Plasma body fuel cell

A plasma and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, fuel cell additives, etc., can solve the problems of unrecoverable fuel residual gas and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

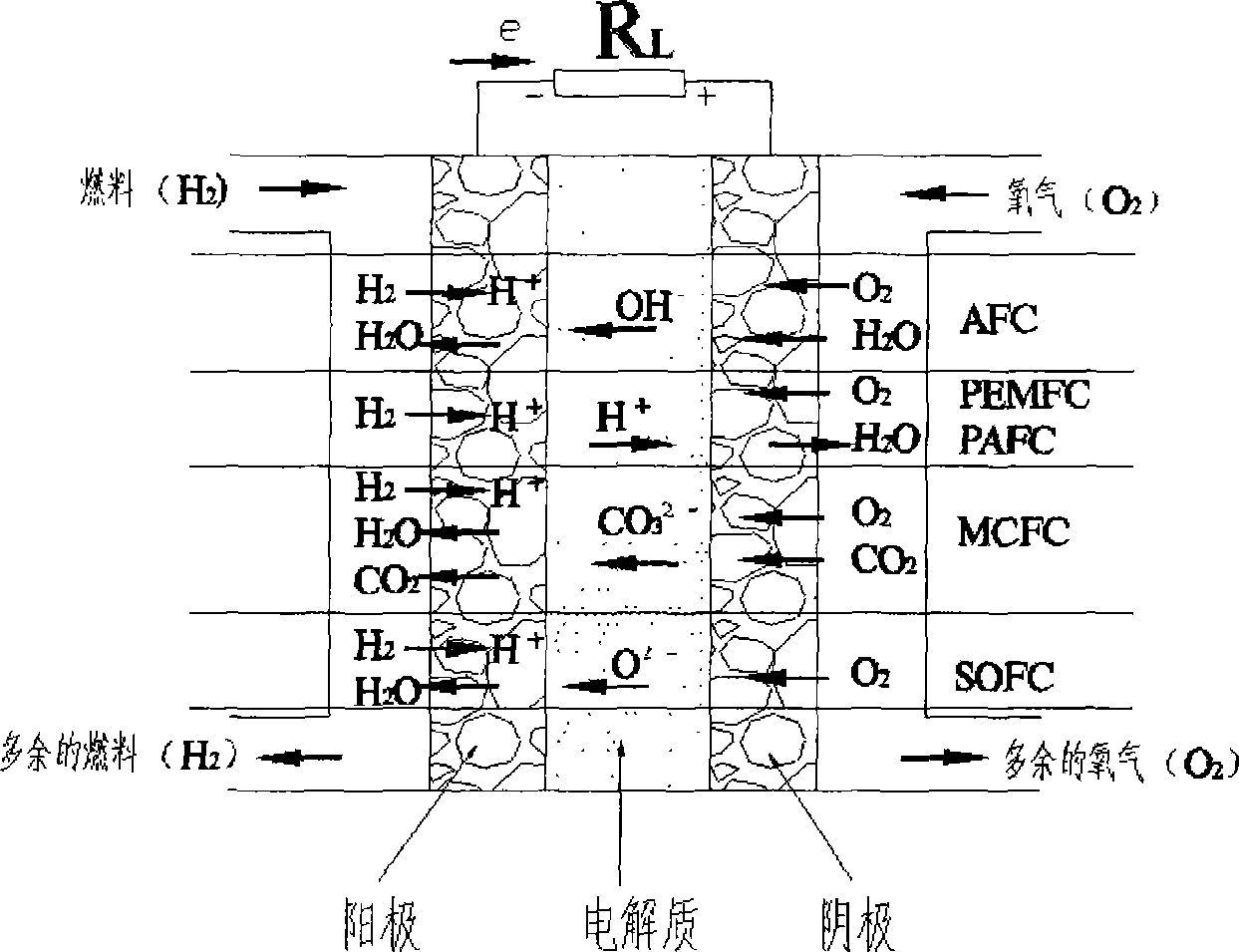

[0075] figure 1 Shown are currently reported, including alkaline fuel cell (AFC), phosphoric acid fuel cell (PAFC), molten carbonate fuel cell (MCFC), solid oxide fuel cell (SOFC), proton exchange membrane fuel cell The basic working principles of fuel cells such as (PEMFC) are as mentioned above.

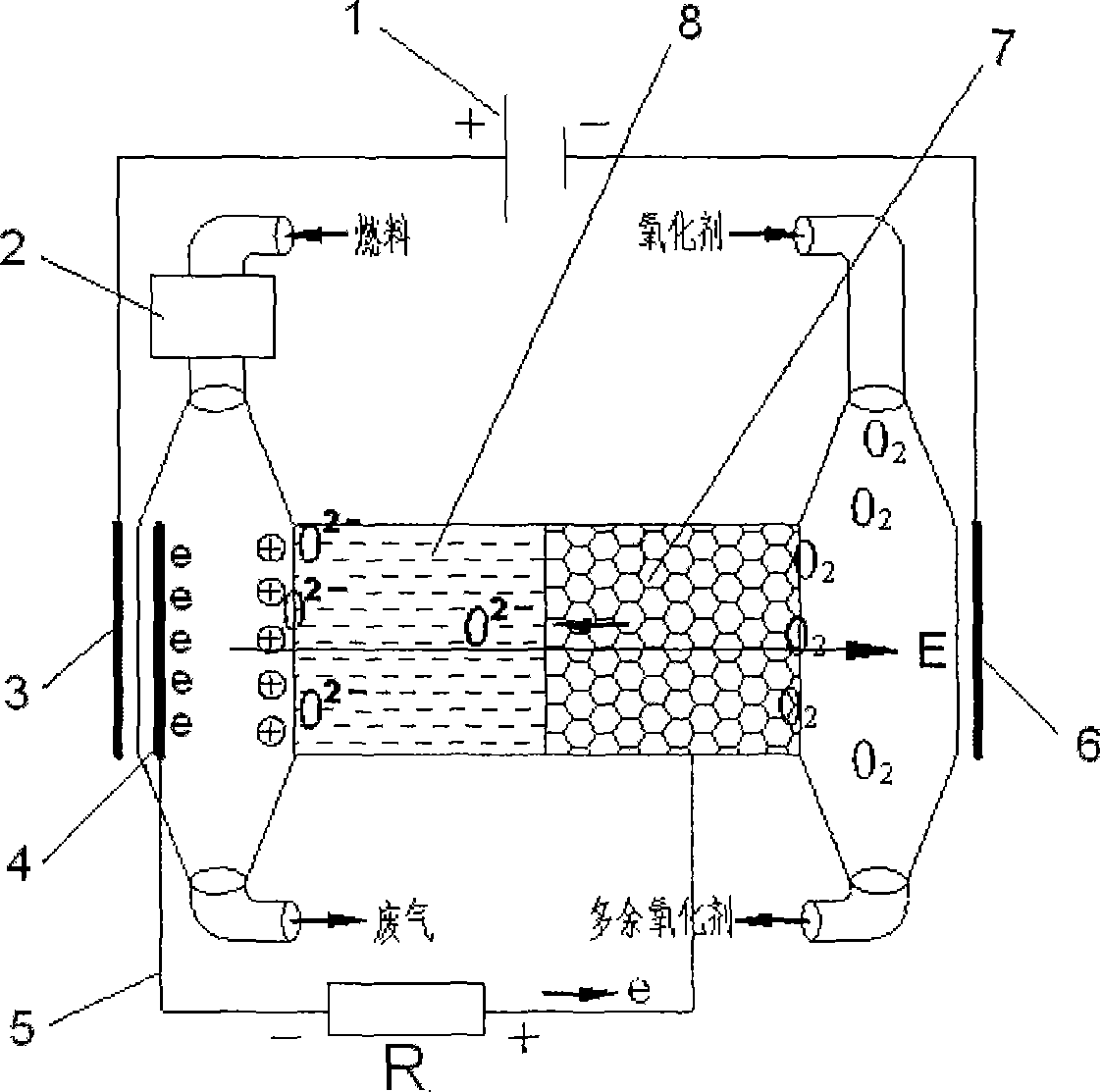

[0076] figure 2 It is the structural principle of the plasma fuel cell of the present invention. The plasma jet flow generation unit 2 that is equipped with a pressurized blowing mechanism such as the air plasma cutting machine commonly used at present is used as the plasma source for making the fuel gas into plasma, and in the direction of the running path of the plasma flow ejected by it. A plasma separation field in the form of an applied electric field or magnetic field (shown in the figure as an electrostatic separation field) is provided with a field force direction perpendicular to its running direction. In the direction of movement of the positive and negative ions sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com