Patents

Literature

36results about How to "Reduce extrusion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

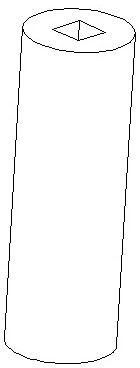

Machining method of high-quality large-diameter thin-wall metal barrel body

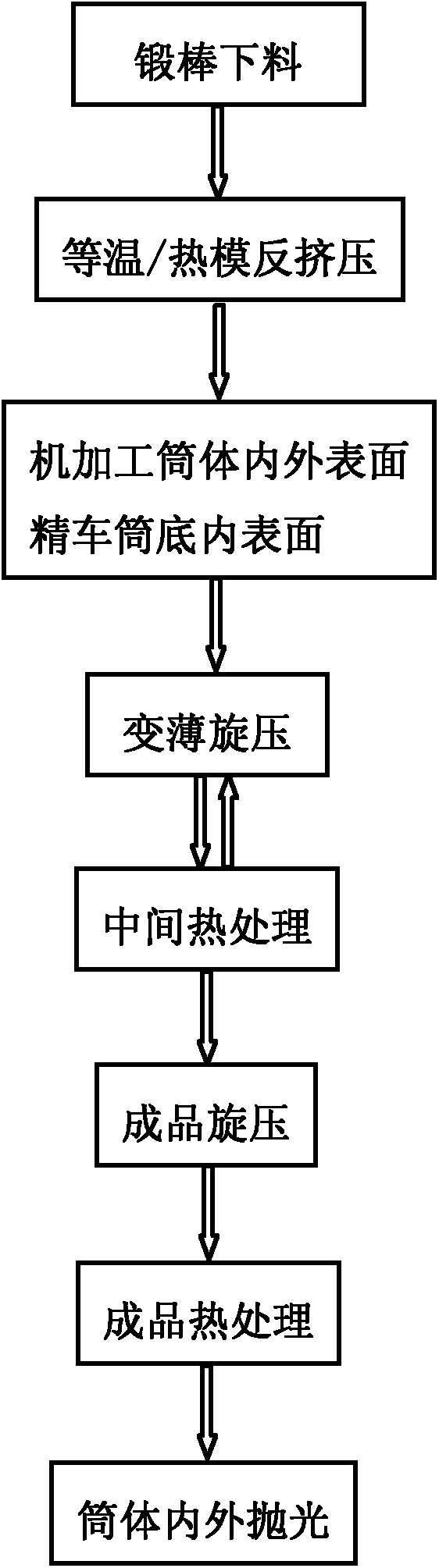

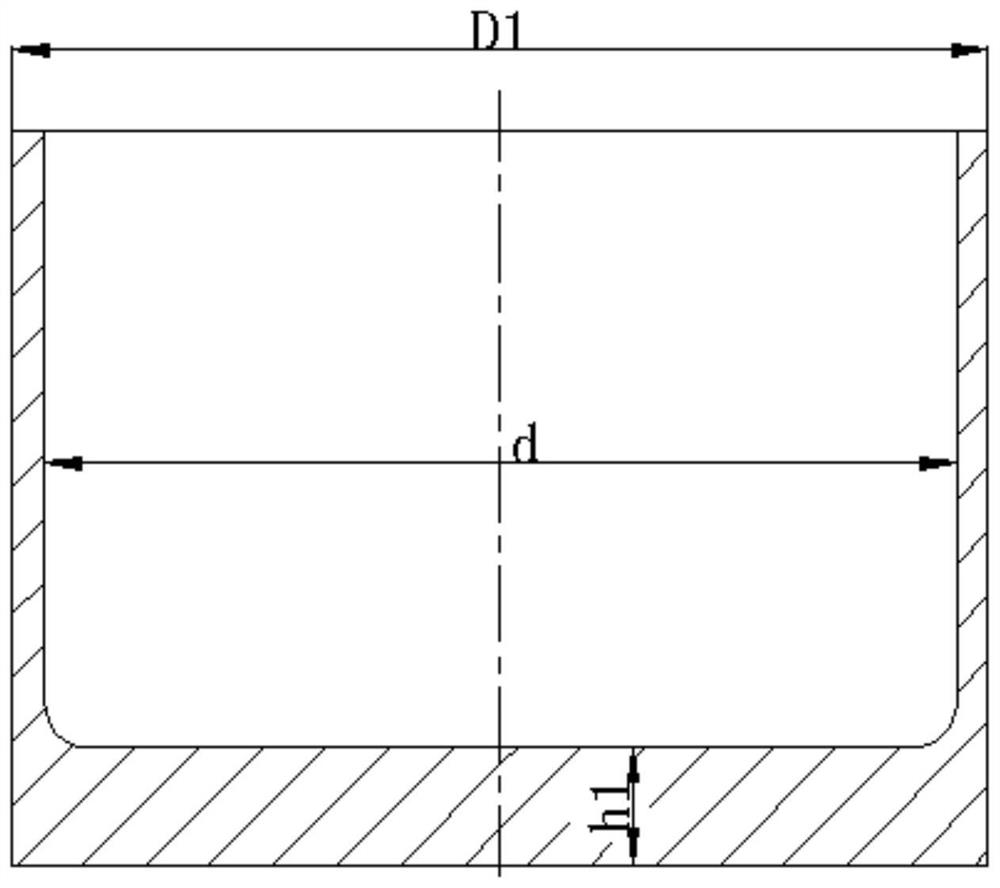

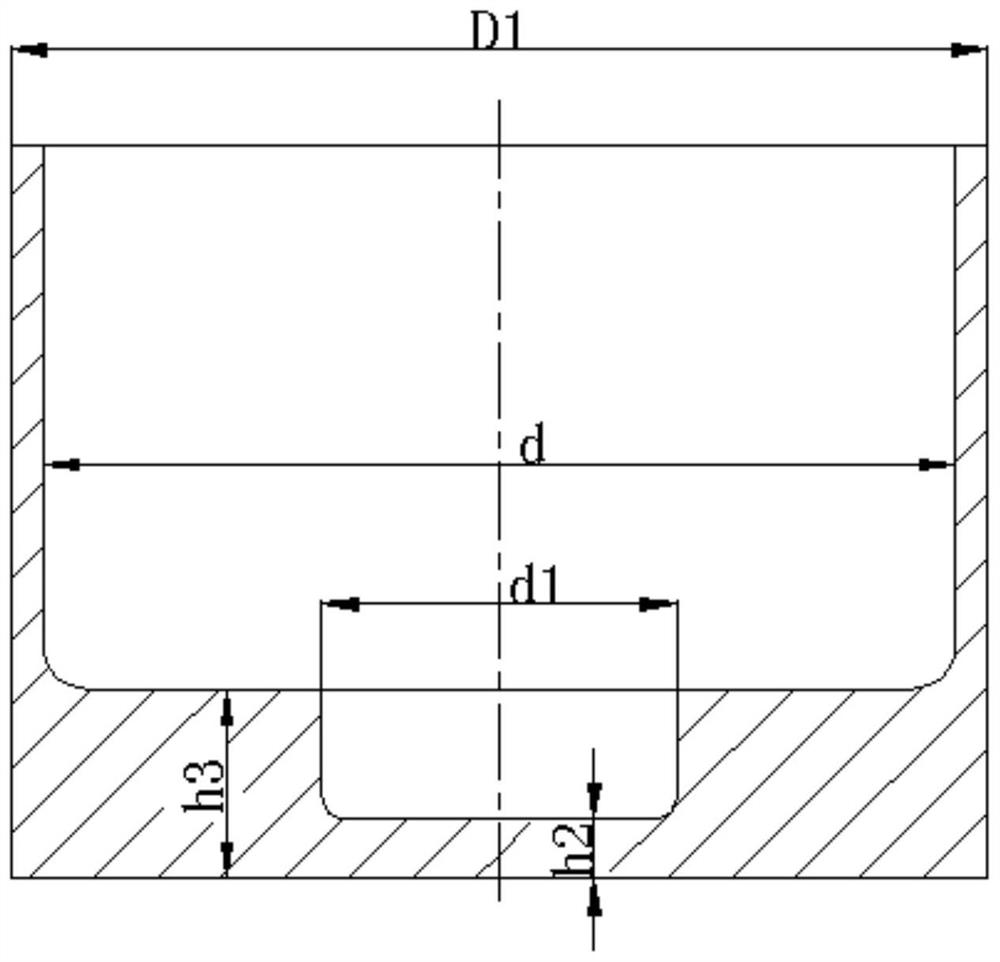

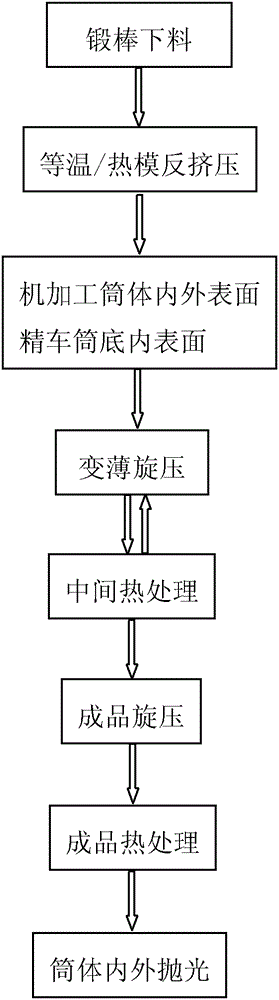

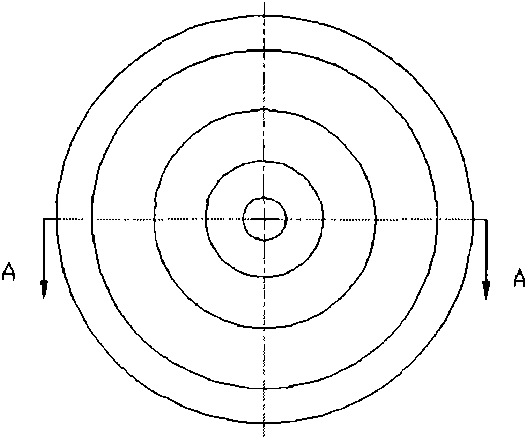

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

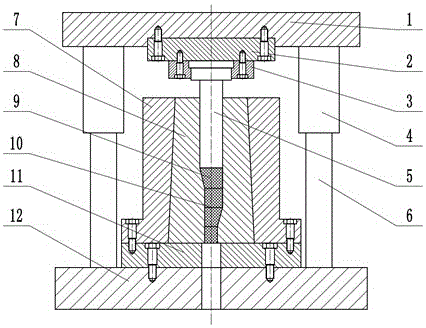

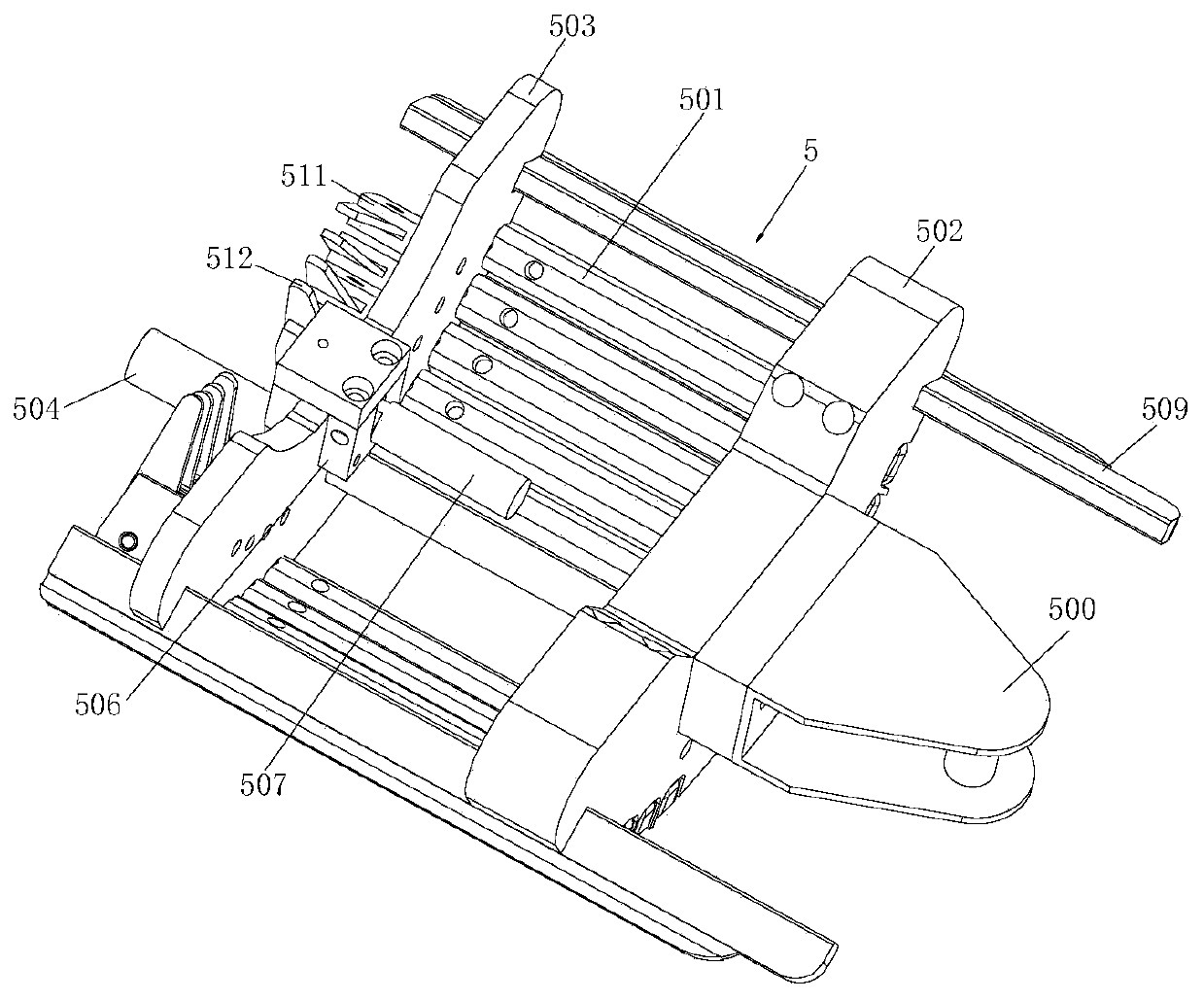

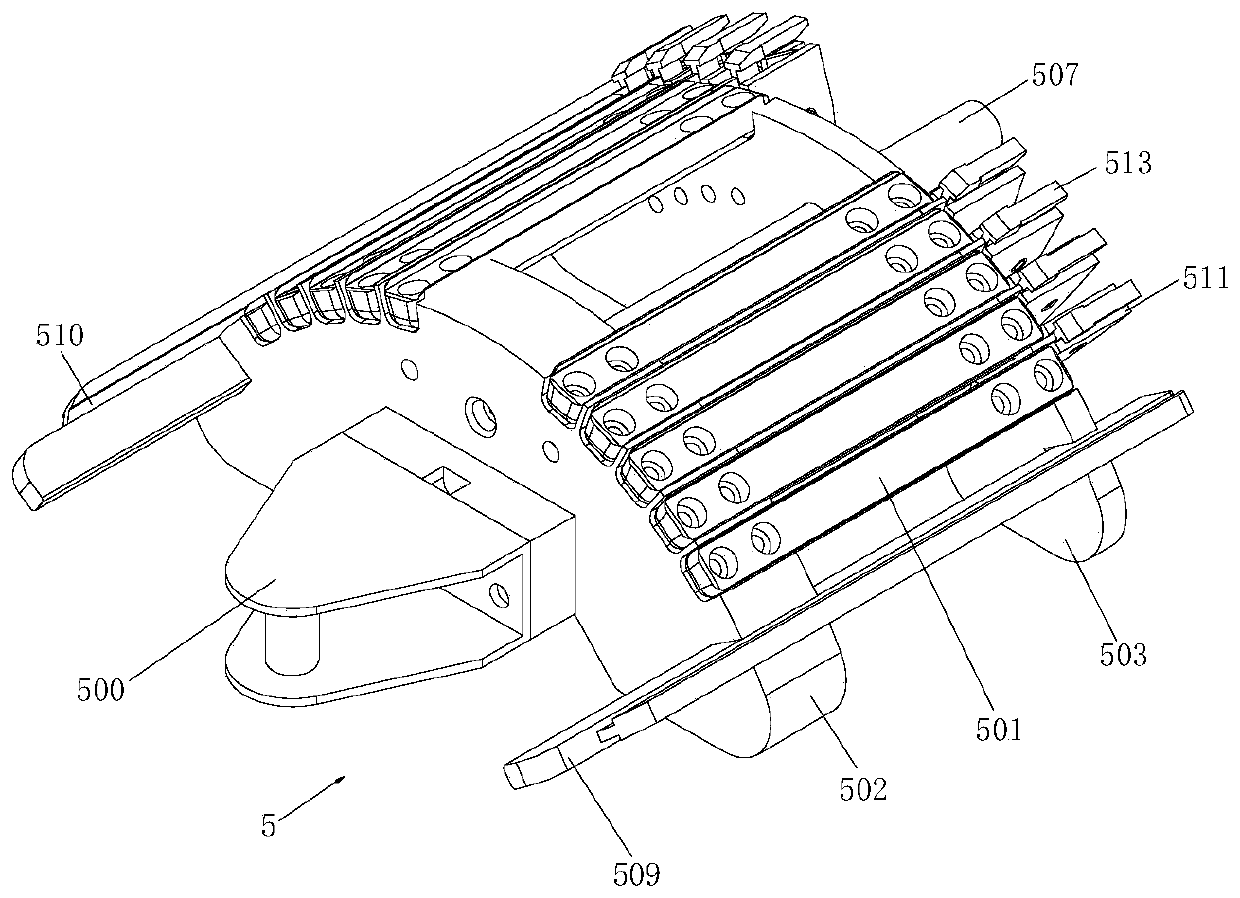

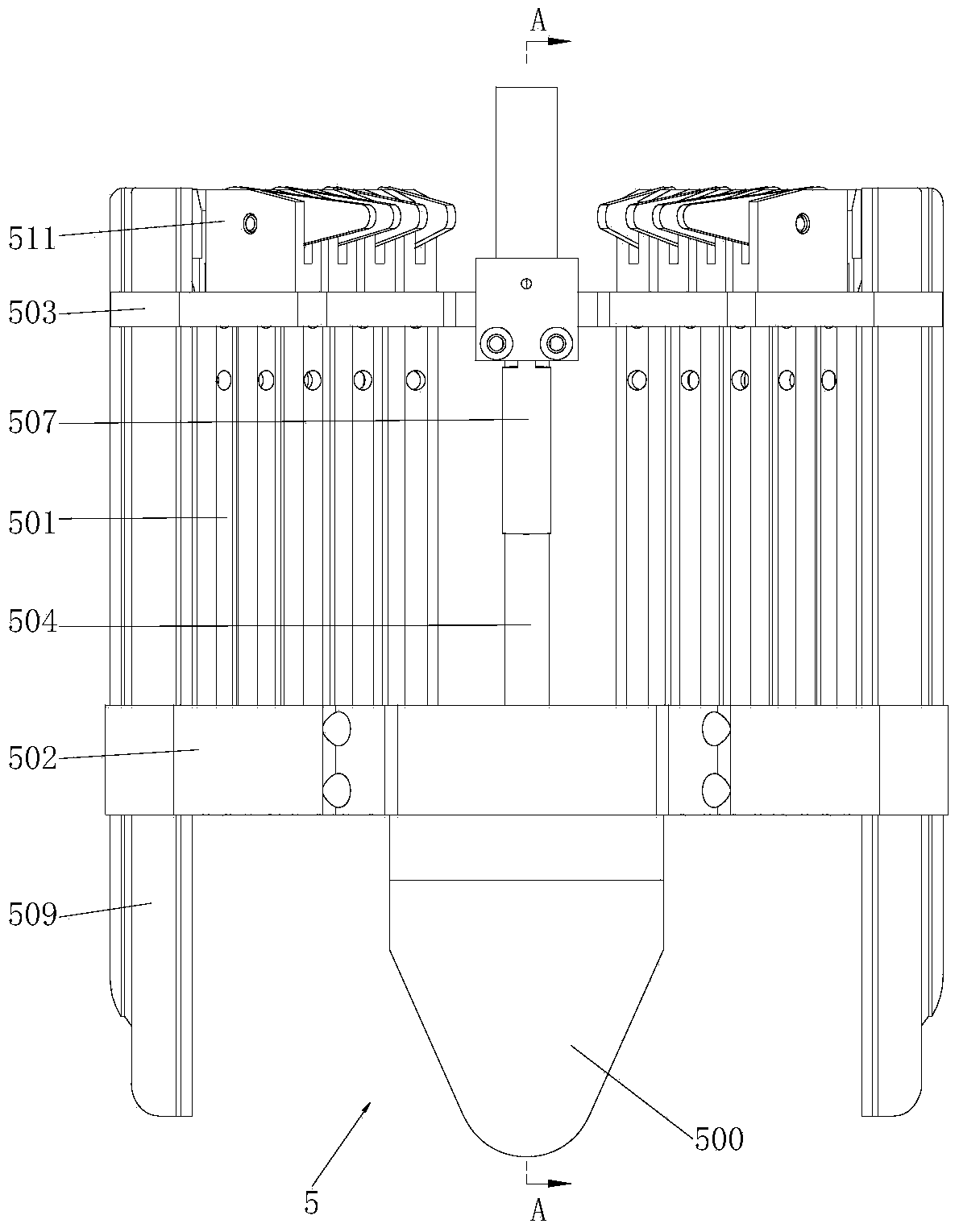

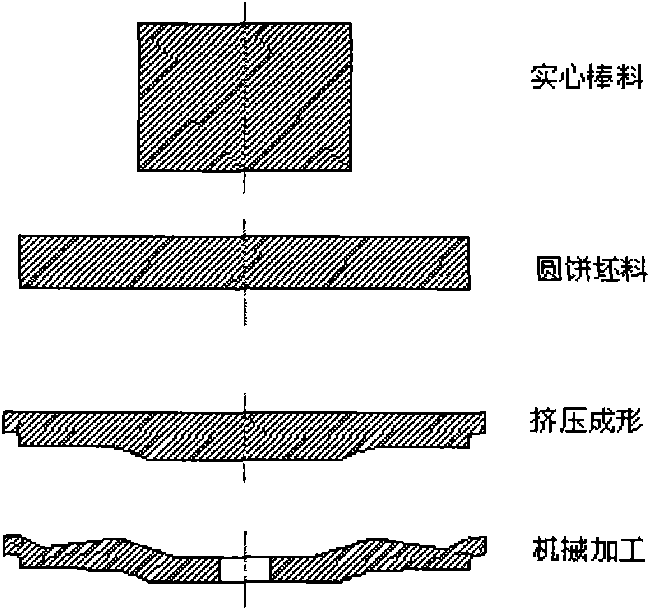

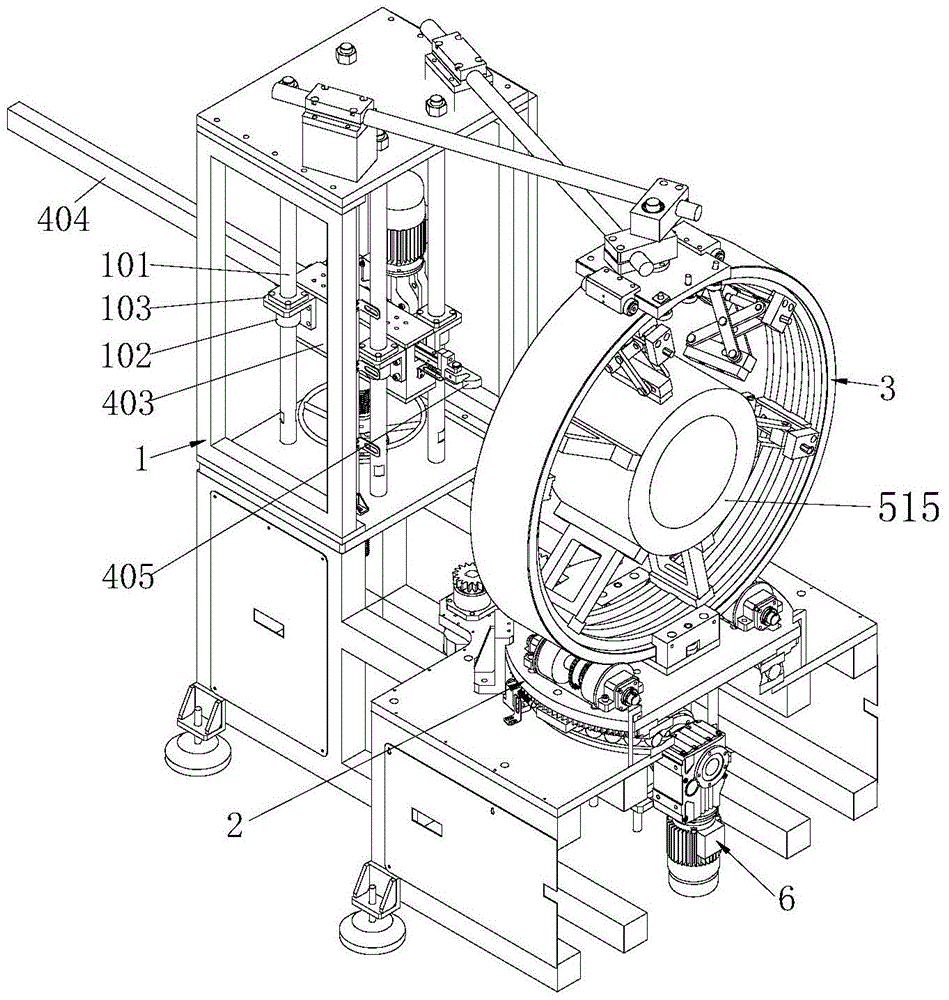

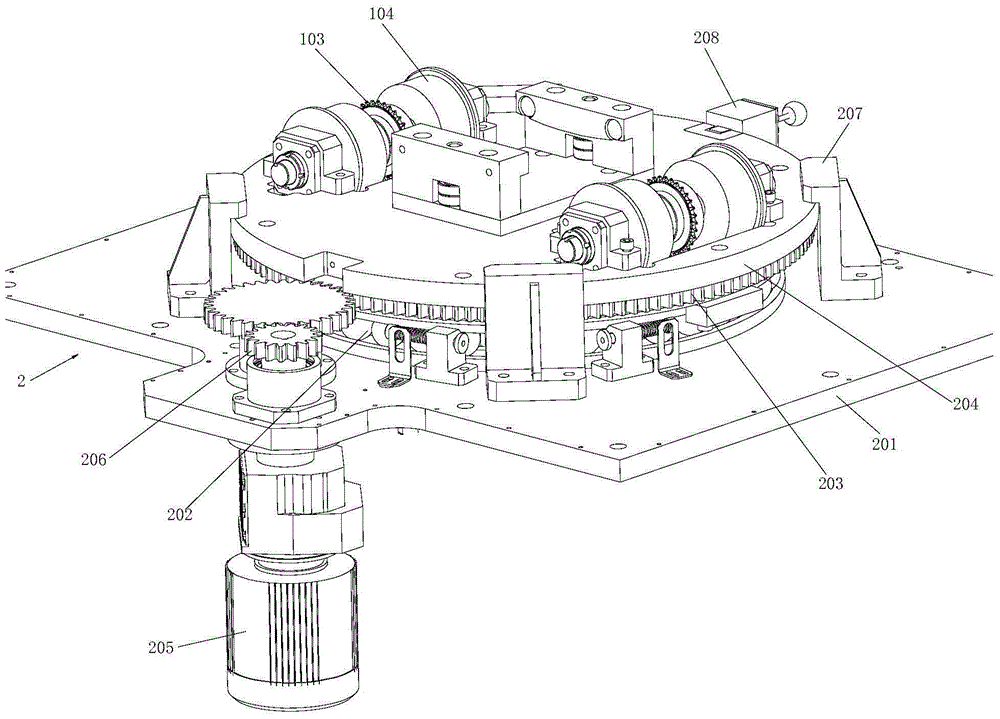

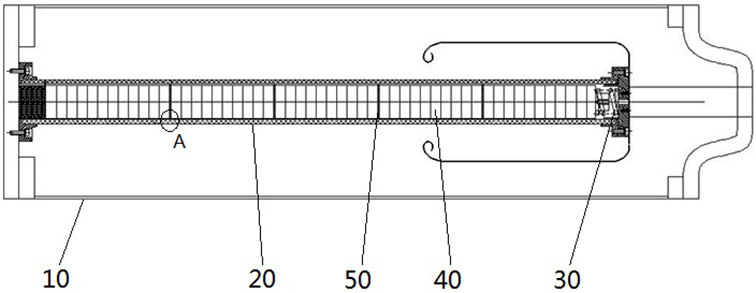

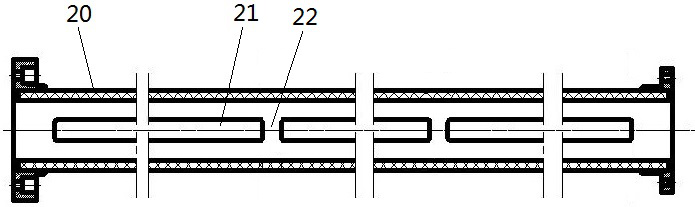

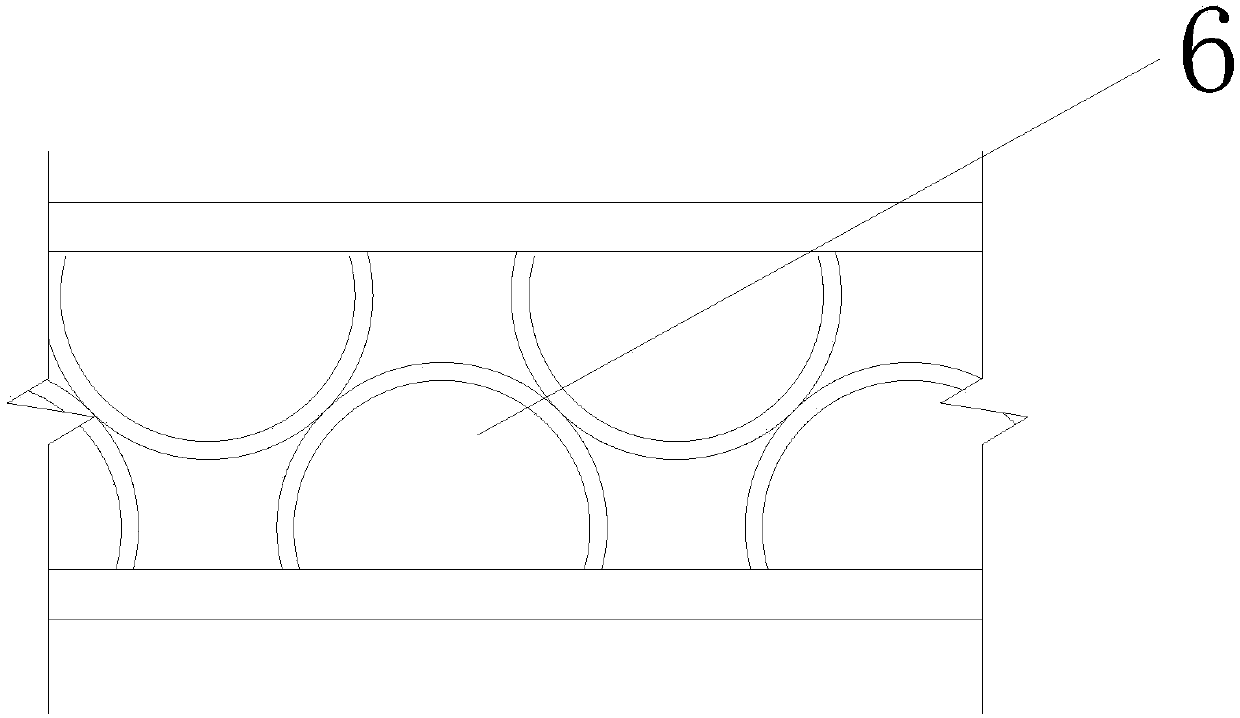

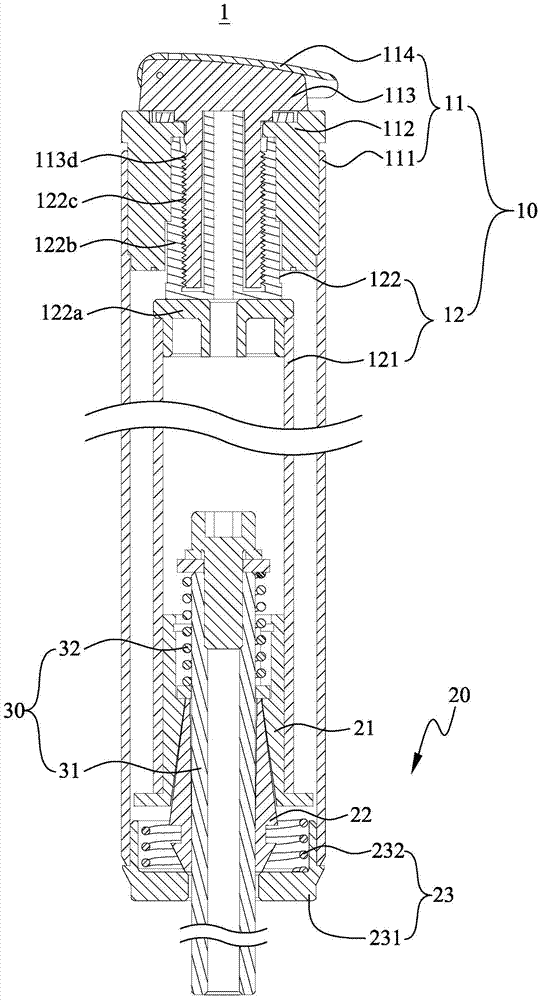

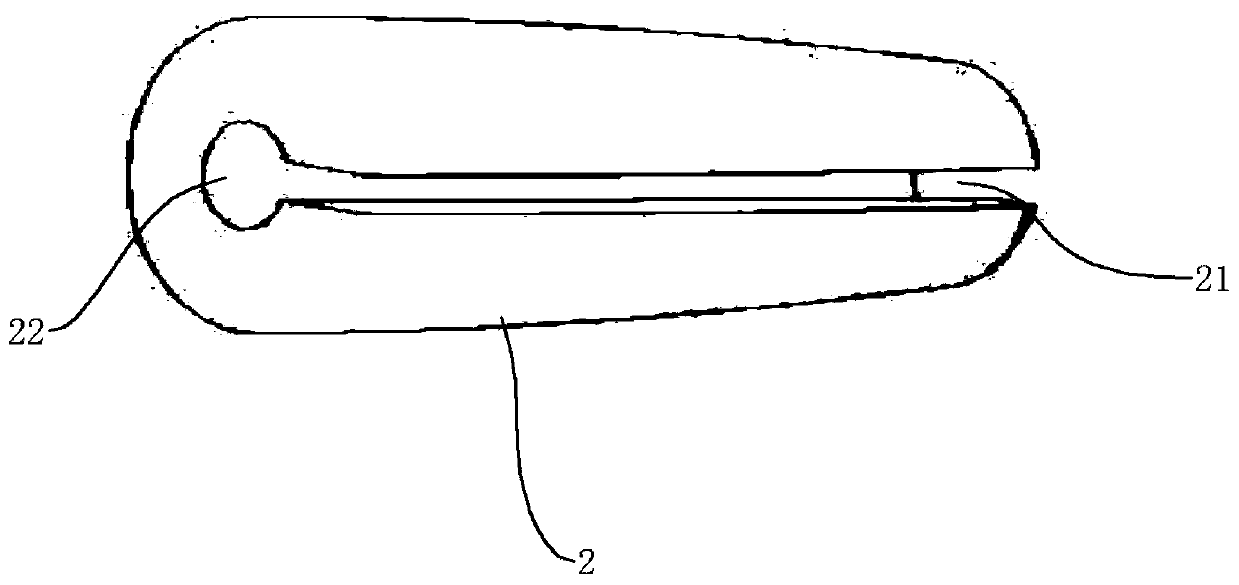

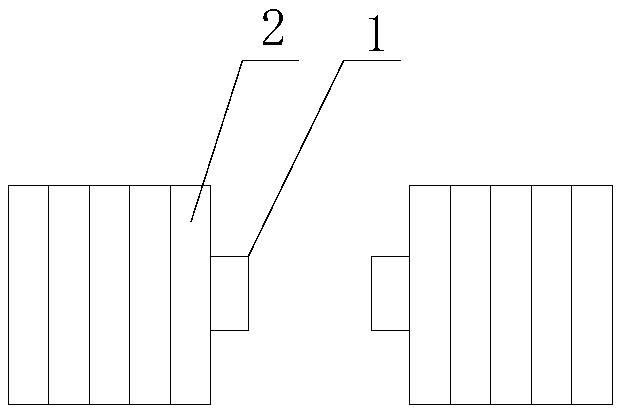

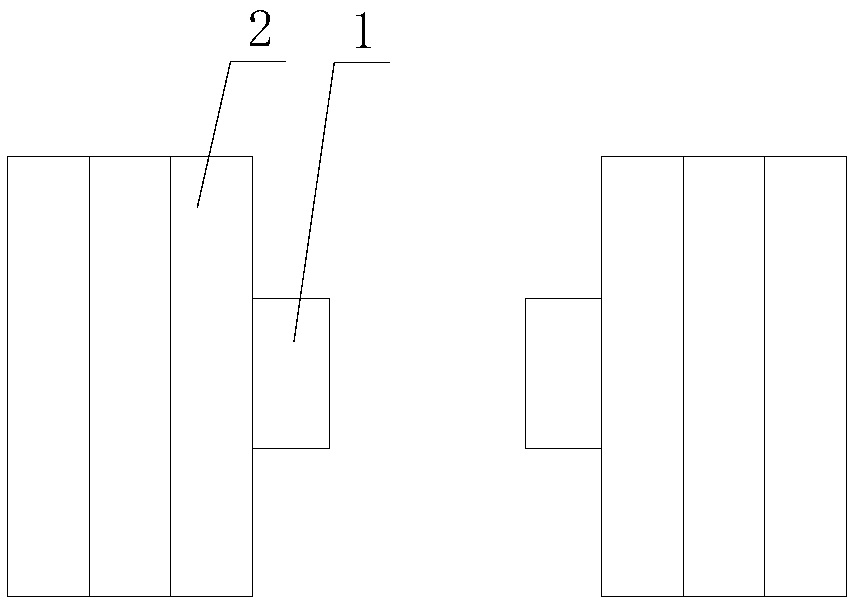

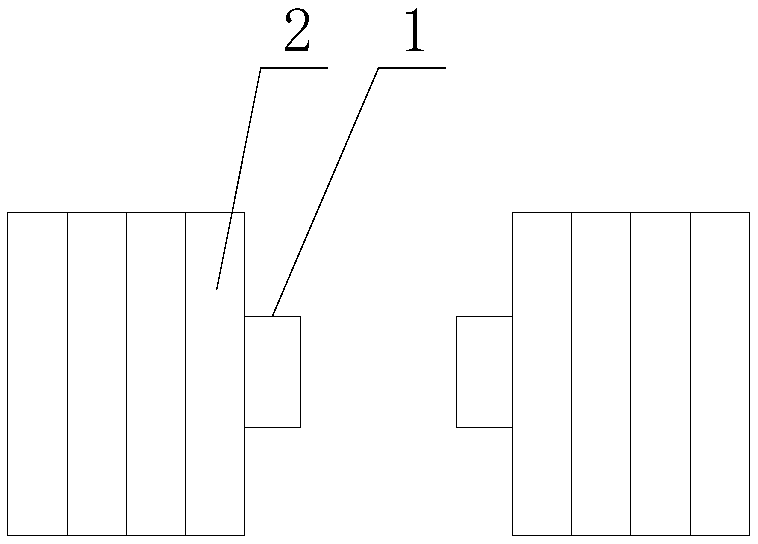

Drawing die coil inserting apparatus of motor stator iron core

ActiveCN104300748AReduce resistanceReduce extrusion forceManufacturing dynamo-electric machinesEngineeringConductor Coil

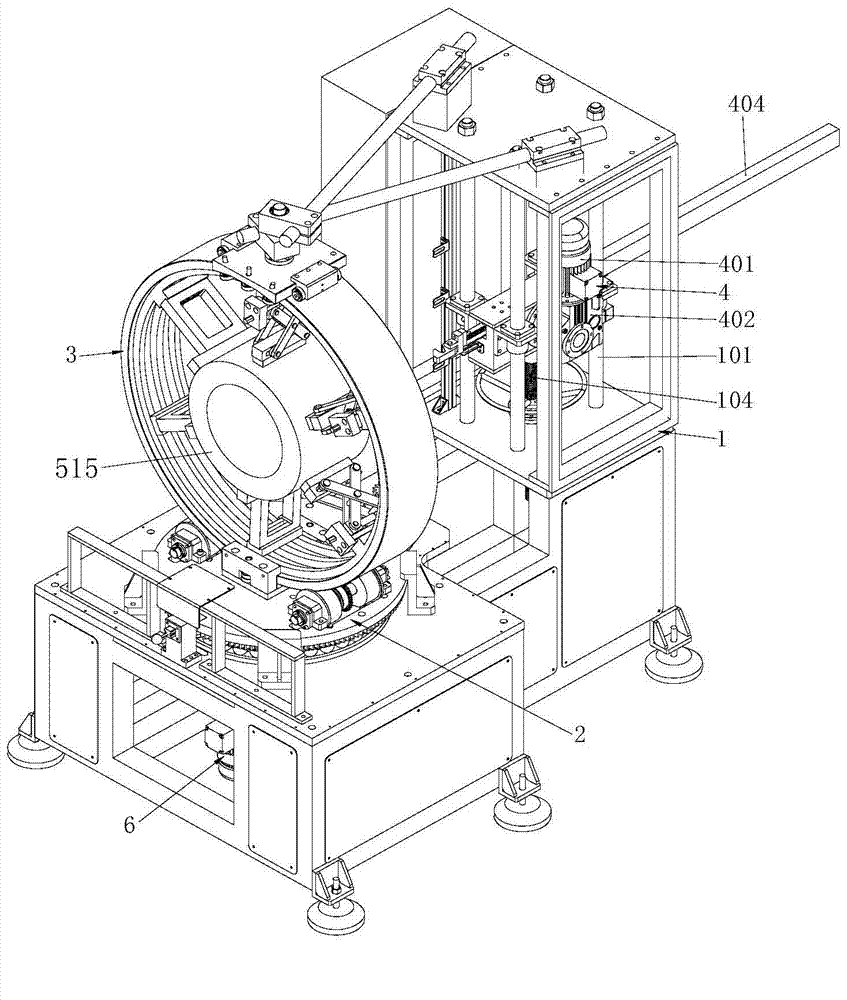

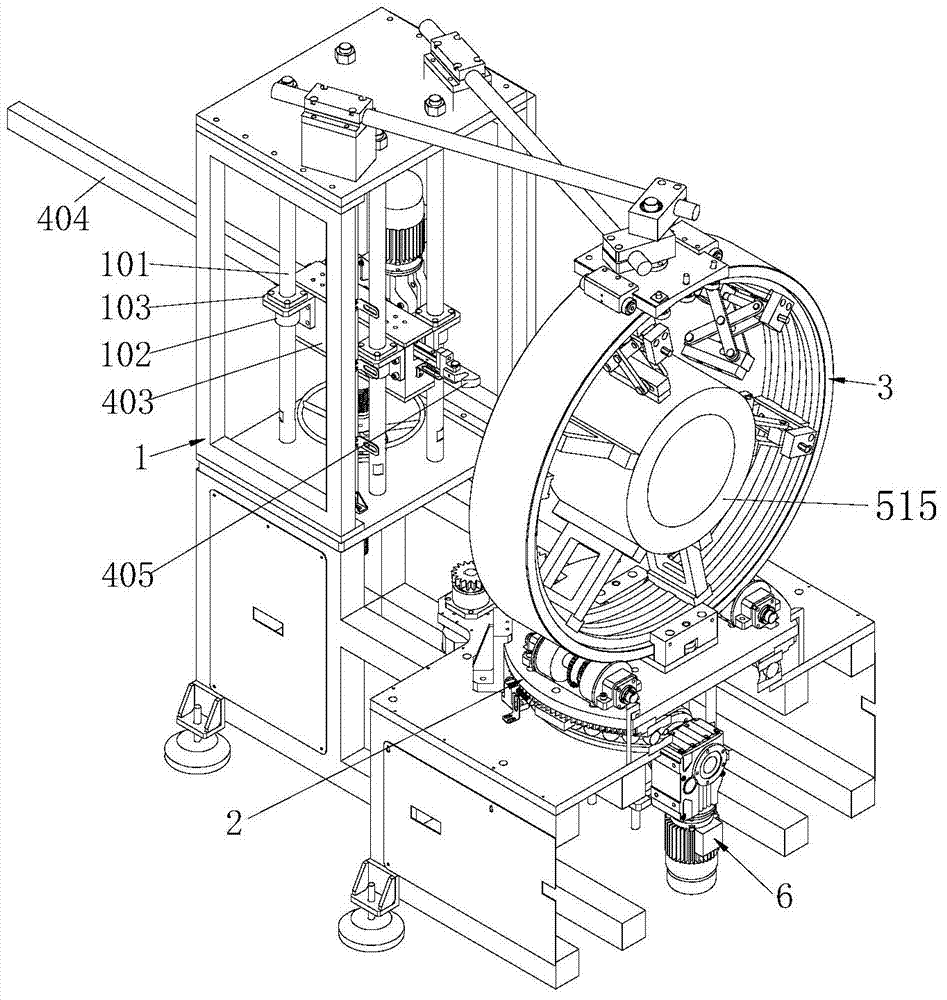

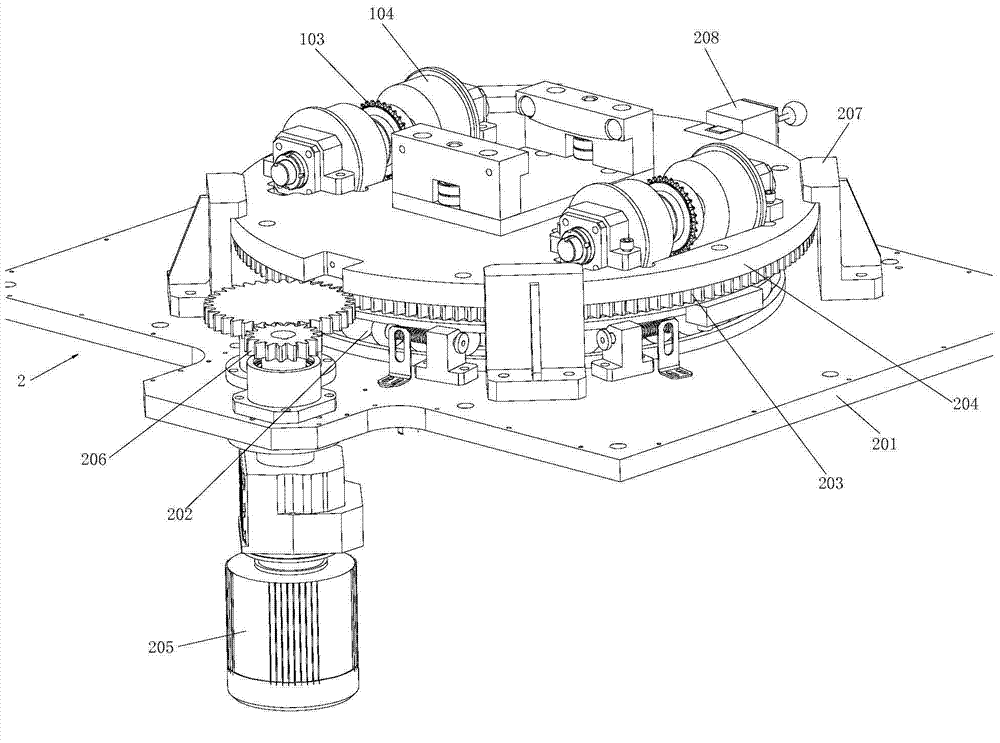

The invention discloses a drawing die coil inserting apparatus of a motor stator iron core. The drawing die coil inserting apparatus comprises a work bench arranged at a rack, a stator clamping device arranged at a rack and a drawing device can move in and out of the stator clamping device. The stator clamping device is fixed at the work bench. An inserting die includes guide bars, a kidney-shaped pedestal, a kidney-shaped cover plate, a connecting rod, and a locking device; insertion slots are formed in the peripheral surfaces of the pedestal and the cover plate at intervals; and one end of each guide bar is fixed in the insertion slot of the pedestal and the other end of each guide bar is arranged in the insertion slot of the cover plate in a clearance fit mode. A through hole passing through two axial end surfaces of the cover plate is formed in the cover plate. One end of the connecting rod is fixed at the axial end surface, opposite to the cover plate, of the pedestal; and the other end of the connecting rod passes through the through hole of the cover plate and the connecting rod and the cover plate are fastened together by the locking device. Besides, a drag hook seat connecting the drawing device is arranged at the axial end surface, away from the cover plate, of the pedestal. According to the invention, line insertion is carried out on all-phase windings by multiple times, thereby preventing the enameled wires in the windings from being damaged.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

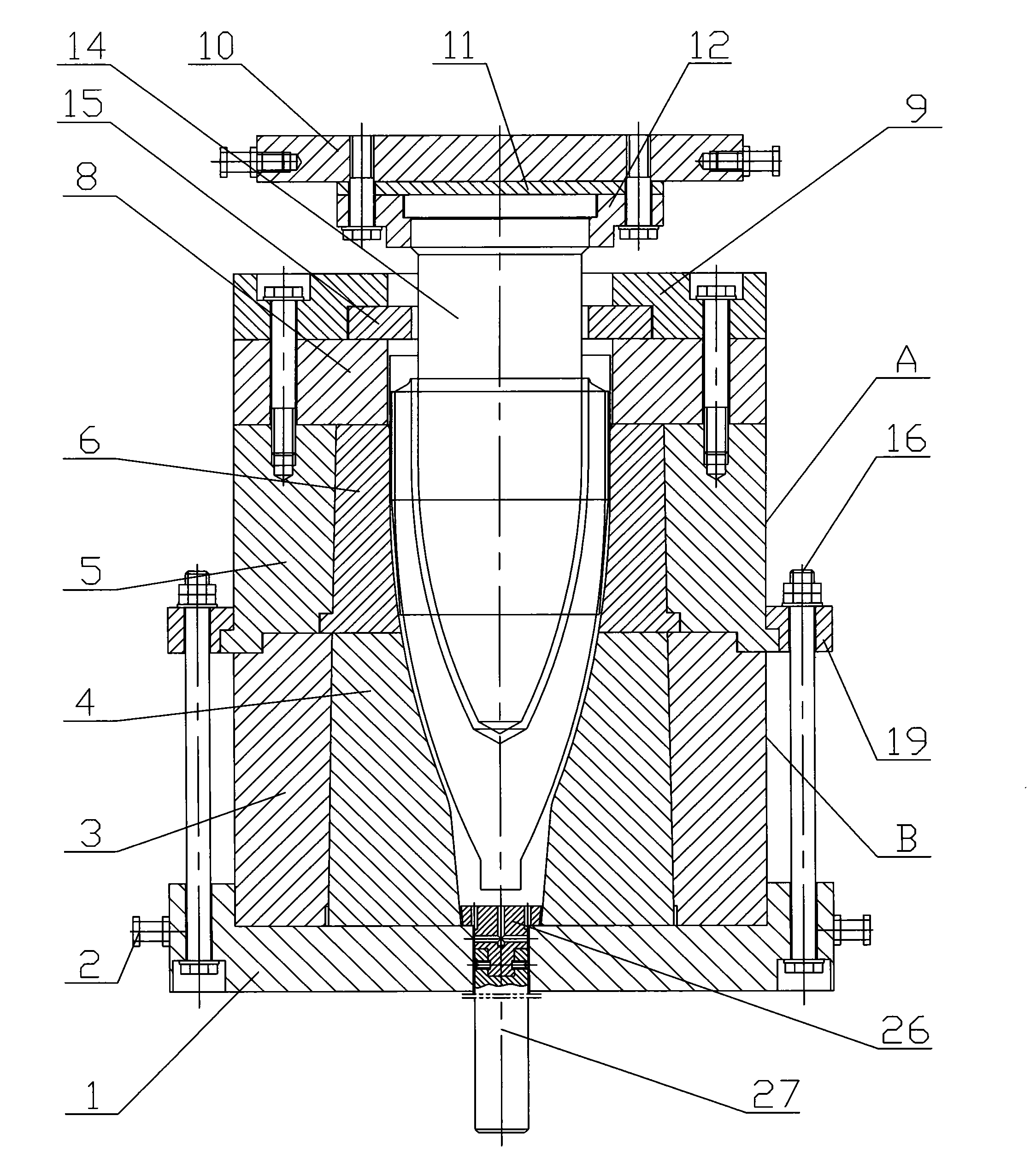

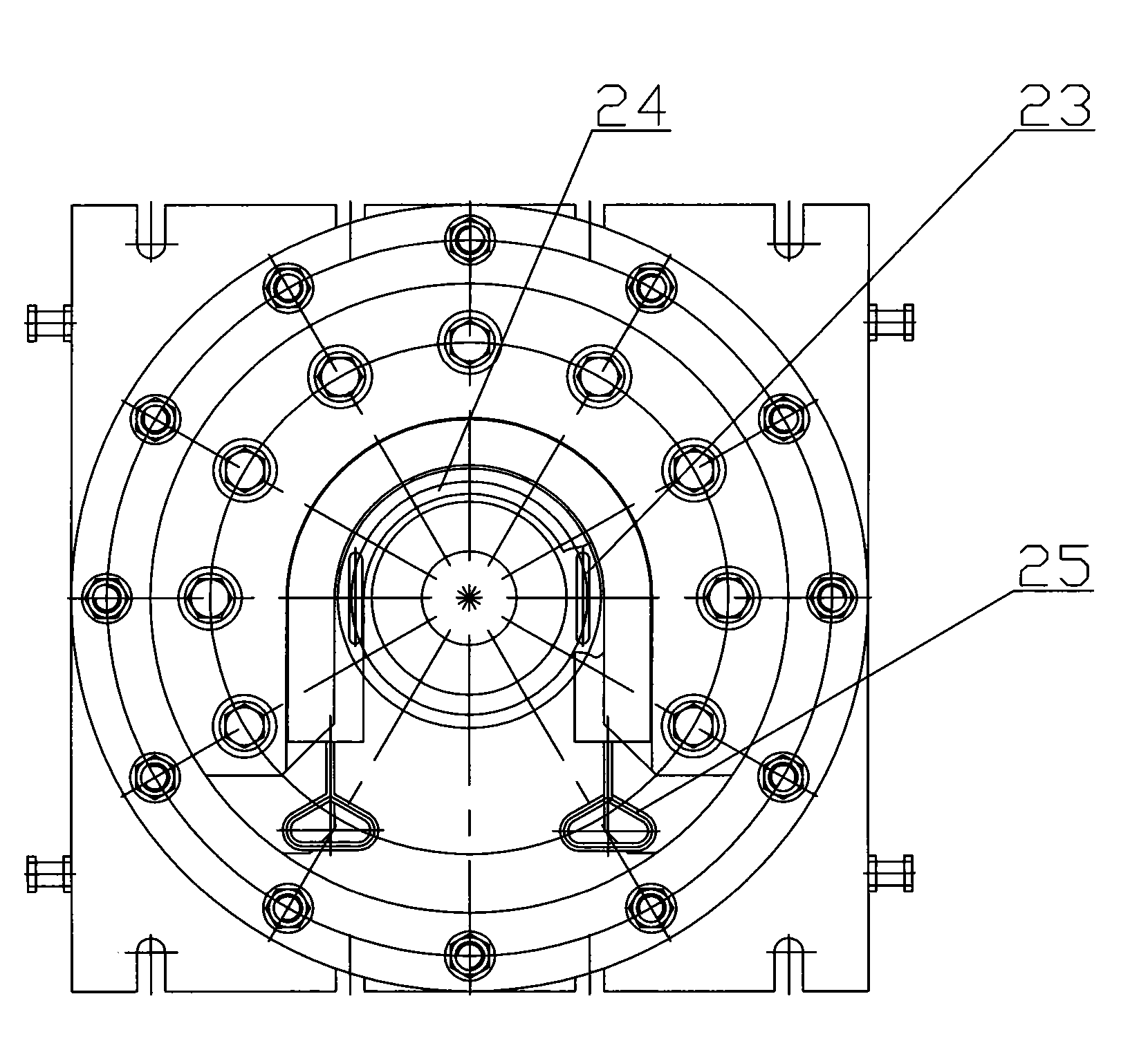

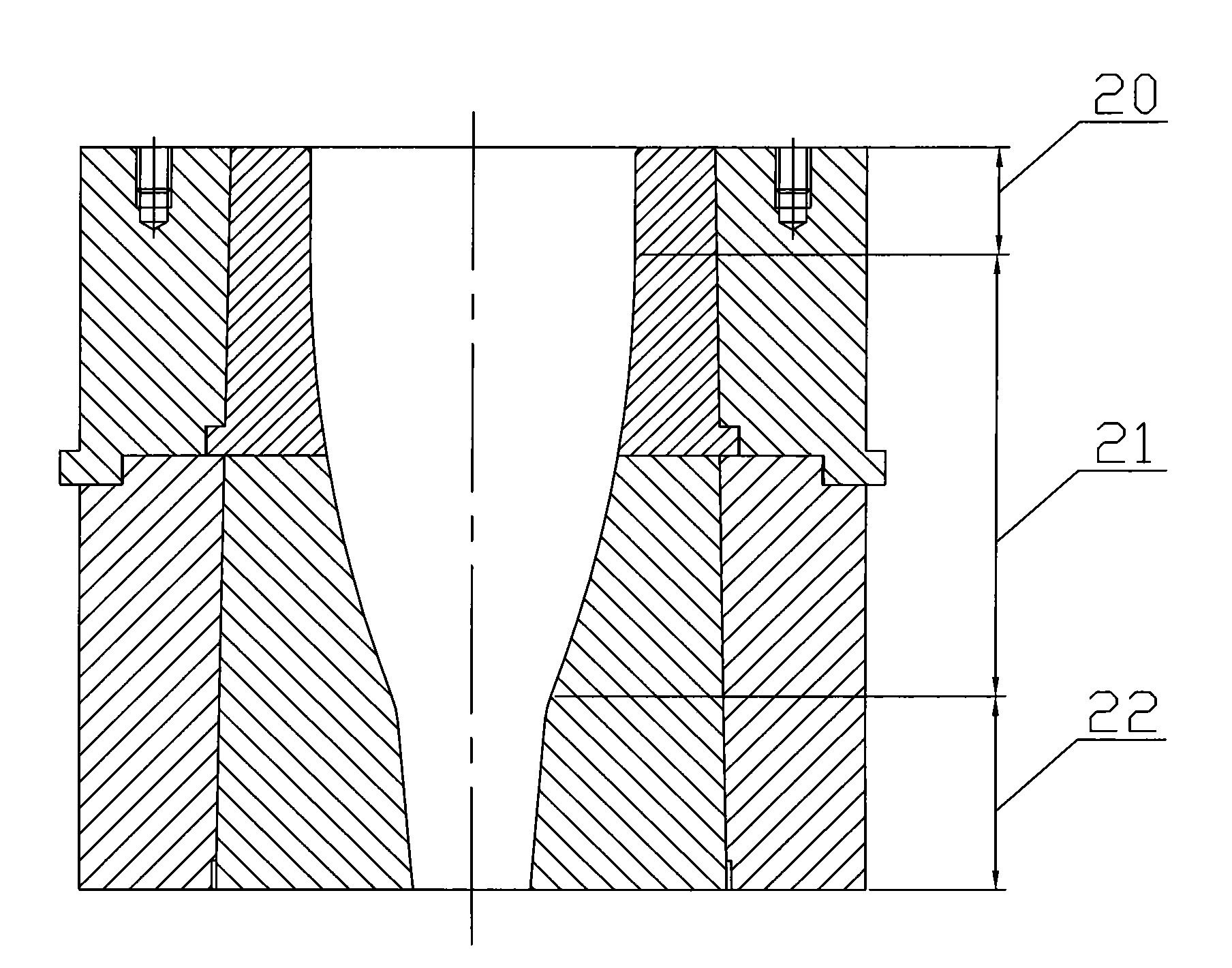

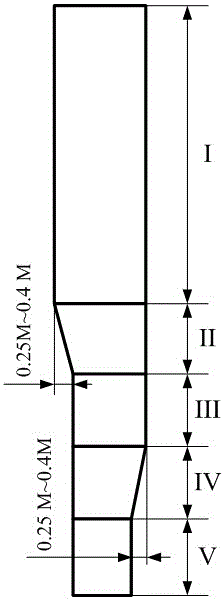

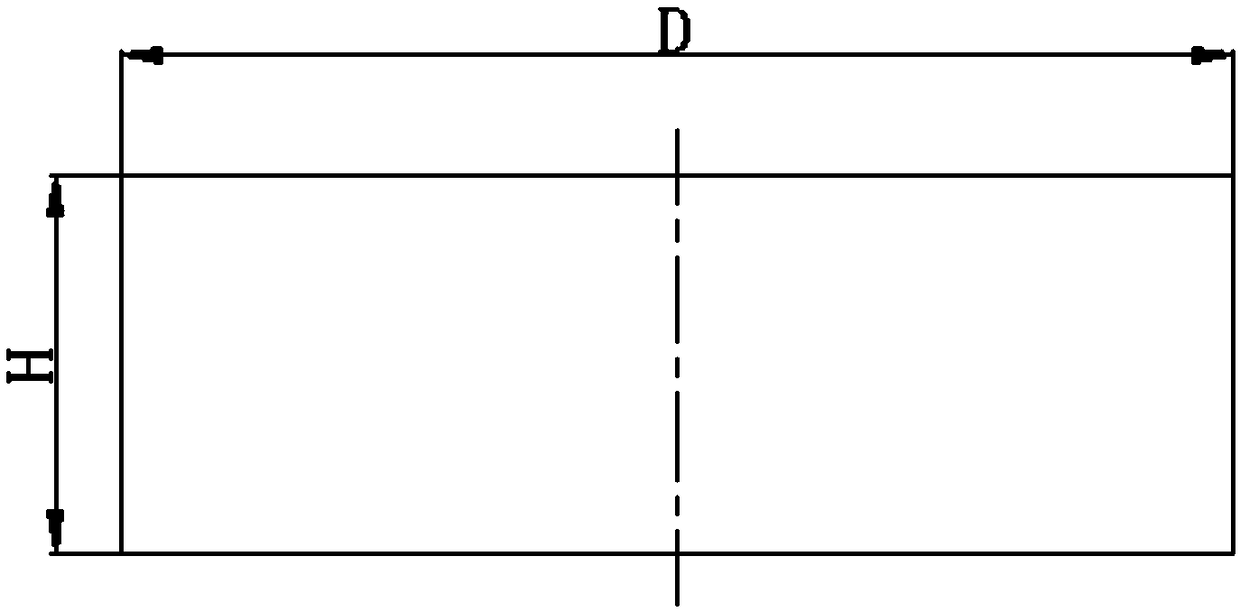

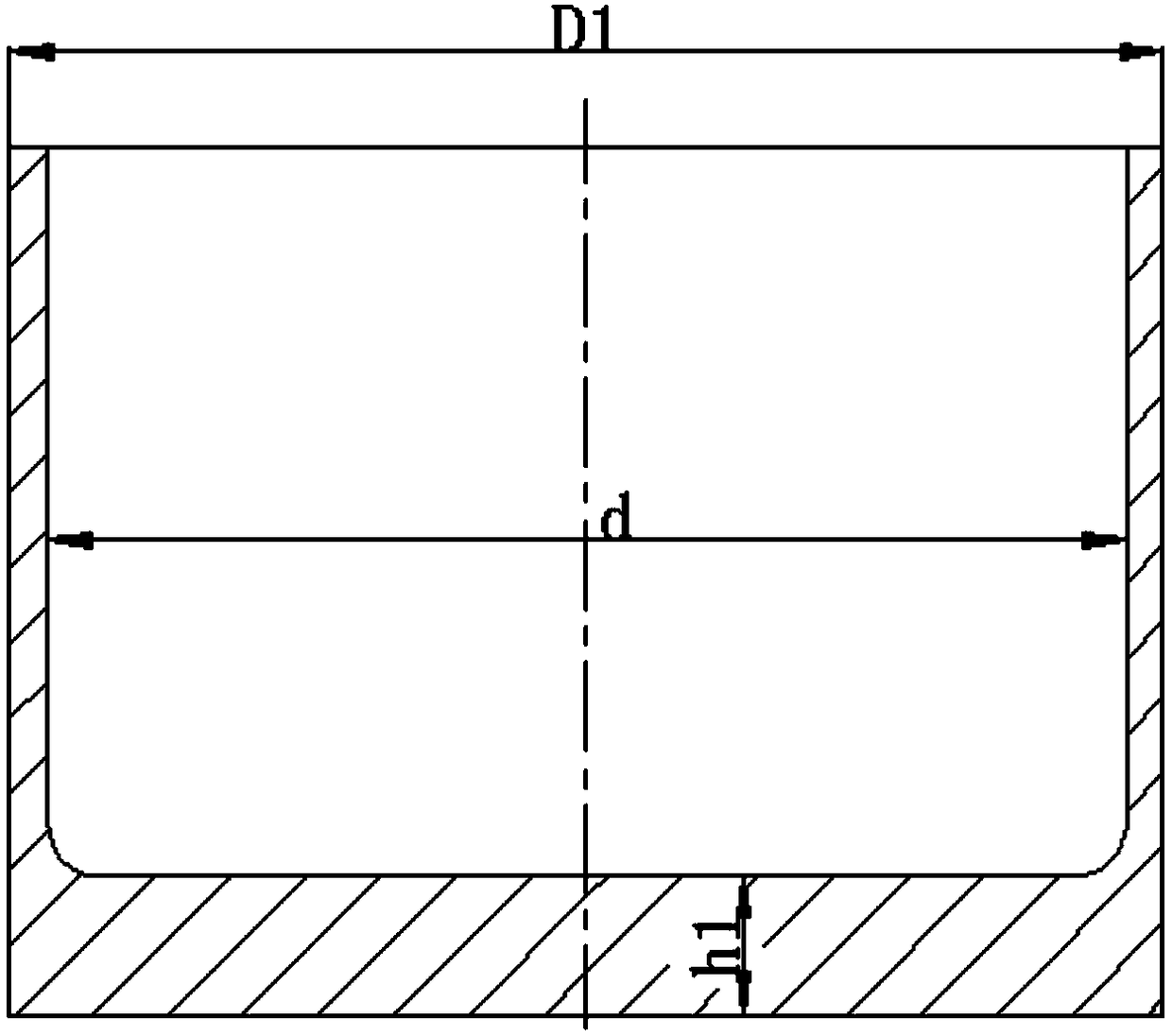

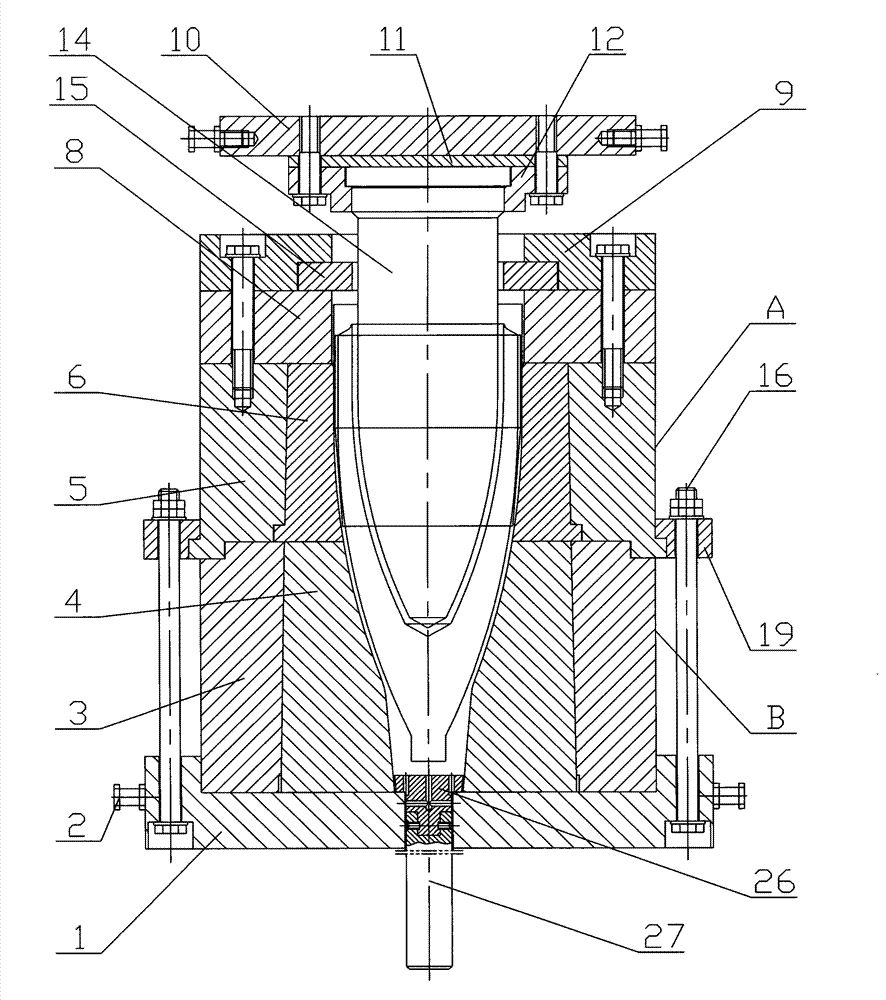

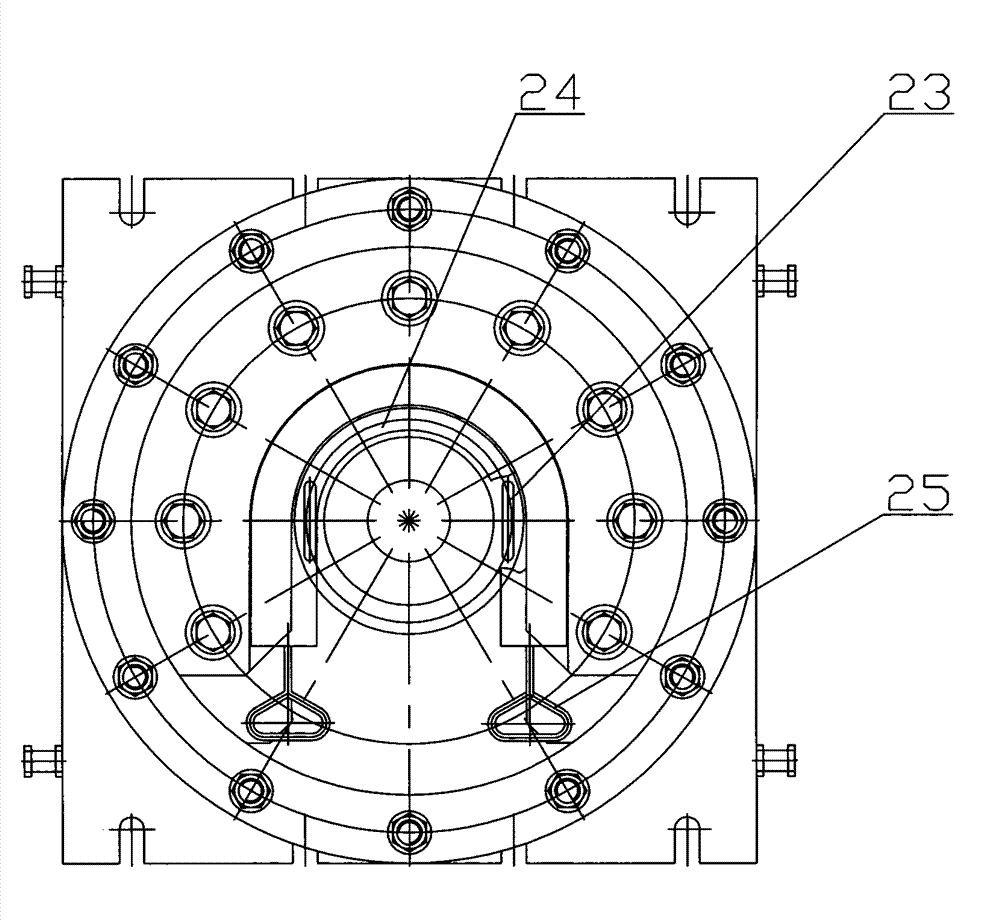

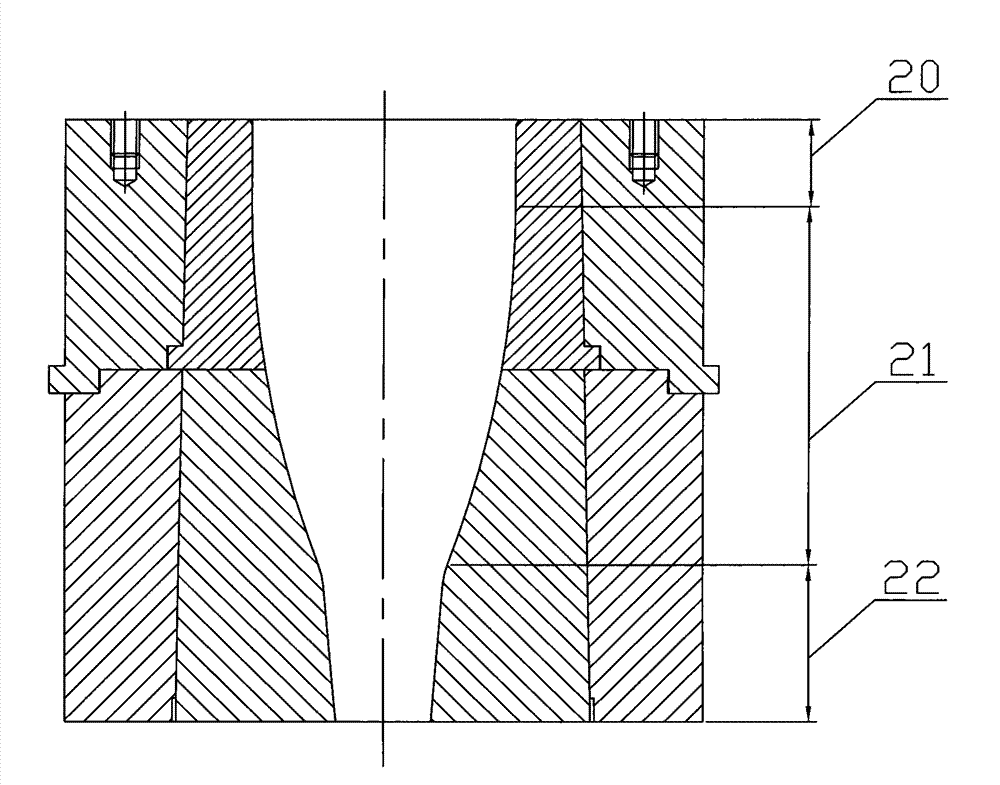

Extrusion die and method for extrusion molding inside and outside reduction blank by same

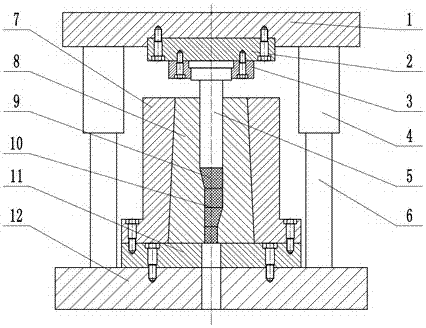

The invention provides an extrusion die and a method for extrusion molding inside and outside reduction blank by the same, which relate to a die and a method for extrusion molding blanks by the die, and are aimed to solve the problems that the adoption of the common blank extrusion molding die and method cannot mold a workpiece with an external shape of one end of a larger diameter and the other end of a smaller diameter, and the workpiece with an internal hole end of a larger diameter, a bottom part of a smaller internal diameter and a long axial length. The die is characterized in that a second assembly is arranged on a lower die seat; a first assembly is arranged on a second assembly; the die holes of a first lower die and a second lower die are combined to form into a lower die cavity; a cushion block and a discharging plate are detachably connected with a first pre-stressed ring; a convex die is arranged in the lower die cavity; the connection part of the convex die is arranged in a stepped through hole of a fixing plate of the convex die; and the fixing plate of the convex die is detachably connected with the cushion block and an upper die seat. The method comprises the following steps of blanking, turning, heating, extruding and annealing treatments, wherein the heating temperature is between 1100 DEG C and 1150 DEG C. With the adoption of the extrusion die and the method provided by the invention, the extrusion molding of inside and outside reduction blanks can be realized.

Owner:HARBIN JIANCHENG GRP

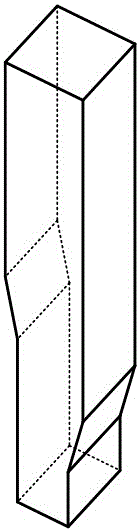

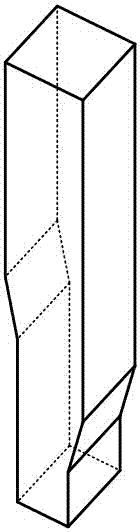

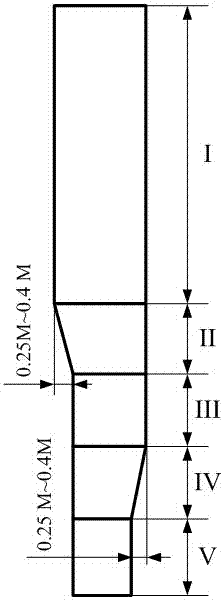

Asymmetric extrusion die and blank formation method thereof

The invention discloses an asymmetric extrusion die and a blank formation method thereof. The asymmetric extrusion die comprises a male die and a female die; the male die comprises a top plate, a joint plate and an extrusion rod; the female die is of a circular truncated cone-shaped structure externally and is hollow internally, a die cavity is formed inside the female die and is sequentially divided into an extrusion-into section, a first asymmetric extrusion section, a uniform extrusion section, a second asymmetric extrusion section and an extrusion-out section from an extrusion inlet. According to the asymmetric extrusion die and the blank formation method thereof, one sides of blanks are extruded but the other sides of the blanks are not extruded through asymmetric extrusion channels, and therefore uneven shear deformation is generated, and shear deformation facilitates formation of equiaxial small grains of material under the effect of three-dimensional pressure stress; through the asymmetric extrusion effect of two opposite directions, the shapes of the extruded blanks are normal, the material is saved, and the energy consumption is lowered.

Owner:TIANJIN POLYTECHNIC UNIV +1

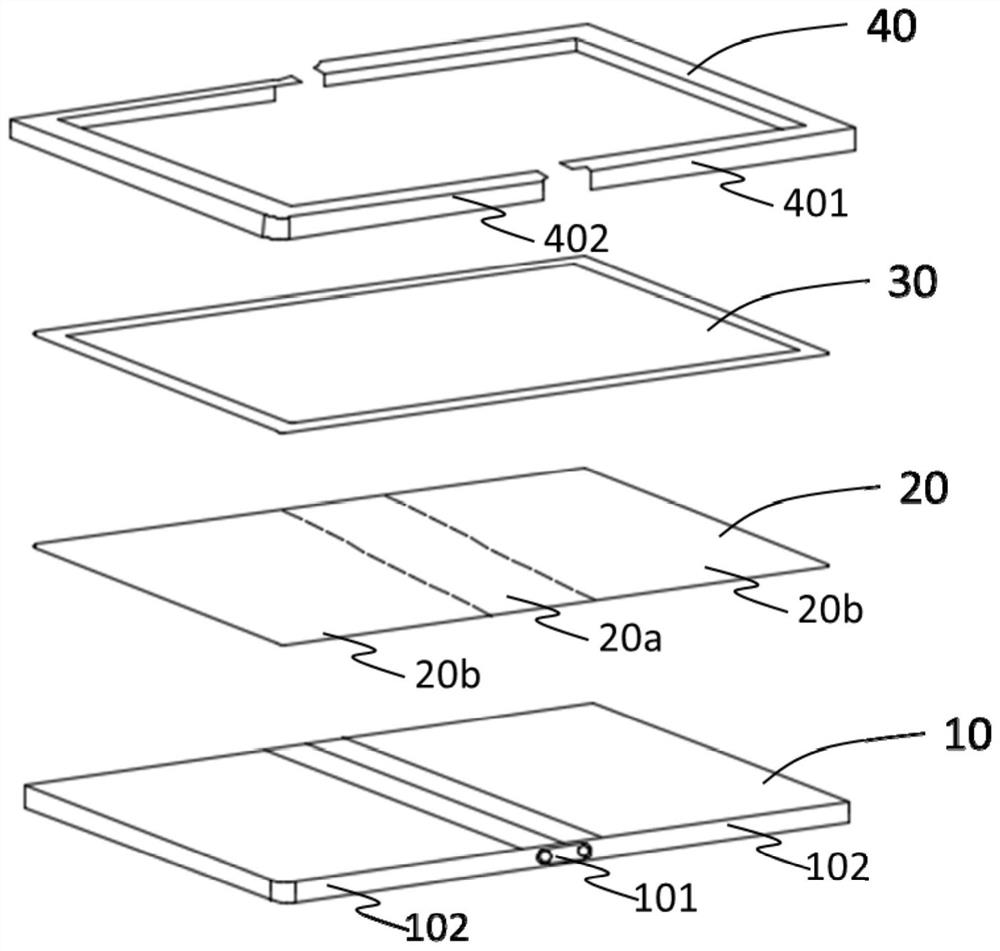

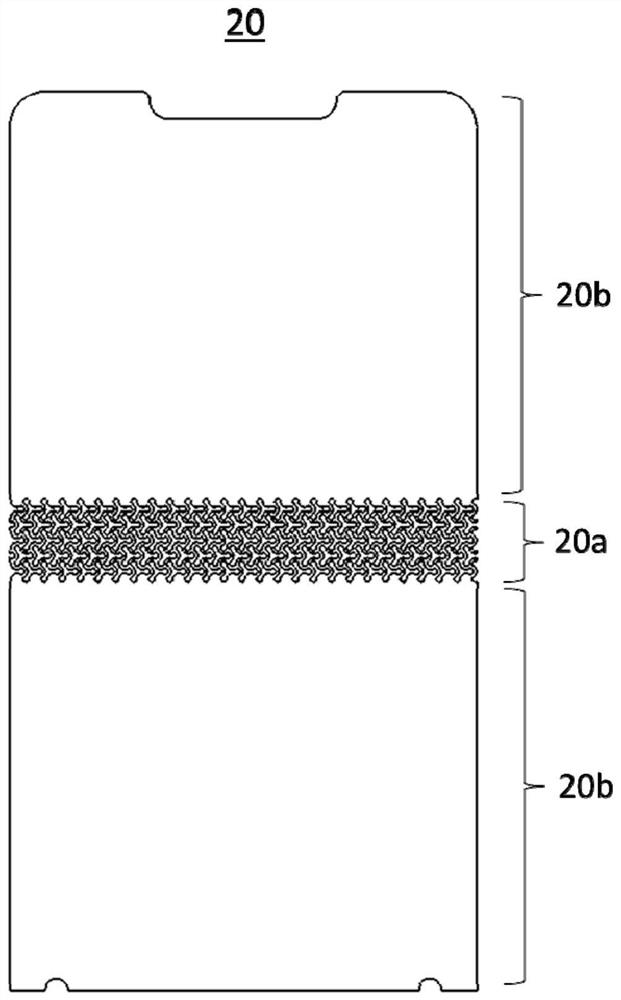

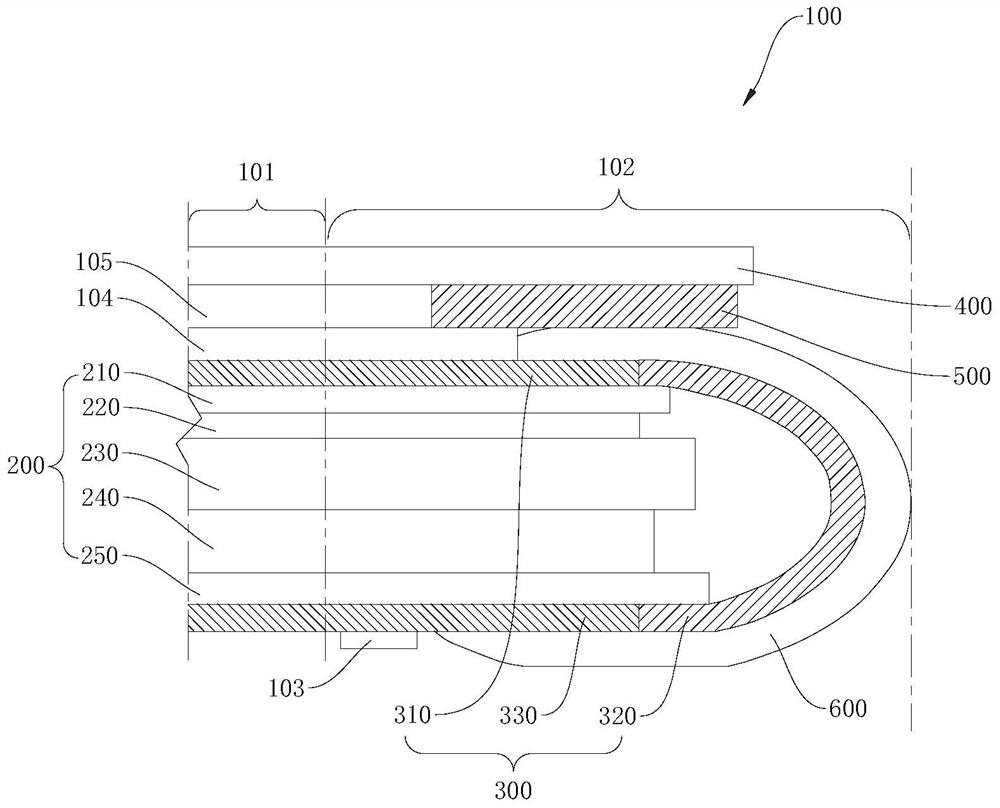

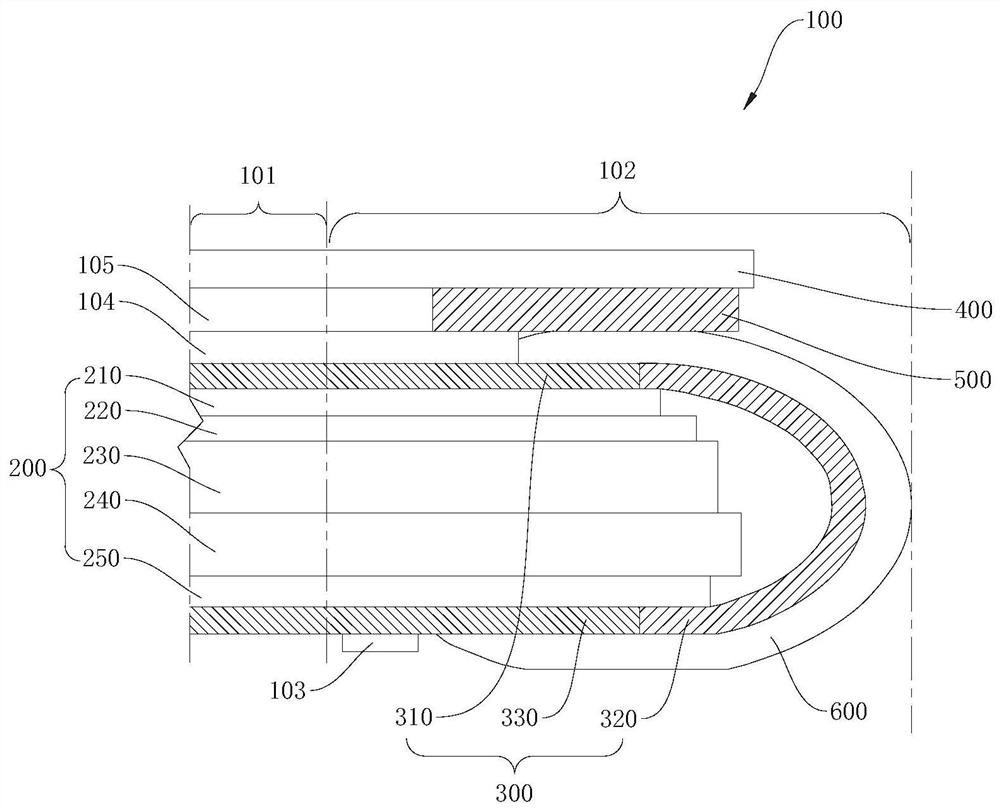

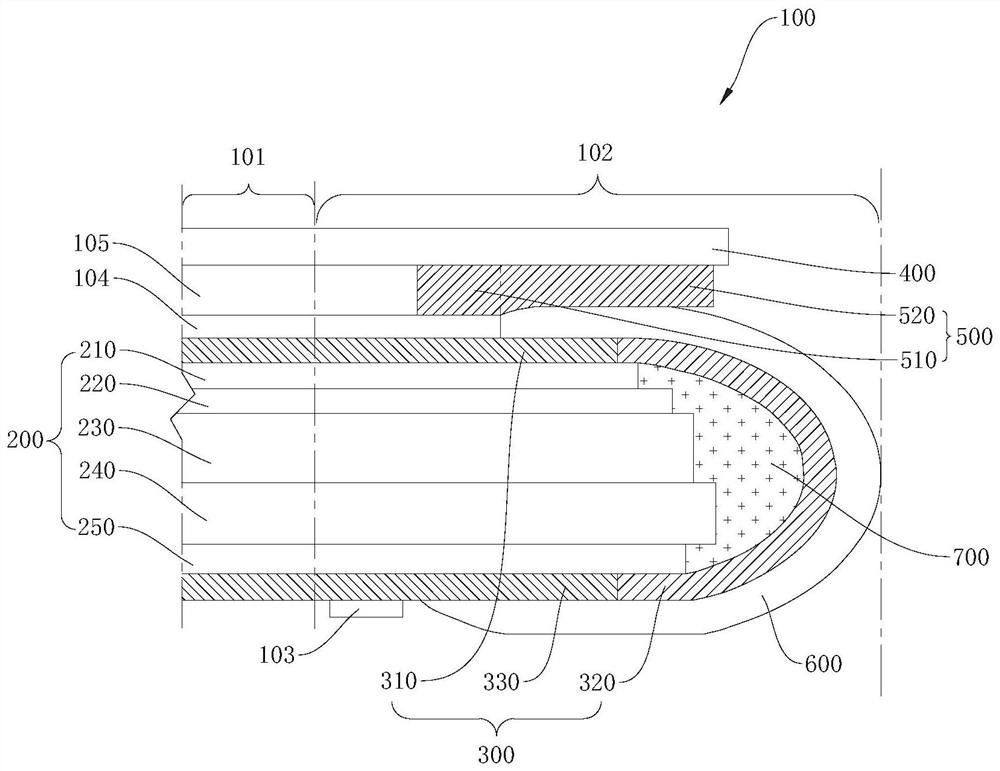

Folding display device

ActiveCN112002230AReduce thicknessReduce extrusion forceDigital data processing detailsIdentification meansDisplay deviceFlexible display

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

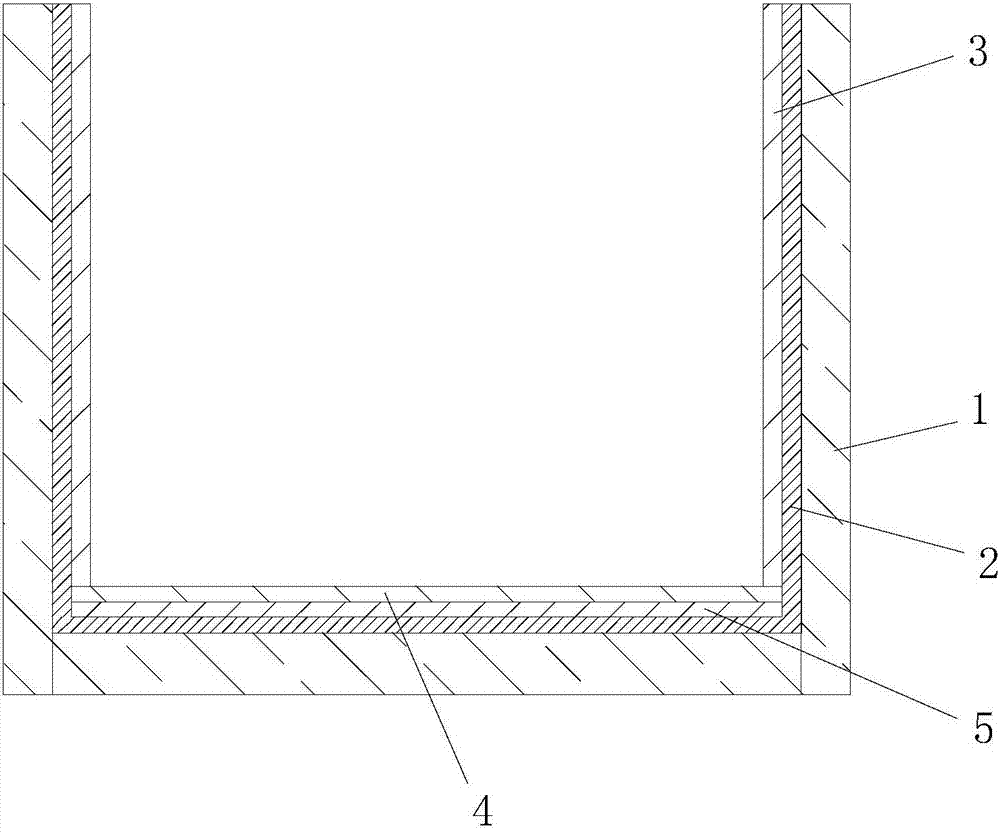

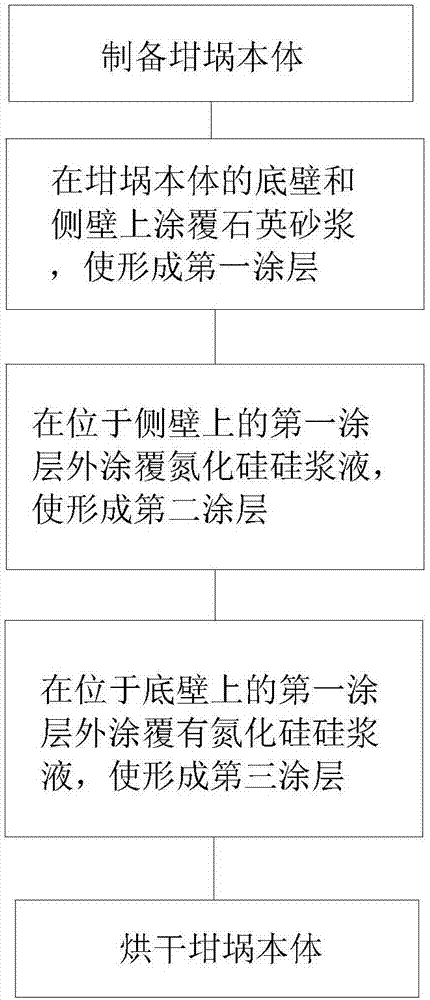

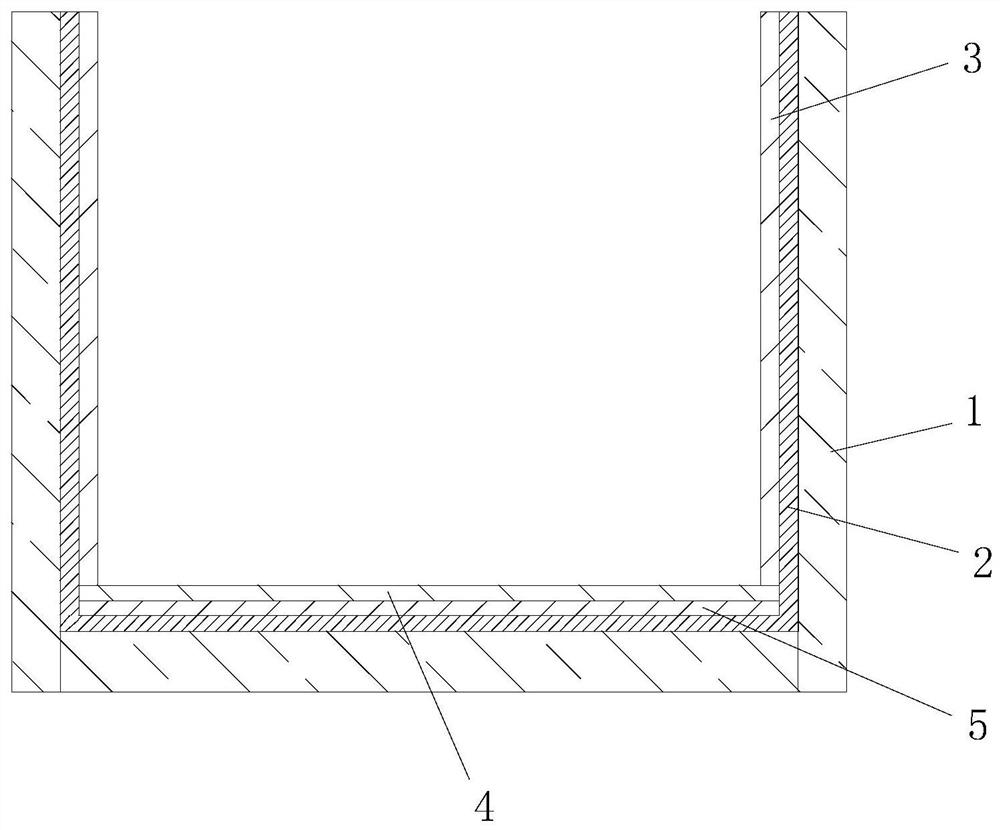

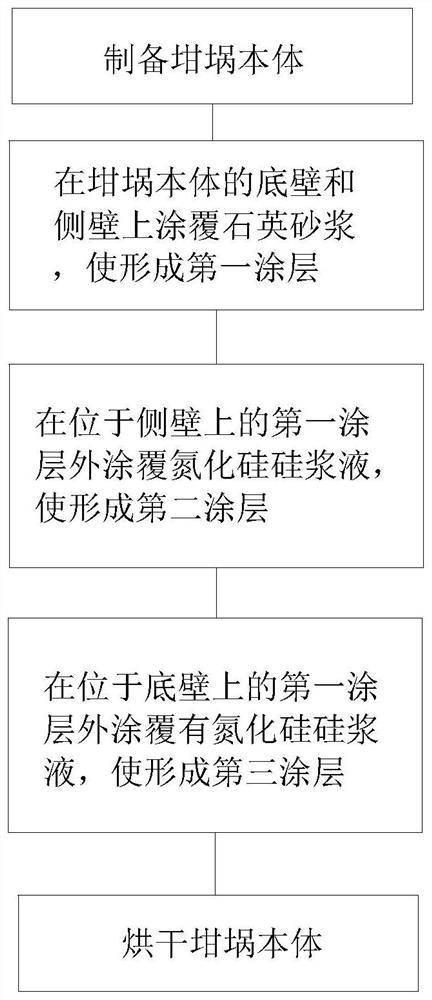

Crucible and preparation method thereof

ActiveCN107573101AReduce spreadReduce defect densityPolycrystalline material growthSingle crystal growth detailsCrucibleMetal impurities

The invention provides a crucible and a preparation method thereof. The crucible comprises: a crucible body, a first coating, a second coating and a third coating, wherein the crucible body comprisesa bottom wall and a side wall; the first coating layer is arranged on the bottom wall and the side wall for preventing metal impurities from diffusing to crystalline grains in the crucible body, the second coating is arranged on the outside of the first coating layer on the side wall, the second coating layer is used to assist in nucleating the crystalline grains within the crucible body; the third coating is arranged on the outside of the first coating layer on the bottom wall, the third coating layer is used to assist in separating the crystalline grains within the crucible body from the crucible body. The crucible of the invention can effectively reduce diffusion of the metal impurities in the crucible body into polycrystalline crystals located in the crucible body, so that purity of the prepared polycrystalline silicon is high.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

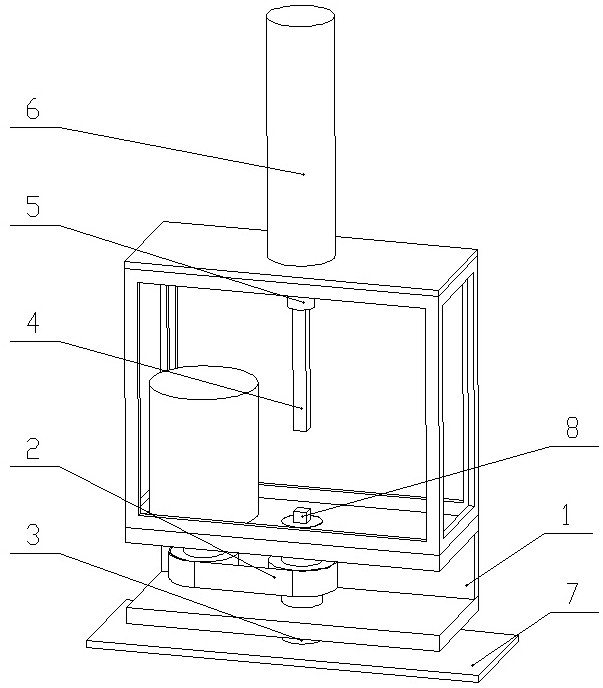

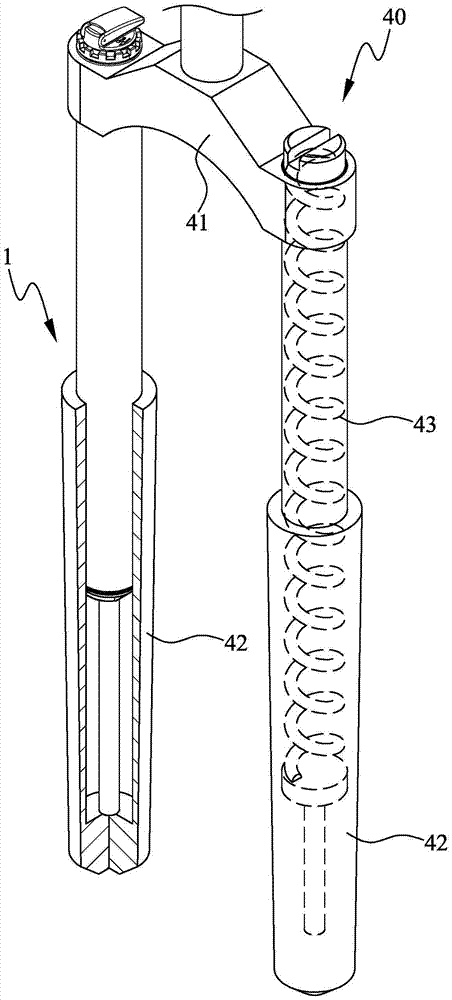

Friction welding material adding equipment and method

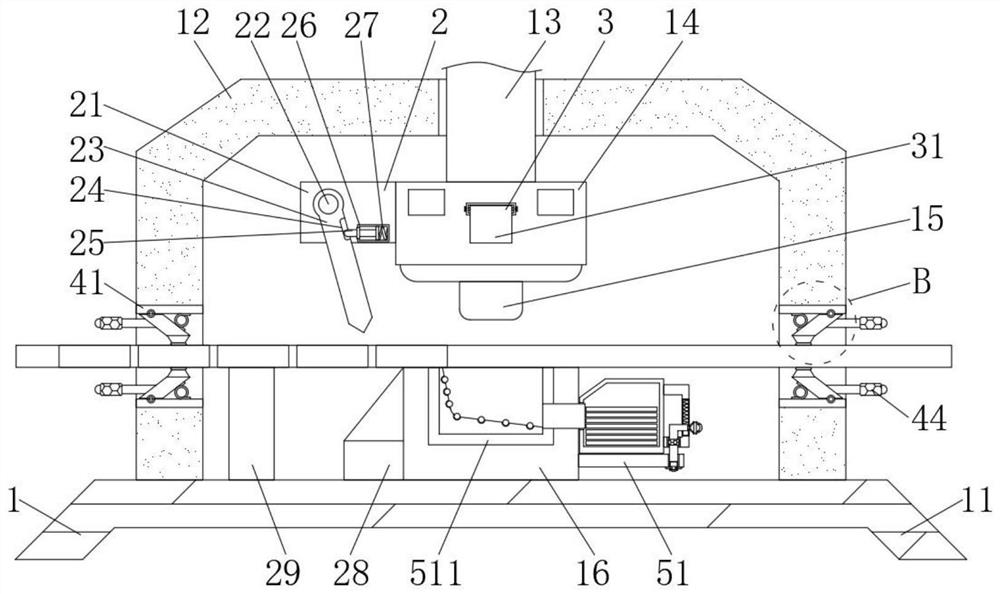

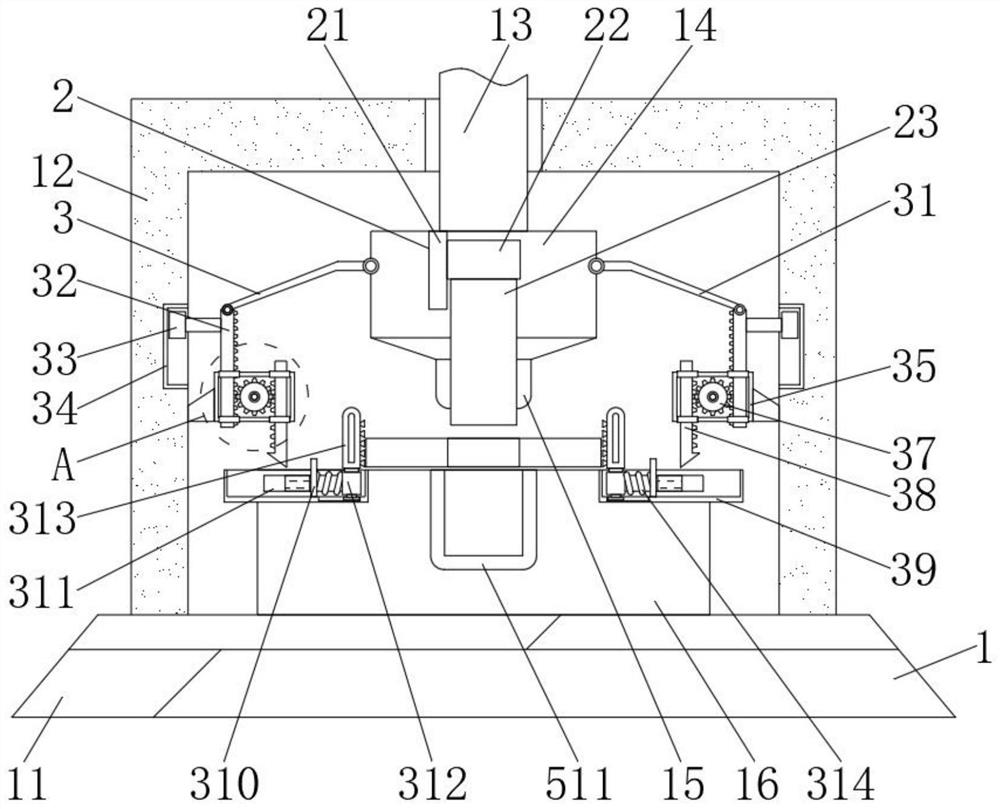

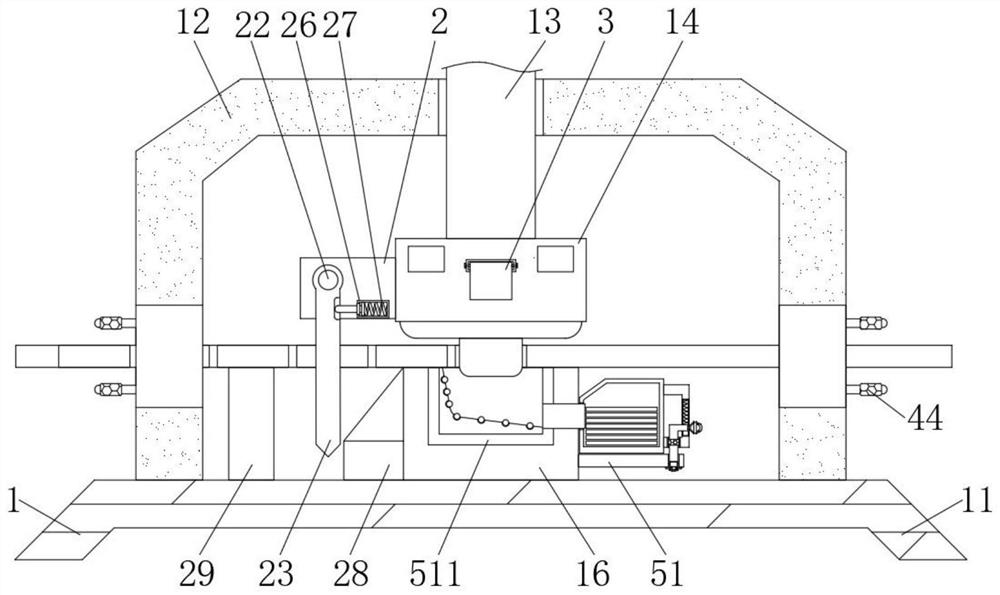

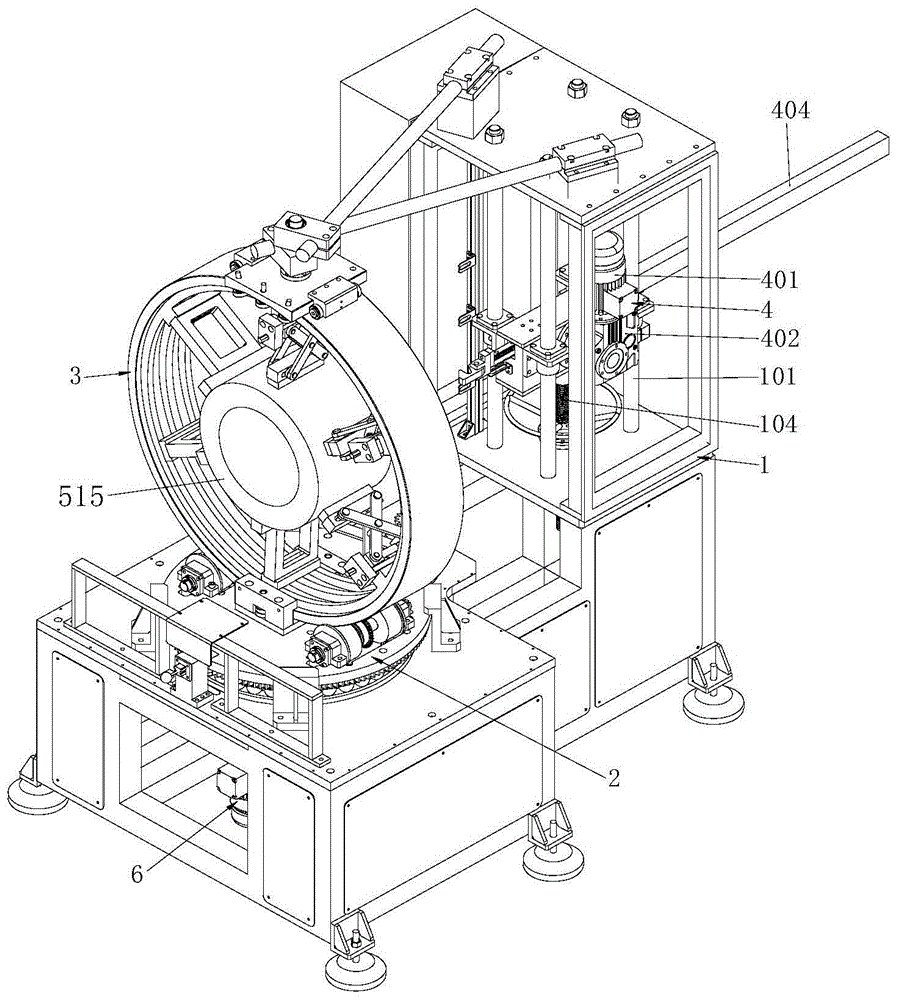

ActiveCN113500287AReduce extrusion forceNo chance of clogging the hollow lumen of the shaft shoulderAdditive manufacturing apparatusNon-electric welding apparatusFriction weldingMetallic materials

The invention relates to friction welding material adding equipment. The friction welding material adding equipment comprises a machine base, a rotating device, a shaft shoulder, an extrusion rod, a shaft sleeve and an extrusion device. The invention further provides a method for carrying out material adding manufacturing by adopting the friction welding material adding equipment. According to the friction welding material adding equipment, high-quality material adding manufacturing of metal materials such as aluminum alloy can be achieved, and the material utilization rate and the production efficiency are improved.

Owner:长沙弗瑞克科技有限公司

Multi-convex die step-by-step reverse extrusion forming method

InactiveCN109304375ASubstantiveIncrease productivityExtrusion diesMechanical engineeringForming force

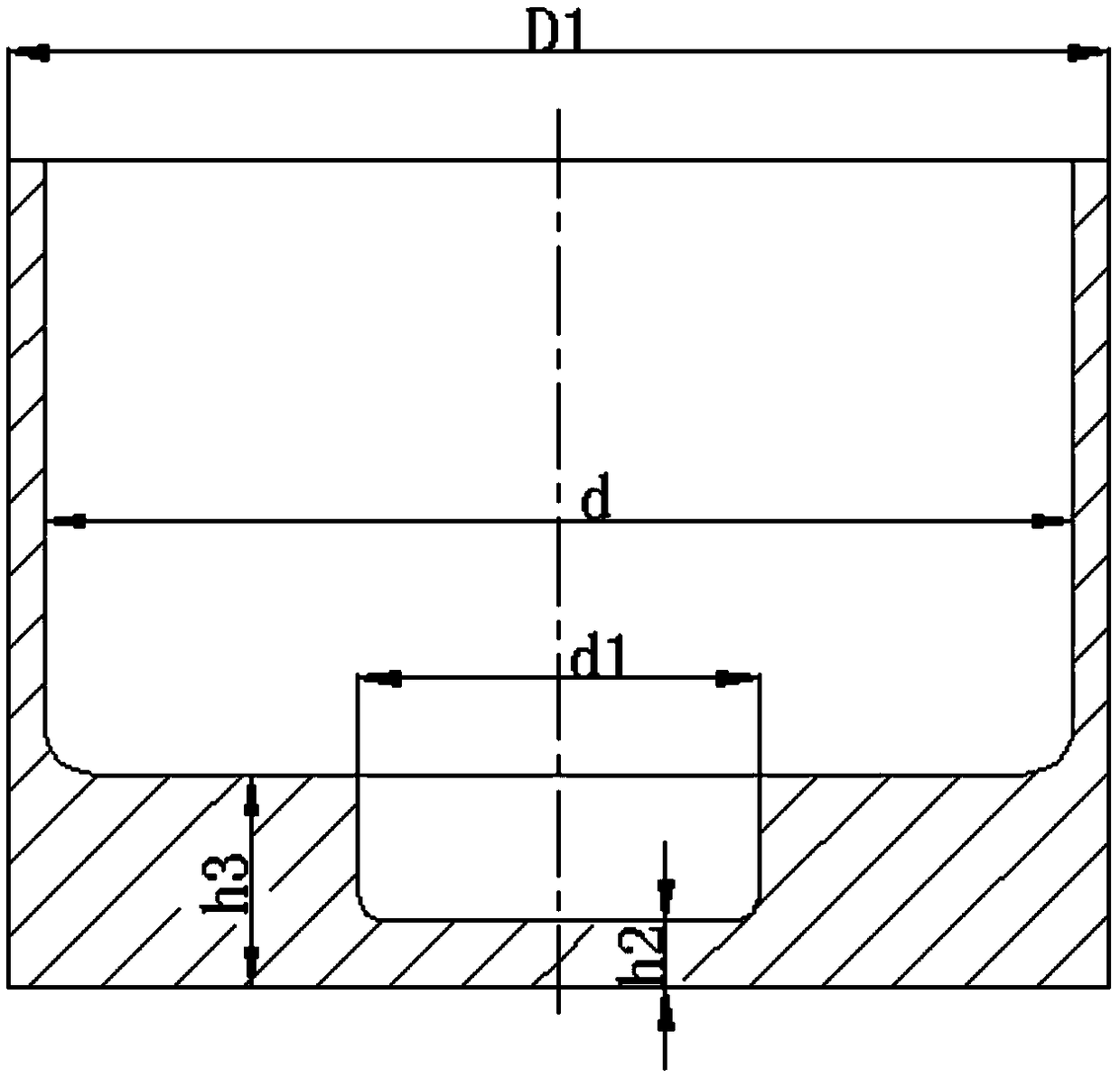

The invention relates to a multi-convex die step-by-step reverse extrusion forming method. A multi-convex die is composed of an inner convex die and an outer convex die, and steps of discharging, blank making, step-by-step reverse extrusion and subsequent processing are included. The multi-convex die step-by-step reverse extrusion forming method is characterized in that according to step-by-step reverse extrusion, the inner convex die and the outer convex die are used for extruding blank metal at least once, the blank metal generates flow deformation under the action of the multi-convex die, the stroke of the inner convex die and the outer convex die is controlled to obtain a hollow member with the bottom being the solid flat bottom or concave bottom or convex bottom. According to the multi-convex die step-by-step reverse extrusion forming method, in one die, forming manufacturing of the hollow parts with the flat bottoms, the convex bottoms, the concave bottoms and the like can be achieved; and the extrusion forming contact area is reduced, the extrusion forming force is reduced, and the amount of extrusion deformation can be improved.

Owner:ZHONGBEI UNIV

Stamping device with anti-deviation structure for mechanical part machining

InactiveCN113102591AImprove stabilityConvenient position adjustment and movementShaping toolsMetal-working feeding devicesMachine partsMechanical components

The invention relates to the technical field of mechanical part machining equipment, and discloses a stamping device with an anti-deviation structure for mechanical part machining. The stamping device comprises a stamping forming device, wherein the stamping forming device comprises a base, a machining bin, a power device, a first fixing plate, an upper die, a bottom box and a machined part. A feeding mechanism, an extrusion limiting mechanism and a limiting extrusion mechanism are arranged, the stability of the machined part during stamping separation treatment is improved, manual supporting and fixing are not needed all the time, the labor intensity of operators is reduced, and a poke rod can conveniently adjust and move the position of the machined part. The device is provided with a recycling mechanism and a buffering mechanism, the situation that the bottom end of the upper die is damaged due to collision between the upper die and the machined part is effectively avoided, the service life of the upper die is prolonged, workers can conveniently recycle excess materials in a storage box in a centralized mode, and the workload of operators is reduced.

Owner:方鑫源

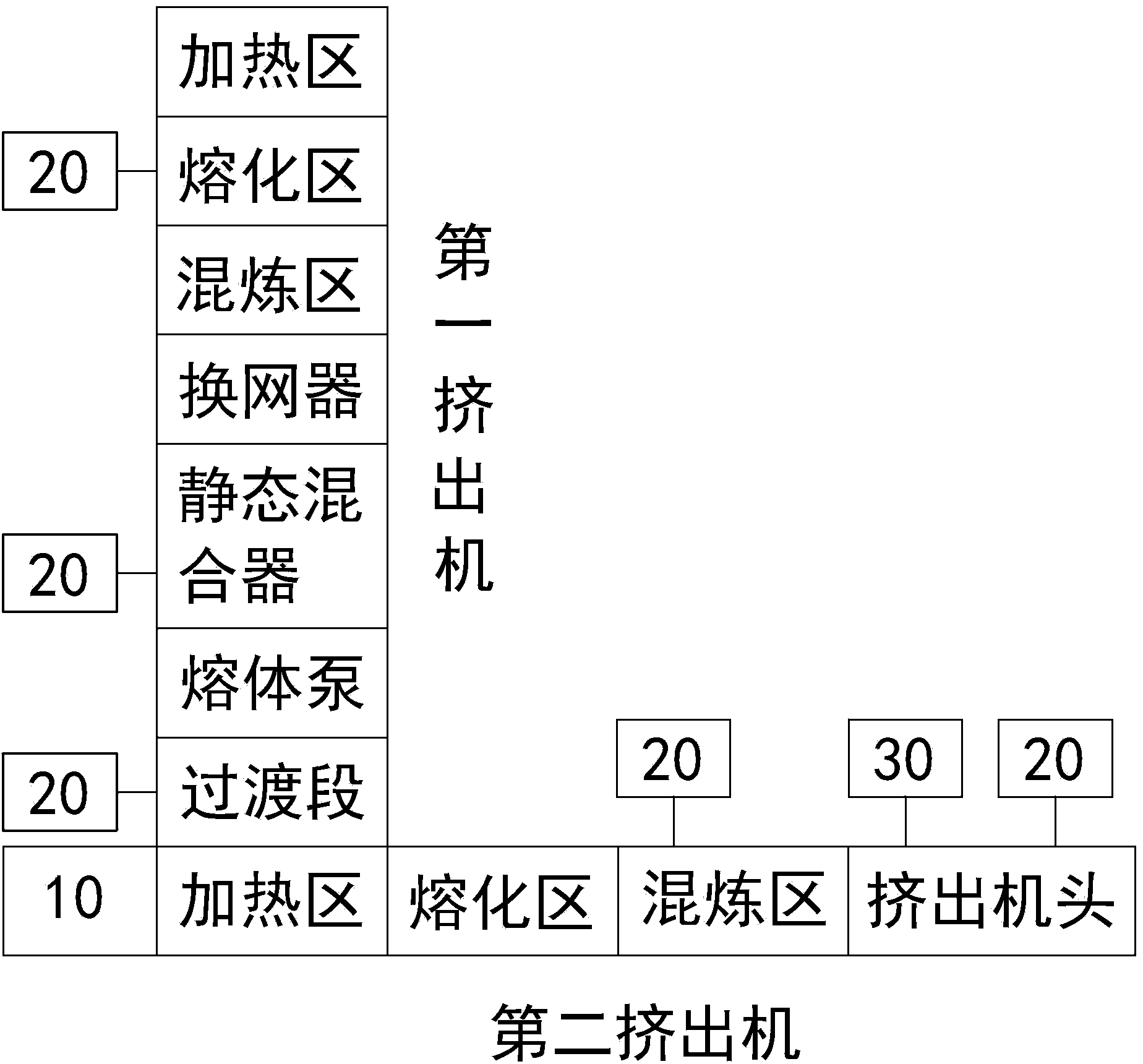

Extruder unit

The invention relates to an extruder unit. The extruder unit comprises a first extruder, wherein a heating area, a melting area, a mixing area, a screen exchanger and a static mixer are sequentially arranged in the first extruder; an outlet of the static mixer is communicated with an inlet of a melt pump through a pipeline; an outlet of the melt pump is communicated with a feeding opening of a second extruder through a pipeline. The extruder unit has the advantages that the first extruder is connected with the second extruder through the melt pump, so that mixing extrusion force transiting from the first extruder to the second extruder can be effectively reduced, and the working efficiency is correspondingly improved; a back-leakage prevention sealing device is arranged in front of the feeding opening of the second extruder, so that the sealing performance of the feeding opening of the second extruder is improved; meanwhile, the extruder unit is capable of preventing back-leakage air from flowing out of a rotary gap when a screw rod rotates and extrudes, and thus the quality of products is guaranteed, the pressure leakage of the extruder is avoided and a power device can save certain power energy.

Owner:天台诚一新材料有限公司

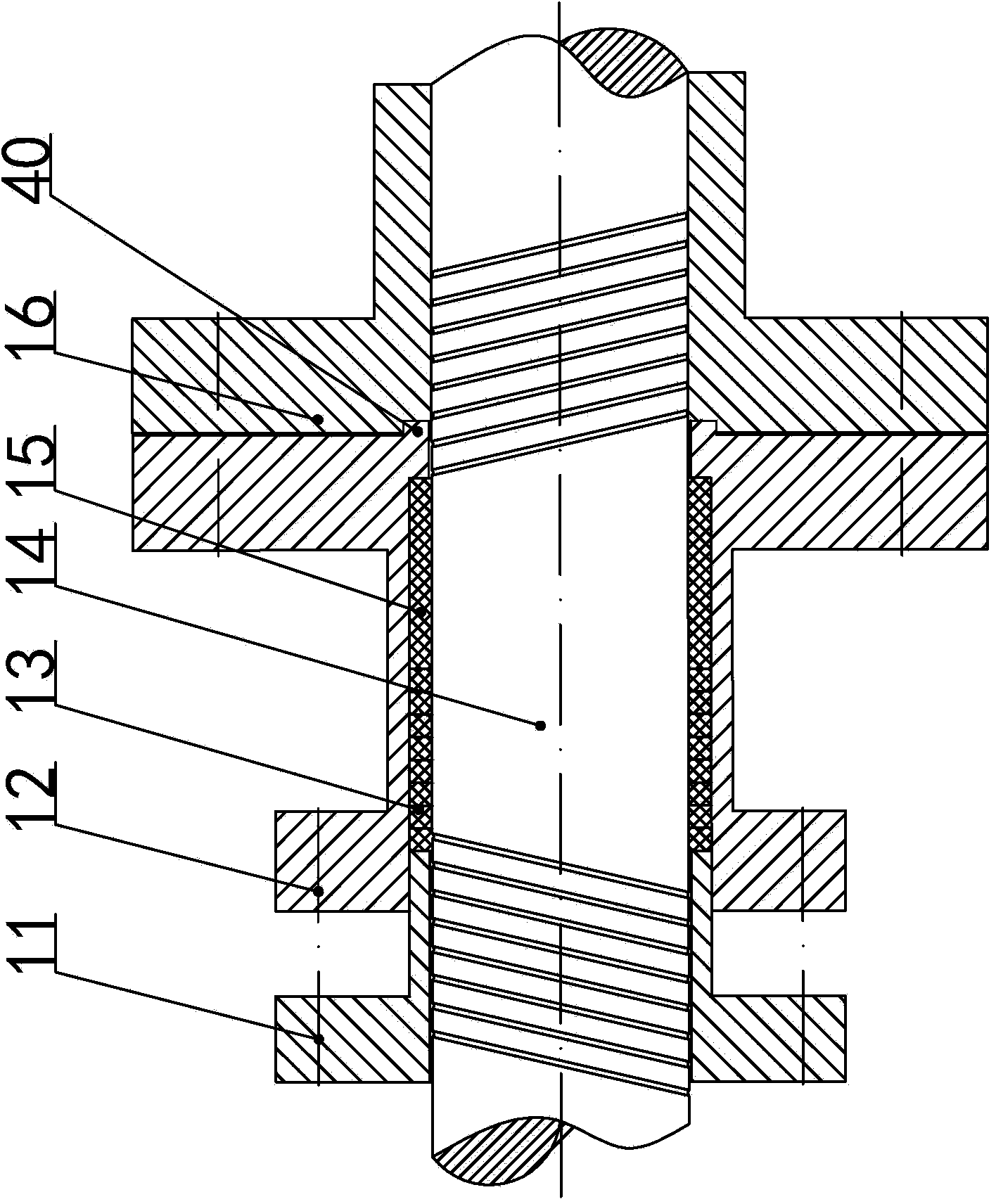

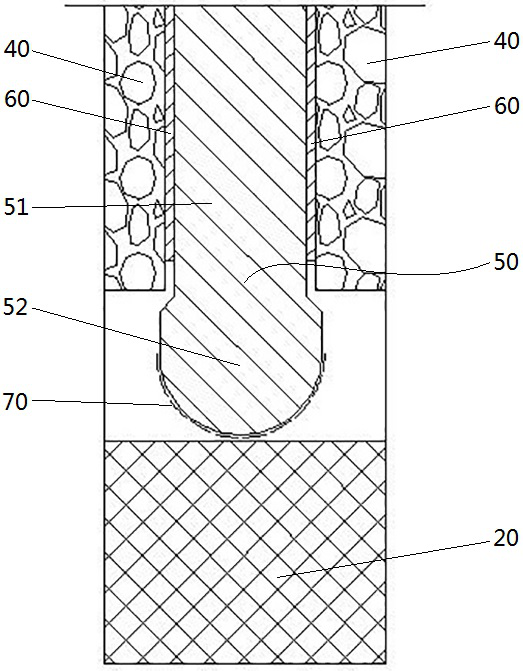

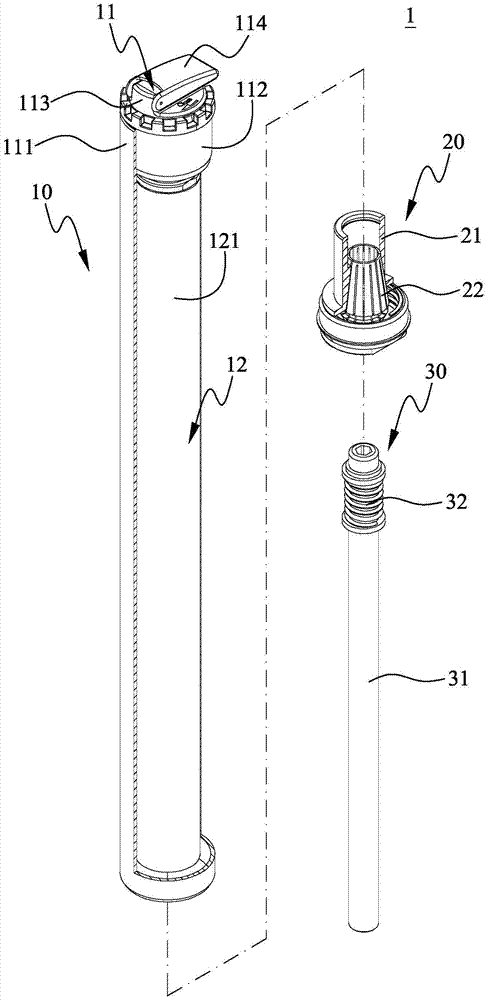

Wire inserting mold of motor stator iron core

ActiveCN104269983AReduce resistanceReduce extrusion forceManufacturing dynamo-electric machinesStatorConductor Coil

The invention discloses a wire inserting mold of a motor stator iron core. The wire inserting mold comprises guide strips, a kidney-shaped base, a kidney-shaped cover plate, a connecting rod and a locking device. Slots are formed in the outer circumferential face of the base and the outer circumferential face of the cover plate at intervals respectively, one end of each guide strip is fixed to the corresponding slot in the base, the other end of each guide strip is in clearance fit with the interior of the corresponding slot in the cover plate, a through hole penetrating through the two axial end faces of the cover plate is formed in the cover plate, one end of the connecting rod is fixed to the axial end face, facing the cover plate, of the base, the connecting rod and the cover plate are integrally fastened through the locking device after the other end of the connecting rod penetrates through the through hole in the cover plate, and a dragging hook base connected with a wire dragging device is arranged on the axial end face, deviating from the cover plate, of the base. By means of the wire inserting mold, wire inserting of windings with various phases is carried out in a multi-time mode, and varnished wires in the windings are prevented from being damaged.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

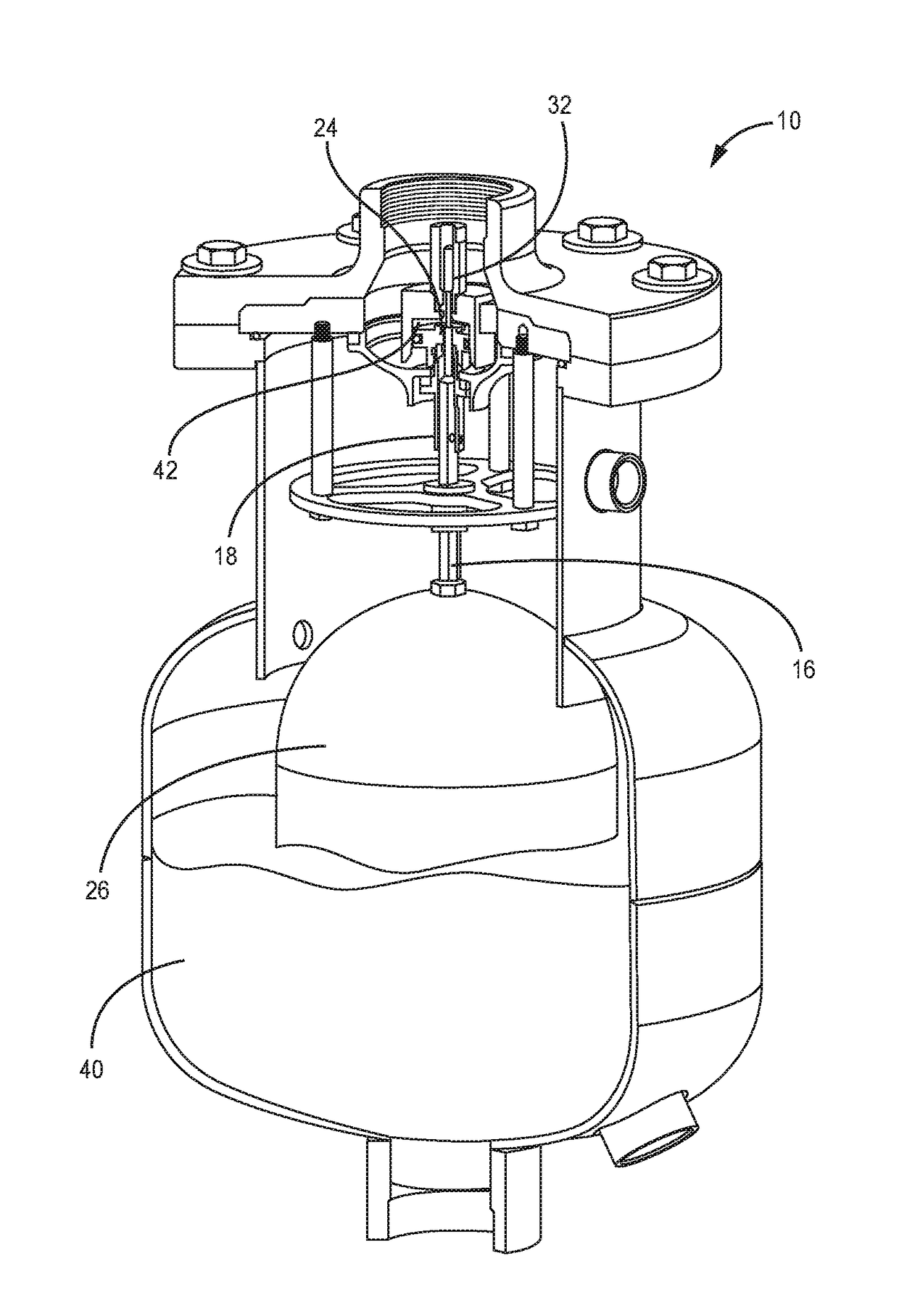

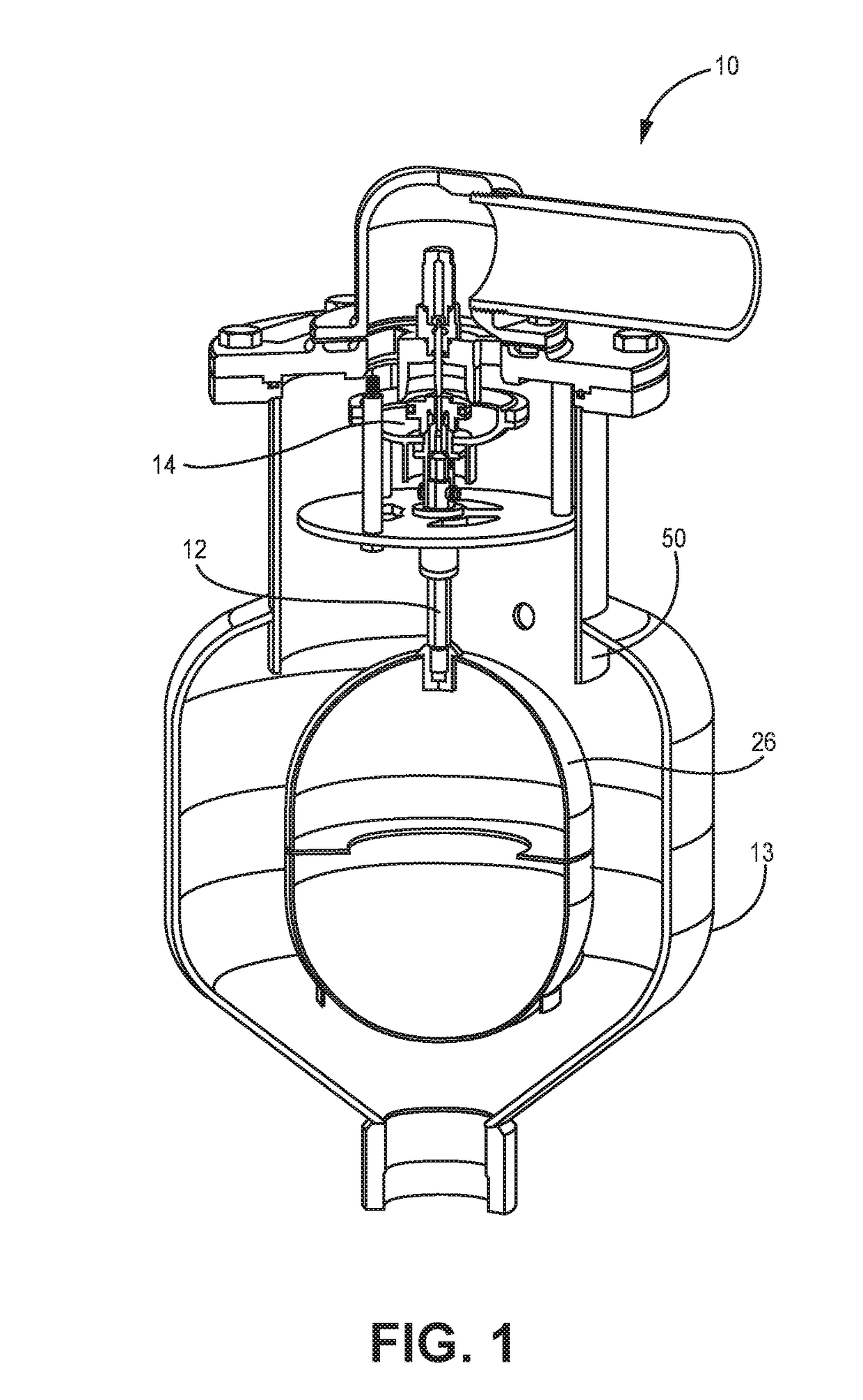

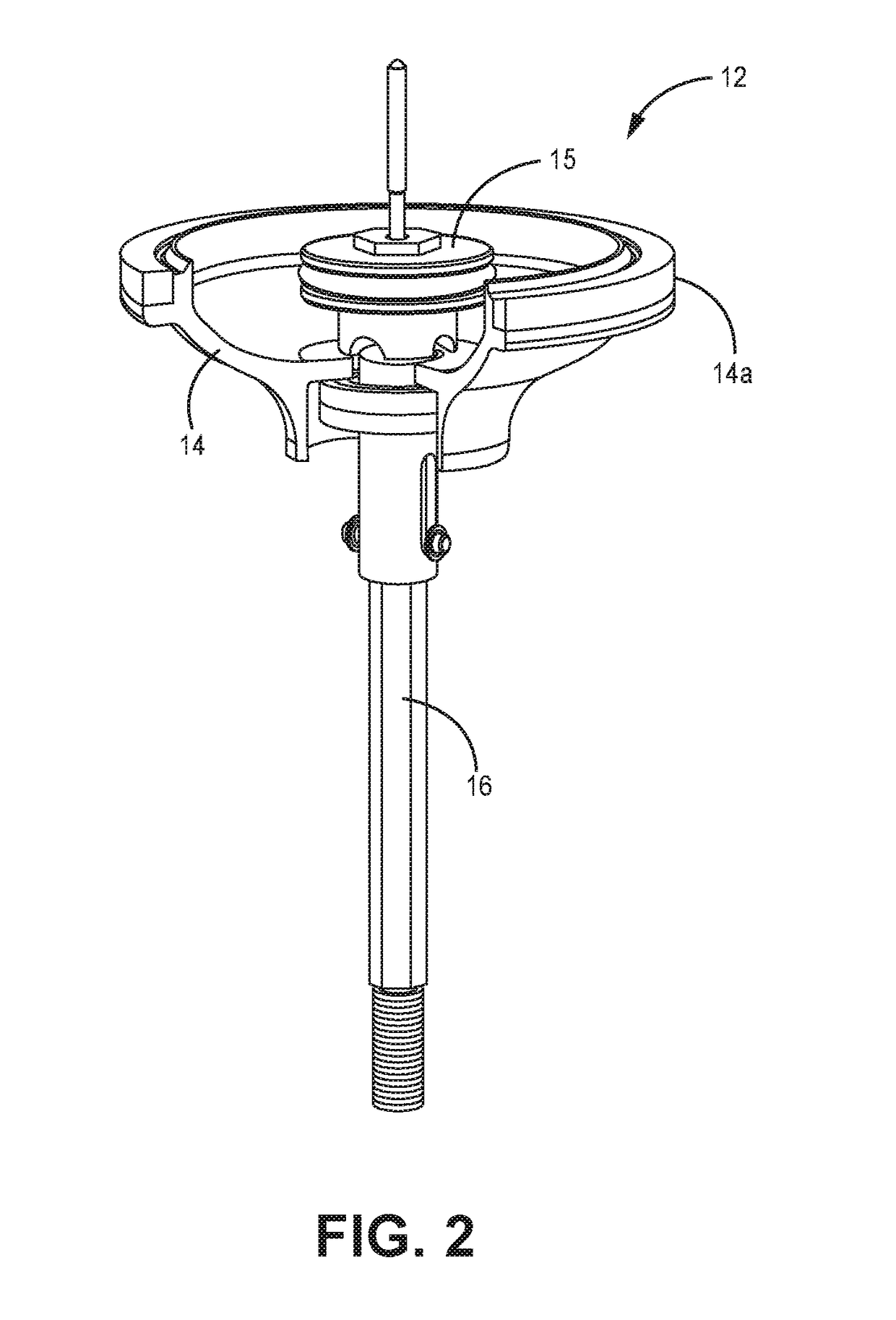

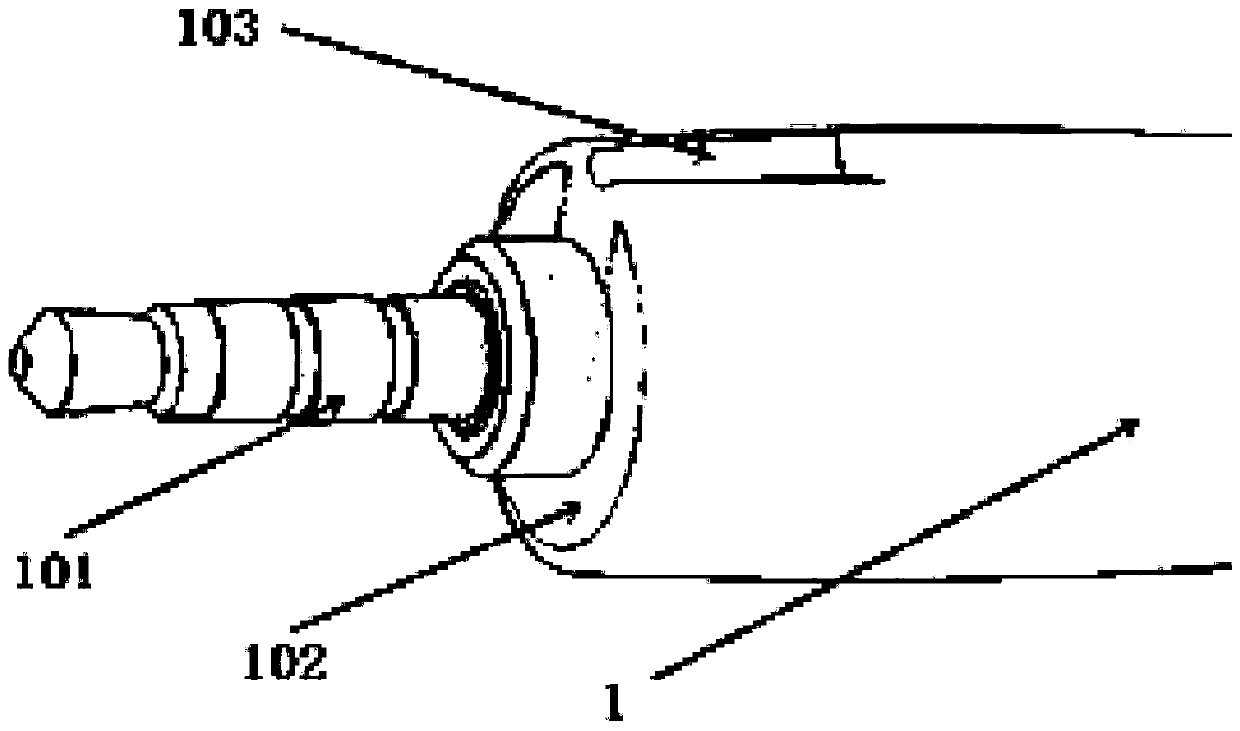

Combination air valve

ActiveUS20170356567A1Reduce extrusion forceHigh pressureOperating means/releasing devices for valvesSewerage structuresEngineeringPressure equilibrium

The present disclosure is directed to a combination air valve that uses buoyancy to lift seals into place, preventing media from escaping from the valve. Once the seals are in place, pipeline pressure is used to open and close the valve. The combination air valve includes a low flow vent configured with a pressure equalizing configuration allowing for reduced extrusion forces along the low flow vent, allowing vertical movement of a float shaft at high valve gas pressures with reduced forces.

Owner:DEZURIK

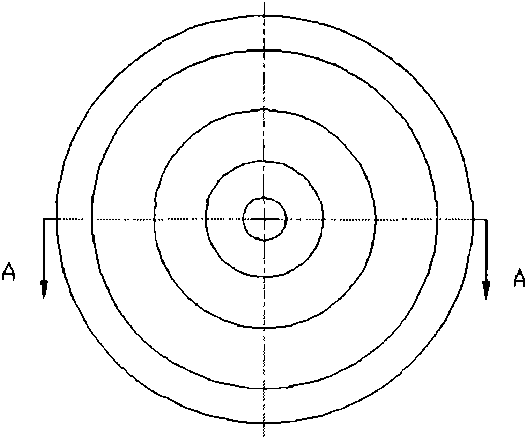

Pre-diverging-wedge pressing precision forming die and disc forming method

InactiveCN103447340BSmall machining allowanceSmall forming forceExtrusion diesEngineeringMechanical property

The invention provides an extruding terrace die which is formed by assembling a pre-diverging die, a wedge pressing die and a terrace die core shaft. Firstly, the pre-diverging die is used for realizing the pre-distribution of metal plastic flow volumes, reducing the remain of forged pieces and increasing the utilization rate of materials; the wedge pressing die compels a metal to plastically flow under the action of the wedge pressing force, and as the plastic flow process of the metal is added, the influence on the mechanical properties of the formed part caused by machining is avoided and the purpose of improving the mechanical properties of the formed part is achieved; the terrace die core shaft and a concave die are combined to form a closed cavity so as to restrain the further radial flow of the deformed metal, as a result, the contact area between the terrace die and the deformed metal is reduced and the extruding forming force is reduced.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Drawing Die Inserting Machine for Motor Stator Core

ActiveCN104300748BReduce resistanceReduce extrusion forceManufacturing dynamo-electric machinesEngineeringKidney

The invention discloses a drawing die coil inserting apparatus of a motor stator iron core. The drawing die coil inserting apparatus comprises a work bench arranged at a rack, a stator clamping device arranged at a rack and a drawing device can move in and out of the stator clamping device. The stator clamping device is fixed at the work bench. An inserting die includes guide bars, a kidney-shaped pedestal, a kidney-shaped cover plate, a connecting rod, and a locking device; insertion slots are formed in the peripheral surfaces of the pedestal and the cover plate at intervals; and one end of each guide bar is fixed in the insertion slot of the pedestal and the other end of each guide bar is arranged in the insertion slot of the cover plate in a clearance fit mode. A through hole passing through two axial end surfaces of the cover plate is formed in the cover plate. One end of the connecting rod is fixed at the axial end surface, opposite to the cover plate, of the pedestal; and the other end of the connecting rod passes through the through hole of the cover plate and the connecting rod and the cover plate are fastened together by the locking device. Besides, a drag hook seat connecting the drawing device is arranged at the axial end surface, away from the cover plate, of the pedestal. According to the invention, line insertion is carried out on all-phase windings by multiple times, thereby preventing the enameled wires in the windings from being damaged.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

Asymmetric extrusion die and method for forming billet thereof

The invention discloses an asymmetric extrusion die and a blank formation method thereof. The asymmetric extrusion die comprises a male die and a female die; the male die comprises a top plate, a joint plate and an extrusion rod; the female die is of a circular truncated cone-shaped structure externally and is hollow internally, a die cavity is formed inside the female die and is sequentially divided into an extrusion-into section, a first asymmetric extrusion section, a uniform extrusion section, a second asymmetric extrusion section and an extrusion-out section from an extrusion inlet. According to the asymmetric extrusion die and the blank formation method thereof, one sides of blanks are extruded but the other sides of the blanks are not extruded through asymmetric extrusion channels, and therefore uneven shear deformation is generated, and shear deformation facilitates formation of equiaxial small grains of material under the effect of three-dimensional pressure stress; through the asymmetric extrusion effect of two opposite directions, the shapes of the extruded blanks are normal, the material is saved, and the energy consumption is lowered.

Owner:TIANJIN POLYTECHNIC UNIV +1

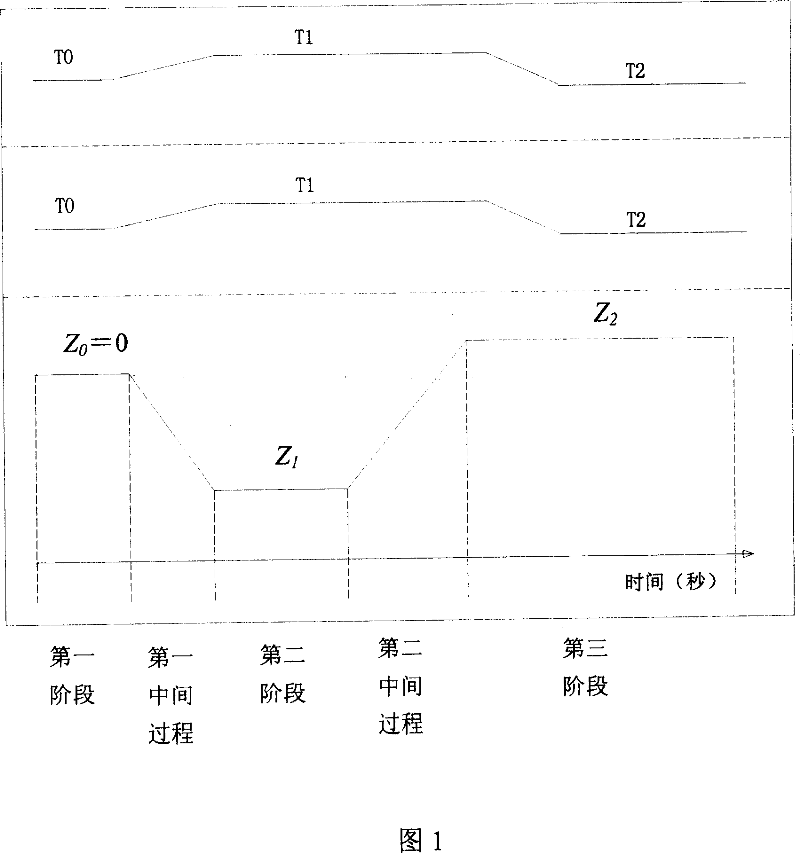

Back-flow pulling face down welding method of infrared focus planar detector

InactiveCN100355051CPrecise control of interplanar spacingReduce extrusion forceSemiconductor/solid-state device manufacturingMechanical engineeringFocal plane detector

This invention discloses a back-flow pulling flip-chip method of an infrared focal plane detector characterizing in preparing an In ball array on a Si read-out circuit, preparing welding pressing points and applying a single edge In ball back-flow vibration pulling flip-chip method, which is advantaged at avoiding the bad influence on the performance brought with the high temperature back flow endured by In melting point processed to an infrared photosensitive array chip by this invented method and generating tiny swing come-and go movement between the welding pressing points and the In ball of the read-out circuit to rub the oxidation layer of the In ball surface to increase the moist of the In ball at the back-flow state and the welding pressing points.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Lightning arrester

PendingCN114171268AIncrease frictionReduce extrusion forceOvervoltage protection resistorsPhysicsElectrical conductor

The lightning arrester comprises a shell, an insulating cylinder is arranged in the shell, a plurality of resistor discs are stacked in the insulating cylinder, at least one end of the insulating cylinder is provided with springs matched with the resistor discs in a jacking mode, and the resistor discs are divided into at least two resistor disc sets which are sequentially arranged in the stacking direction. A supporting pad is arranged between any two adjacent resistor disc groups, the supporting pad is a conductor, the supporting pad is adaptively arranged in the insulating cylinder, and the supporting pad is supported on the cylinder wall of the insulating cylinder when the insulating cylinder is transversely arranged. Compared with the prior art, when the lightning arrester is horizontally placed and transported, the damage of the resistor disc caused by vibration generated during transportation can be avoided, and the damage of the lightning arrester caused by the damage of the resistor disc can be avoided.

Owner:HENAN PINGGAO ELECTRIC

A multi-convex step-by-step reverse extrusion forming method

The invention relates to a multi-convex die step-by-step reverse extrusion forming method. A multi-convex die is composed of an inner convex die and an outer convex die, and steps of discharging, blank making, step-by-step reverse extrusion and subsequent processing are included. The multi-convex die step-by-step reverse extrusion forming method is characterized in that according to step-by-step reverse extrusion, the inner convex die and the outer convex die are used for extruding blank metal at least once, the blank metal generates flow deformation under the action of the multi-convex die, the stroke of the inner convex die and the outer convex die is controlled to obtain a hollow member with the bottom being the solid flat bottom or concave bottom or convex bottom. According to the multi-convex die step-by-step reverse extrusion forming method, in one die, forming manufacturing of the hollow parts with the flat bottoms, the convex bottoms, the concave bottoms and the like can be achieved; and the extrusion forming contact area is reduced, the extrusion forming force is reduced, and the amount of extrusion deformation can be improved.

Owner:ZHONGBEI UNIV

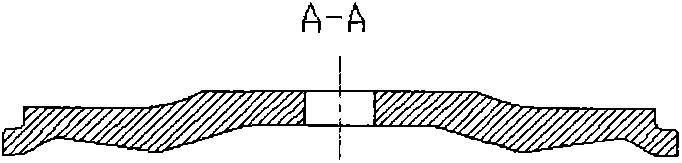

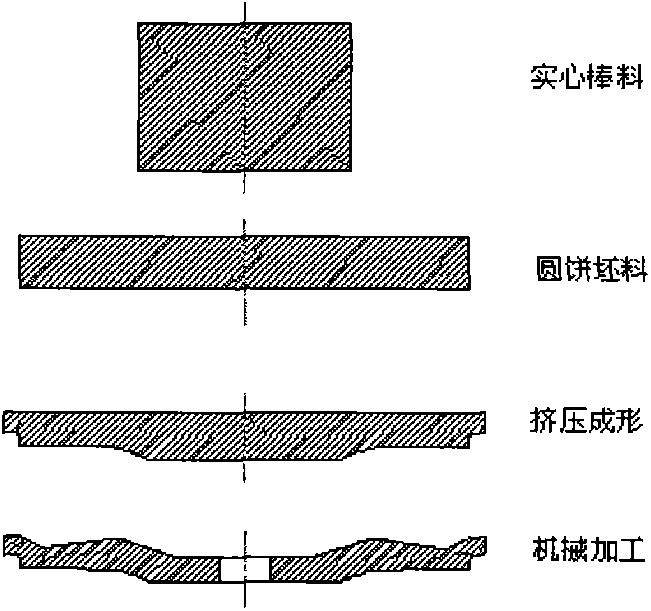

A processing method of high-quality large-diameter thin-walled metal cylinder

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

Pre-diverging-wedge pressing precision forming die and disc forming method

InactiveCN103447340AReduce contact areaReduce extrusion forceExtrusion diesForming forceClosed cavity

The invention provides an extruding terrace die which is formed by assembling a pre-diverging die, a wedge pressing die and a terrace die core shaft. Firstly, the pre-diverging die is used for realizing the pre-distribution of metal plastic flow volumes, reducing the remain of forged pieces and increasing the utilization rate of materials; the wedge pressing die compels a metal to plastically flow under the action of the wedge pressing force, and as the plastic flow process of the metal is added, the influence on the mechanical properties of the formed part caused by machining is avoided and the purpose of improving the mechanical properties of the formed part is achieved; the terrace die core shaft and a concave die are combined to form a closed cavity so as to restrain the further radial flow of the deformed metal, as a result, the contact area between the terrace die and the deformed metal is reduced and the extruding forming force is reduced.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

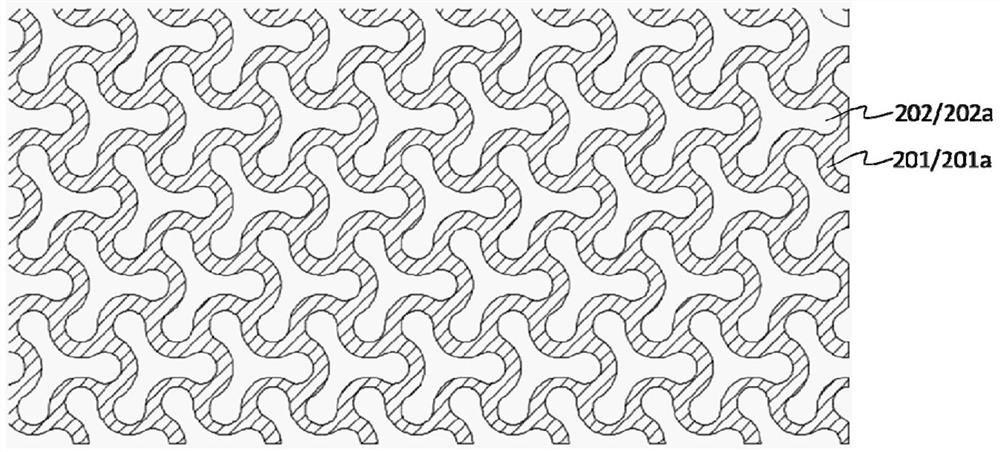

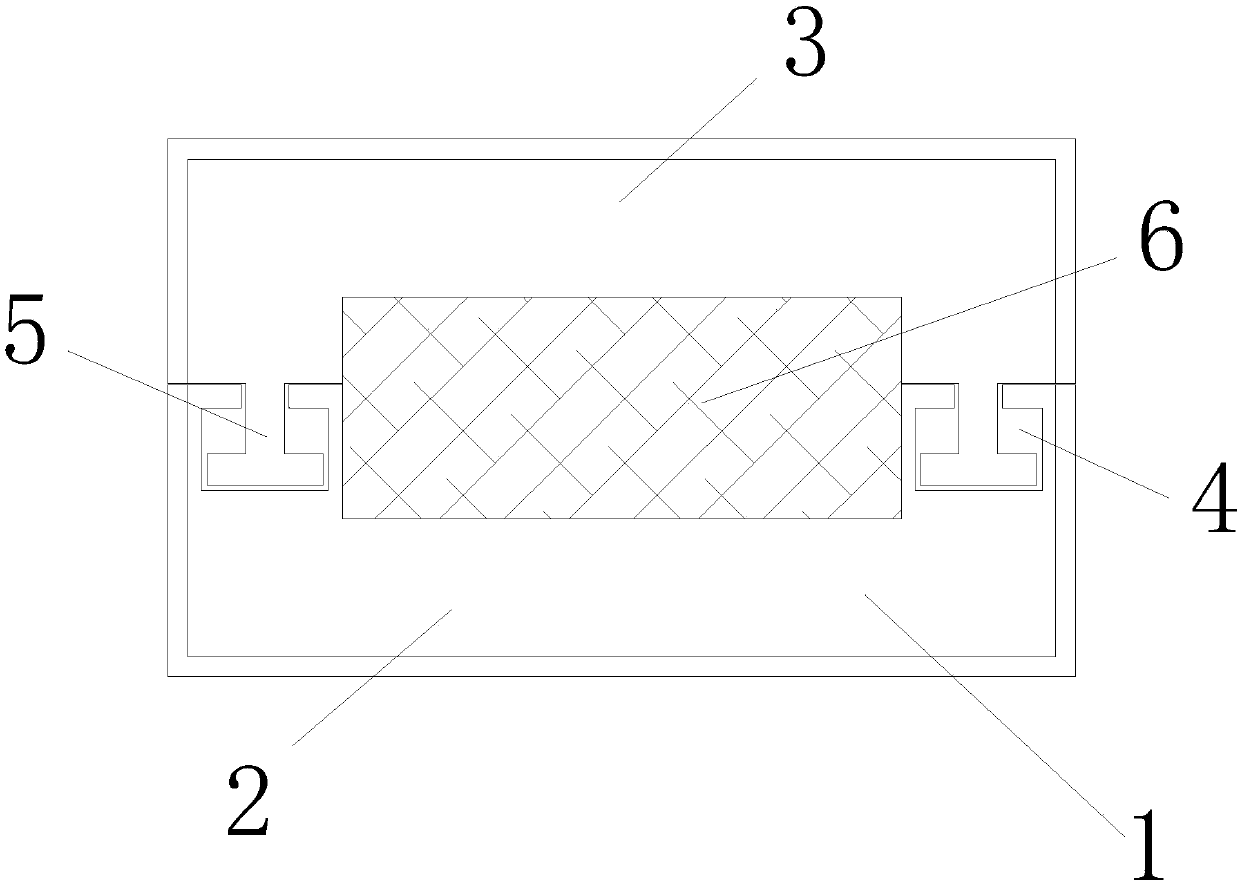

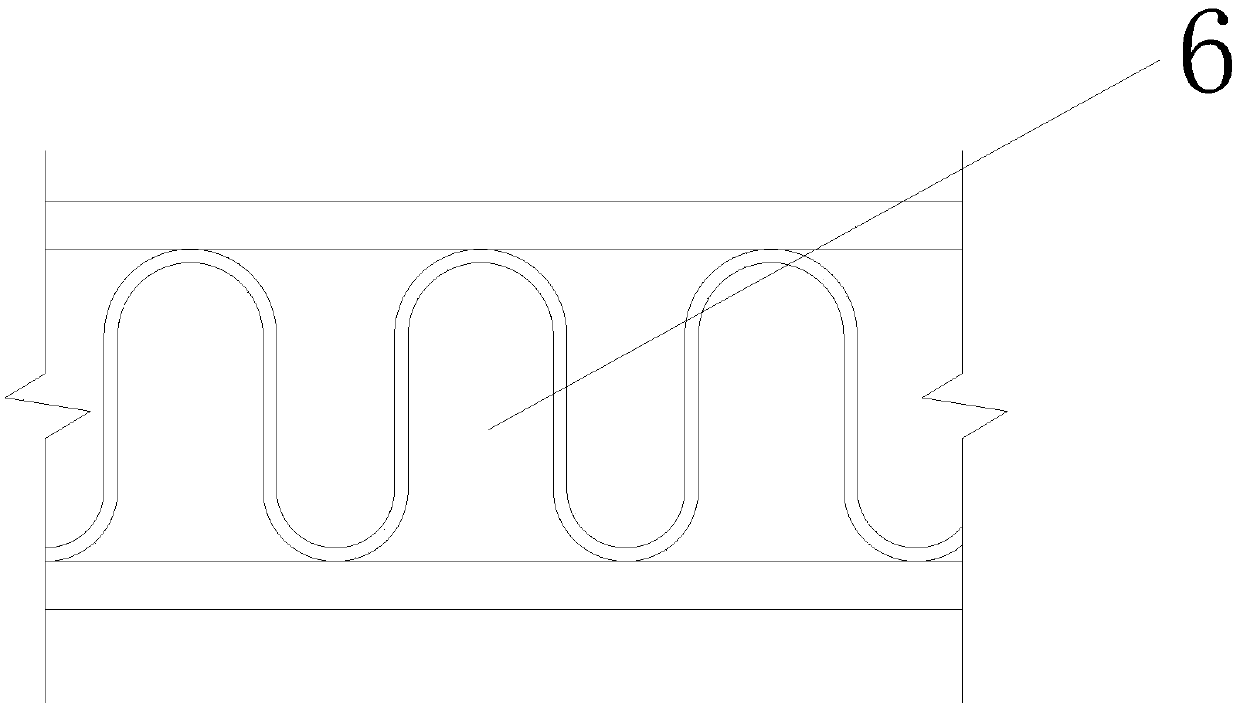

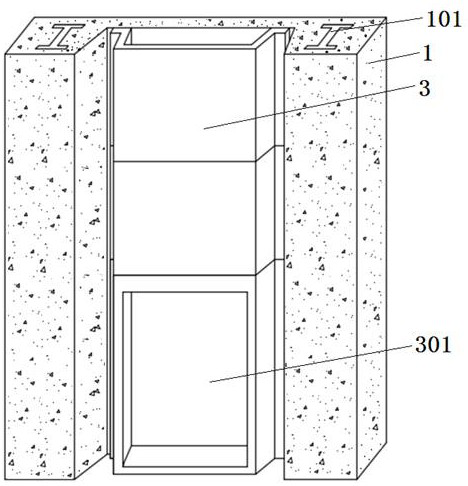

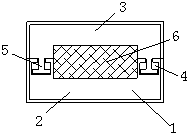

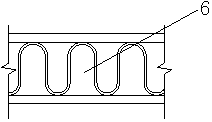

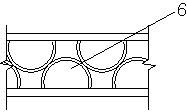

Novel composite material plate

InactiveCN109958873AReduce extrusion forceAvoid deformationSheets/panelsElastic dampersWave shapeEngineering

The invention discloses a novel composite material plate. The novel composite material plate comprises a shell, wherein the shell comprises a first shell and a second shell, the left upper end and theright upper end of the first shell are provided with grooves correspondingly, fixing pieces are arranged inside the two grooves in a sliding mode, the second shell is fixedly connected to the upper ends of the fixing pieces, and a damping body is arranged inside the shell. According to the hollow novel composite material plate, a buffer space is reserved between the first shell and the second shell by separating the shell of the plate into two parts, and the shell is supported by adding wave-shaped corrugated paper and arc-shaped elastic plates, so that the extrusion stress of the plate is reduced, and the phenomenon of deformation is avoided.

Owner:TIANJIN LONGHE STEEL ALTERED METAL PROD CO LTD

A kind of crucible and preparation method thereof

ActiveCN107573101BReduce spreadReduce defect densityPolycrystalline material growthSingle crystal growth detailsCrucibleMetal impurities

The invention provides a crucible and a preparation method thereof. The crucible comprises: a crucible body, a first coating, a second coating and a third coating, wherein the crucible body comprisesa bottom wall and a side wall; the first coating layer is arranged on the bottom wall and the side wall for preventing metal impurities from diffusing to crystalline grains in the crucible body, the second coating is arranged on the outside of the first coating layer on the side wall, the second coating layer is used to assist in nucleating the crystalline grains within the crucible body; the third coating is arranged on the outside of the first coating layer on the bottom wall, the third coating layer is used to assist in separating the crystalline grains within the crucible body from the crucible body. The crucible of the invention can effectively reduce diffusion of the metal impurities in the crucible body into polycrystalline crystals located in the crucible body, so that purity of the prepared polycrystalline silicon is high.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

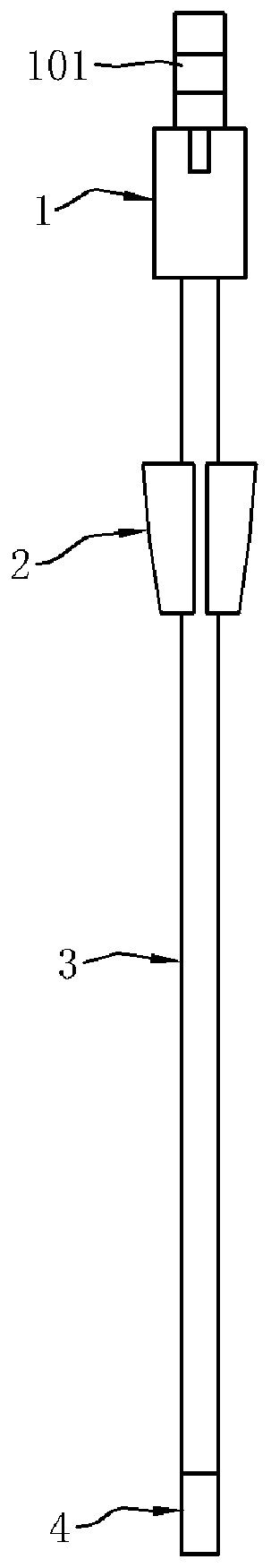

Disposable tube core for laryngoscope

PendingCN109793487AReduce extrusion forceEasy to observeBronchoscopesLaryngoscopesThroatMedical staff

The invention discloses a disposable tube core for a laryngoscope. The disposable tube core comprises a connecting terminal, a tube body, a positioner and a probe. The connecting terminal and the probe are fixedly connected at two ends of the tube body respectively, and the positioner slidably connected with the tube body is located between the connecting terminal and the probe; the connecting terminal comprises an audio connector; the probe electrically connected with the audio connector is used for acquiring image information; the frictional resistance between the positioner and the tube body prevents the positioner from sliding relative to the tube body to realize positioning; the tube body is flexible; the audio connector is connected with a connector of an external display device, andis used for transmitting the image information acquired by the probe to the display device for observation by medical staff. In the working process, the outer wall of the tube body is bent after being squeezed by the inner wall of the throat, the tube body is inserted along the throat to reduce the squeezing force on the inner wall of the throat, and operations such as shaping and epiglottis bypassing are facilitated.

Owner:宁夏赛创医疗科技有限公司

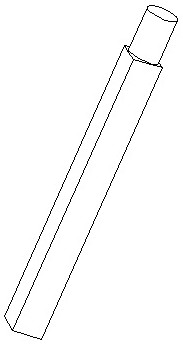

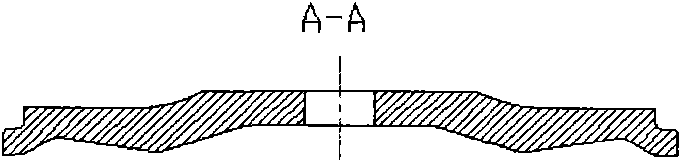

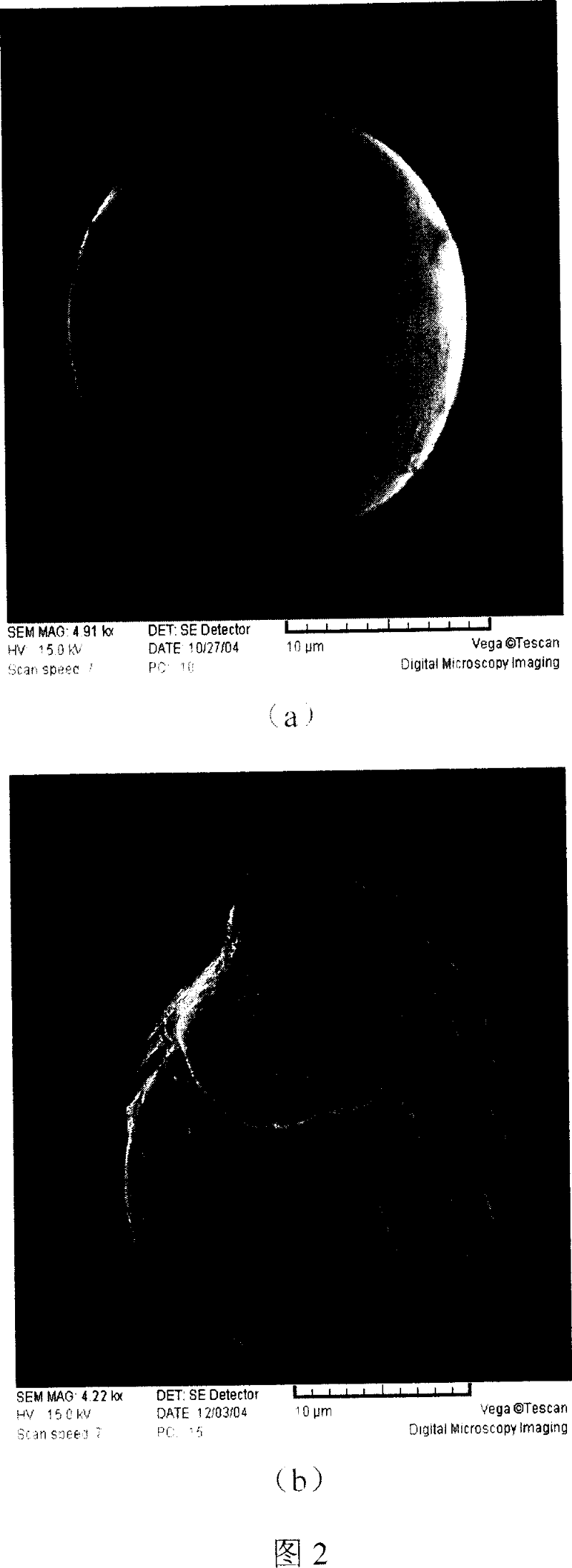

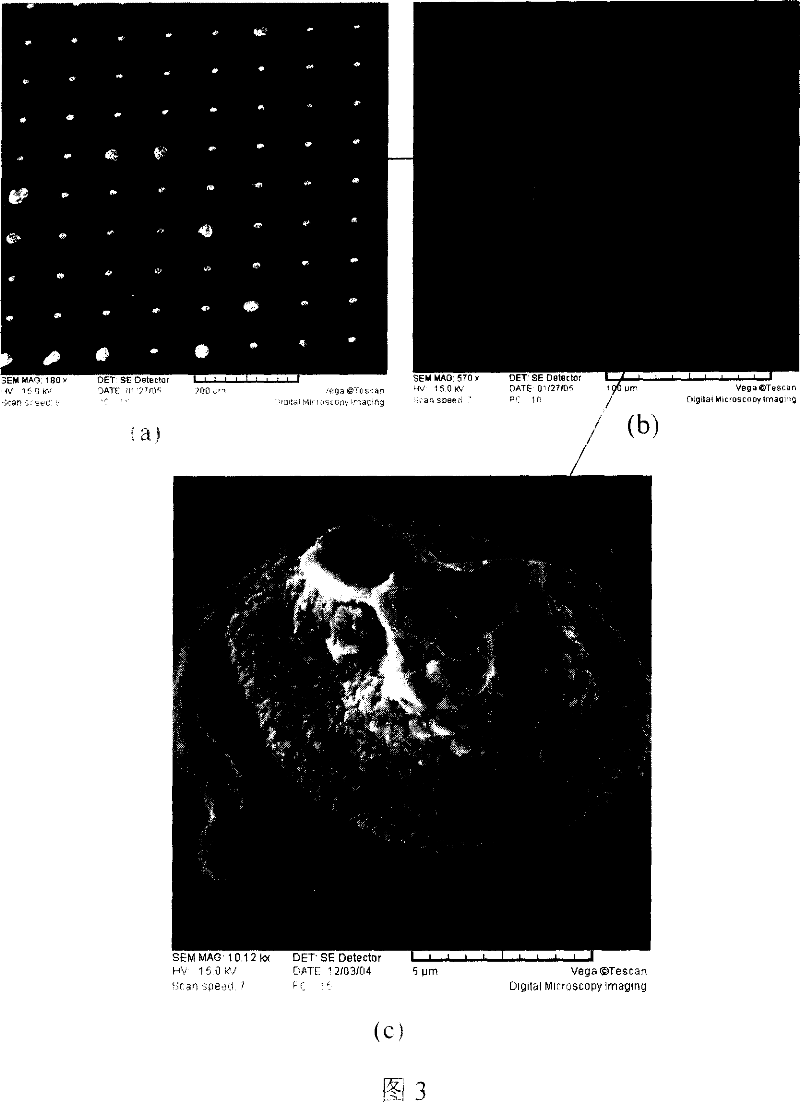

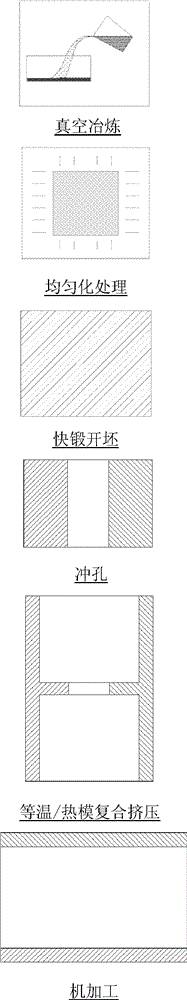

A compound extrusion preparation method of large-diameter and high-quality tube blank or ring blank

ActiveCN103170797BImprove thermoplasticityIncrease profitMetal-working apparatusPolymer scienceIngot

The invention relates to a compound extrusion preparation method of a large-diameter high-quality tube blank or an annular blank. The compound extrusion preparation method is mainly aimed at materials which are large in deformation resistance, narrow in heat processing temperature range, difficult in heat processing, and difficult to deform. The compound extrusion preparation method comprises the following steps: (1) a high-quality ingot blank with high purity is prepared through a vacuum melting process; (2) homogenization treatment is carried out alternatively, multi-pass pier drawing fast forging cogging-down is carried out, an organization is refined, and the homogeneity of the organization is improved; (3) hollow blank material is prefabricated in a punch mode; (4) isothermality / heat molding compound extrusion is carried out on the prefabricated hollow blank material, the tube blank with the uniform and thin organization is prepared; and (5) subsequent machining is carried out, and a finished tube (ring) and the high-quality ingot blank are obtained. The novel preparation method is used for preparing the large-diameter tube (ring) blank with the uniform and thin organization. The preparation method is labor-saving in shaping, energy-saving, high in material utilization rate, high in product quality, and capable of resolving the problems that a tube (ring) blank prepared through a traditional process is thick in organization, poor in uniformity, large in shaping force and the like.

Owner:GRIMAT ENG INST CO LTD

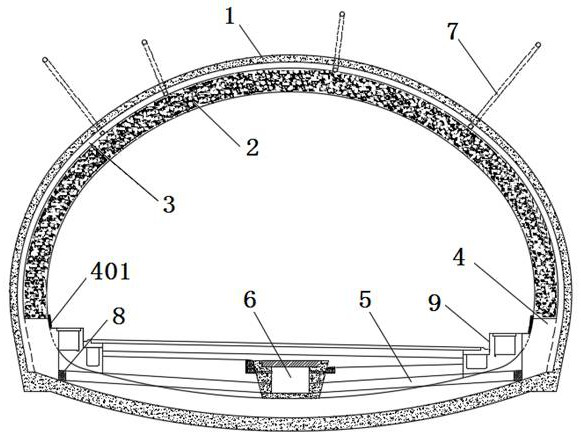

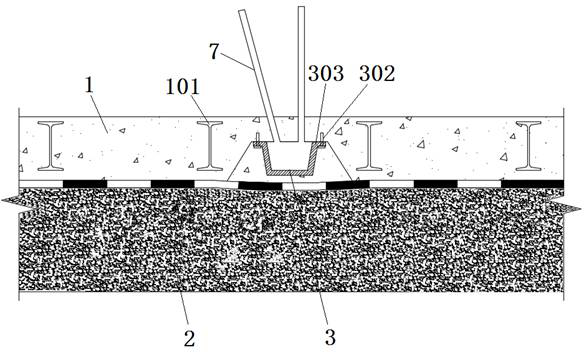

Tunnel diversion system suitable for water-rich stratum and construction method

PendingCN114151130AHigh structural reliabilityImprove layout flexibilityUnderground chambersDrainageWater flowOutfall

The invention discloses a tunnel diversion system suitable for a water-rich stratum and a construction method. The tunnel diversion system comprises an annular channel steel structure which is arranged between two truss I-shaped steel of a primary support and corresponds to the outline of a tunnel. Water outlets in the two ends of the annular channel steel structure communicate with the center drainage ditch through the side wall water collecting wells and the transverse buried grooves in sequence. In the tunnel excavation process, it is found that strand-shaped water flows out of the surrounding rock surface or the primary support surface, a water outlet and drainage groove can be formed between two truss I-shaped steel in front of and behind a concentrated water outlet point, and an annular channel steel structure is arranged in the drainage groove for water drainage. According to the method, construction is simple, pre-judgment expanding excavation is not needed, universality is high, the annular channel steel structure is buried in the gap between the two truss I-shaped steel for drainage, the annular drainage capacity of the tunnel and the reliability of the drainage structure are greatly improved, the drainage requirement of the water-rich stratum tunnel can be effectively met, and practicability is high.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

Composite metal plate

InactiveCN106337545AReduce extrusion forceAvoid deformationCovering/liningsProtective buildings/sheltersEngineeringMetal

The invention discloses a composite metal plate, which comprises a shell, wherein the outer shell comprises a first shell and a second shell; and the left side upper end and the right upper end of the first shell are each provided with a groove, and the inside of the two grooves is slidably mounted with a fixing part, the upper end of the fixing part is fixedly connected with the second shell, the inside of the shell is provided with a shock absorber, and the hollow composite metal plate is divided into two parts, and a buffer space is reserved between the two shells, and the shell is supported by adding corrugated paper and arc elastic plate, so as to reduce the pressing force of the plate and avoid the deformation.

Owner:TIANJIN LONGHE STEEL ALTERED METAL PROD CO LTD

Extrusion die and method for extrusion molding inside and outside reduction blank by same

Owner:HARBIN JIANCHENG GRP

A display module and mobile terminal

ActiveCN113470522BReduce the degree of deformation and sagGood buffer protectionDigital data processing detailsSynthetic resin layered productsComputer hardwareFlexible display

This application proposes a display module and a mobile terminal; the display module includes a display area and a non-display area located on one side of the display area, and a support part is arranged in the non-display area, and a support part is located on the support part A flexible display panel on the flexible display panel, the flexible display panel includes a bending portion, a flexible cover layer on the flexible display panel, and a first flexible filler between the bending portion and the flexible cover layer part; this application sets the first flexible filling part between the bending part and the flexible cover layer in the non-display area to fill the gap between the flexible cover layer and the flexible display panel, thereby reducing the flexible cover The extruding force of the plate layer on the flexible display panel improves the problem of line breakage on the flexible panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD +1

Ear acupuncture magnetic therapy health device

InactiveCN110353981AIncrease the areaReduce areaDevices for pressing relfex pointsAcupuncturePhysical therapy

The invention discloses an ear acupuncture magnetic therapy health device. The ear acupuncture magnetic therapy health device comprises two magnet units having an embossed cross section, wherein one end of the magnet unit protruding outward is an N pole, and the other end of the other magnet unit protruding outward is an S pole. The ear acupuncture magnetic therapy health device has the advantagesof small volume, light weight, convenient carrying, simple structure, convenient use and no pain, low cost and high comfort, and no need of a professional physician, a user can complete the treatmentby self-operation, and the effect is obvious.

Owner:包云鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com