Wire inserting mold of motor stator iron core

A technology for inserting wire molds and motor stators, which is used in the manufacture of motor generators, electrical components, electromechanical devices, etc., and can solve the problems of enameled wire strain, uneven winding movement, and large winding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

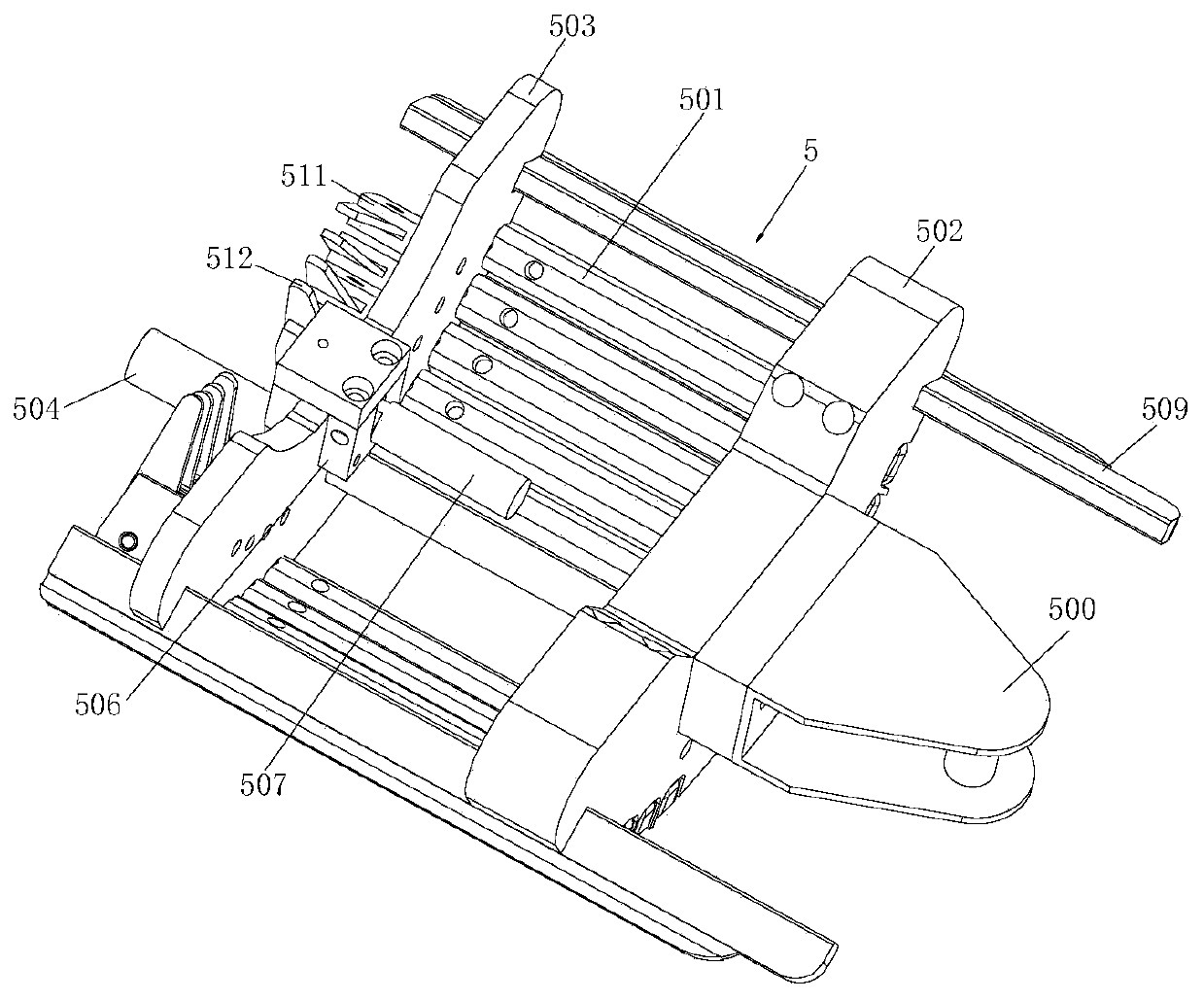

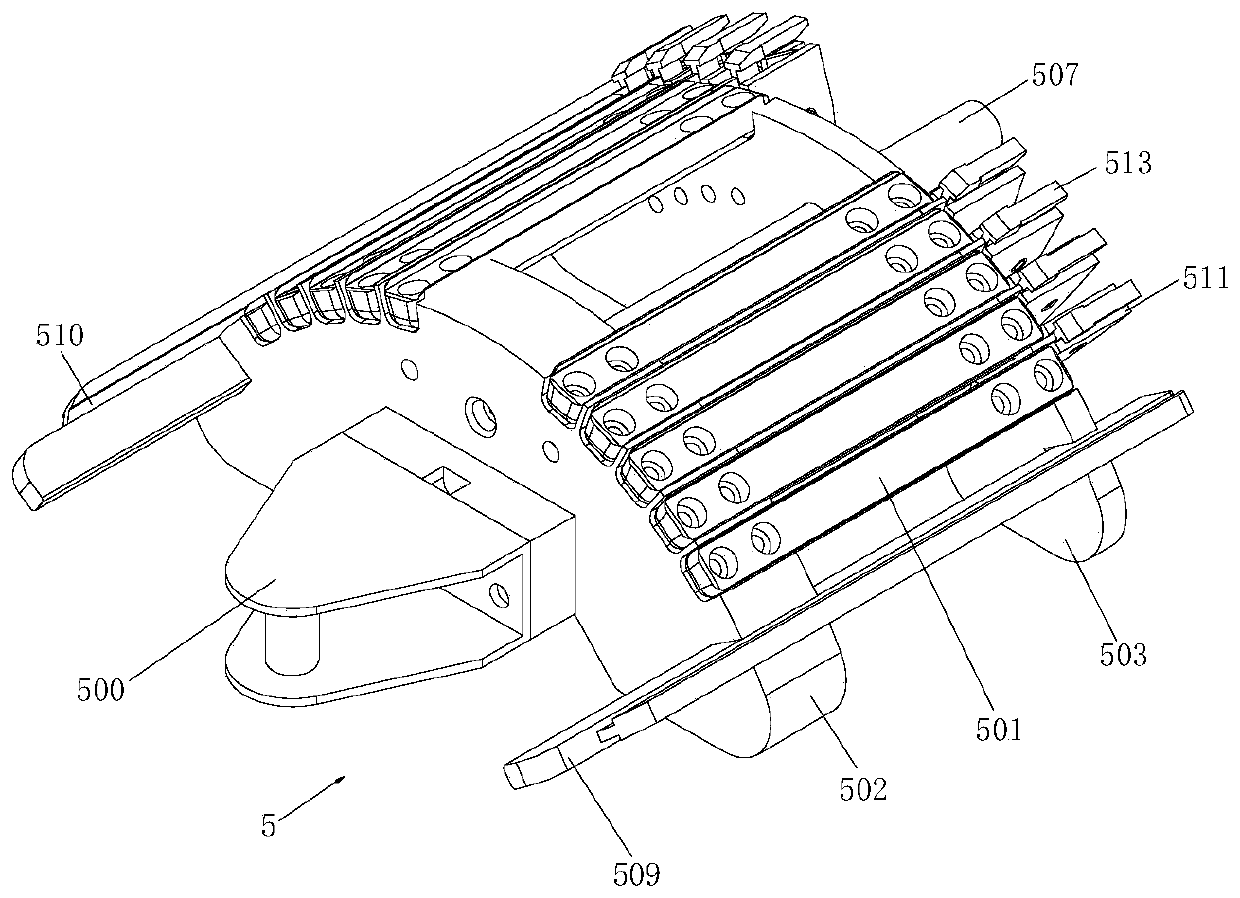

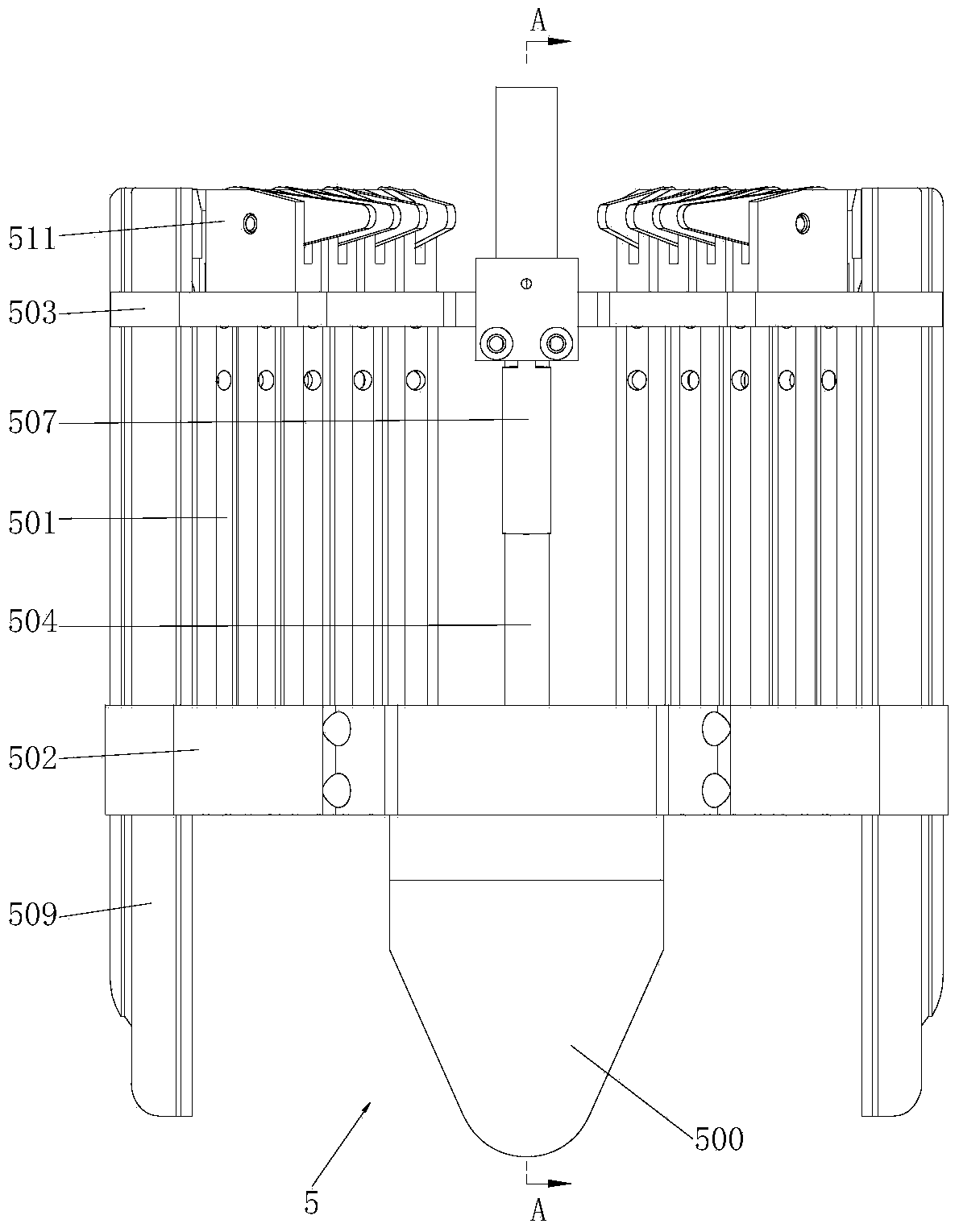

[0021] refer to Figure 1 to Figure 4 , The wire embedding mold of the motor stator core of the present invention includes a guide bar 501, a waist-shaped base 502, a waist-shaped cover plate 503, a connecting rod 504 and a locking device. The axial end surface of the base 502 away from the cover plate 503 is provided with a draw hook seat 500 connected to the pull wire device, and the draw hook seat is used to connect the pull hook in the pull wire device. The outer peripheral surfaces of the base 502 and the cover plate 503 are evenly provided with slots at intervals, one end of the guide bar 501 is fixed in the slot of the base 502, and the other end of the guide bar 501 is gap-fitted in the slot of the cover plate 503, and the guide bar 501 is used to articulate the stator windings. As can be seen from the schematic diagram of the wire embedding die 5 of the present invention, at most two packs of windings can be hung on the wire embedding die (each phase of the motor cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com