Copper etching liquid

A technology of copper etching and ammonium salt, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve problems such as circuit disconnection, circuit resistance increase, etc., and achieve easy bath management and inhibition of electrochemical corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

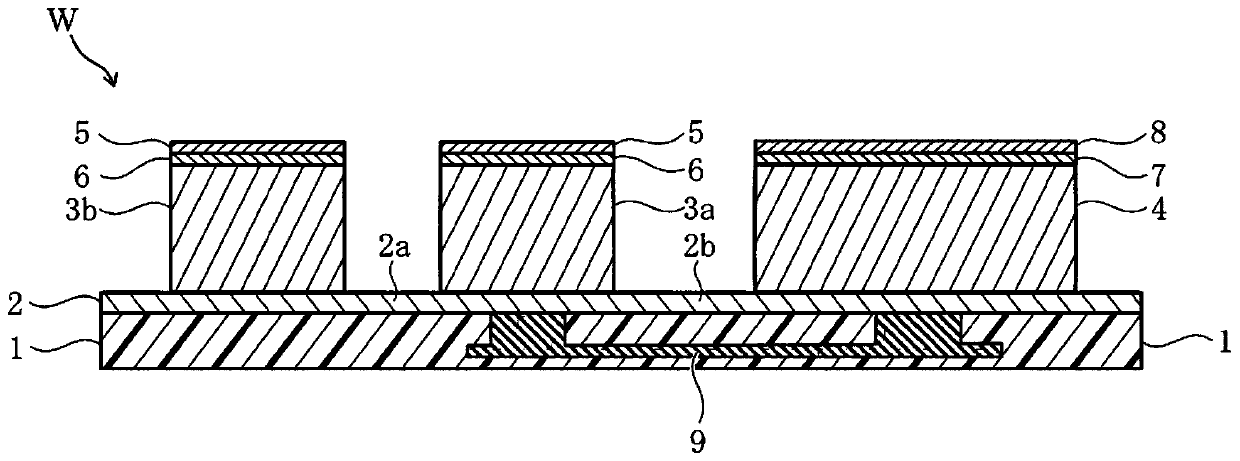

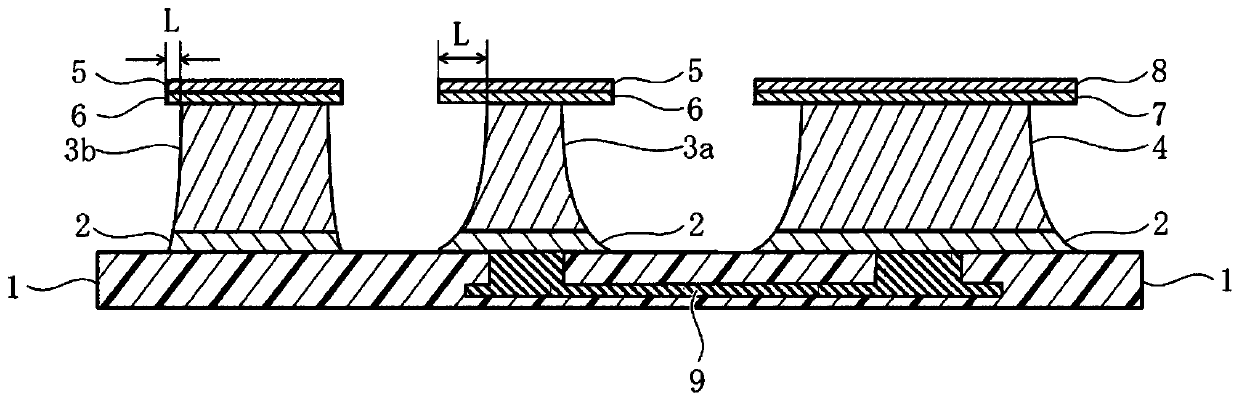

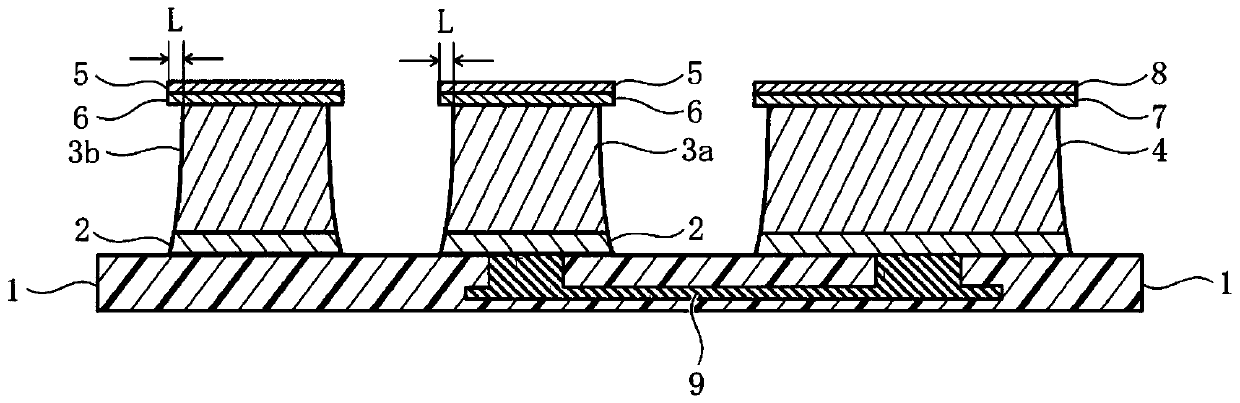

Image

Examples

Embodiment

[0071] 1. Etching test using circuit substrate

[0072] 1-1. Preparation of copper etching solution

[0073] Here, an etching test was performed using a circuit board. First, the copper etching solutions of Examples 1 to 3 shown in Table 1 were prepared. In Table 1, "-" means that this component is not added. In Table 1, the numerical value shown in the column ( ) of copper sulfate pentahydrate is the numerical value converted into copper. In Comparative Example 1, a commercially available copper etching solution (sulfuric acid-hydrogen peroxide, pH 1 or less) was used. In Comparative Example 2, a commercially available copper etching solution (acid bath containing chlorine, pH 1 or less) was used. In Comparative Example 3, an acidic copper etching solution (pH 1 or less) containing iron sulfate was prepared, and the bath temperature was set to 35°C.

[0074] Table 1

[0075] Example 1 Example 2 Example 3 Ammonium sulfate (g / L) 31.2 31.2 31.2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com