Lightning arrester

A lightning arrester and insulating cylinder technology, which is applied in the field of lightning arresters, can solve problems such as damage to the resistance sheet, achieve the effects of increasing friction, avoiding damage to the resistance sheet, and reducing the extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

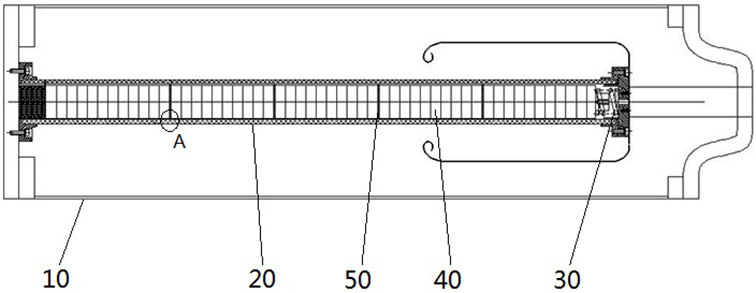

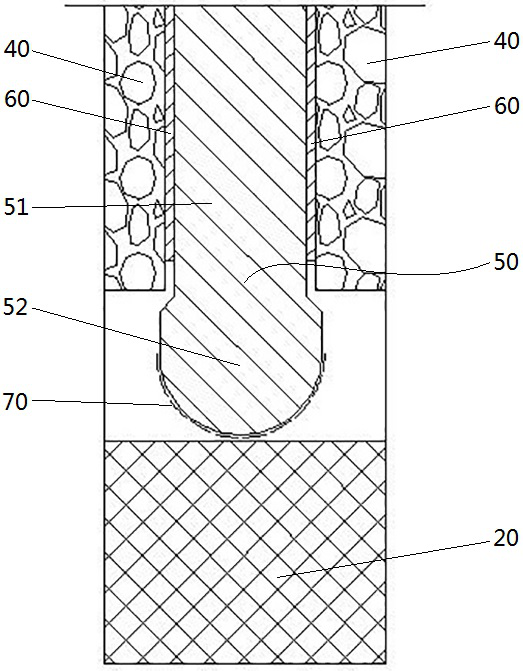

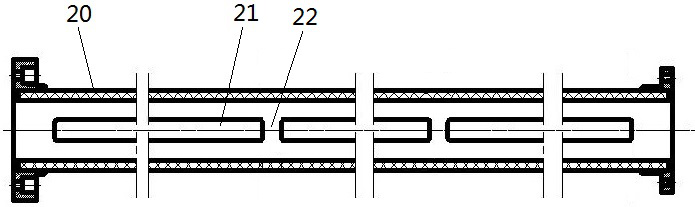

[0039] Such as figure 1As shown, the lightning arrester includes a housing 10, an insulating cylinder 20 is arranged inside the housing 10, and a plurality of resistor sheets 40 are sequentially stacked in the insulating cylinder 20 along the axial direction of the insulating cylinder 20, and one end of the insulating cylinder 20 is provided with a resistor The pieces 40 are press-fitted against the spring 30 , that is, a plurality of resistance pieces 40 can be pressed and fixed in the insulating cylinder 20 through the elastic force of the spring 30 . Wherein a plurality of resistive slices 40 are divided into at least two sections of resistive strips arranged sequentially along the stacking direction. In this embodiment, the resistive strips are provided with five sections, and the number of resistive strips 40 in each section of resistive strips is the same. Supporting pads 50 are provided between two adjacent segments of resistance sheet groups. The supporting pads 50 are...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the plurality of resistive slices 40 are divided into five segments of resistive slices arranged sequentially along the stacking direction. In this embodiment, however, the plurality of resistor sheets 40 can be divided into two, three, four, six or more resistor sheet groups arranged in sequence along the stacking direction.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, three exhaust holes 21 are arranged at intervals along the axial direction of the insulating cylinder 20 . However, in this embodiment, two, four or more exhaust holes 21 may be arranged at intervals along the axial direction of the insulating cylinder 20 . Certainly, the air hole 21 may also be a long hole capable of covering all the resistive sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com