Waterborne epoxy anticorrosive coating containing composite active salt and preparation method of coating

A technology of water-based epoxy and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., and can solve the problems of poor anti-corrosion performance of water-based epoxy coatings, limited inhibition of corrosion ions, and imperfect preparation process of modified products and other problems, to achieve the effect of improving the overall anti-corrosion performance, excellent adhesion, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

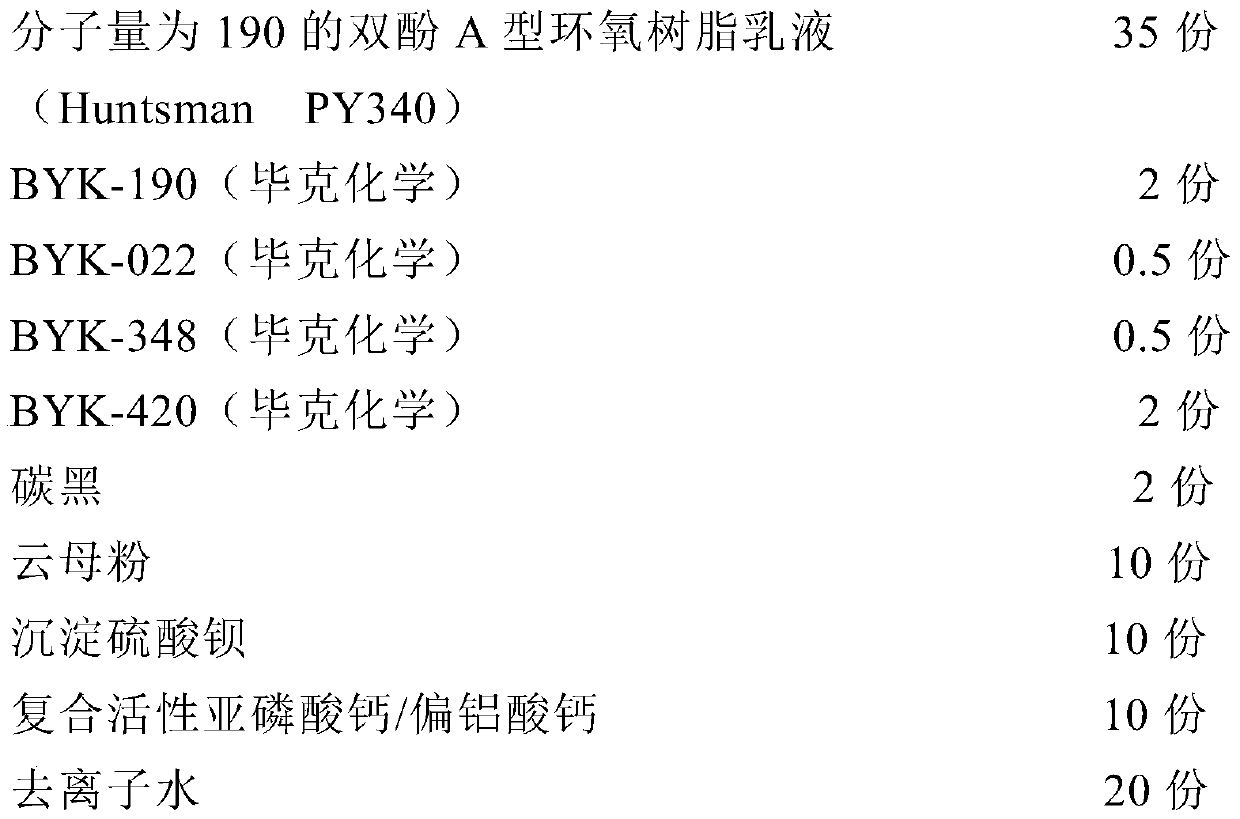

[0033] A component:

[0034]

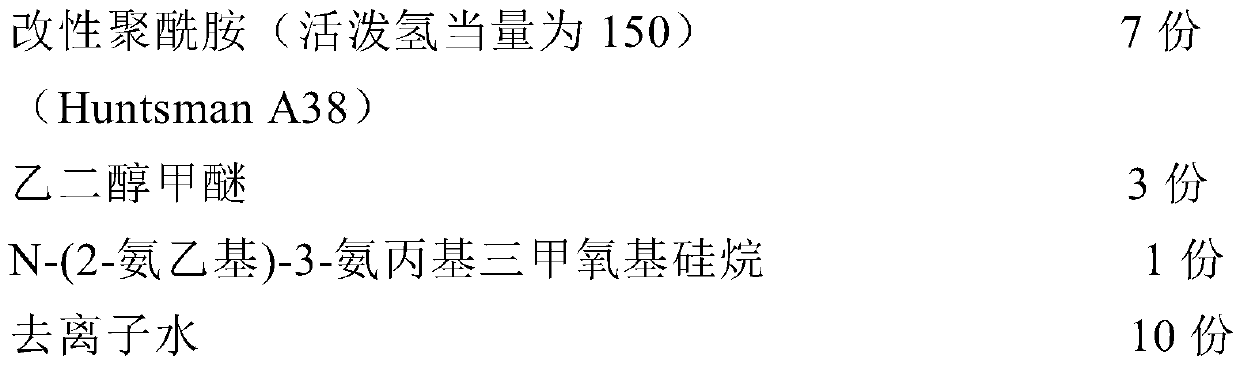

[0035] B component:

[0036]

[0037] A component: B component is mixed according to the mass ratio = 3:1, and the water-based epoxy anticorrosion coating is prepared.

[0038] Wherein, the preparation of the composite active calcium phosphite / calcium metaaluminate is to mix calcium phosphite and calcium metaaluminate in a mass ratio of 7:3 to obtain 100 g of the mixture, which is then added to 100 g of γ-aminopropanol containing 2%. Base triethoxysilane / ethanol solution, stirred at 70°C for 2h, and kept condensing to reflux. After standing still for 24 hours, the mixture was suction filtered and dried at 70°C.

[0039] The preparation method of the water-based epoxy anti-corrosion coating of this embodiment is as follows: in the state of stirring, first mix the acrylic polymer BYK-190, the silicone defoamer BYK-022 and the polyether modified polydimethyl Mix siloxane BYK-348 with deionized water evenly, then add carbon black, mica powder,...

Embodiment 2

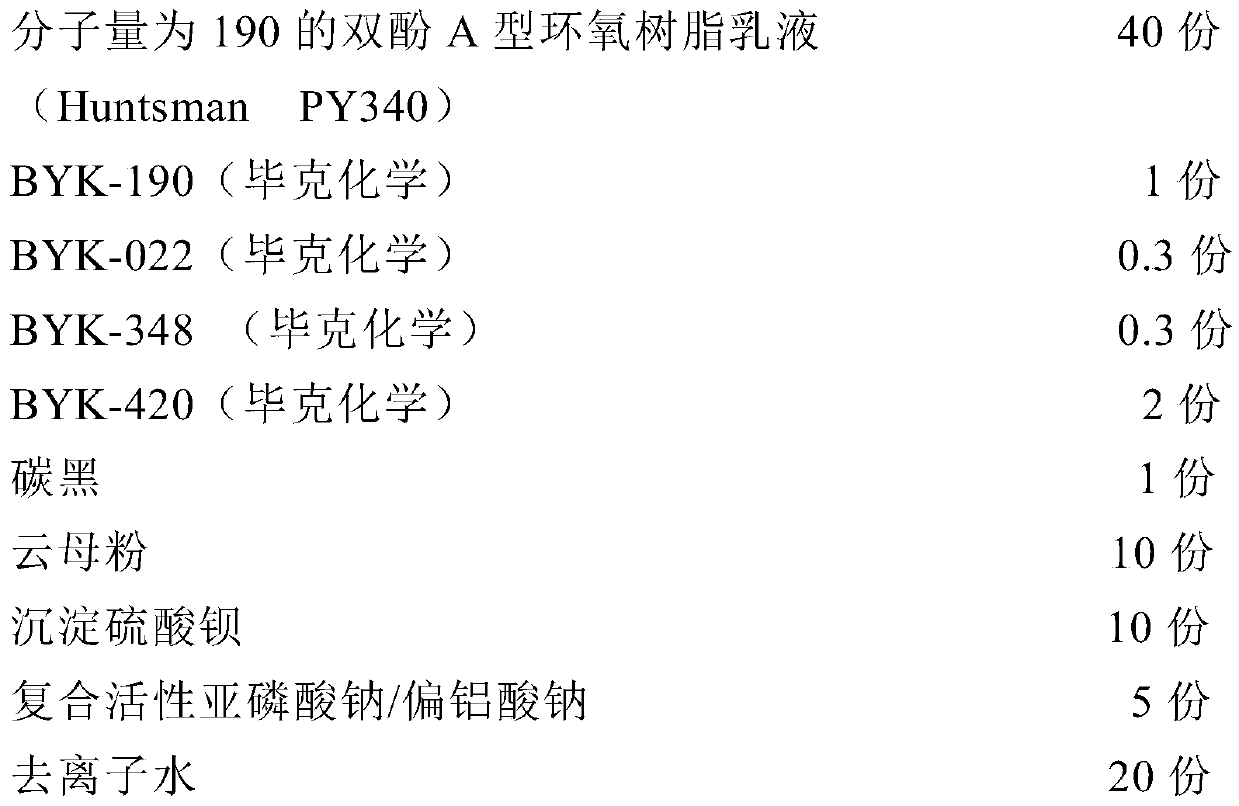

[0041] A component:

[0042]

[0043] B component:

[0044]

[0045] A component: B component is mixed according to the mass ratio = 4:1, and the water-based epoxy anticorrosion coating is prepared.

[0046] Among them, the preparation method of composite active sodium phosphite / sodium metaaluminate is as follows: mix sodium phosphite and sodium metaaluminate at a mass ratio of 6:4, and put the mixture into γ-aminopropyl tris In the ethoxysilane / ethanol solution, stir at 60°C for 4h, and keep condensing to reflux; after standing still for 36h, the mixture is suction filtered and dried at 80°C. Others are the same as embodiment 1.

Embodiment 3

[0048] A component:

[0049]

[0050] B component:

[0051]

[0052] A component: B component is mixed according to the mass ratio = 5:1, and the water-based epoxy anticorrosion coating is prepared. other same

[0053] Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com