Rubber particle sheet pavement material and method for paving rubber particle sheet pavement

A technology of rubber granules and asphalt pavement, which is applied in the direction of roads, roads, and on-site paved condensate pavements. It can solve the problems that asphalt pavement does not have the ability to suppress ice and snow, affects the traffic capacity of the working surface, and has low equipment utilization. Environmental protection value, convenient mechanized snow removal and road surface management and maintenance, and the effect of reducing mechanical energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

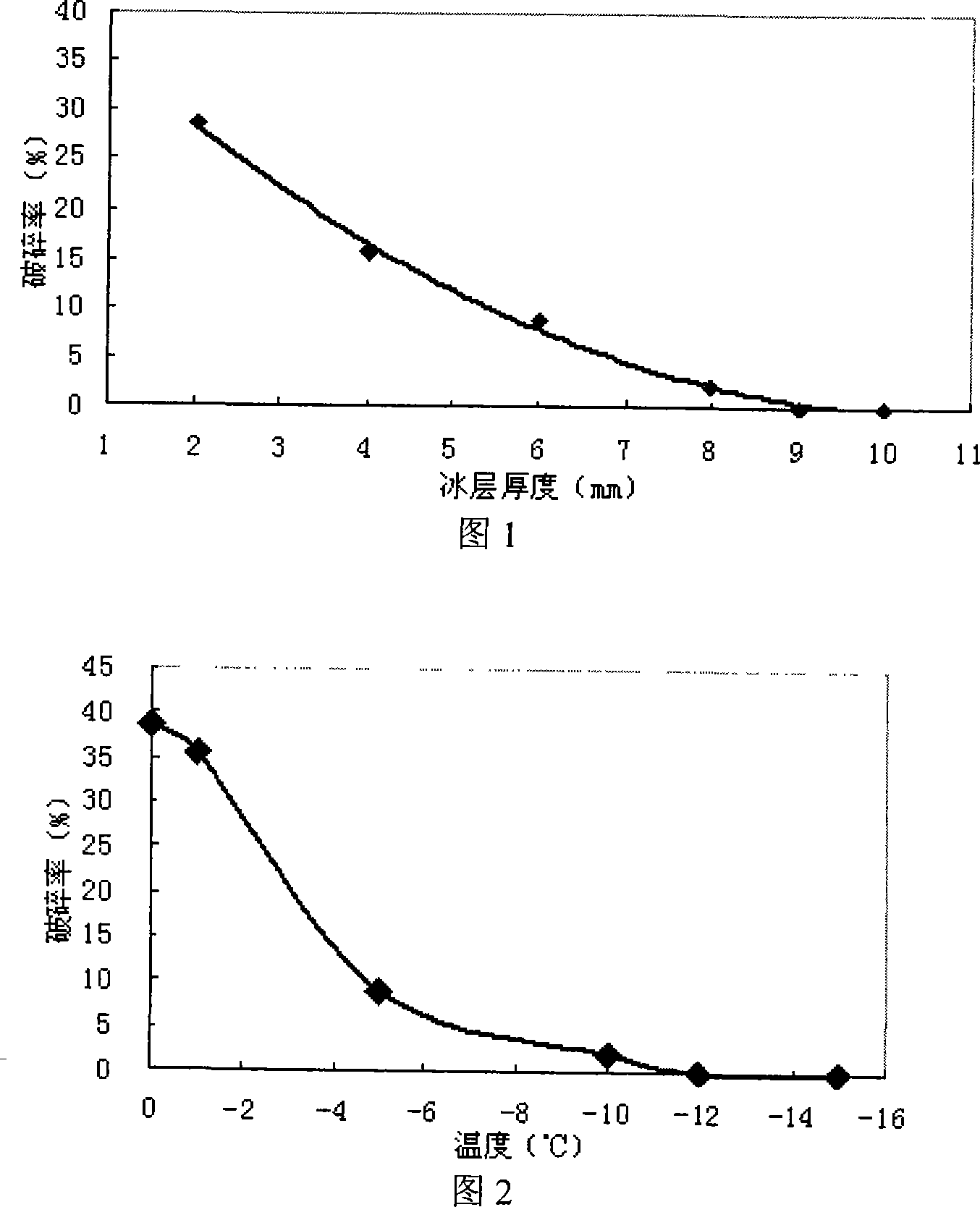

Image

Examples

specific Embodiment approach 1

[0012] Embodiment 1: The rubber particle asphalt pavement material in this embodiment is made of 76.5-91.5 parts of ore aggregate, 2.5-7.5 parts of asphalt, 4-10 parts of mineral powder and 2-6 parts of rubber particles.

[0013] In this embodiment, the ore aggregate is massive, and the mineral powder is powder; in this embodiment, the ore aggregate is ore aggregate for conventional asphalt pavement laying, and the mineral powder is conventional mineral powder for laying asphalt pavement.

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the rubber particle asphalt pavement material is composed of 78 to 90 parts of ore aggregates, 5 to 7 parts of asphalt, 5 to 9 parts of mineral powder and Made from 3-5 parts of rubber granules.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the rubber particle asphalt pavement material is composed of 80 to 88 parts of ore aggregate, 6 parts of asphalt, 6 to 8 parts of mineral powder and 4 parts by weight. Made of rubber granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fiber content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com