Preparation process of self-lubricating ceramic base composite material

A composite material and preparation process technology, used in electrolytic coatings, electrophoretic coatings, anodizing and other directions, can solve the problems of low bonding strength, complex and harsh stress, and it is difficult to independently meet the high temperature and high pressure of the piston, so as to improve the bonding strength and improve the use. Longevity and working effect, the effect of increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

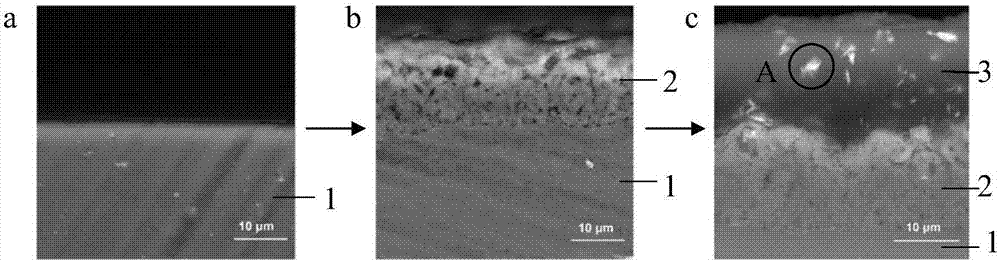

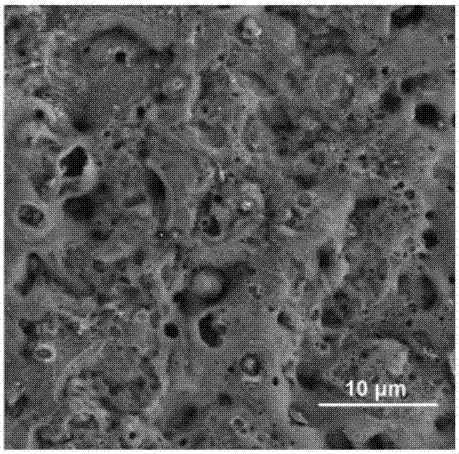

[0027] Such as figure 1 a to figure 1 As shown in c, a preparation process of a self-lubricating ceramic matrix composite material, including a micro-arc oxidation ceramic layer process and an electrophoretic deposition coating process;

[0028] The composition and concentration of the micro-arc oxidation electrolyte are: Na 2 SiO 3 4g / l, Na 2 WO 3 is 4g / l, KOH is 2g / l, and EDTA-2Na is 2g / l, the solvent of the micro-arc oxidation electrolyte is deionized water, and the temperature of the micro-arc oxidation electrolyte is 30°C to form a micro-arc oxidation ceramic layer;

[0029] The electrical parameters of micro-arc oxidation are: forward voltage 420v, negative voltage 120v, power frequency 1500Hz, forward duty cycle 60%;

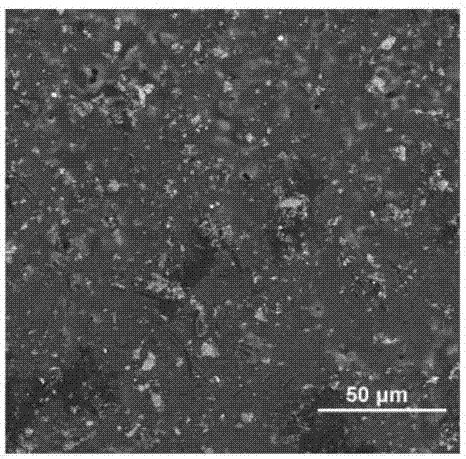

[0030] The components of the electrophoretic deposition electrolyte are: 10% solids acrylic anode electrophoretic paint, MoS with a particle size of 40nm 2 nanoparticles, polyethylene glycol, the MoS 2 The concentration of nanoparticles is 10g / l, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com