Ultrasonic-assisted laser material additive manufacturing device and realization method thereof

An auxiliary laser and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, and process efficiency improvement, etc., can solve the problems of poor macroscopic deformation of formed workpieces, poor fusion of pores, inclusions and fusion, influence of mechanical properties of formed parts, uneven stress distribution, etc. , to achieve the effects of reducing residual stress, refining grains, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

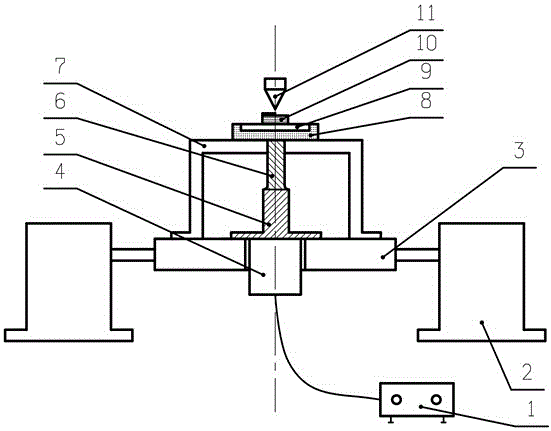

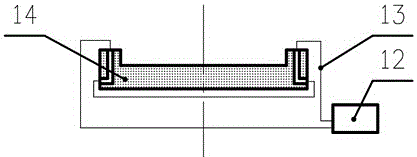

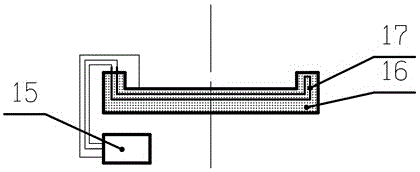

[0032] Such as Figure 1 to Figure 3 As shown, the ultrasonic-assisted laser additive manufacturing device includes a precision two-axis numerical control turntable mainly composed of a double support turntable 2 and a processing table 3, a support fastening base 7 arranged on the processing table, and a support fastening base 7 arranged on the support fastening A mold 8 with a groove on the base, an ultrasonic device that passes through the processing table and the supporting fastening base and is connected to the bottom of the mold, a substrate 9 placed in the groove on the mold, and a Powder feeding nozzle 11 above the substrate;

[0033] Wherein, the ultrasonic device includes an ultrasonic transmitter 1, an ultrasonic transducer 4, an ultrasonic horn 5 and an ultrasonic vibrating rod 6 connected in sequence, and the ultrasonic horn is fixed to the processing table through an outer ring flange Above, the ultrasonic vibrating rod passes through the supporting fastening bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com