Extrusion die and method for extrusion molding inside and outside reduction blank by same

A technology for extruding dies and billets, which is applied in the field of dies and extruded billets by using the dies, can solve the problems of large external shape diameter, long axial length, small bottom inner diameter, etc., to improve utilization rate, facilitate mold release, The effect of reducing the closing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

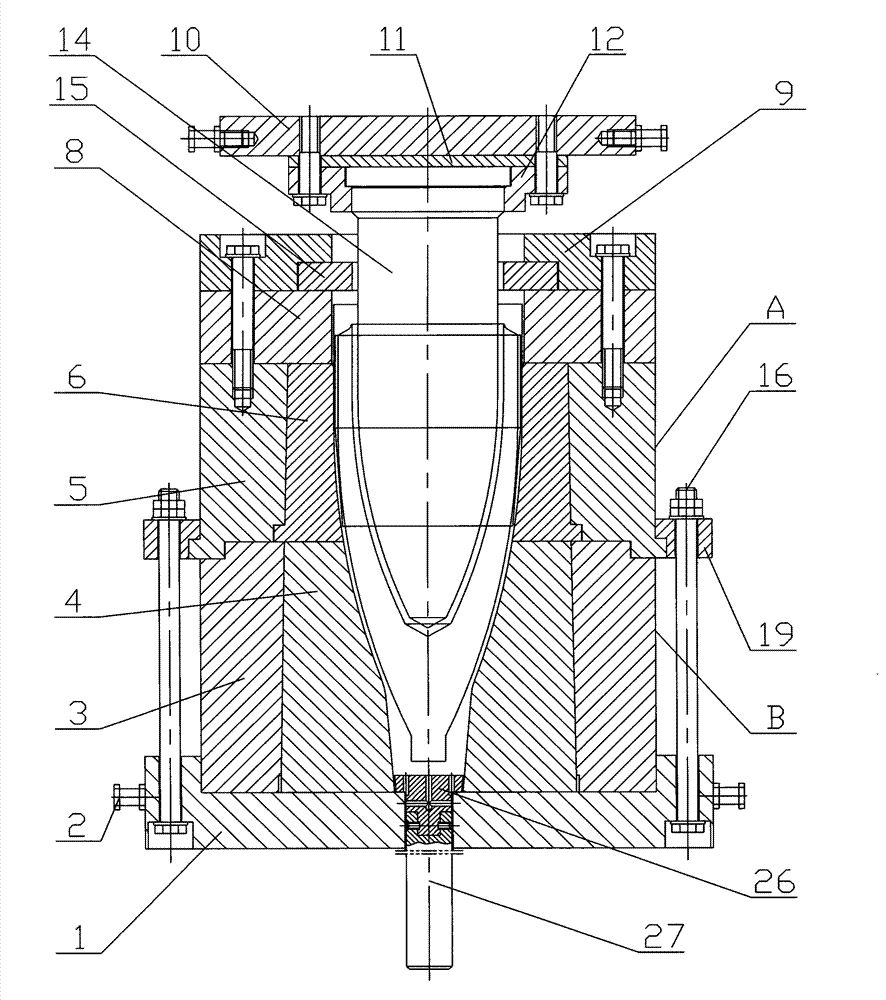

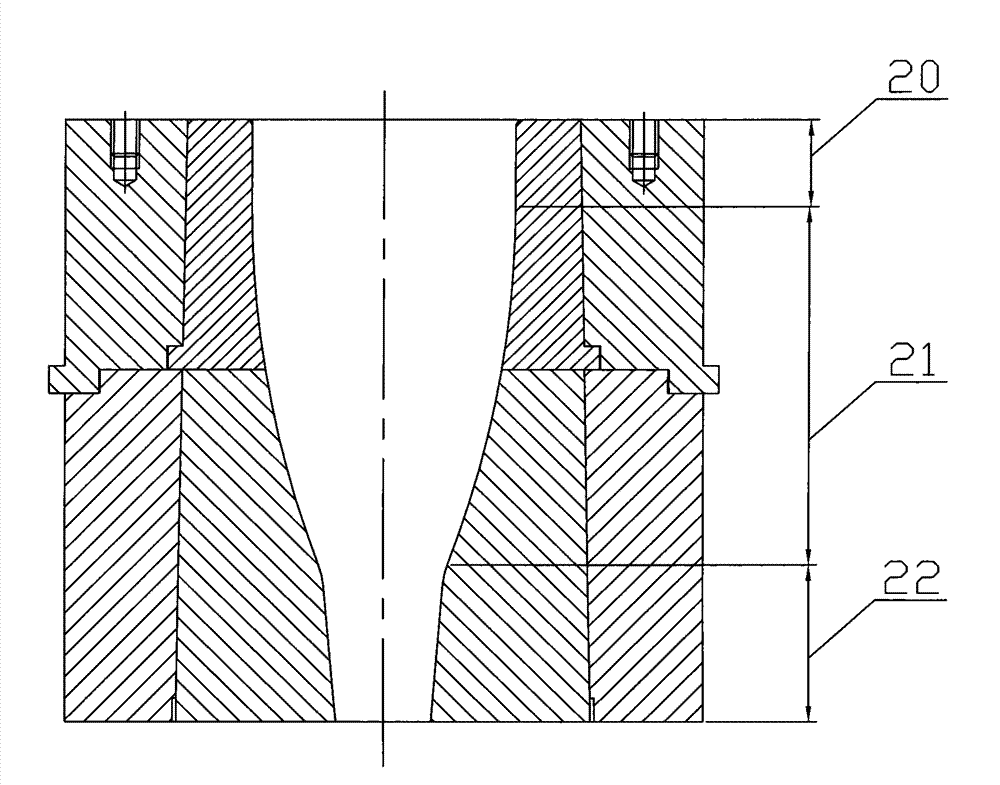

[0015] Specific implementation mode 1: Combination Figure 1-Figure 4 with Figure 7 Explain that the extrusion die of this embodiment is composed of an upper die seat 10, a backing plate 11, a punch fixing plate 12, and a punch 14; the lower die includes a lower die seat 1, a first prestressing ring 5, and a first lower die 6. , The second prestressing ring 3, the second lower mold 4, the cushion block 8, the stripping plate 9, the stripping card plate 15, the pressure ring 19, the ejector plate 26, the ejector rod 27, three to four hanging mold rings 2 And a plurality of connecting components 16; the first prestressing ring 5 is sleeved on the first lower mold 6, and the two interference fits form the first component A, the second prestressing ring 3 is sleeved on the second lower mold 4, and The interference fit of the two forms the second component B. The second component B is installed on the lower mold base 1. Three to four lifting mold rings 2 are evenly distributed on th...

specific Embodiment approach 2

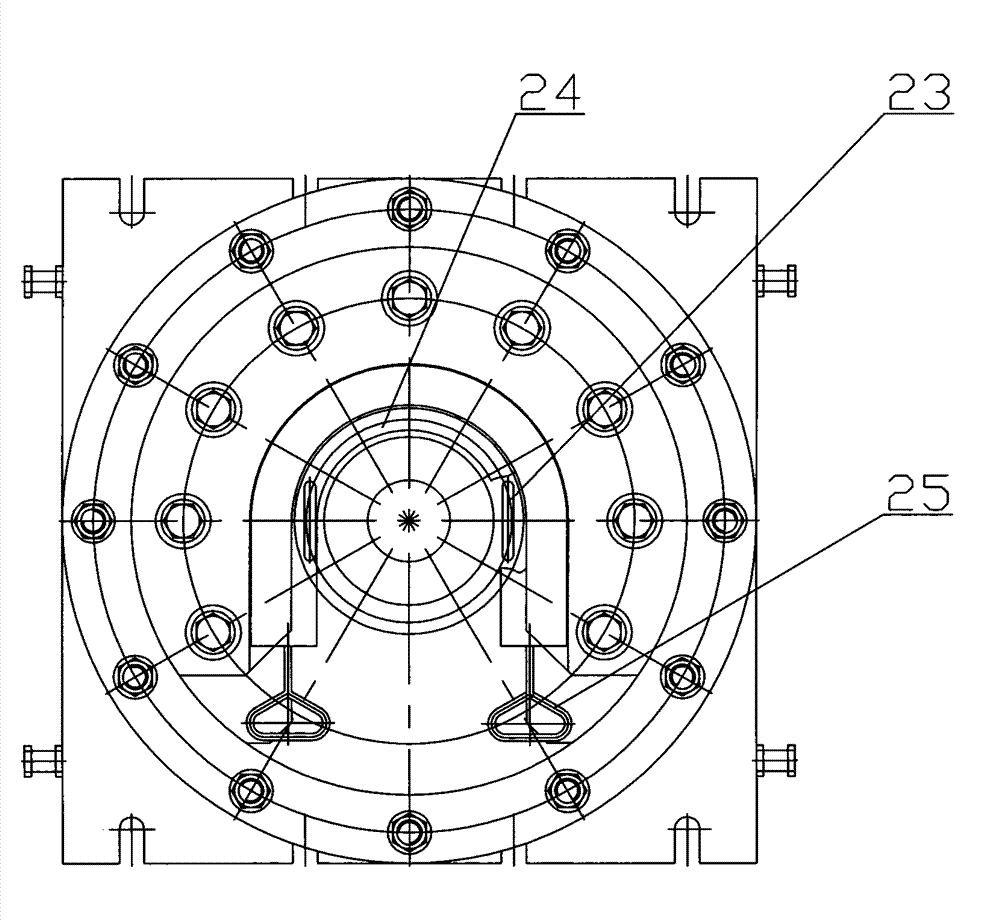

[0016] Specific implementation manner two: combination figure 1 with figure 2 Explain that the lower mold of this embodiment also includes a mold ring 24 and two mold ring handles 23; the mold ring 24 is set in the lower mold cavity, and the punch 14 passes through the mold ring 24 and is set in the lower mold cavity. The mold ring handle 23 is symmetrically arranged with respect to the center axis of the mold ring 24, and the two mold ring handles 23 are screwed to the upper end surface of the mold ring 24. The purpose of the die ring 24 is to make the upper and lower dies coaxial when the extrusion die is installed on the equipment, and it is removed after the extrusion die is installed, and the extrusion die is not used when it is working. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 2 It is explained that the lower mold of this embodiment also includes two return card handles 25; the two return card handles 25 are set in one-to-one correspondence with the two ends of the U-shaped return card, and the return card handle 25 is The ends of the U-shaped return card are screwed together, which is convenient for the operator to take and place. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com