Alkaline zinc-manganese dioxide cell and preparation method thereof

A zinc-manganese battery, alkaline technology, applied in the field of electrochemistry, can solve the problems of zinc-nickel battery self-discharge, poor high-rate discharge performance, short battery storage period, etc., to improve diffusion and transfer, increase discharge capacity, reduce The effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

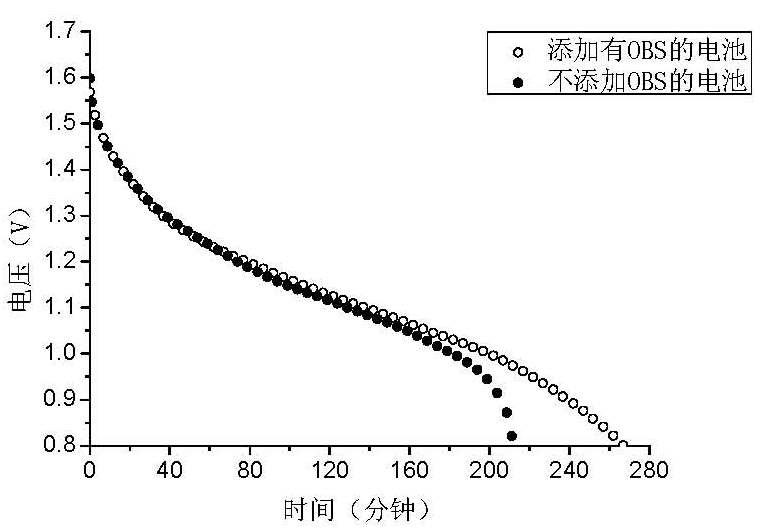

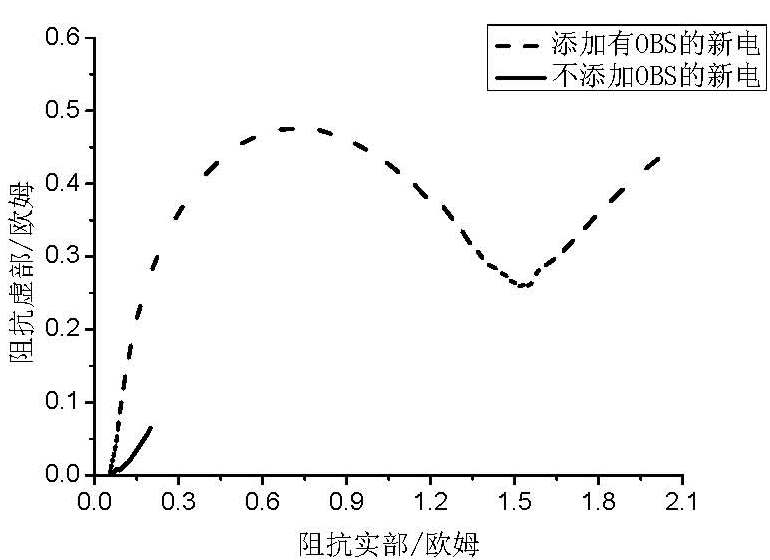

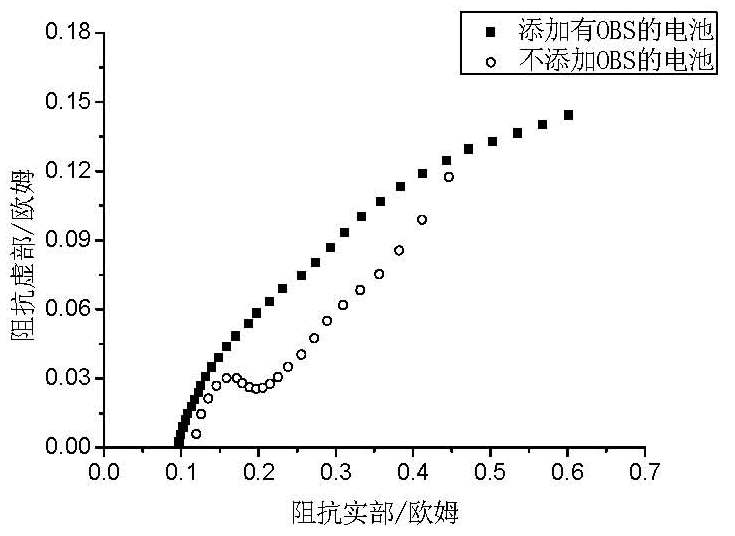

[0044] Example 1: Manufacture of Alkaline Zinc-Manganese Batteries

[0045] (1) Manufacture of positive electrode ring

[0046] 500g of electrolytic manganese dioxide, 40g of expanded graphite powder (Baotou Jingyuan) and 2.5g of polytetrafluoroethylene wax xy-300 with an average particle size of 2μm, after rapid stirring and dispersion, add 25g of potassium hydroxide electrolyte solution with a mass concentration of 38%, continue After stirring for 10 minutes, roll into tablets and granulate. The size of the positive electrode material after granulation is 20 mesh to 80 mesh particles, and the apparent specific gravity is 1.54g / ml. After ringing, the ring height of the positive electrode material of AA type (No. 5) battery is 10.5mm, the outer diameter is 13.4mm, and each battery 4 The total weight of each positive electrode ring is 10.6-10.7g.

[0047] (2) Preparation of negative electrode zinc paste

[0048] Add 100g of 468 zinc alloy powder, 0.5g of polyacrylic acid 7...

Embodiment 2

[0051] Example 2: Manufacture of Alkaline Zinc-Manganese Batteries

[0052] (1) Manufacture of positive electrode ring

[0053] 500g of electrolytic manganese dioxide, 40g of expanded graphite powder (Baotou Jingyuan) and 3g of polytetrafluoroethylene wax xy-300 with an average particle size of 0.5μm, after rapid stirring and dispersion, add 25g of potassium hydroxide electrolyte solution with a mass concentration of 45%, continue After stirring for 10 minutes, roll into tablets and granulate. The parameters of the prepared positive electrode ring are the same as those in Example 1.

[0054] (2) Preparation of negative electrode zinc paste

[0055] Add 100g of 468 zinc alloy powder, 0.5g of polyacrylic acid 720B, 0.4g of sodium polyacrylate DK500 and OBS accounting for 0.001% of the total mass of the mixture to 50g of a 40% potassium hydroxide aqueous solution containing a mass fraction of 2% ZnO, and stir After uniformity, vacuum degassing to make zinc paste, which is us...

Embodiment 3

[0058] Example 3: Manufacture of Alkaline Zinc-Manganese Batteries

[0059] (1) Manufacture of positive electrode ring

[0060] 500g of electrolytic manganese dioxide, 40g of expanded graphite powder (Baotou Jingyuan) and 4g of polytetrafluoroethylene wax xy-300 with an average particle size of 5μm, after rapid stirring and dispersion, add 25g of potassium hydroxide electrolyte with a mass concentration of 40%, and continue stirring After 10 minutes, it was rolled into tablets and granulated. The parameters of the prepared positive electrode ring are the same as those in Example 1.

[0061] (2) Preparation of negative electrode zinc paste

[0062] Add 100g 468 zinc alloy powder, 0.5g polyacrylic acid 720B, 0.4g polyacrylic acid sodium DK500 and OBS accounting for 0.01% of the total mass of the mixture to 50g of potassium hydroxide aqueous solution containing 4% ZnO with a mass concentration of 35%, and stir evenly After vacuum degassing, it is made into zinc paste, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com