Water-based modified two-component PU finishing coat and preparation method thereof

A water-based modification, two-component technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor adhesion, low curing agent viscosity, low VOC content, etc. The effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

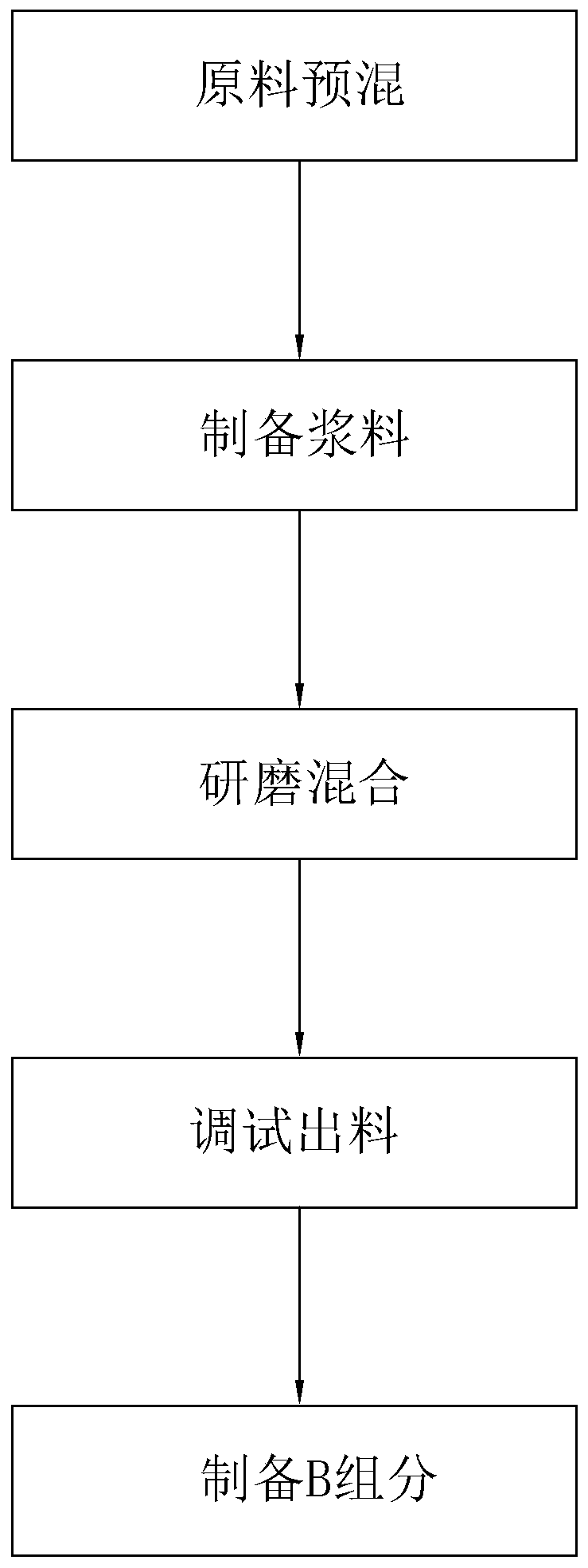

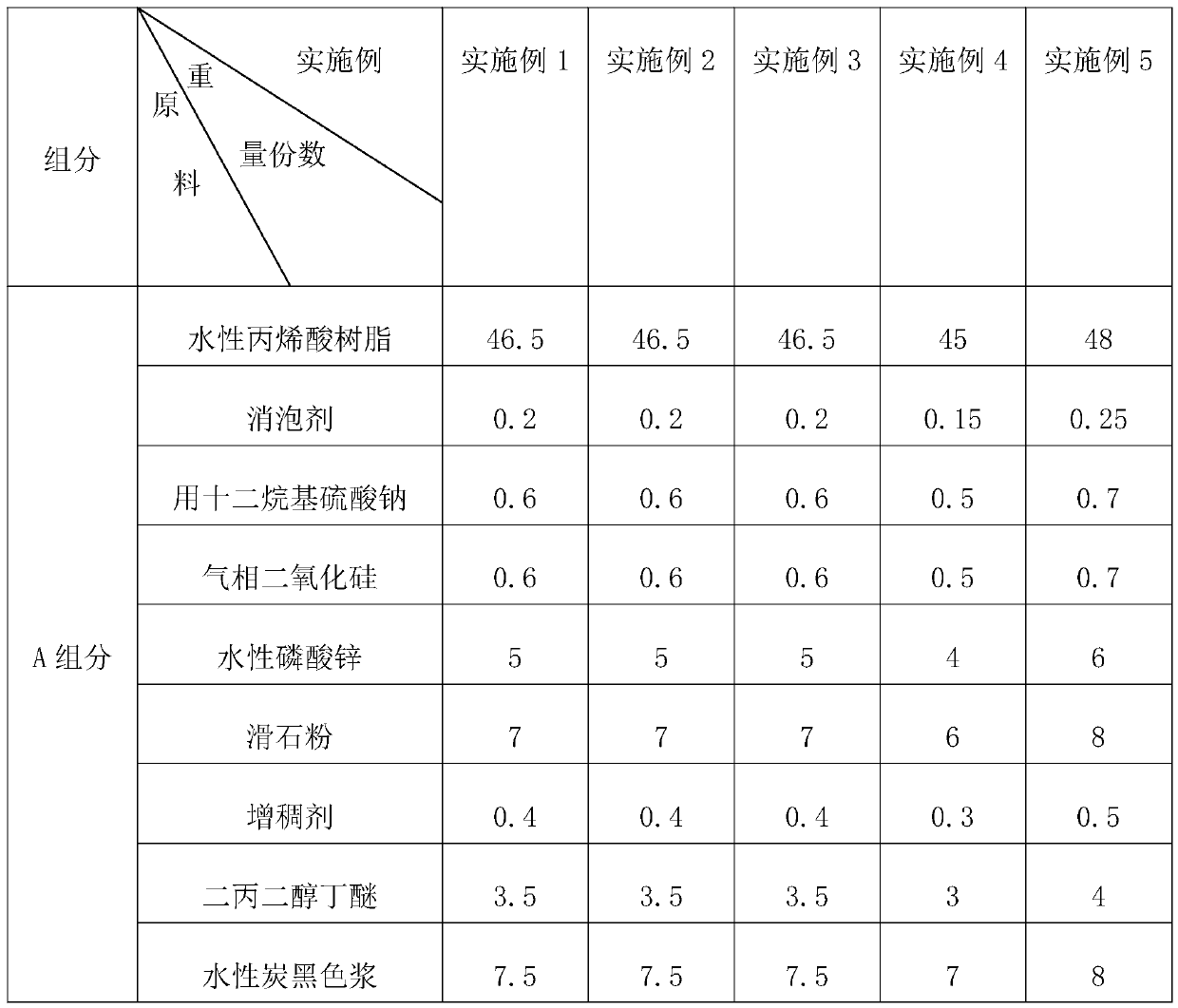

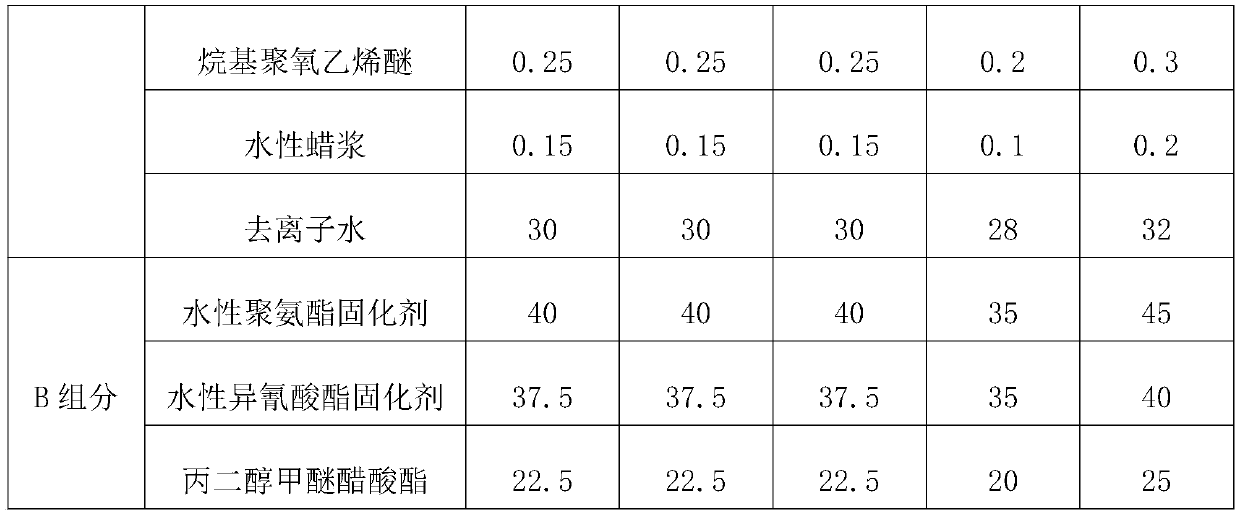

[0052] Embodiment 1: A kind of water-based modified two-component PU topcoat, including A component and B component that are stored separately and mixed in a ratio of 6:1 by weight and number when used, each component and its corresponding The parts by weight are shown in Table 1, and are prepared through the following steps:

[0053] Step 1: Premix the raw materials, weigh the water-based acrylic resin in the corresponding parts by weight into a plastic jar, add 9.5 parts of deionized water in the machine stirring, stir at 550rpm for 6 minutes, and then add The antifoaming agent of corresponding parts by weight and with sodium lauryl sulfate, 550rpm stirs 6 minutes, obtains premix;

[0054] Step 2: prepare the slurry, add fumed silica, water-based zinc phosphate and talcum powder in the corresponding parts by weight in sequence, the feeding time is 7.5min, and the middle is continuously stirred, and the stirring speed is 550rpm, and the After finishing the material, use 5.5 ...

Embodiment 2

[0059] Embodiment 2: A kind of water-based modified two-component PU topcoat, including the A component and the B component that are stored separately and mixed in a ratio of 5:1 by weight and number when used, different from that of Example 1 The feature is that it is prepared by the following steps:

[0060] Step 1: Premix the raw materials, weigh the corresponding parts by weight of water-based acrylic resin into a plastic jar, add 9 parts by weight of deionized water to the machine, stir at 500rpm for 8 minutes, and then add The antifoaming agent of corresponding parts by weight and sodium lauryl sulfate, 500rpm stirs 8 minutes, obtains premix;

[0061] Step 2: Prepare the slurry, add fumed silica, water-based zinc phosphate and talcum powder in the corresponding parts by weight in sequence, the addition time is 5 minutes, and stir continuously in the middle, and the stirring speed is 600rpm. Wash the powder bonded to the tank wall with 5 parts of deionized water, and the...

Embodiment 3

[0065] Embodiment 3: A kind of water-based modified two-component PU finish paint, comprises the A component and the B component that the ratio of parts by weight is 7:1 when being preserved separately and mixed in use, and the difference of embodiment 1 The feature is that it is prepared by the following steps:

[0066] Step 1: Premix the raw materials, weigh the corresponding parts by weight of water-based acrylic resin into a plastic jar, add 10 parts by weight of deionized water to the mixing machine, stir at 600rpm for 4 minutes, and then add The antifoaming agent of corresponding parts by weight and sodium lauryl sulfate, 600rpm stirs 4 minutes, obtains premix;

[0067] Step 2: Prepare the slurry, add fumed silica, water-based zinc phosphate and talcum powder in the corresponding parts by weight in sequence, the addition time is 10 minutes, and stir continuously in the middle, and the stirring speed is 500rpm. Wash the powder bonded on the tank wall with 6 parts of deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com