Method for preparing phenolic resin system Z-pin by using twisted carbon fibers

A technology of twisting carbon fiber and phenolic resin, which is applied in the preparation of carbon fiber\phenolic resin system Z-pin, and in the field of composite material manufacturing, to achieve the effect of good bonding state, improved implantation depth, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This example illustrates the preparation method of the twisted carbon fiber reinforced phenolic resin system Z-pin provided by the present invention.

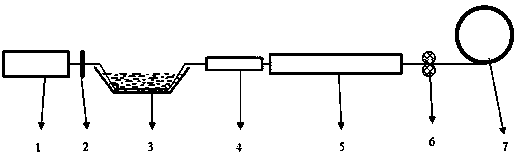

[0012] ① Use T300 carbon fiber to place figure 1 On the line twisting device in the middle, the fibers are sequentially passed through figure 1 The fiber guiding device 2, the dipping device 3, the pultrusion die 4, the post-curing device 5, the traction device 6, and the winding device 7 in the fiber online twisting device 1 are set to the rotation speed of the rotating shaft and the pultrusion of the pultrusion die 4. Speed, the fiber twist obtained is 80 twists / meter.

[0013] ②Put the B30 phenolic resin in a vacuum oven for 60°C and 1h defoaming treatment, then pour it into the glue tank for use.

[0014] ③ Set the mold temperature to 90°C, and the post-curing device temperature to 180°C.

[0015] ④ After the system is stable, turn on the traction device.

[0016] ⑤ Check that the Z-pin diameter is 0.5±0.01mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com