Glass shell absorption type adsorption refrigeration element manufacturing method equipment and products

An adsorption refrigeration, glass shell technology, applied in refrigeration components, refrigerators, adsorption machines, etc., can solve the problems of increasing investment and operating costs, and achieve the effects of good sealing, increased strength and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

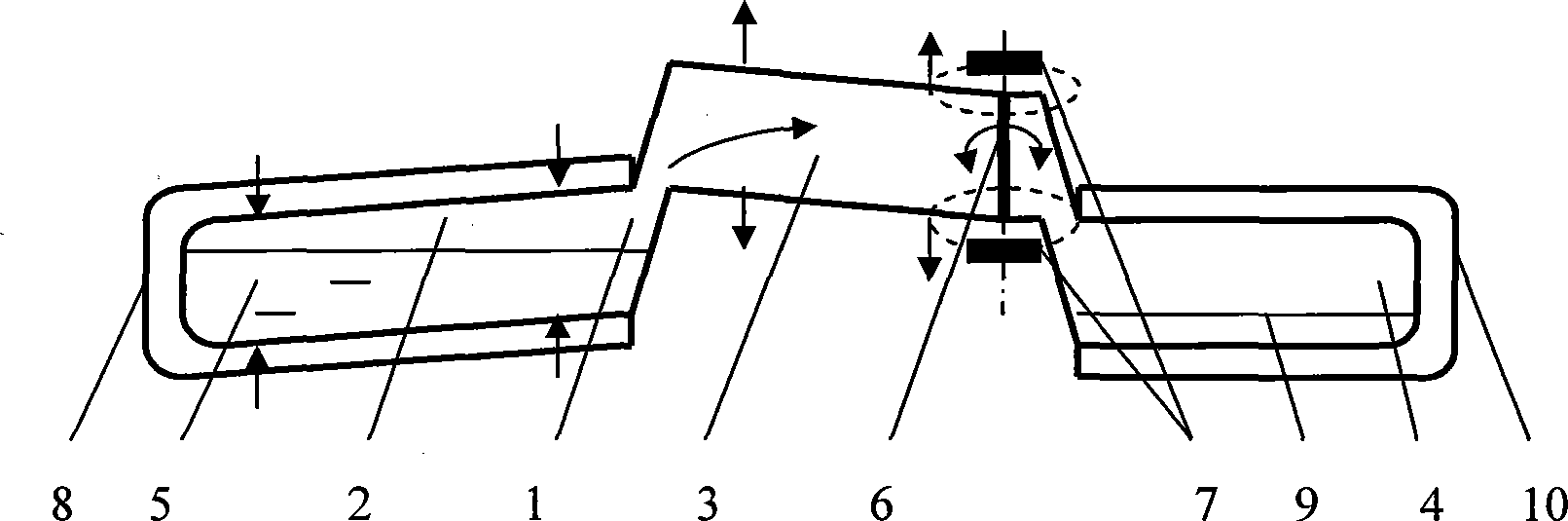

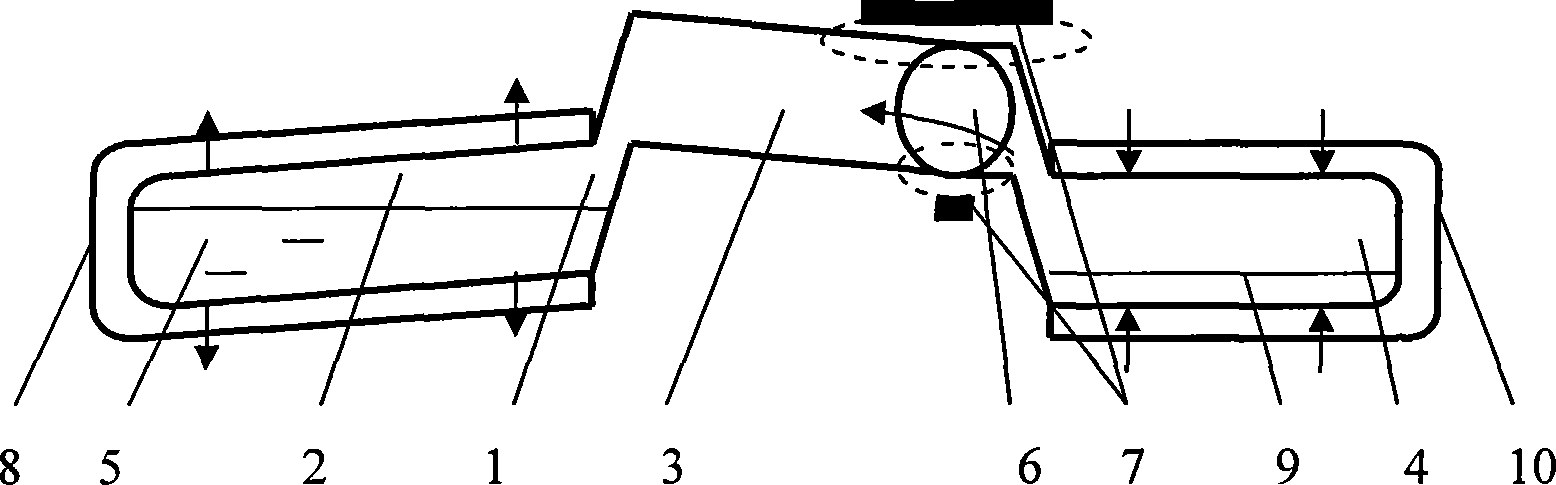

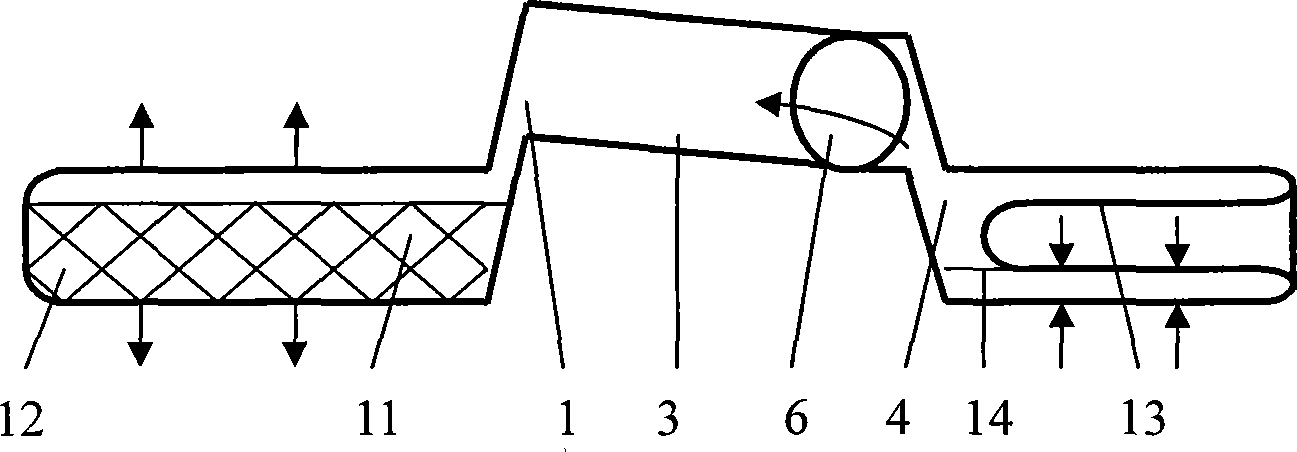

[0021] figure 1 and figure 2 Among them, the glass tube absorption refrigeration element 1 has an absorption chamber / regeneration chamber 2, a condensation section 3 and an evaporation chamber 4 arranged in the shape of a "pin", and the lithium bromide solution 5 is concentrated in the absorption chamber / regeneration chamber 2. At the end of the condensing section 3, a valve core 6 which is movably matched with the condensing section 3 is arranged. A magnetic external drive member 8 is arranged outside the glass container corresponding to the valve core 6 . The state of the spool 6 changes according to the state change of the movable magnetic external driver 7, such as being in figure 1 in the closed state or in the figure 2 open state in .

[0022] figure 1 and figure 2 The working principle of the embodiment is: close the valve core 6, heat the diluted lithium bromide solution 5 in the absorption chamber / regeneration chamber 2 to regenerate, for example, use a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com