High strength heat resistant aluminium alloy

A technology for heat-resistant alloys and aluminum alloys, applied in the field of casting aluminum-silicon alloys and high-strength heat-resistant aluminum alloys, can solve the problems of low stable working temperature, high cost, and no literature reports on alloy materials have been found, and achieve high-temperature mechanical properties. , high dimensional stability, the effect of solving performance stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

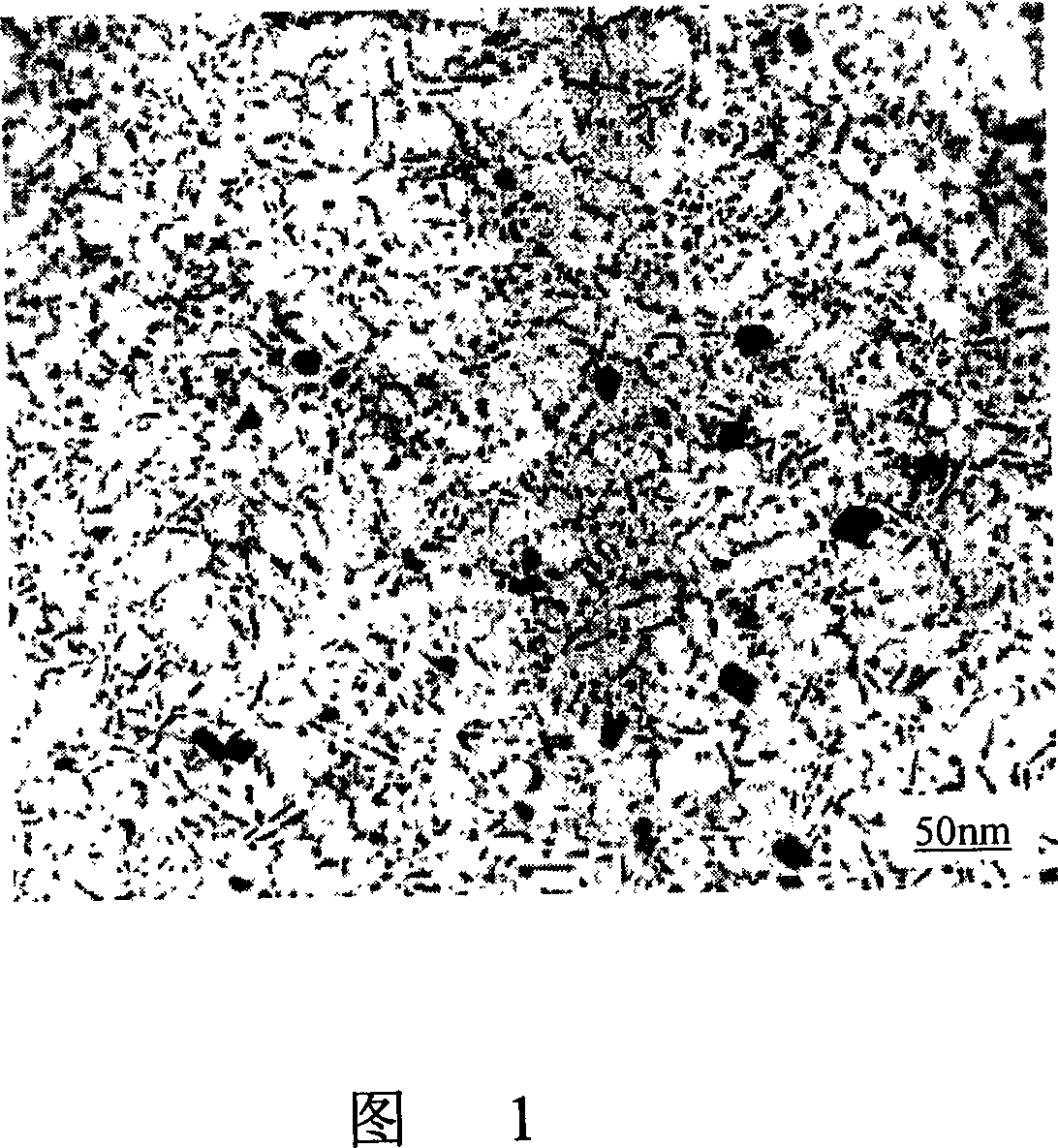

[0044]Referring to Fig. 1, the alloy of the present invention is welded by alloy smelting method, and its chemical composition (wt%) is as follows: Si: 12.5, Cu: 3.5, Ni: 1.5, Mn: 0.7, Mg: 0.8, Ti: 0.1, B: 0.08, Zr: 0.6, Cd: 0.2, P: 0.03, and the rest are aluminum, Si / Mg is 15.6, and Cu / Mg is 4.375. Put industrial pure aluminum, pure magnesium, crystalline Si, electrolytic nickel Ni, electrolytic copper Cu, titanium Ti, manganese Mn or Al-Si, Al-Cu, Al-Ti, Al-Mn, Al-Ni master alloy in the crucible furnace Melting, pouring parts after refining, metamorphism, and static. The room temperature tensile strength of the obtained material is 320-380MPa, and the high-temperature (350°C) tensile strength is 120-160MPa, which is 3-4 times of the tensile strength of ordinary aluminum-silicon alloy under the same experimental conditions. The hardness is 50% higher than that of the aluminum-silicon matrix alloy, and the elastic modulus is 40% higher than that of the aluminum-silicon matrix...

Embodiment 2

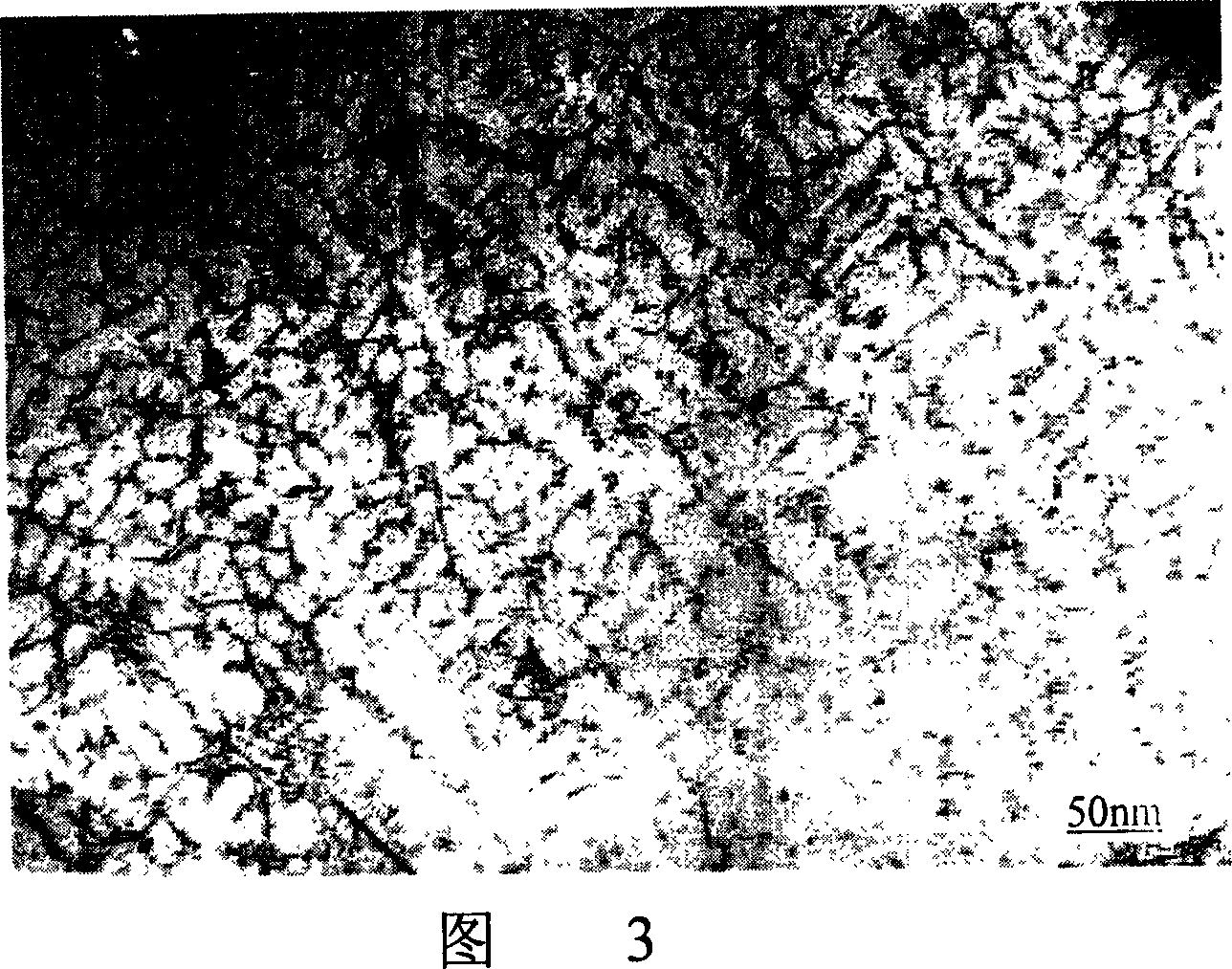

[0046] The preparation method is the same as in Example 1, and the alloy of the present invention is prepared by using the alloy smelting technology. Its chemical composition (wt%) is as follows: Si: 6.5, Cu: 3.5, Ni: 1.5, Mn: 0.7, Mg: 0.6, Ti: 0.1, B: 0.08, Zr: 0.6, Cd: 0.2, P: 0.03, the rest It is aluminum, Si / Mg is 10.8, and Cu / Mg is 5.8. Figure 3 is a photo of the as-cast metallographic structure of the alloy

Embodiment 3

[0048] The preparation method is the same as in Example 1, and the alloy of the present invention is prepared by using the alloy smelting technology. Its chemical composition (wt%) is as follows: Si 17.5, Cu: 5.0, Ni: 1.5, Mn: 0.7, Mg: 0.9, Ti: 0.1, B: 0.08, Zr: 0.6, Cd: 0.2, P: 0.03, and the rest are Aluminum, Si / Mg is 19.4, Cu / Mg is 5.55. Figure 4 shows the alloy coherent nanophase Al 3 TEM topography of Ti; Figure 5 is the coherent nanophase TiB of the alloy 2 The TEM topography of the alloy, its size is 120 nanometers, Figure 6 is the alloy nanophase TiB 2 Diffraction spots, Figure 7 is the alloy nanophase TiB 2 Photo of the coherent relationship with the base aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength at room temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com