Method and device of adhering polarizer onto substrate

一种偏振器、粘接的技术,应用在偏振元件、仪器、胶粘剂等方向,能够解决工作效率低、偏振器粘接、粘接变差等问题,达到工作效率高、减小空间、提高生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the present invention will be described below with reference to the drawings.

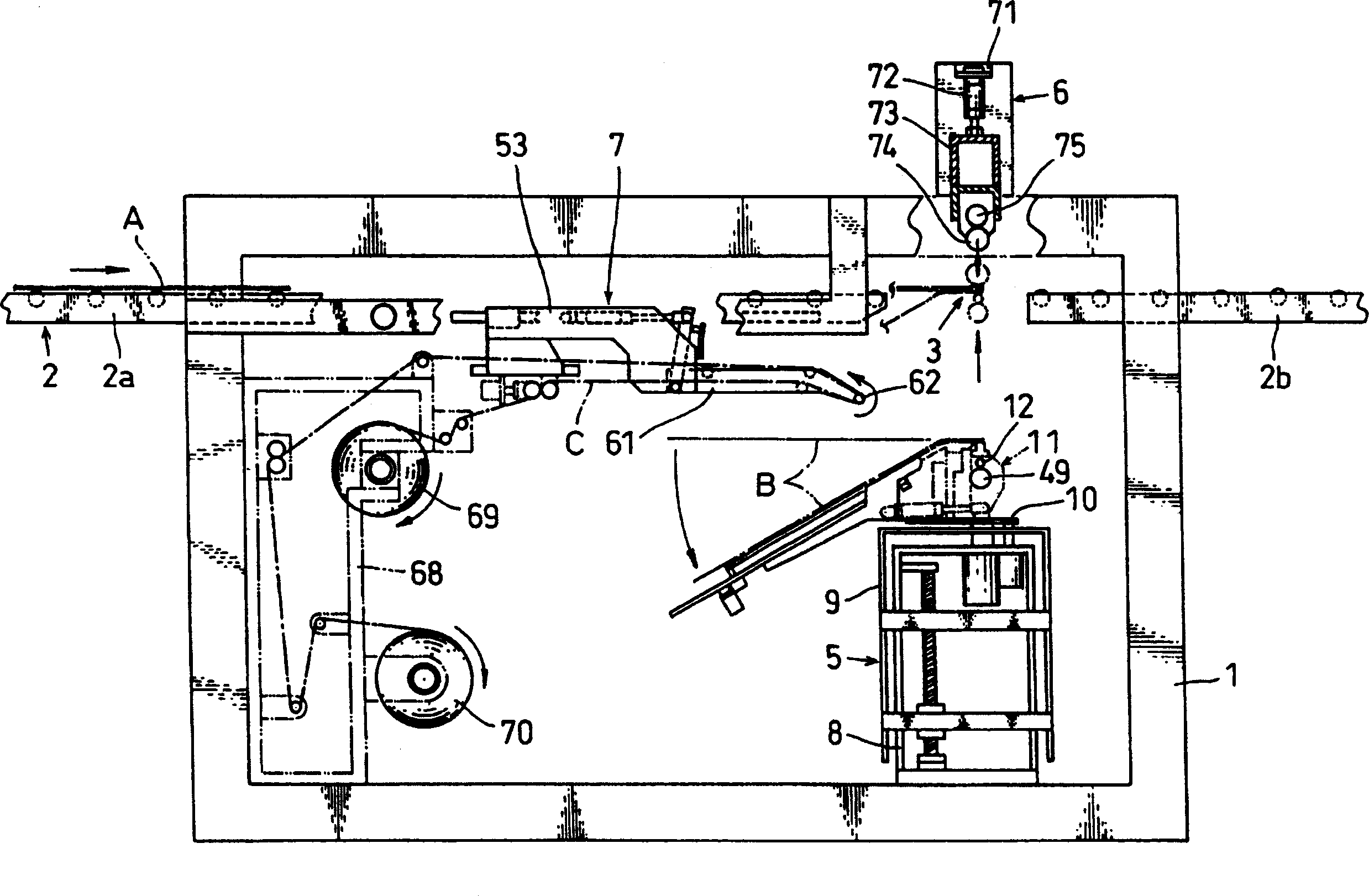

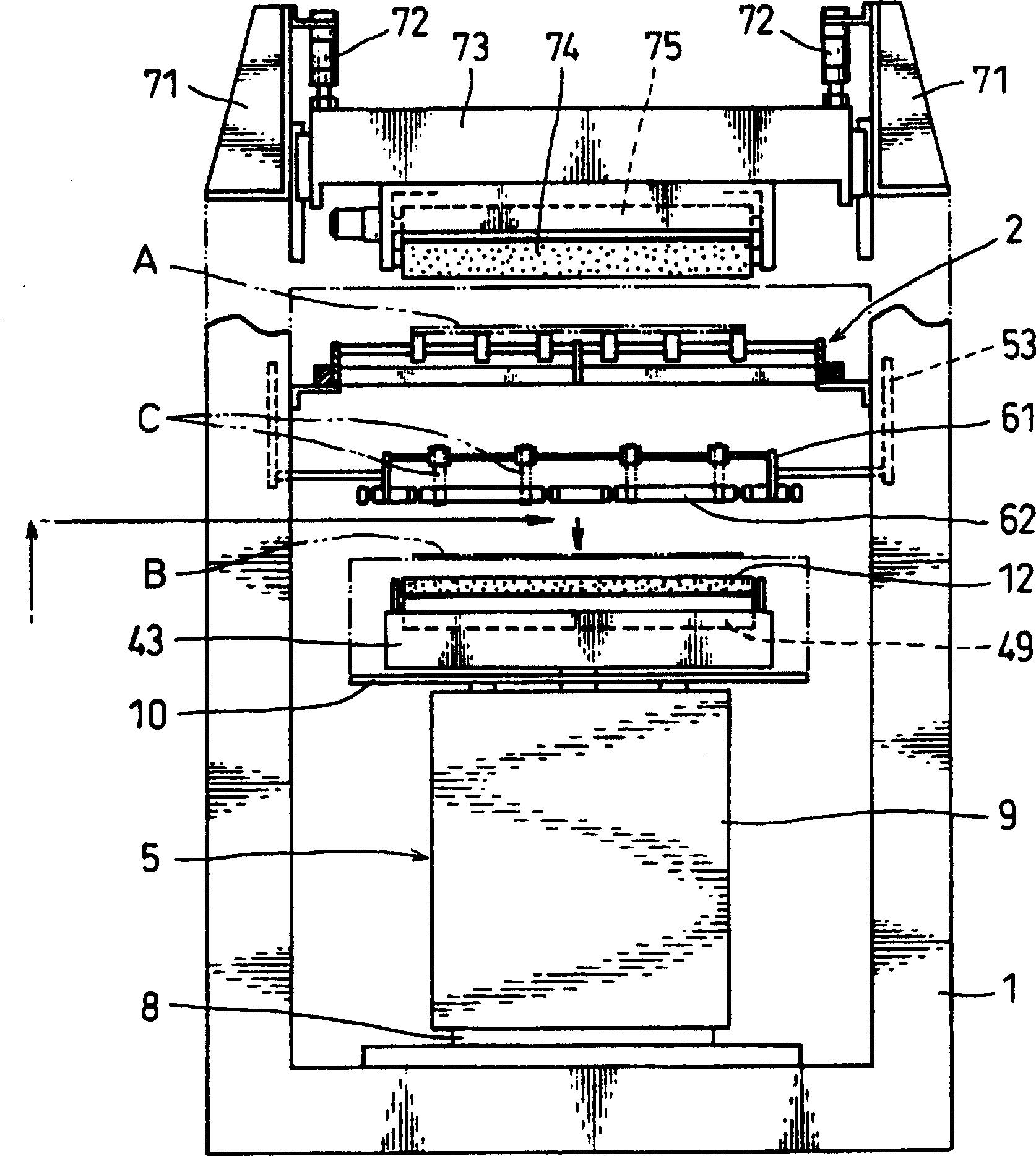

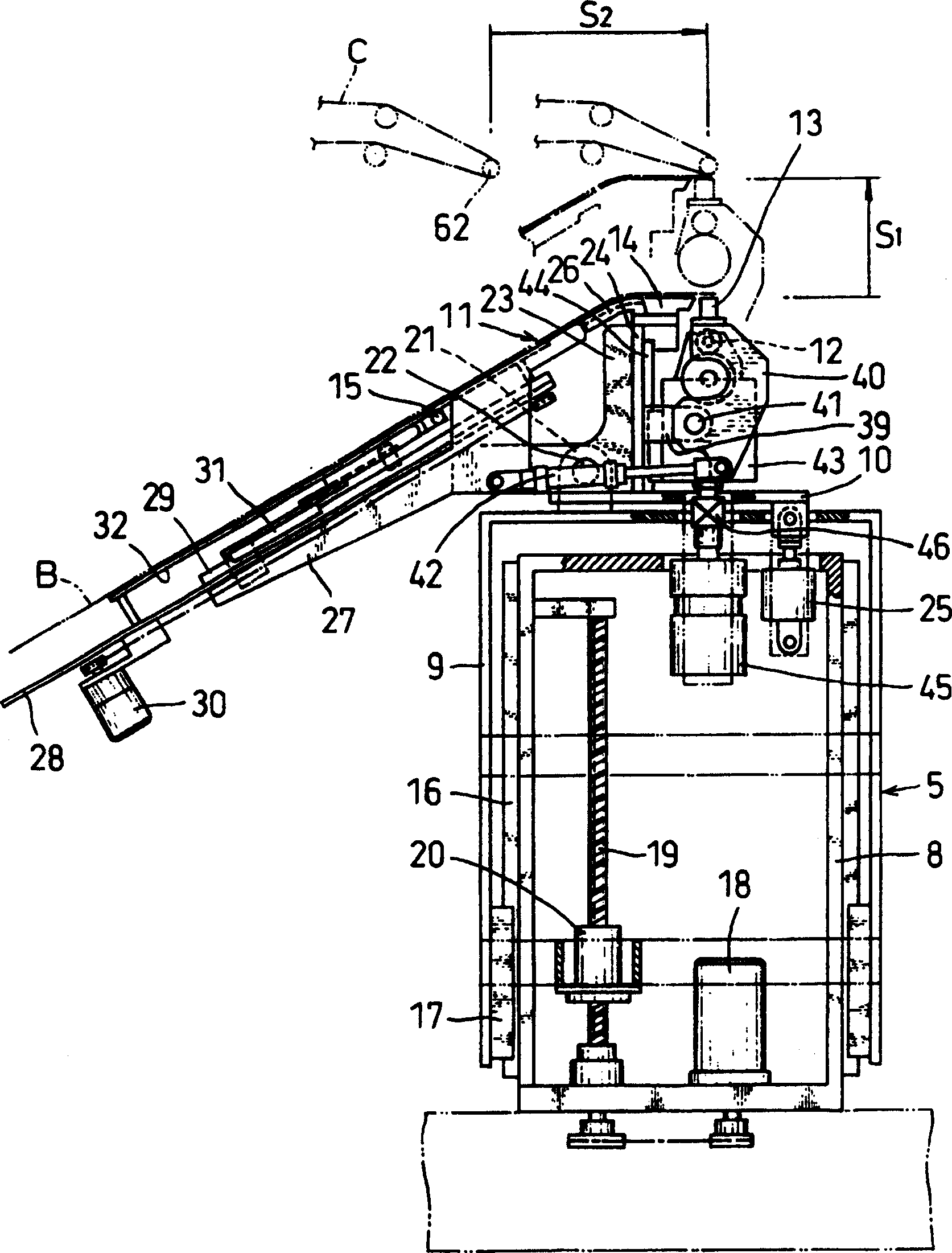

[0067] figure 1 The general structure of the device in which the polarizer is bonded to the liquid crystal panel (substrate) is shown. The transmission line 2 of the liquid crystal panel A is horizontally arranged in the upper part of the support stand body 1 . The conveying line 2 is a conveying path for a liquid crystal panel, in which a roller conveyor 2a on the input side, a roller conveyor 2b on the output side, and a polarizer B arranged at a predetermined interval between the roller conveyors 2a and 2b The bonding sites 3 are arranged in a straight line. The polarizer bonding unit 5 is arranged at a position just below the bonding position 3 . The vertically movable pressure roller mechanism 6 is arranged at a position just above the gluing station 3 . The separator peeling unit 7 is arranged at a position below the roller conveyor 2 a on the input side.

[0068] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com