Slab heating furnace without water-cooled furnace door

A slab heating, no water cooling technology, applied in the field of thick slab rolling hot processing, can solve the problems of furnace temperature fluctuation, box plate frame deformation, large heat loss, etc., achieve high temperature strength improvement, improve overall strength and sealing performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

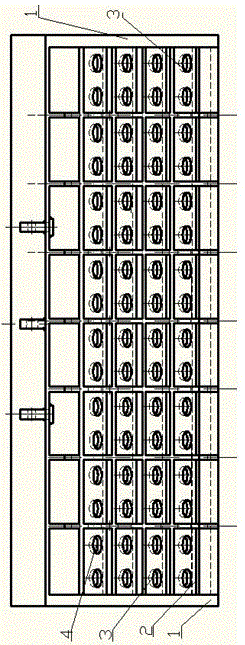

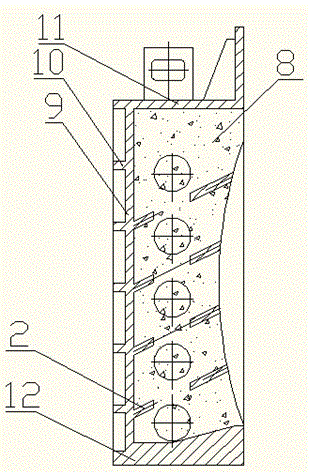

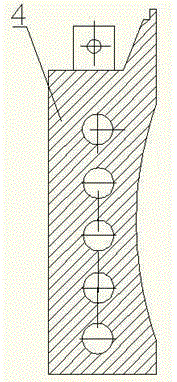

[0040] A non-water-cooled furnace door for a slab heating furnace includes side plates 1 and ribs located between the side plates 1. The ribs include multiple sets of transverse ribs and multiple sets of longitudinal ribs 4, and the transverse ribs include internal transverse ribs 2 And the outer transverse ribs 10, the inner transverse ribs 2 are perpendicular to the side plates 1, the inner transverse ribs 2 are inclined upward, the angle between the inner transverse ribs 2 and the horizontal direction is 30°, and the lower end of the inner transverse ribs 2 is with the front face One side of the plate 9 is connected, and the other side of the front face plate 9 is fixedly connected with an outer transverse rib plate 10, which is perpendicular to the front face plate 9 and the side plate 1 respectively;

[0041] The aforementioned inner transverse rib 2 has a plurality of inner transverse rib holes 3, and the longitudinal rib 4 has a plurality of longitudinal rib holes.

[0042] ...

Embodiment 2

[0052] A non-water-cooled furnace door for a slab heating furnace includes side plates 1 and ribs located between the side plates 1. The ribs include multiple sets of transverse ribs and multiple sets of longitudinal ribs 4, and the transverse ribs include internal transverse ribs 2 And the outer transverse ribs 10, the inner transverse ribs 2 are perpendicular to the side plates 1, the inner transverse ribs 2 are inclined upward, the inclination angle between the inner transverse ribs 2 and the horizontal direction is 20°, the lower end of the inner transverse ribs 2 and the front face One side of the plate 9 is connected, and the other side of the front face plate 9 is fixedly connected with an outer transverse rib plate 10, which is perpendicular to the front face plate 9 and the side plate 1 respectively;

[0053] The aforementioned inner transverse rib 2 has a plurality of inner transverse rib holes 3, and the longitudinal rib 4 has a plurality of longitudinal rib holes.

[00...

Embodiment 3

[0064] A non-water-cooled furnace door for a slab heating furnace includes side plates 1 and ribs located between the side plates 1. The ribs include multiple sets of transverse ribs and multiple sets of longitudinal ribs 4, and the transverse ribs include internal transverse ribs 2 And the outer transverse ribs 10, the inner transverse ribs 2 are perpendicular to the side plate 1, the inner transverse ribs 2 are inclined upward, the inclination angle between the inner transverse ribs 2 and the horizontal direction is 50°, the lower end of the inner transverse ribs 2 and the front face One side of the plate 9 is connected, and the other side of the front face plate 9 is fixedly connected with an outer transverse rib plate 10, which is perpendicular to the front face plate 9 and the side plate 1 respectively;

[0065] The aforementioned inner transverse rib 2 has a plurality of inner transverse rib holes 3, and the longitudinal rib 4 has a plurality of longitudinal rib holes.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com