Gas jet impact drying and infrared radiation drying combined method and device

A gas jet, infrared radiation technology, applied in the direction of drying gas layout, drying solid materials, local stirring dryer, etc., can solve the problems of excessive water vapor retention in the drying chamber, easy crusting of materials, and weakening of material absorption, so as to avoid The effect of temperature control overshoot, high degree of automation, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

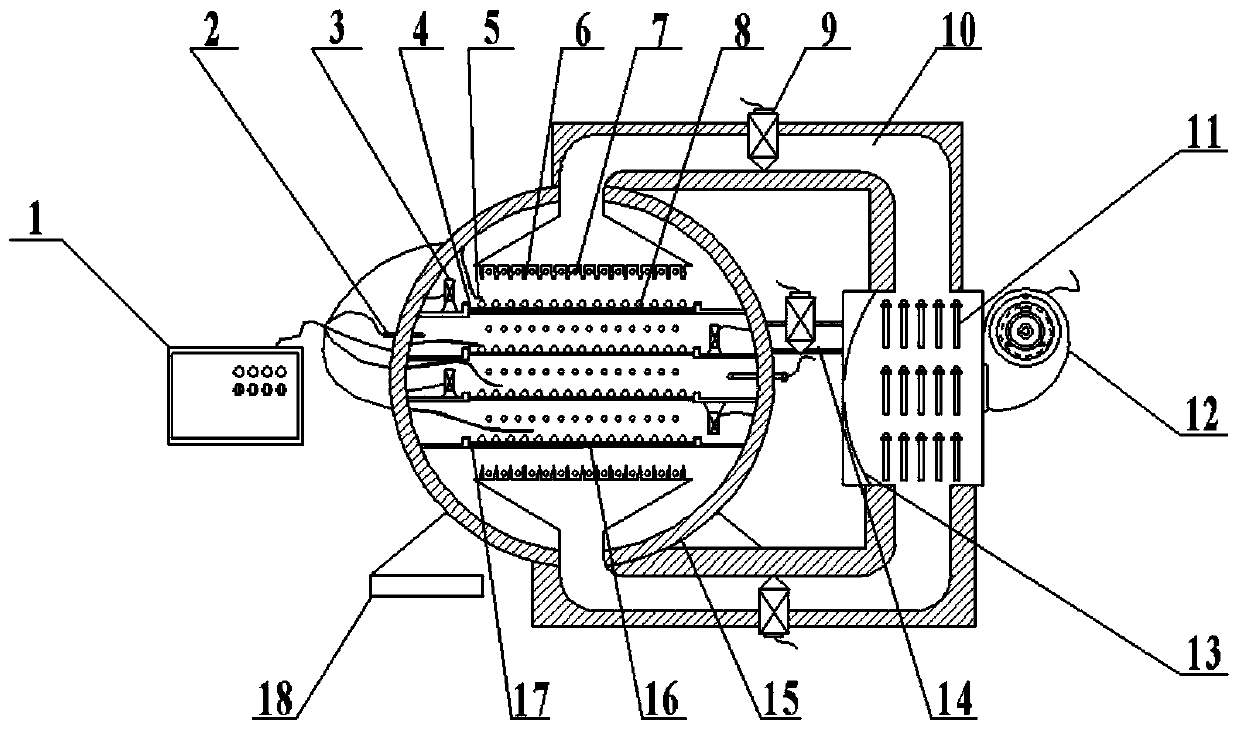

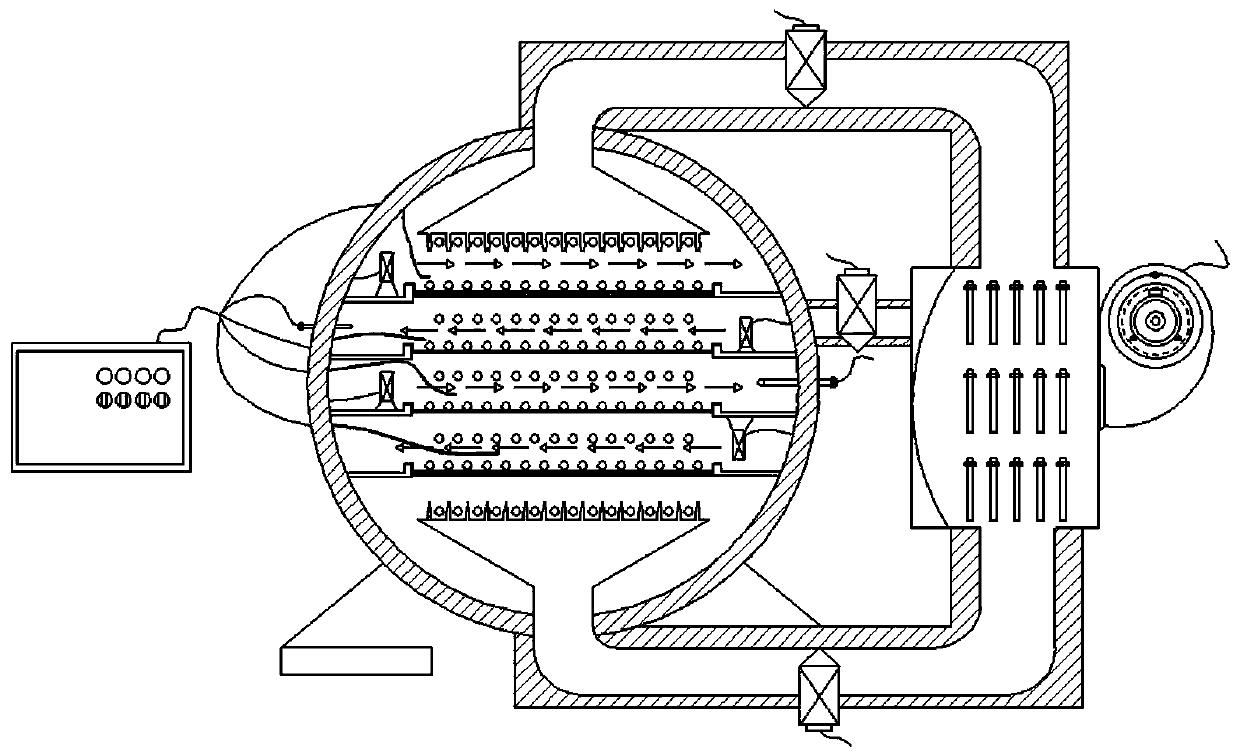

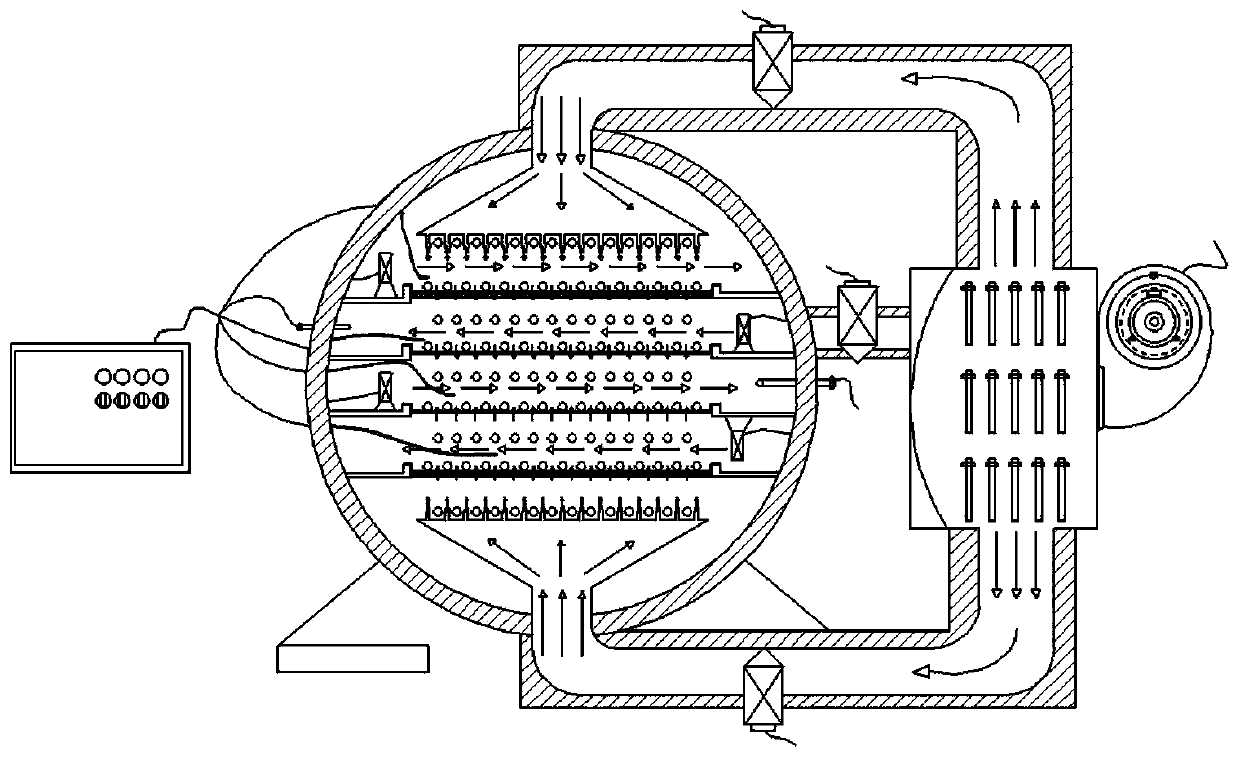

[0051] Such as figure 1 and Figure 4 As shown, a gas jet impact drying combined with infrared radiation drying device, including: industrial control touch all-in-one machine 1, temperature and humidity sensor 2, cross-flow fan 3, material tray 4, PT100 temperature sensor 5, nozzle 6, infrared heating tube 7, Material 8, one-way solenoid valve 9, air inlet pipe 10, electric heating pipe 11, blower 12, arc deflector 13, return air pipe 14, box body 15, patch temperature sensor 16, sensor bracket 17 , box support 18 and dehumidification fan 19.

[0052] The inside of the box 15 is provided with a temperature and humidity sensor 2 , a cross-flow fan 3 , a feed tray 4 , a PT100 temperature sensor 5 , a nozzle 6 , an infrared heating tube 7 , a chip temperature sensor 16 , and a sensor bracket 17 . in,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com