Method of manufacturing steel structure provided with metal anti-corrosion protective layer

A technology of anti-corrosion protection and anti-corrosion layer, applied in the direction of coating, device for coating liquid on the surface, pre-treatment surface, etc., can solve the problem of corrosion of steel structure, etc. Effects of Fastener Corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

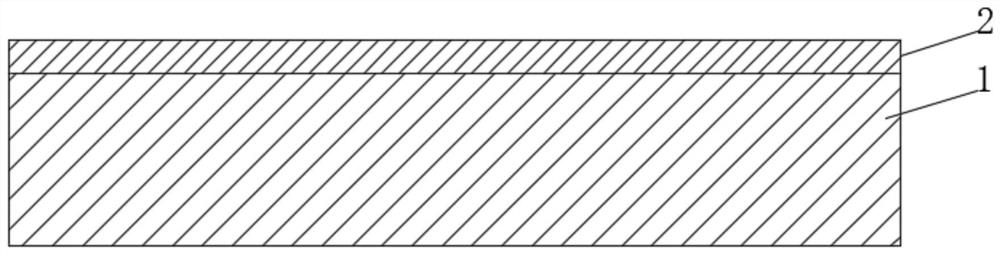

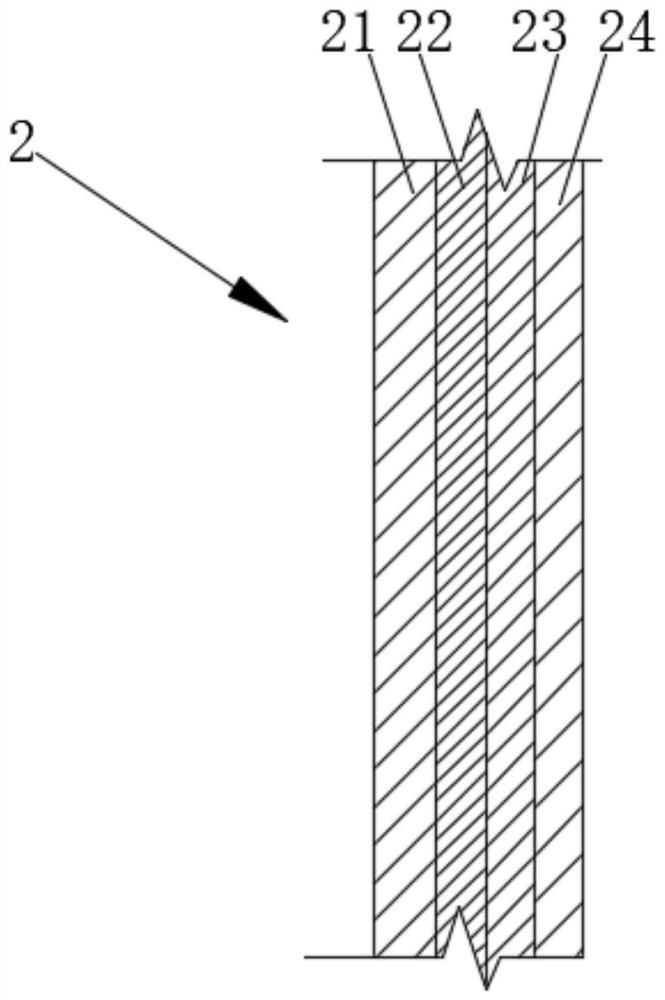

[0026] see figure 1 and figure 2 A method for manufacturing a steel structure provided with a metal anti-corrosion protective layer, comprising a steel structure body 1 covered with a protective layer 2, the protective layer 2 sequentially includes a wear-resistant layer 21, a waterproof layer 22, The first anti-corrosion layer 23 and the second anti-corrosion layer 24 .

[0027] see figure 1 and figure 2 , the wear-resistant layer 21 is made of polyvinyl chloride material, and its thickness is not more than 3 mm. The polyvinyl chloride material has good wear-resistant effect, and as the outermost layer, it can protect the waterproof layer 23 and the two anti-corrosion layers.

[0028] see figure 1 and figure 2 , the waterproof layer 22 is made of polyethylene material and has a thickness of 1.5 to 2.5 mm, which prevents water from intruding into the two anti-corrosion layers and plays a second protective effect on the two anti-corrosion layers.

[0029] see figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com