Titanium aluminum-ceramic layered material and preparation method thereof

A technology of layered materials and ceramic layers, applied in the field of layered materials and their preparation, can solve the problems of uncontrollable composition, aluminum melting loss, etc., and achieve the effects of low cost, improved performance, and dense materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

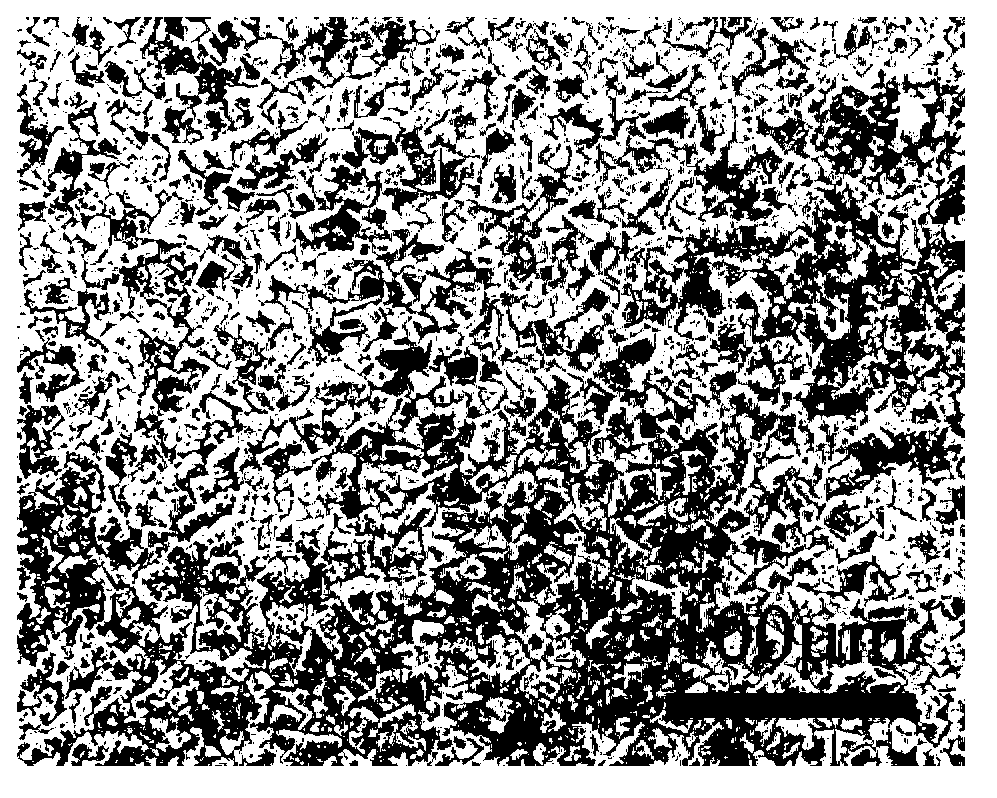

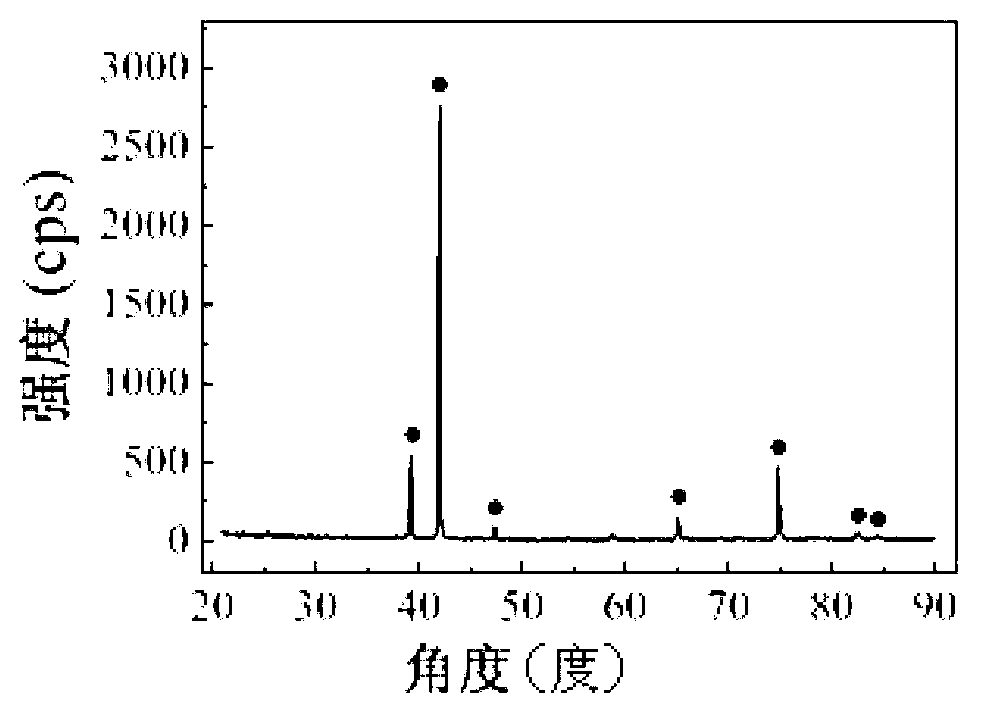

[0020] Specific Embodiment 1: In this embodiment, a titanium-aluminum-ceramic layered material is made by using in-situ autogenous technology to alternately laminate pure Ti foils and Al-based composite material foils, hot press and reactive annealing; the titanium-aluminum-ceramics In the ceramic layered material, the TiAl layer and the ceramic layer are distributed alternately, the stacking distance is 5 μm to 100 μm, and the ceramic layer includes Ti 2 AlC phase and Ti 3 AlC phase, TiAl layer is lamellar γ-TiAl / α 2 -Ti 3 Al, the lamellar spacing is 100nm-500nm; the Al-based composite material foil is made of reinforcement and pure Al powder through powder mixing, hot-pressing sintering and rolling.

[0021] The lamination spacing described in this embodiment refers to the distance between TiAl layers or the distance between ceramic layers; the interlamellar spacing refers to the distance between γ-TiAl sheets in the TiAl layer or α 2 -Ti 3 Distance between Al sheets.

...

specific Embodiment approach 2

[0028]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the single-layer thickness of the pure Ti foil is 50 μm to 200 μm, and the single-layer thickness ratio of the pure Ti foil to the Al-based composite material foil is (1.04 ~1.14):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume fraction of pure Al powder in the Al-based composite material foil is 85% to 99.9%, and the reinforcement in the Al-based composite material foil The volume fraction is 0.1% to 15%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com