Method for separating salt from coal-chemical-industry wastewater through electroosmosis technique

A technology of coal chemical wastewater and electrodialysis, applied in chemical instruments and methods, general water supply conservation, inorganic chemistry, etc., can solve the problems of no application reports, avoid solid waste landfill, improve secondary utilization value, and realize repeated use The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

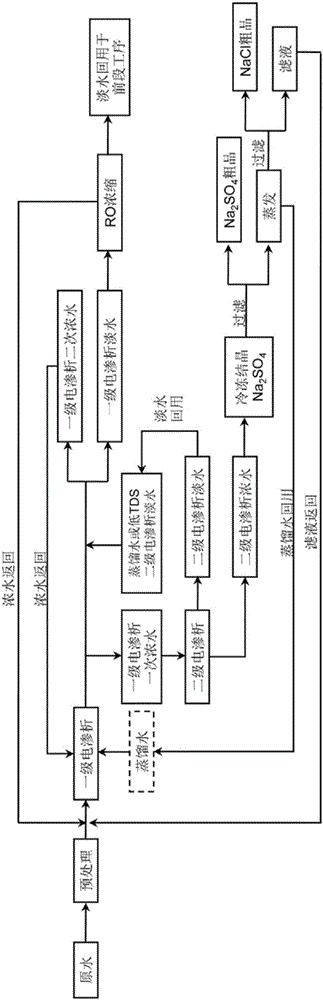

Method used

Image

Examples

Embodiment 1

[0023] The electrodialysis equipment used in this example is the CJED-90*210-5 type equipment produced by Hefei Kejia Polymer Material Technology Co., Ltd. The electrodialysis cation exchange membrane and anion exchange membrane used are respectively Hefei Kejia polymer CJMC and CJMA membranes produced by Material Science and Technology Co., Ltd.

[0024] The raw water of coal chemical industry wastewater is pretreated, including removal of organic matter, removal of heavy metals, softening treatment, filtration, and RO concentration, so that the TDS of the RO concentrate is 45000-55000mg / L, and the COD content is 550-700mg / L.

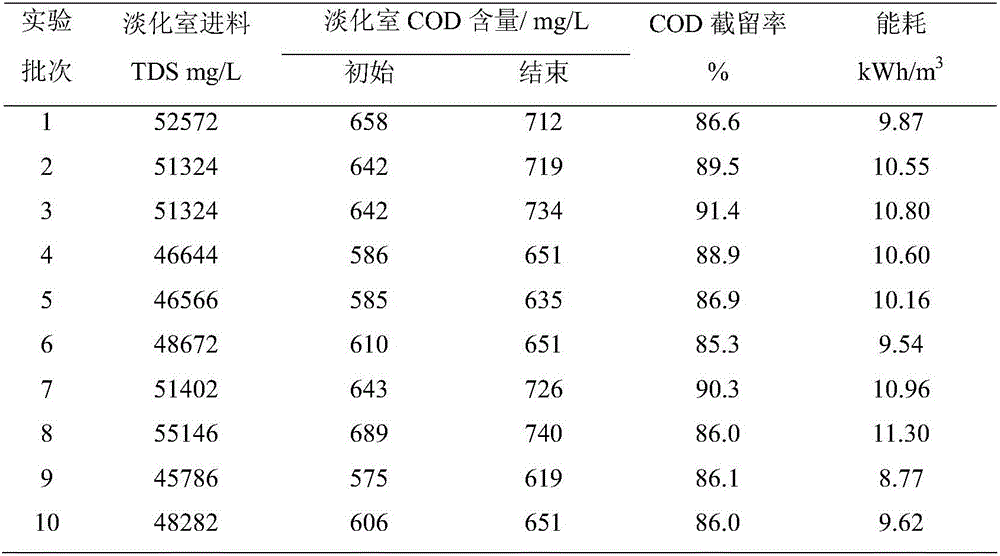

[0025] The electrodialysis experiment of the present embodiment is the COD and salt in the separation waste water of one-stage electrodialysis, specifically, the waste water of different concentrations is taken and processed in batches, and each batch of waste water (electrodialysis desalination chamber) is 6L, in order to improve the concentrated solut...

Embodiment 2

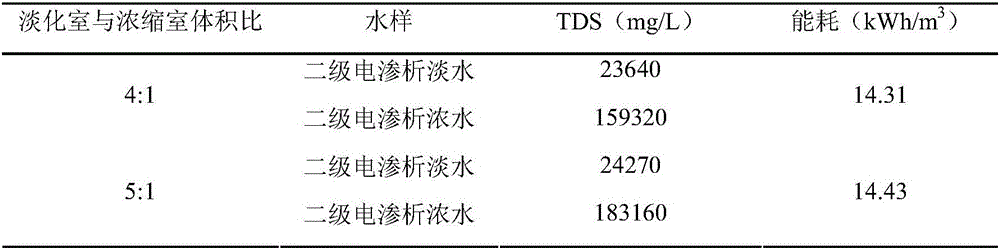

[0030]Concentrate again for the primary electrodialysis concentrated water (TDS is 91500 mg / L) in Example 1. The concentration methods here are generally multi-effect evaporation and MVR, but the operation energy consumption of these two processes is relatively high, and electrodialysis is an ideal concentration method. Therefore, in this embodiment, the concentrated water of the first-stage electrodialysis is reconcentrated by the second-stage electrodialysis. The electrodialysis equipment is the same as the equipment in Example 1. During the operation of the second-stage electrodialysis, the voltage is fixed at 6V, and the feed materials of the concentration chamber and the desalination chamber are concentrated water of the first-stage electrodialysis, and the volume ratio of the concentration chamber and the desalination chamber is 1. :4 and 1:5, the experiment runs until the TDS of the second-stage electrodialysis fresh water drops below 30000mg / L, stops the concentration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com