Waste paper pulping and papermaking advanced waste water treatment technique

A pulp and papermaking and advanced treatment technology, which is applied in the direction of processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effects of scientific and reasonable design, improved reaction degree, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

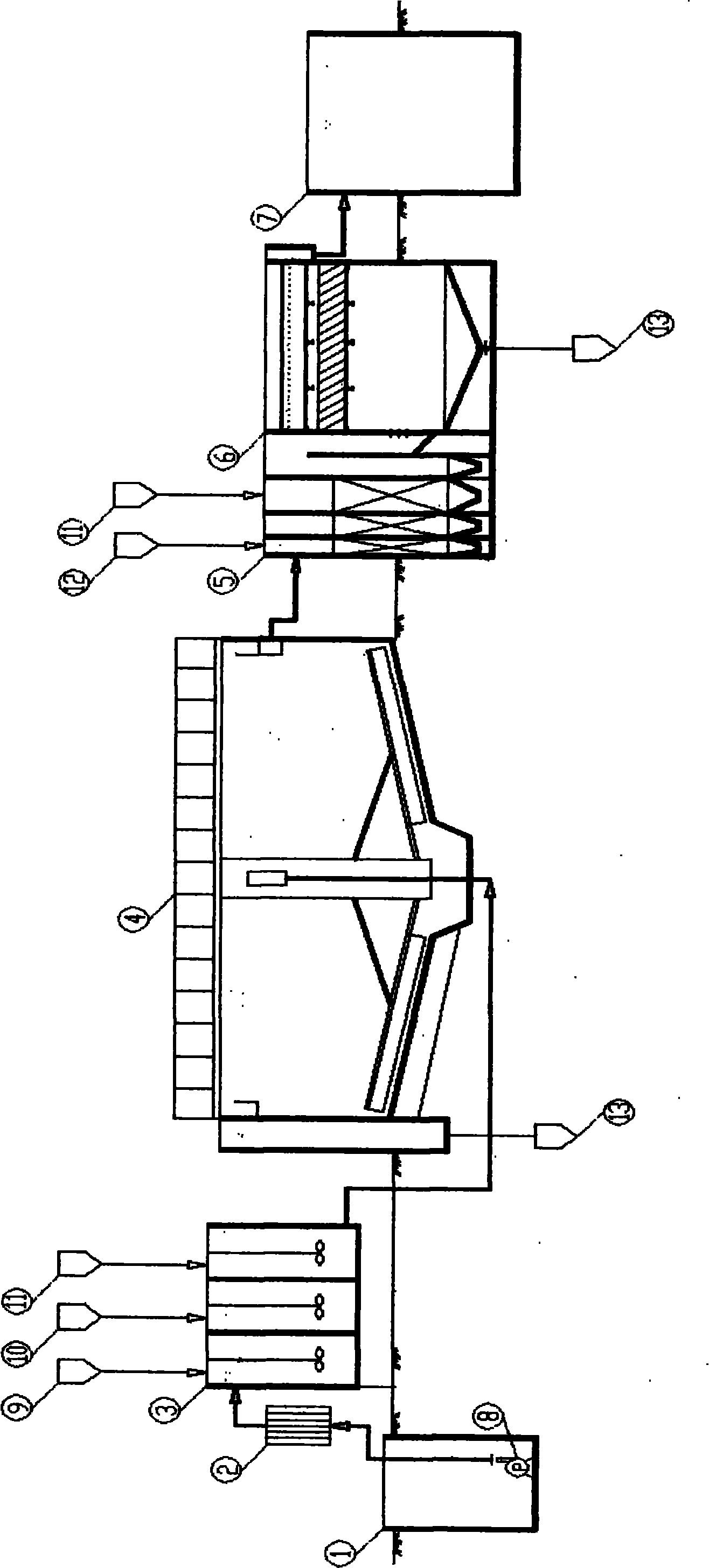

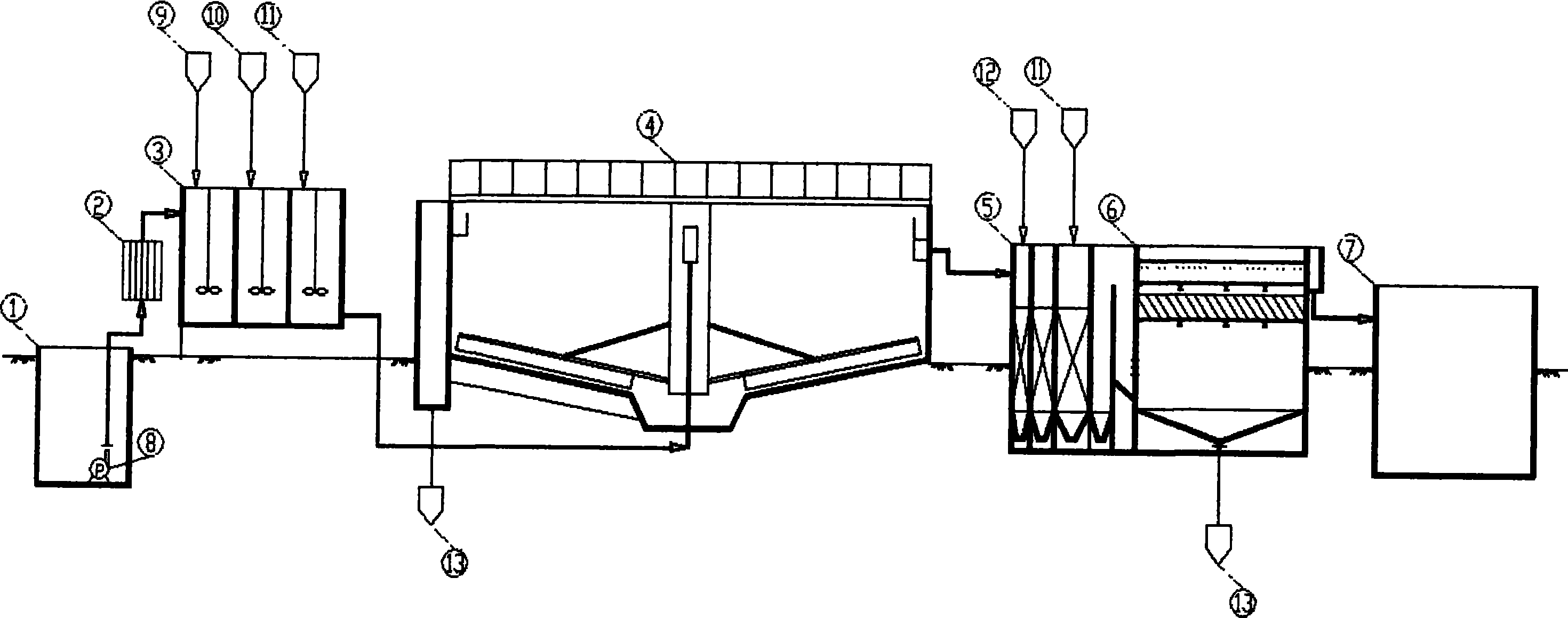

[0021] As shown in Figure 1, waste paper pulping and papermaking wastewater is treated according to the following steps:

[0022] In the first step, the 1000m 3 of waste paper pulping and papermaking wastewater was collected in the sump 1, after testing, its COD cr The content is 137.6mg / L;

[0023] In the second step, the waste water is lifted to the magnetizer 2 for magnetization treatment by the lifting pump 8;

[0024] In the third step, the magnetized waste water is discharged into the primary dosing mixing reaction tank 3, and then the 0.3kg / m 3 According to the standard, add ferrous sulfate 9 to the reaction tank. After the ferrous sulfate 9 is fully mixed with the wastewater, add calcium hydroxide 10 to the reaction tank to adjust the pH of the wastewater to 8.5. 3 Add anionic polyacrylamide 11 to the reaction pool to promote floc aggregation;

[0025] In the fourth step, the wastewater treated in step 3 is discharged into the first-stage sedimentation tank 4 to re...

Embodiment 2

[0032] As shown in Figure 1, waste paper pulping and papermaking wastewater is treated according to the following steps:

[0033] In the first step, the 1500m 3 of waste paper pulping and papermaking wastewater was collected in the sump 1, after testing, its COD cr The content is 126.9mg / L;

[0034] In the second step, the waste water is lifted to the magnetizer 2 for magnetization treatment through the lifting pump;

[0035] In the third step, the magnetized waste water is discharged into the primary dosing mixing reaction tank 3, and then the 0.4kg / m 3 According to the standard, add ferrous sulfate 9 to the reaction tank, and after the ferrous sulfate 9 is fully mixed with the wastewater, add calcium hydroxide 10 to the reaction tank to adjust the pH of the wastewater to 9.0, stir and mix for 15 minutes, and then use 1g / m 3 Add anionic polyacrylamide 11 to the reaction pool to promote floc aggregation;

[0036] In the fourth step, the wastewater treated in step 3 is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com