Process control method for reducing damage of electrolytic cell shutdown to cathode chamber

A process control and electrolytic cell technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of inability to rapidly reduce ion exchange membrane damage, electrochemical corrosion, increase in power consumption, etc., to inhibit electrochemical corrosion, save production costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

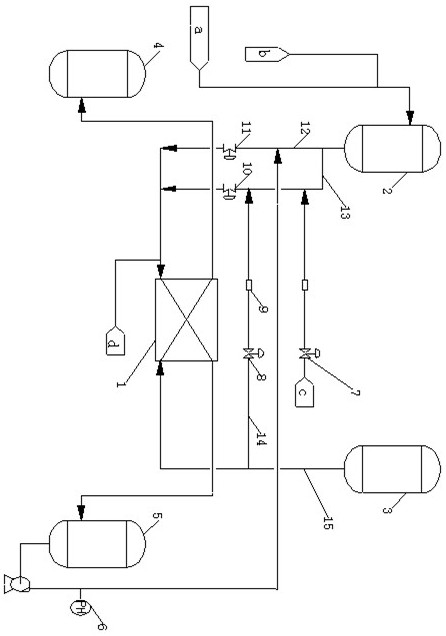

[0016] Embodiment 1: In order to describe the present invention in more detail, it will be explained in conjunction with the accompanying drawings. The specific method is as follows: when the current of the electrolytic cell (1) is greater than 6.0KA during the current reduction process, the refined brine and acid flow adjustment should be adjusted in time according to the process index Valve, brine adding acid flow regulating valve into the tank, 15% return brine flow regulating valve, reduce the flow of refined brine adding acid, brine adding acid flow into the tank, and 15% return brine flow according to the process indicators. When the current of the electrolytic cell drops to 6.0KA, close the flow regulating valve of refined brine adding acid, the flow regulating valve of adding acid to brine entering the tank, and the flow regulating valve of 15% return brine. Under the low current operation of the electrolyzer, wait for the anode outlet pH monitor (6) to stabilize and op...

Embodiment 2

[0017]Embodiment 2: A process control method for reducing the damage to the cathode chamber caused by the shutdown of the electrolytic cell, including the electrolytic cell (1), the brine high level tank (2), the alkali high level tank (3), the cathode circulation tank (4), and the anode circulation tank (5); anode part: Secondary refined brine (a) enters the high level tank of brine, under the action of high head difference, enters the anode chamber of the electrolytic cell (1) by gravity through the main pipe of refined brine (12), and under the action of direct current, the secondary The refined brine is electrolyzed in the anode chamber to produce chlorine gas and light brine. The light brine flows into the anode circulation tank (5) by itself, and the 15% light brine is returned to the brine line through the 15% brine line to be introduced into the refined brine main pipe of the electrolytic cell to protect the titanium tube; the cathode Part: the catholyte enters the alka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com