Pre-diverging-wedge pressing precision forming die and disc forming method

A precision forming and pre-splitting technology, applied in the direction of metal extrusion dies, etc., can solve the problems of large forming force, high equipment tonnage requirements, high manufacturing cost, etc., to reduce extrusion forming force, reduce contact area, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

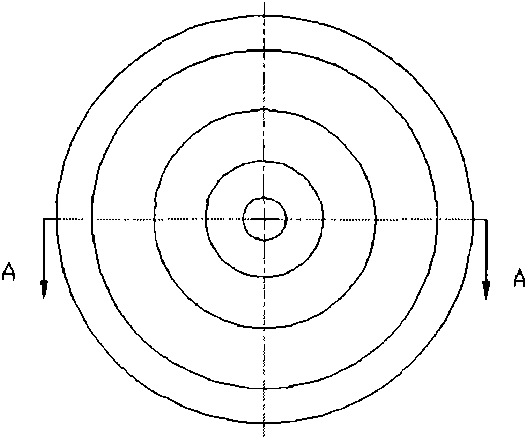

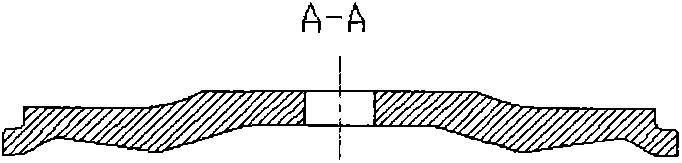

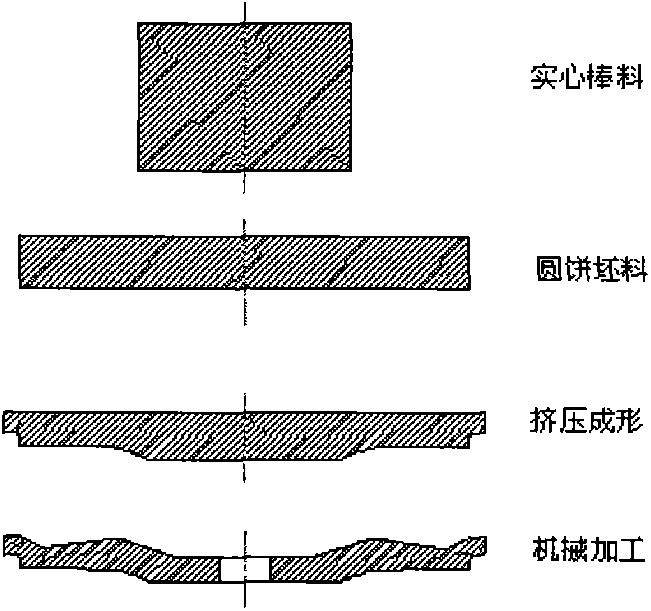

[0033] This embodiment is used to form the outer diameter of 480mm, the inner diameter of 50mm figure 1 The LC4 aluminum alloy disc of the structure shown. The mold includes: a pre-split die, a wedge die, a punch mandrel and a template to form an extrusion punch, and a die.

[0034] Specific steps when using this mold:

[0035] Step 1: Heat the assembled precision extrusion mold to 370°C±5°C and keep it warm for 4-5 hours, then assemble the punch and die on the forming hydraulic press, and place the mold and hydraulic press table and slide Install thermal insulation pads on the block contact surface.

[0036] Step 2: Put the LC4 aluminum alloy ring blank (outer diameter 425±2mm, inner diameter 248±2mm, height 75±2mm) heated to 370°C±5°C and keep warm for 2-3 hours into the die, and start the hydraulic press Perform precision extrusion molding.

[0037] Step 3: Remove the load of the hydraulic press, and after the upper slider of the hydraulic press returns, the formed part...

Embodiment 2

[0039] This embodiment is used to form the outer diameter of 480mm, inner diameter of 50mm figure 1 The AZ80 magnesium alloy disc of the structure shown. The mold includes: the mold includes: a pre-split mold, a wedge die, a punch mandrel and a template to form an extrusion punch, and a die.

[0040] Step 1: Heat the assembled precision extrusion mold to 390°C±5°C and keep it warm for 4-5 hours, then assemble the punch and die on the forming hydraulic press, and place them on the mold and the hydraulic press table and slide Install thermal insulation pads on the block contact surface.

[0041] The second step: put the AZ80 magnesium alloy ring blank (outer diameter 425±2mm, inner diameter 248±2mm, height 75±2mm) heated to 380°C±5°C and held for 2-3 hours into the die, and start the hydraulic press Perform precision extrusion molding.

[0042] Step 3: Remove the load of the hydraulic press, and after the upper slider of the hydraulic press returns, the formed part is ejected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com