Drawing Die Inserting Machine for Motor Stator Core

A technology of motor stator and wire inserting machine, which is applied in the field of drawing die inserting machine, and can solve problems such as complex structure of indexing device, large winding resistance, and unsmooth winding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

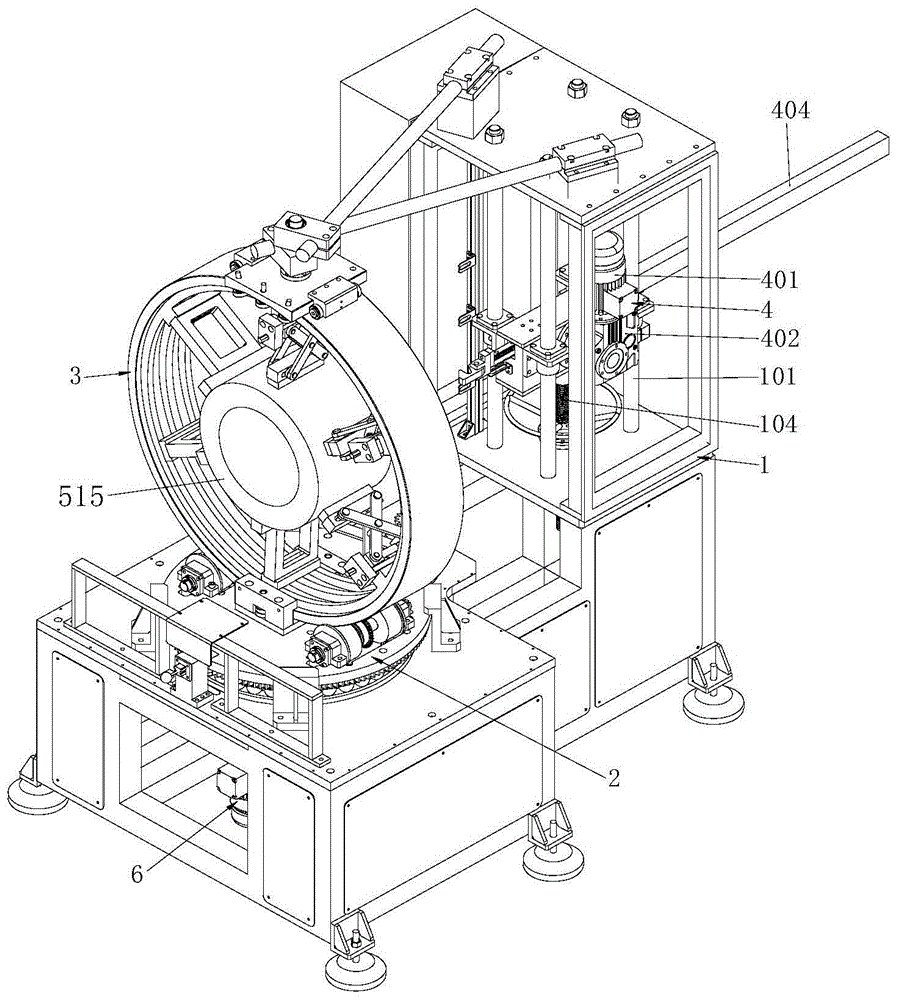

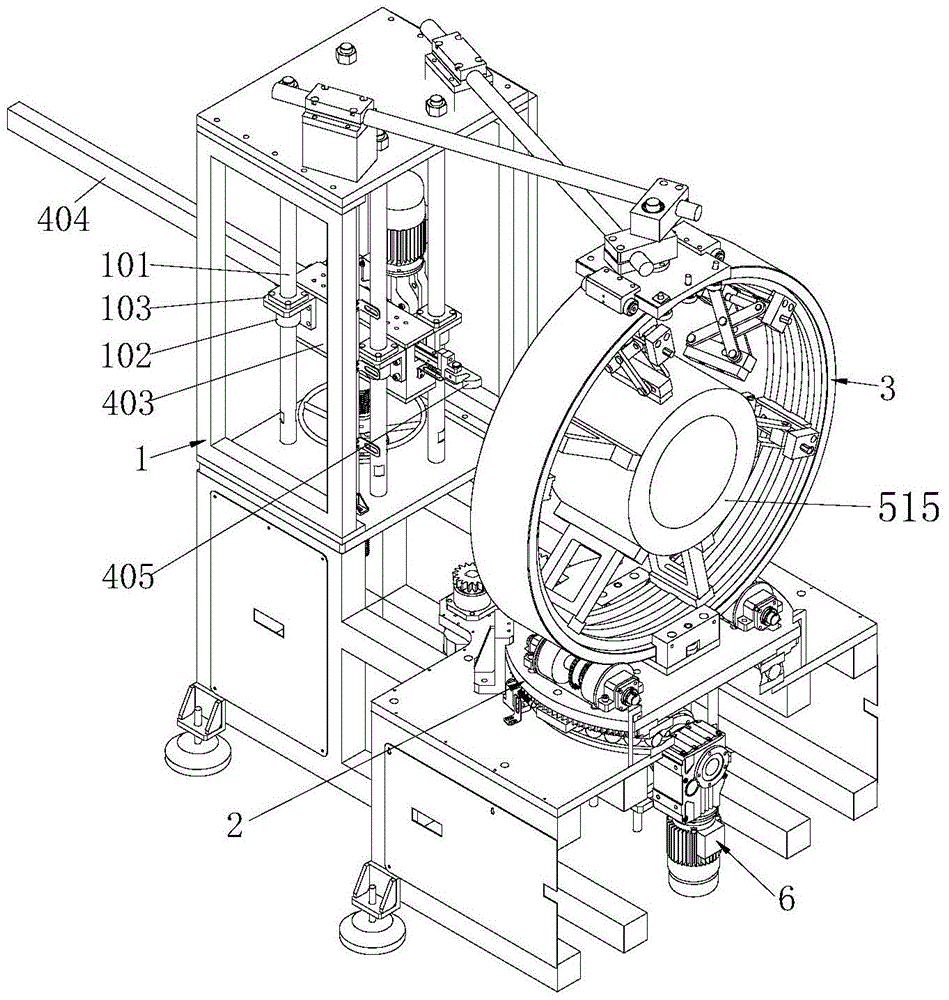

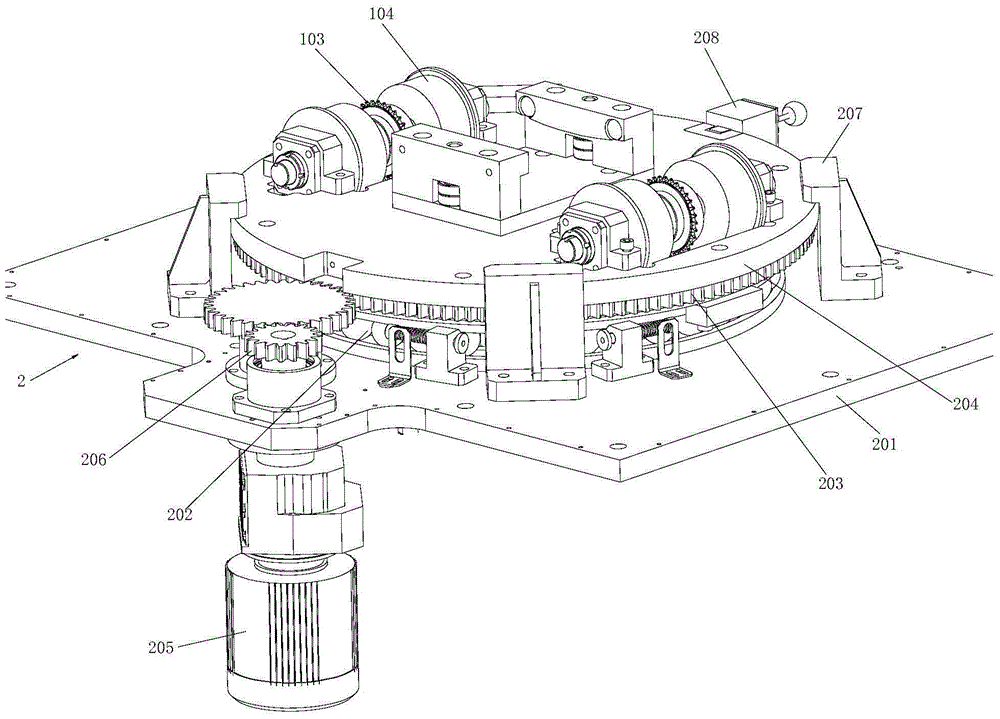

[0038] see figure 1 , a drawing die inserting machine for motor stator core, including a frame 1, a workbench 2 set on the frame, a stator clamping device 3, a wire drawing device 4 that can enter and exit from the stator clamping device, and a wire inserting mold 5 1. The indexing device is composed of 6 parts. The structure of each part will be described in detail below:

[0039] refer to figure 1 , the frame of the present invention is provided with four guide columns 101, a lifting motor (not shown), a first transmission wheel, and a second transmission wheel, each guide column 101 is provided with a linear bearing 102, and a mounting seat 103 It is fixedly connected with each linear bearing 102 . The wire pulling device 4 is fixed on the mounting base 103, and the wire pulling device 4 is threadedly connected with one end of a screw mandrel 104 to form a screw mechanism. Specifically, a nut is installed at the bottom of the casing in the wire pulling device, and the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com