Back-flow pulling face down welding method of infrared focus planar detector

A technology of infrared focal plane and welding method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to achieve precise control of In bumps, improve mechanical and electrical properties, and reduce extrusion. strength, the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Taking a preferred embodiment as an example below, the specific implementation manner of the present invention is described in further detail:

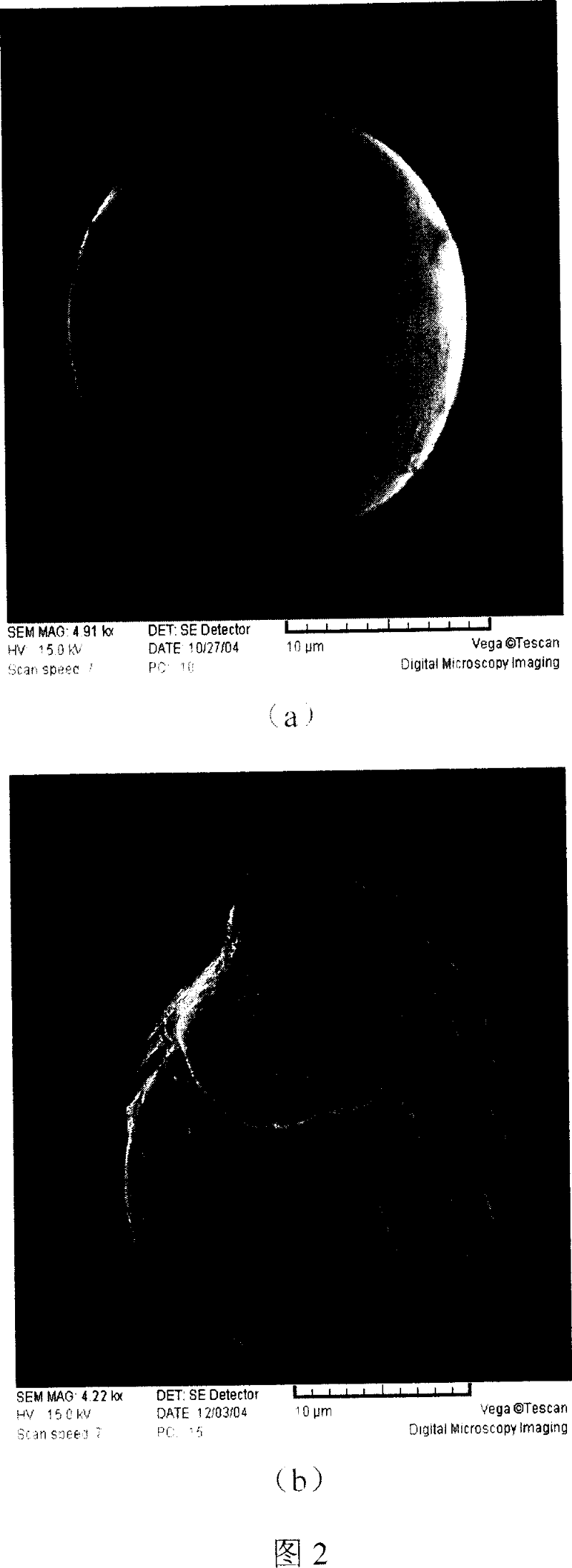

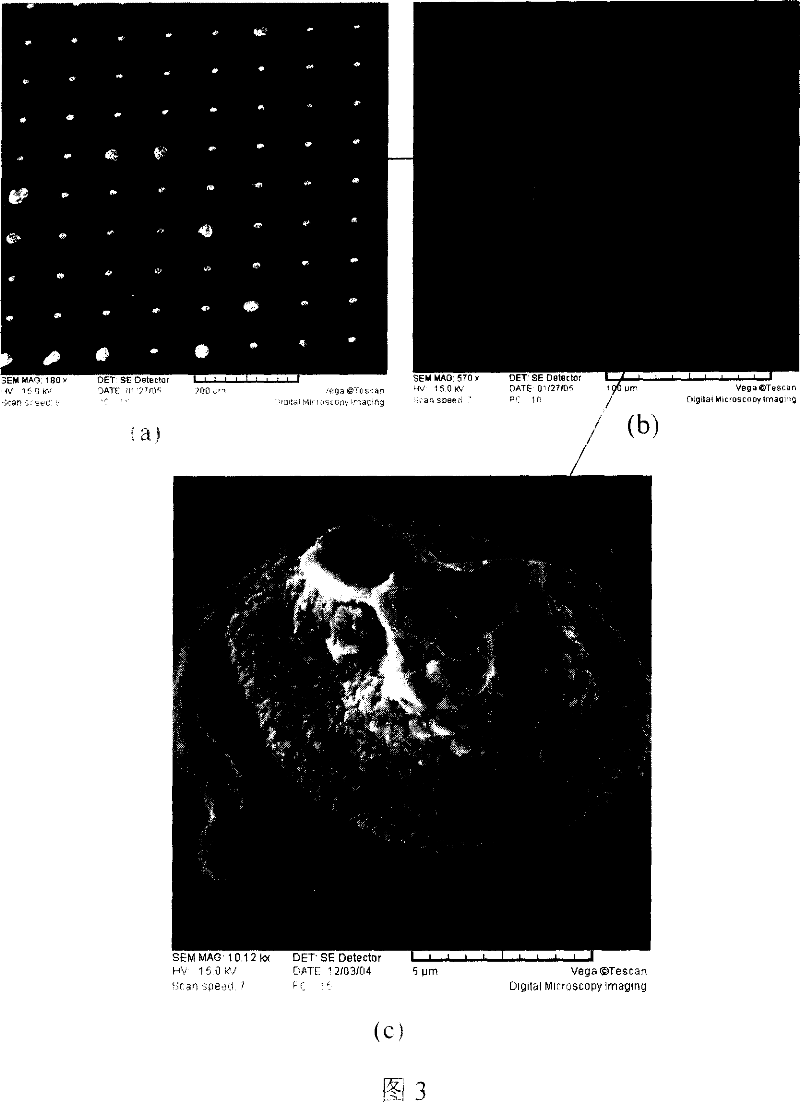

[0023] Flip-chip soldering sample of the present invention: the area of the silicon readout circuit is 6×9mm 2 , a total of 2040 In ball arrays, and the area of the HgCdTe photosensitive array chip on the GaAs substrate is 4×6mm 2 , also prepared 2040 Cr / Au soldering pad arrays. Among them, the height of the In bump is 16.5 μm, the diameter is 19.5 μm, and the diameters of the welding pressure point and the In bump are both 14 μm.

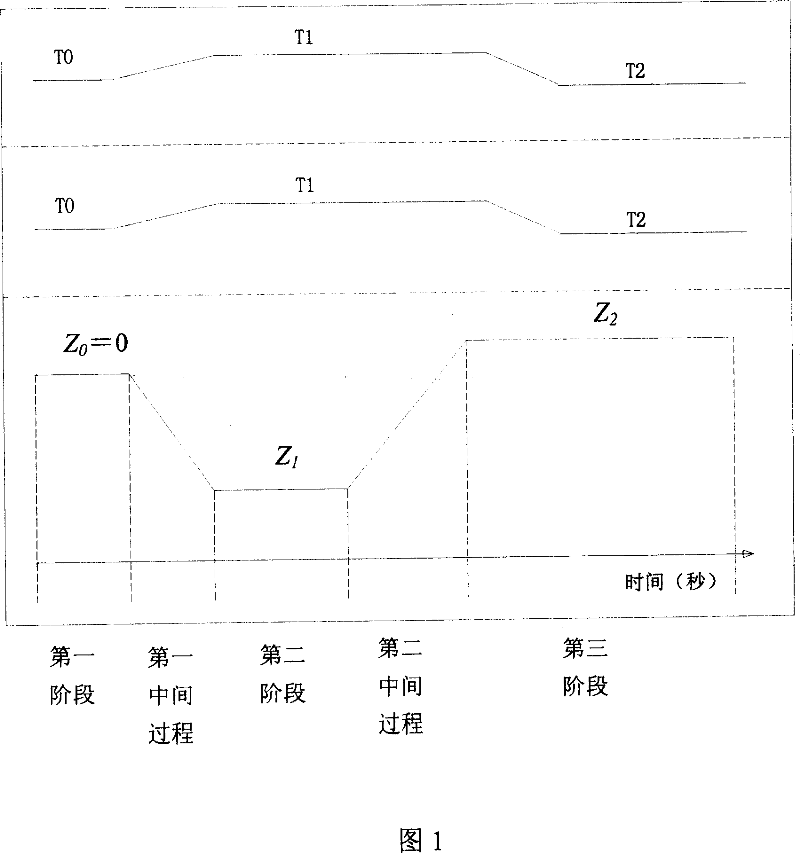

[0024] Install the above-prepared In ball array silicon readout circuit and the array chip with soldering pads on the French SUSS company model FC150 flip-chip welding equipment, and perform single-sided In ball reflow pull-up welding, as shown in Figure 1 :

[0025] A. The first stage: the silicon readout circuit and the array chip start to contact and maintain the contact state.

[0026] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com