A control method for a cooling system of an electrical cabinet

A heat dissipation system and control method technology, applied in the direction of electrical components, cooling/ventilation of substation/switchgear, substation/switch layout details, etc., can solve problems such as short circuit, affecting normal operation of electrical components, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

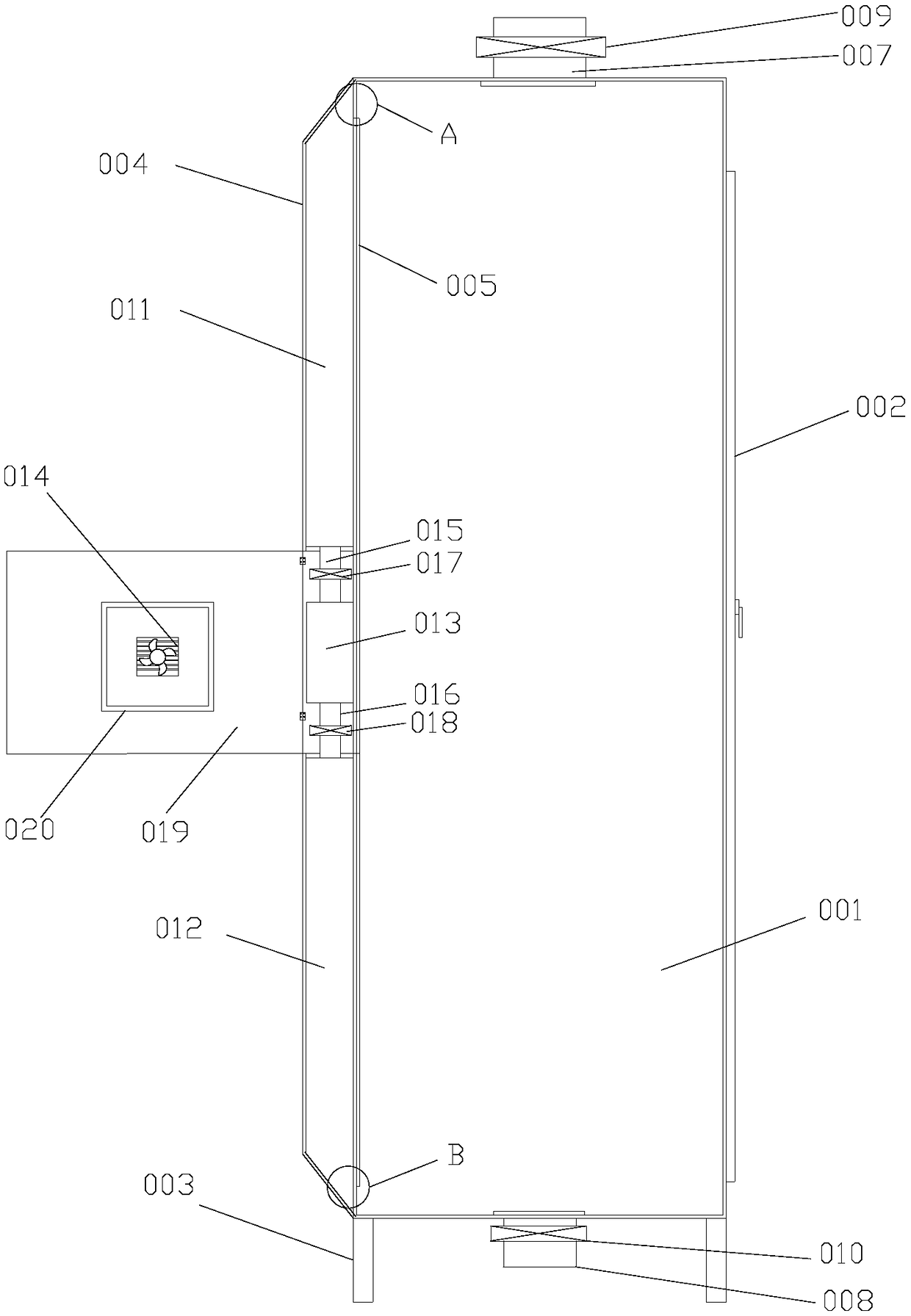

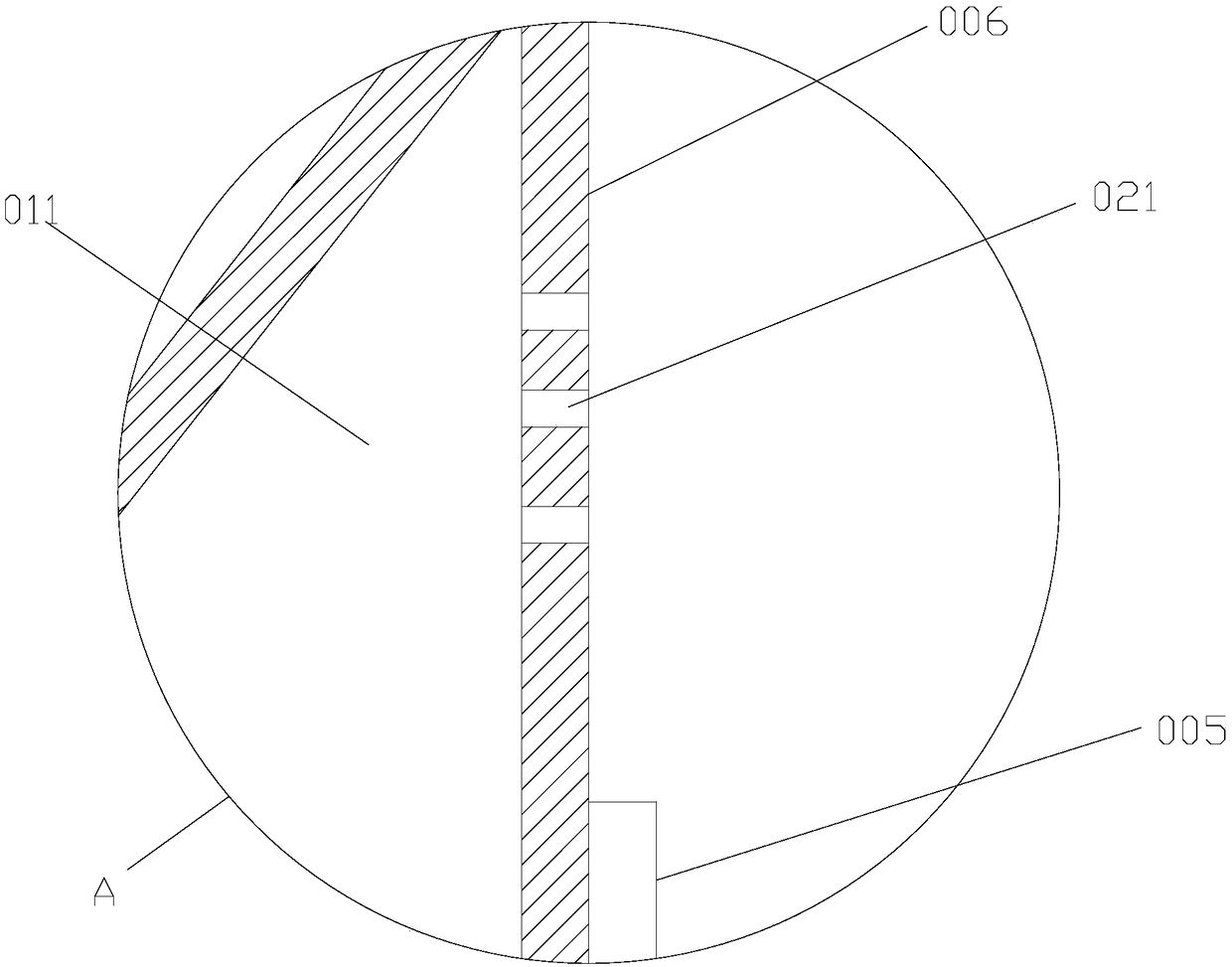

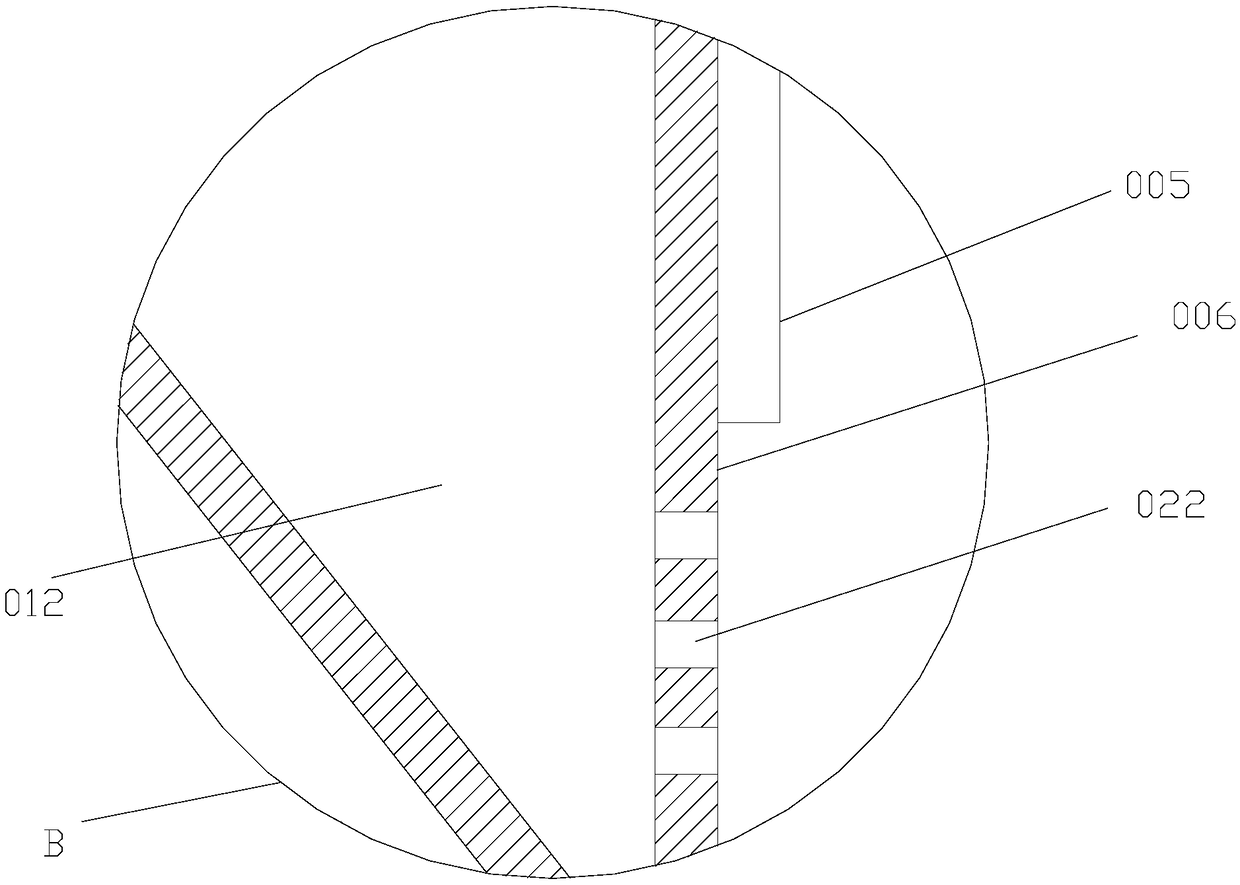

[0031] Such as figure 1 , 2 , 3, the electrical cabinet described in this embodiment includes a cabinet body 001, a cabinet door 002 hinged on the front of the cabinet body 001, a cabinet foot 003 below the cabinet body 001, and a backpack cavity 004 on the back of the cabinet body 001. The back plate 006 of 001 is provided with an electrical component mounting plate 005, and the electrical component mounting plate 005 is separated from the top and bottom of the back plate 006 by a certain distance (this distance is for setting the upper ventilation hole 021 and the lower ventilation hole described below. Hole 022, this section distance can be 5-10 centimetre), is respectively provided with upper ventilation pipe 007 and lower ventilation pipe 008 on the cabinet body 001 top and bottom, is respectively provided with upper ventilation pipe 007 and lower ventilation pipe 008 Valve 009 and lower ventilation valve 010, the upper part of the backpack cavity 004 is a sealed upper w...

Embodiment 2

[0034] Such as Figure 4 , 5 , 6, the heat dissipation system of the electrical cabinet described in this embodiment includes several electrical cabinets 000 arranged side by side on the floor 101 of the power distribution room 100 (the specific number is subject to actual application), and the power distribution room 100 The upper part is provided with a suspended ceiling 102, and a ventilation window 103 is provided above the suspended ceiling 102. A basement 104 is provided below the floor 101 of the power distribution room 100, and an air duct 105 is provided above the electrical cabinet 000 (the air duct 105 is made of thin iron sheet or a rectangular parallelepiped air duct made of stainless steel), the top of the air duct 105 is connected with an exhaust pipe 106 extending to the top of the suspended ceiling 102, and an exhaust valve 107 is arranged on the exhaust pipe 106; Blower 108, described blower 108 is communicated with described basement 104 through blower pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com