A multi-convex step-by-step reverse extrusion forming method

A reverse extrusion and punch technology, which is used in hot extrusion, cold metal material, reverse extrusion of large hollow parts, and warm fields. It can solve the problem of large forming force, poor mold versatility, and increased mold closure Height and other issues, to reduce the extrusion force, enhance the versatility of the mold, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The specific implementation is described in detail below in conjunction with the drawings (this embodiment is a further description of the present invention, rather than any limitation on the present invention).

[0033]The present invention is a stepwise reverse extrusion molding method with multiple punches

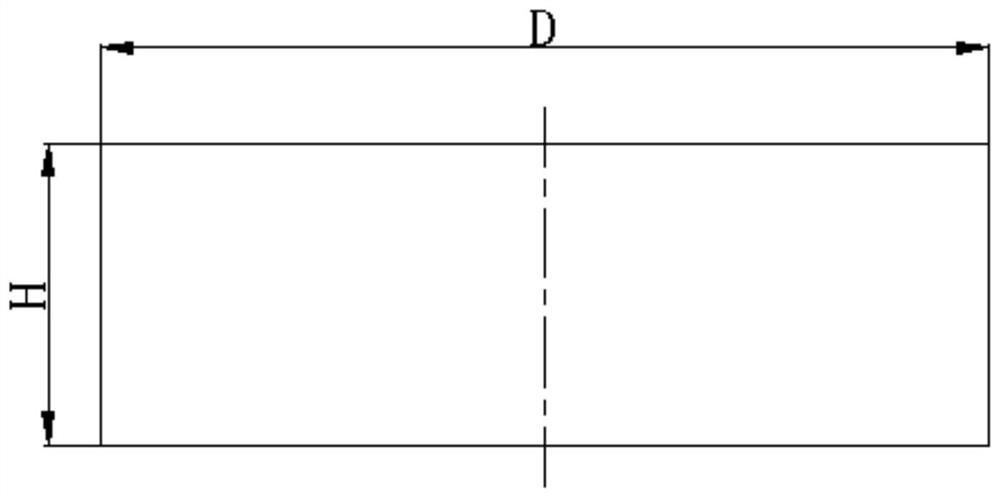

[0034]figure 1 As shown, the blank for multi-punch reverse extrusion molding of the present invention has an outer diameter of D and a height of H, which are obtained by the blanking process.

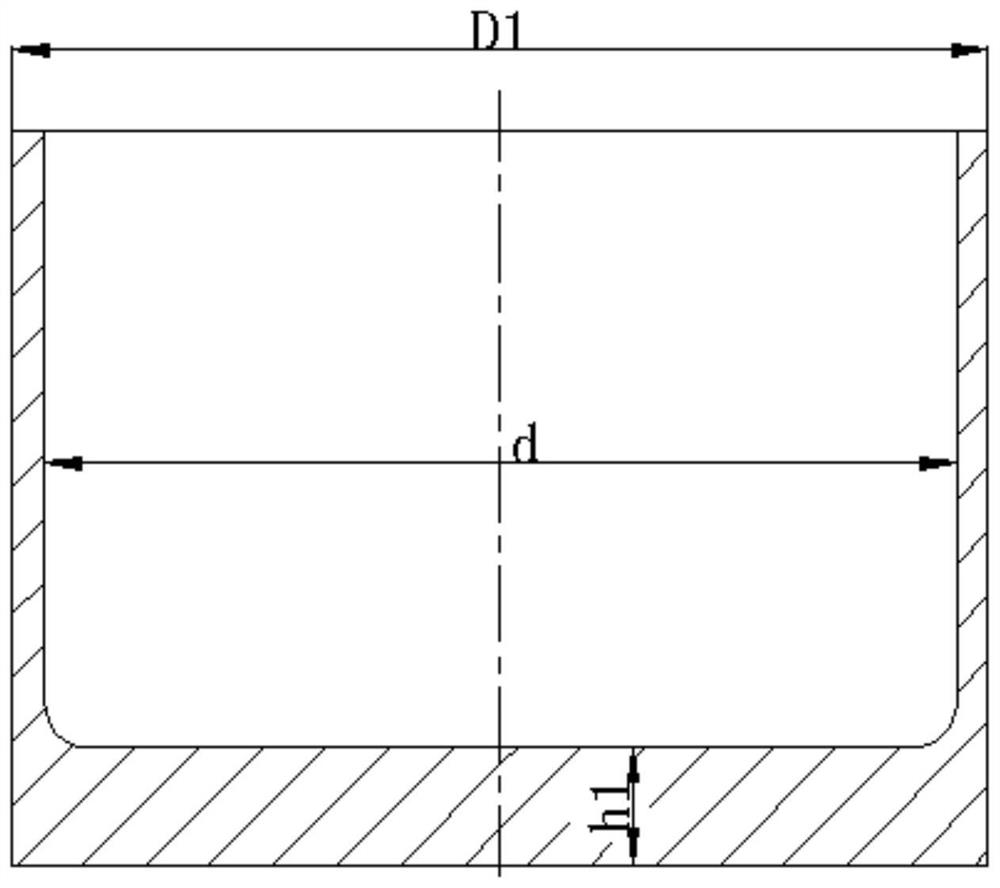

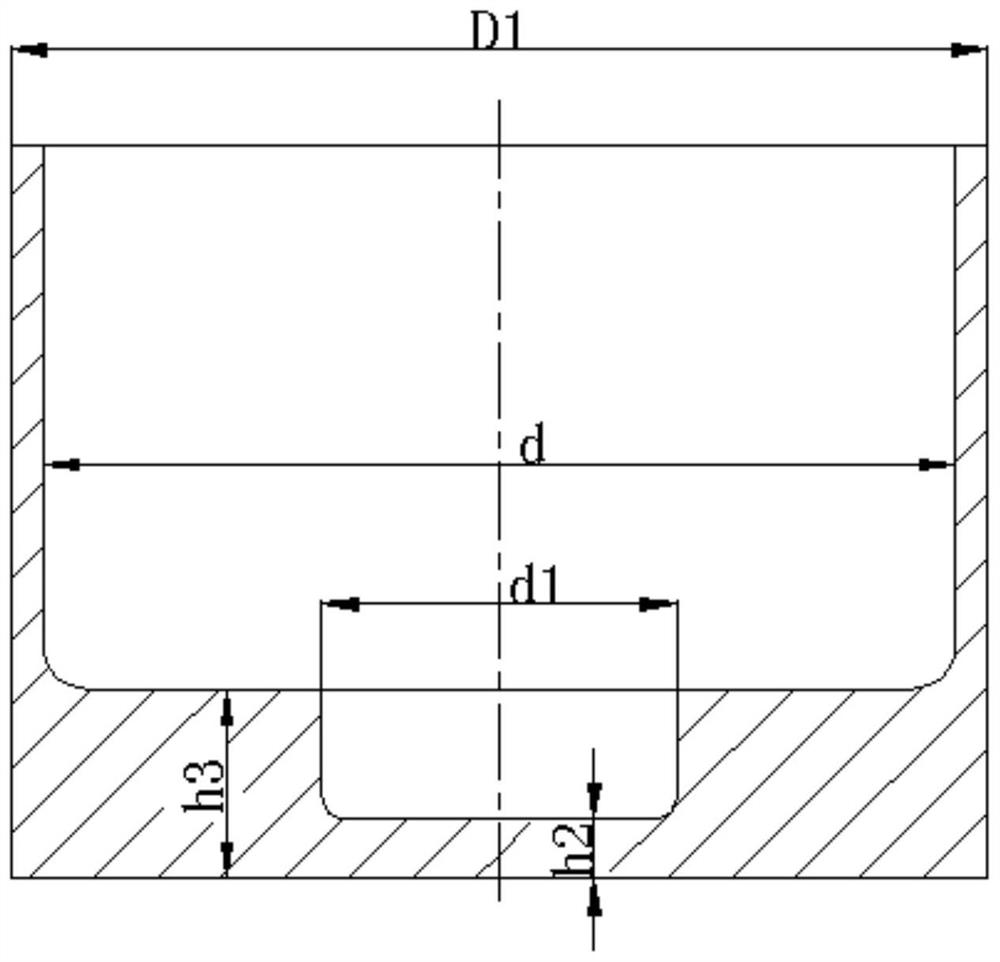

[0035]figure 2 ,image 3 andFigure 4 As shown, the workpieces formed by the stepwise reverse extrusion of the multi-punch mold of the present invention are a solid flat-bottomed extrusion piece, a solid concave-bottomed extrusion piece, and a solid convex-bottomed extrusion piece. among them:

[0036]figure 2 It is a solid flat-bottomed extrusion with an outer diameter of D1, an inner diameter of d, and a bottom thickness of h1;

[0037]image 3 It is a solid concave bottom extrusion, its outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com