Tunnel diversion system suitable for water-rich stratum and construction method

A water-rich stratum and tunnel construction technology, applied in tunnels, tunnel linings, drainage, etc., can solve the problem of water-rich sections of surrounding rocks that are not enough to deal with concentrated strands of water, affecting the smoothness of the tunnel drainage system and the drainage capacity of the waterproof and drainage system Limitation and other problems, to achieve the effect of eliminating the risk of extrusion deformation, low construction cost, and low space occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that preferred embodiments are intended to illustrate the invention, not to limit the scope of the invention.

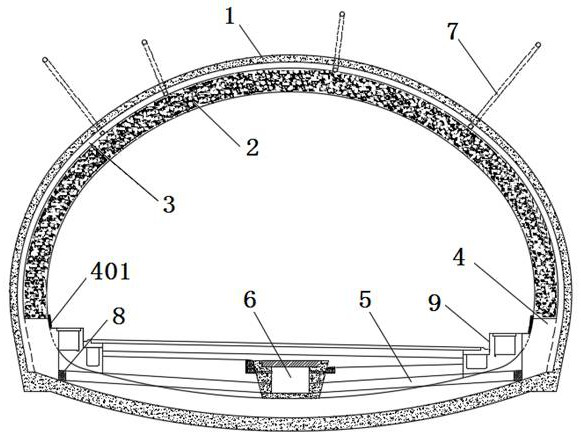

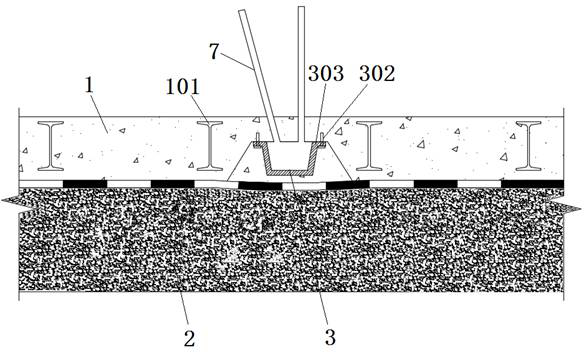

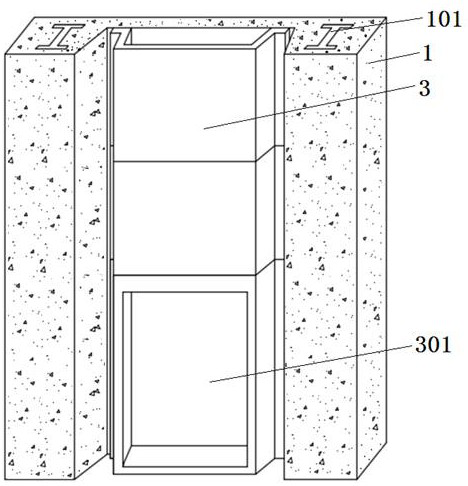

[0041] Such as Figure 1 - Figure 5 As shown, a tunneling system suitable for the rich floors, including a ring groove structure 3 that is provided between the initial support 1 two 榀 字 字 101 and corresponding to the tunnel profile; the annular groove steel structure 3 two The end is provided with a water port 301, and the water port 301 is in turn through the side wall collector 4, and the lateral dark groove 5 is in communication with the central drain 6.

[0042]Surrounding the tunnel equipped with a number of radial or diagonal structure of the drain hole 3 an annular channel 7 of communication. The radial or oblique drain provides a drain passage in the vicinity paragraph. According to the flexible setting of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com