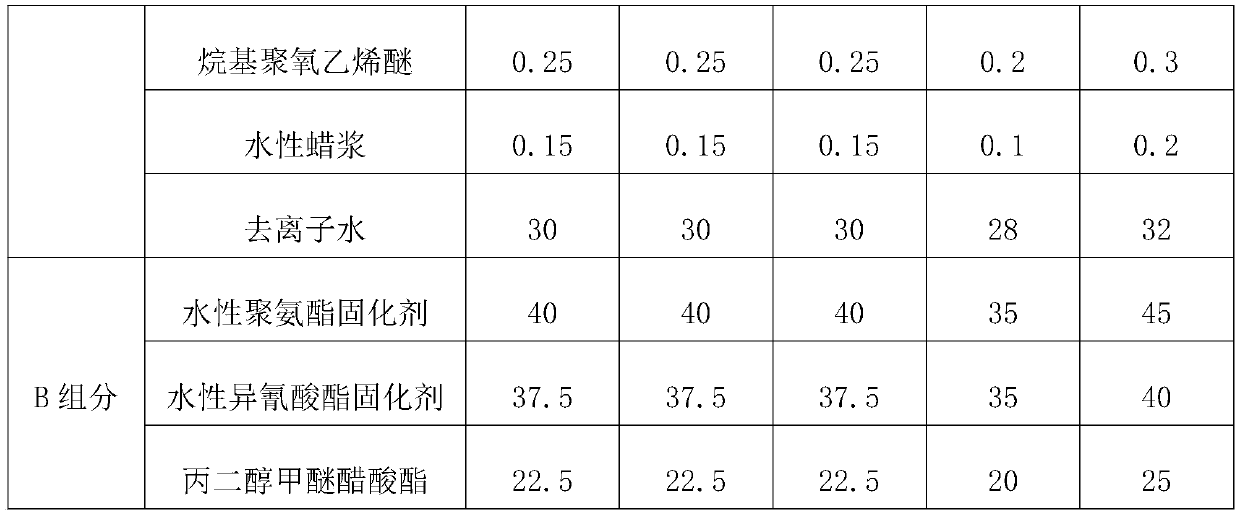

Water-based modified two-component PU finishing coat and preparation method thereof

InactiveCN111057455AGood synergistic effectStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention discloses water-based modified two-component PU finish coat and a preparation method thereof, which relate to the technical field of water-based paint, the water-based coat comprises a component A and a component B, the component A and the component B are independently stored and mixed according to the weight part ratio of (5-7): 1 in use, and the component A is prepared from the following raw materials by weight: 45-48 parts of water-based acrylic resin; 0.15 to 0.25 part of a defoaming agent; 0.5 to 0.7 part of a water-based dispersing agent; 0.5 to 0.7 part of fumed silica; 4-6 parts of water-based zinc phosphate; 6-8 parts of talcum powder; 0.3 to 0.5 part of a thickening agent; 3 to 4 parts of dipropylene glycol butyl ether; 7-8 parts of water-based carbon black color paste; 0.2 to 0.3 part of a water-based wetting agent; 0.1 to 0.2 part of water-based wax slurry; 28 to 32 parts of deionized water; and the component B comprises the following raw materials in parts byweight: 35-45 parts of a waterborne polyurethane curing agent; 35-40 parts of a water-based isocyanate curing agent; and 20 to 25 parts of propylene glycol methyl ether acetate. When the water-basedmodified two-component PU finish coat is sprayed on galvanized materials such as cold galvanizing and hot galvanizing, the water-based modified two-component PU finish coat has excellent adhesive force and good overall application effect.

Owner:湖北锦拓新材料科技有限公司 +2

Method of manufacturing steel structure provided with metal anti-corrosion protective layer

PendingCN112090712AAvoid corrosionInhibits galvanic corrosionPretreated surfacesCoatingsMetalComposite material

The invention discloses a method for manufacturing a steel structure provided with a metal anti-corrosion protective layer. The steel structure comprises a steel structure body, wherein the steel structure body is covered with a protective layer, and the protective layer sequentially comprises a wear-resistant layer, a waterproof layer, a first anti-corrosion layer and a second anti-corrosion layer from top to bottom. The surface of the steel structure body can be effectively prevented from being corroded through the two anti-corrosion layers, so that the service life of the steel structure body is prolonged; and the waterproof layer and the wear-resistant layer also have a protection effect on the two anti-corrosion layers when having waterproof and durable effects.

Owner:漳州市军立工贸有限公司

Embedded metal transition for joining fiber reinforced polymers and metallic structures

ActiveUS11192333B2Inhibits galvanic corrosionAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingPolymer sciencePolymer chemistry

A method for making a joint structure including embedding a portion of at least two layers of a third component into a first component and interleaving at least one layer of a second component with an unembedded portion of the at least two layers of the third component, wherein the third component inhibits galvanic corrosion between the first and second components, the first component has a first CTE, the second component has a second CTE that is different from the first CTE, the third component has a third CTE that is between the first CTA and the second CTE, and the third component comprises a mesh component.

Owner:HONDA MOTOR CO LTD

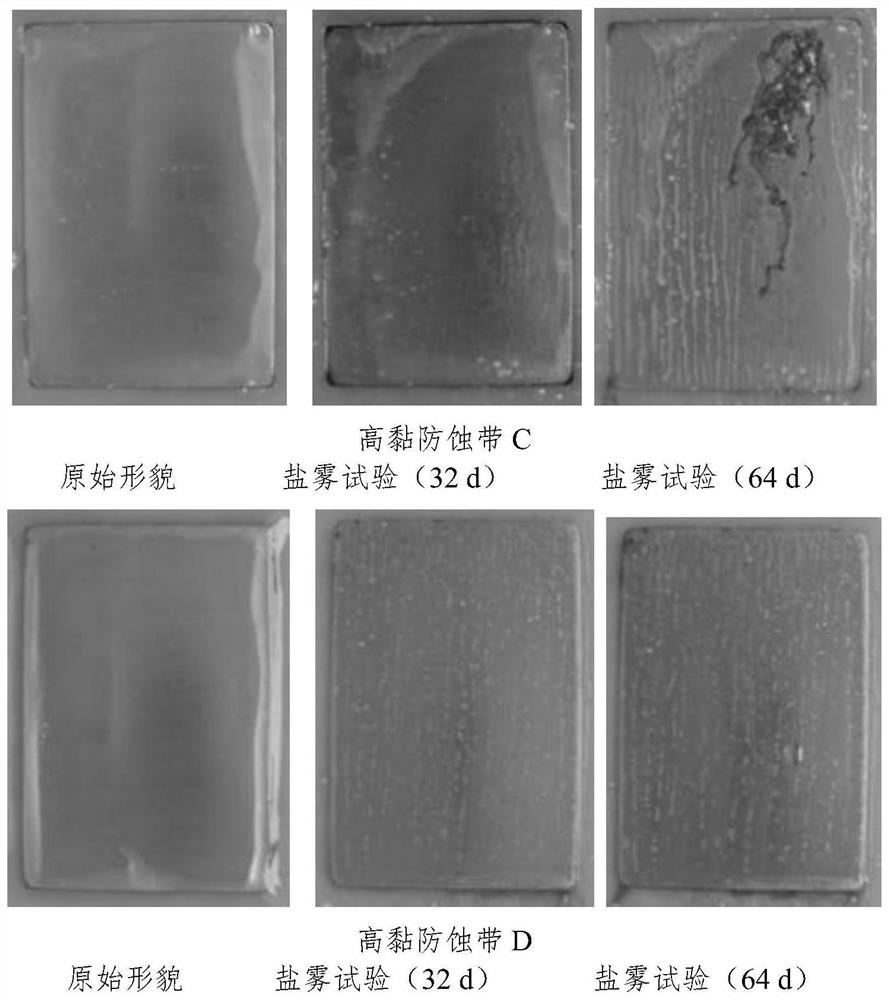

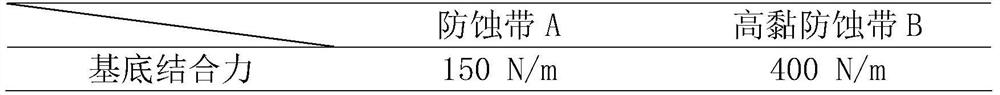

A high-viscosity anti-corrosion strip suitable for marine atmospheric environment and its preparation method and application

The invention belongs to the field of metal anti-corrosion, and in particular relates to a high-viscosity anti-corrosion tape suitable for marine and atmospheric environments, a preparation method and application thereof. The anti-corrosion tape is a non-woven fabric impregnated with anti-corrosion paste at high temperature; the anti-corrosion paste is 28-30% of high-viscosity modified polymerized linseed oil by weight percentage, 2-3% of corrosion inhibitor, and 5-8% of insulating agent. %, flame retardant inorganic filler 59‑65%. The anti-corrosion tape obtained by the invention has excellent bonding performance, wetting performance and anti-corrosion performance, and is applied to high-humidity, high-salt marine atmospheric environment.

Owner:青岛迪恩特新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com