Method of protecting transparent nonmetallic electroconductive parts

A conductive part and non-metal technology, which is applied in the field of transparent non-metal conductive parts from electrochemical corrosion, can solve the problem of undisclosed protection of transparent non-metal conductive parts, inability to satisfactorily inhibit electrochemical corrosion of transparent non-metal conductive parts, etc. problem, to achieve the effect of inhibiting electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0039] The method of the present invention for protecting transparent non-metallic conductive parts will be described in detail using examples. The viscosities reported in the examples are values at 25°C. Electrochemical corrosion testing of transparent non-metallic conductive parts was performed as follows.

[0040] [Electrochemical corrosion test of transparent non-metallic conductive parts]

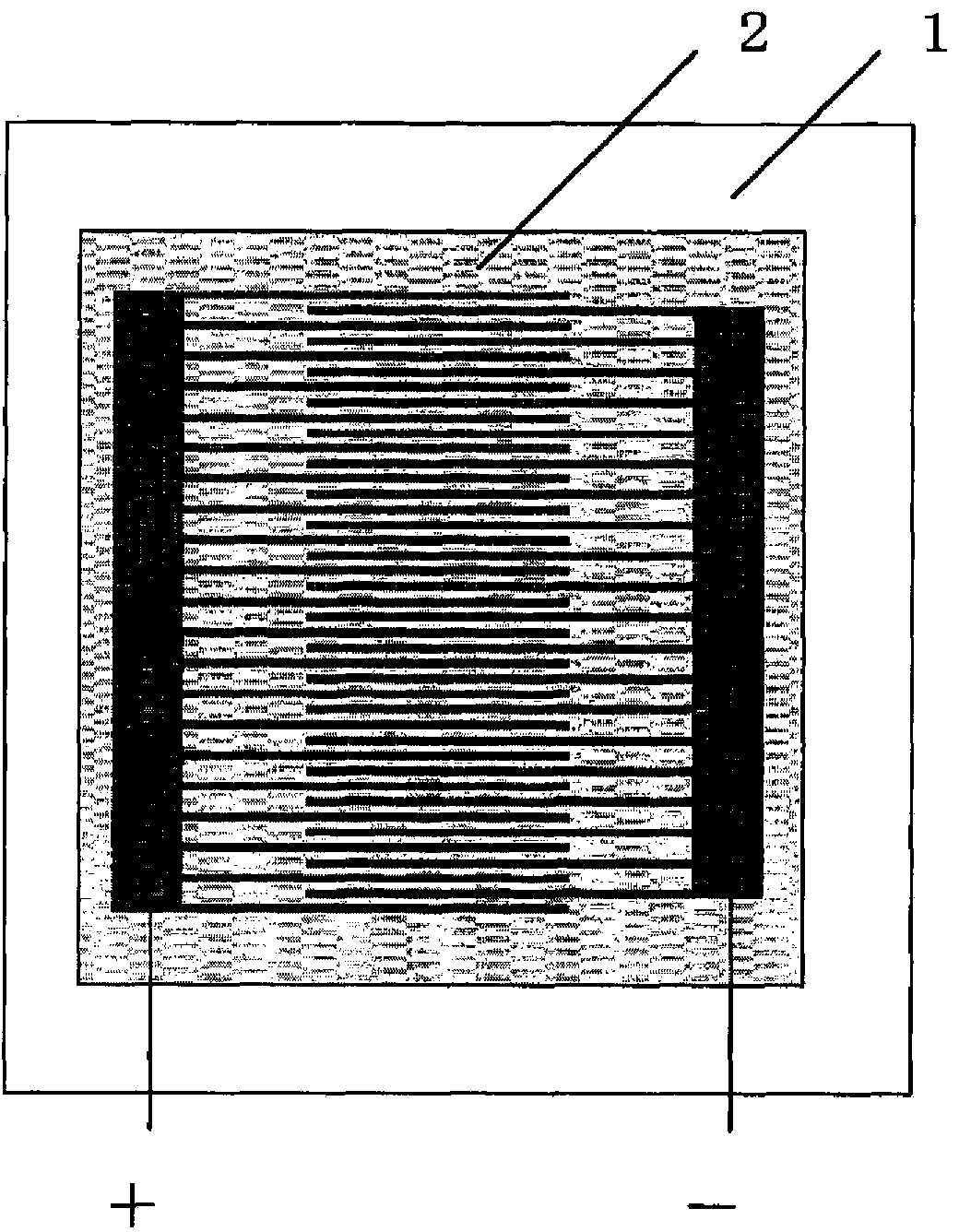

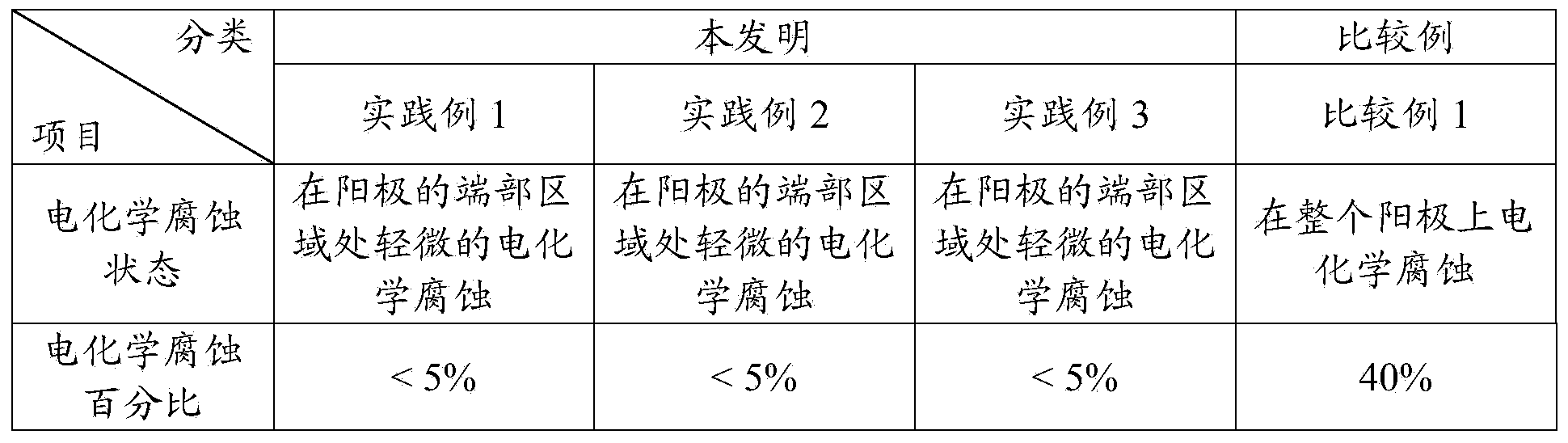

[0041] Test specimens were prepared by coating a room temperature curable silicone rubber composition on a glass substrate to a thickness of 0.6mm, and then standing at 25°C / 50%RH for 1 week to cause curing, as figure 1 As shown, comb electrodes have been formed on the glass substrate using a 10 μm gap between the ITO conductive regions. The test sample was then kept at 60° C. / 95% RH for 96 hours while applying a voltage of 20 V between the electrodes of the test sample. After testing, the state of the transparent non-metallic conductive area was examined using a microscope to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com