A kind of cream flavor peanut oil and preparation method thereof

A cream-flavored, peanut oil technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problems of low product quality and complicated preparation process, and achieve high safety, simple preparation process, and creamy fragrance. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

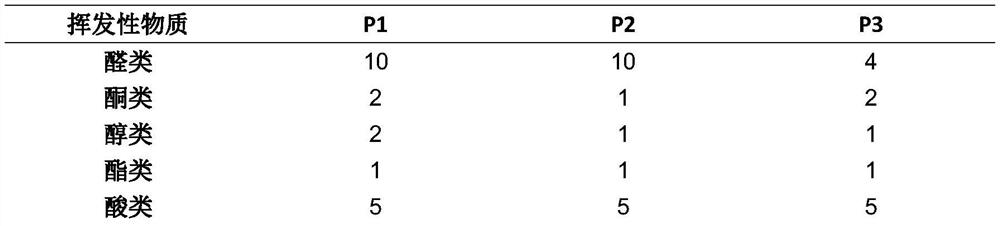

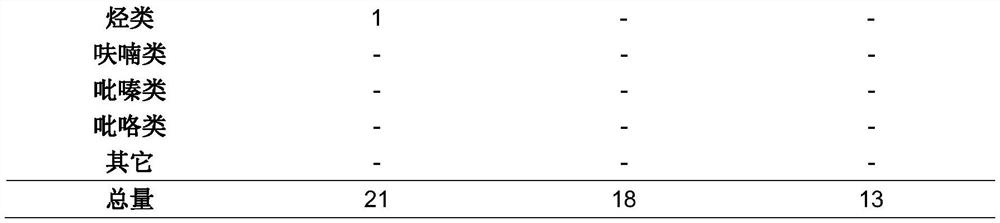

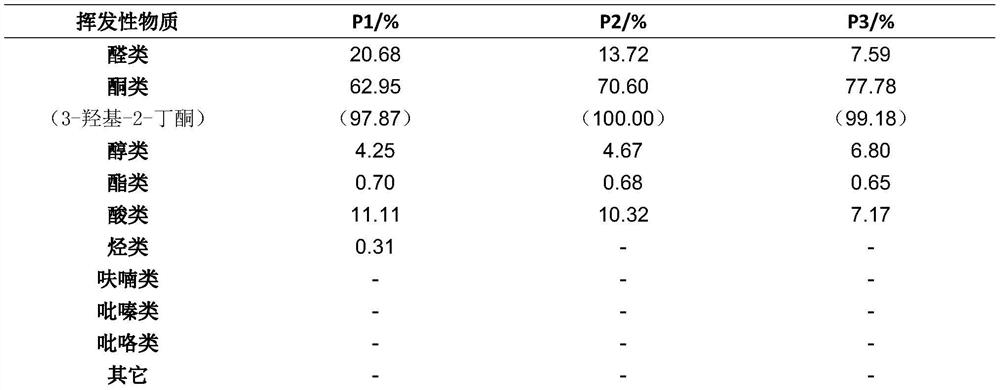

Embodiment 1

[0031] This embodiment provides a method for preparing a cream-flavored peanut oil with pulsed electric field pretreatment and 10 times of pulse treatment, comprising the following steps:

[0032] (1) Raw material pretreatment: select 50 g of freshly produced peeled peanut kernels each time, immerse it in deionized water, and adjust its moisture content to 54-56% for later use.

[0033] (2) Peanuts processed by PEF equipment: Put the prepared peeled peanuts into the processing chamber, add deionized water to fix the distance between the plates to 30mm, press the electrode plates, and exhaust the air bubbles to fill the entire processing chamber with deionized water. Under the condition of intensity of 1.22-1.24kV / cm, frequency of 1Hz, pulse width of 250μs, and pulse treatment times of 10, peanut kernels were treated with PEF.

[0034] (3) Dried peanut kernels: remove the peanut kernels after PEF treatment, put them in a petri dish immediately, put them into an oven at a temper...

Embodiment 2

[0038] This embodiment provides a method for preparing a cream-flavored peanut oil with a pulse electric field pretreatment and pulse treatment times of 20 times, comprising the following steps:

[0039] (1) Raw material pretreatment: select 50 g of freshly produced peeled peanut kernels each time, immerse it in deionized water, and adjust its moisture content to 54-56% for later use.

[0040] (2) Peanuts processed by PEF equipment: Put the prepared peeled peanuts into the processing chamber, add deionized water to fix the distance between the plates to 30mm, press the electrode plates, and exhaust the air bubbles to fill the entire processing chamber with deionized water. Under the condition of intensity of 1.22-1.24kV / cm, frequency of 1Hz, pulse width of 250μs, and pulse treatment times of 20 times, peanut kernels were treated with PEF.

[0041] (3) Dried peanut kernels: remove the peanut kernels after PEF treatment, put them in a petri dish immediately, put them into an ove...

Embodiment 3

[0045]This embodiment provides a pulse electric field pretreatment, a method for preparing cream flavor peanut oil with 40 pulse treatments, comprising the following steps:

[0046] (1) Raw material pretreatment: select 50 g of freshly produced peeled peanut kernels each time, immerse it in deionized water, and adjust its moisture content to 54-56% for later use.

[0047] (2) Peanuts processed by PEF equipment: Put the prepared peeled peanuts into the processing chamber, add deionized water to fix the distance between the plates to 30mm, press the electrode plates, and exhaust the air bubbles to fill the entire processing chamber with deionized water. Under the conditions of intensity 1.22-1.24kV / cm, frequency 1Hz, pulse width 250μs, and pulse treatment times 40 times, peanut kernels were treated with PEF.

[0048] (3) Dried peanut kernels: remove the peanut kernels after PEF treatment, put them in a petri dish immediately, put them into an oven at a temperature of 55-60°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com