Manufacturing process of anti-electrochemical corrosion pipe pile

A manufacturing process, electrochemical technology, applied in the field of manufacturing process of electrochemical corrosion pipe piles, can solve the problems of coating failure, difficult service life, inability to effectively form protective effect, etc., to delay aging, improve anti-corrosion ability, inhibit The effect of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

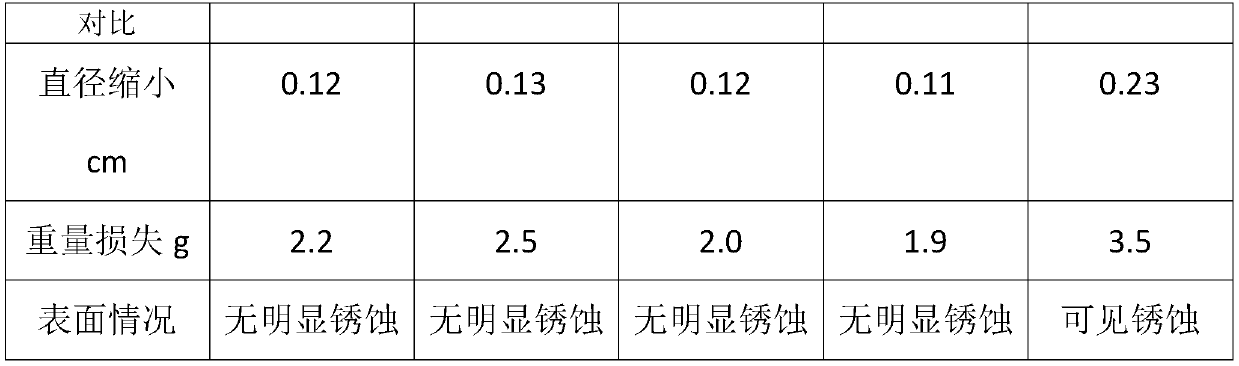

Embodiment 1

[0030] The manufacturing process of the electrochemical corrosion resistant pipe pile comprises the following steps:

[0031] Step 1: Add cement 420kg / m 3 , ground sand 200kg / m 3 , gravel 1700kg / m 3 , Grinding blast furnace slag 70kg / m 3 , water 90kg / m 3 , water reducer 4kg / m 3 , average particle size 7μm superfine aluminum powder 0.5kg / m 3 And conductive fiber 0.3kg / m 3 Make fresh concrete with concrete forced mixer;

[0032] Step 2: Apply insulating paint on the inner surface of the centrifugal steel mold, place the prepared steel skeleton in the centrifugal steel mold, and connect with the prestressed steel anchor plate, tension plate, and tension rod;

[0033] Step 3: Fill the lower half of the mold evenly with the fresh concrete prepared in step 1 along the centrifugal steel mold, and lay more concrete on the pre-tensioned end;

[0034] Step 4: Lift the upper mold half above the lower mold half, and fix the upper and lower mold halves with bolts to ensure that the...

Embodiment 2

[0044] The manufacturing process of the electrochemical corrosion resistant pipe pile comprises the following steps:

[0045] Step 1: Add cement 480kg / m 3 , ground sand 230kg / m 3 , gravel 1800kg / m 3 , Grinding blast furnace slag 120kg / m 3 , water 110kg / m 3 , water reducer 6kg / m 3 , Average particle size 15μm superfine aluminum powder 1.5kg / m 3 And conductive fiber 0.6kg / m 3 Make fresh concrete with concrete forced mixer;

[0046] Step 2: Apply insulating paint on the inner surface of the centrifugal steel mold, place the prepared steel skeleton in the centrifugal steel mold, and connect with the prestressed steel anchor plate, tension plate, and tension rod;

[0047] Step 3: Fill the lower half of the mold evenly with the fresh concrete prepared in step 1 along the centrifugal steel mold, and lay more concrete on the pre-tensioned end;

[0048] Step 4: Lift the upper mold half above the lower mold half, and fix the upper and lower mold halves with bolts to ensure that ...

Embodiment 3

[0058] The manufacturing process of the electrochemical corrosion resistant pipe pile comprises the following steps:

[0059] Step 1: Add cement 450kg / m 3 , ground sand 220kg / m 3 , Gravel 1750kg / m 3 , Grinding blast furnace slag 90kg / m 3 , water 100kg / m 3 , water reducer 5kg / m 3 , average particle size 9μm superfine aluminum powder 1kg / m 3 And conductive fiber 0.45kg / m 3 Make fresh concrete with concrete forced mixer;

[0060] Step 2: Apply insulating paint on the inner surface of the centrifugal steel mold, place the prepared steel skeleton in the centrifugal steel mold, and connect with the prestressed steel anchor plate, tension plate, and tension rod;

[0061] Step 3: Fill the lower half of the mold evenly with the fresh concrete prepared in step 1 along the centrifugal steel mold, and lay more concrete on the pre-tensioned end;

[0062] Step 4: Lift the upper mold half above the lower mold half, and fix the upper and lower mold halves with bolts to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com