Additive for sludge dewatering and sludge dewatering method

A sludge dewatering and additive technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve problems such as waste of resources, reduce resistance, increase nutrients, and improve dewatering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

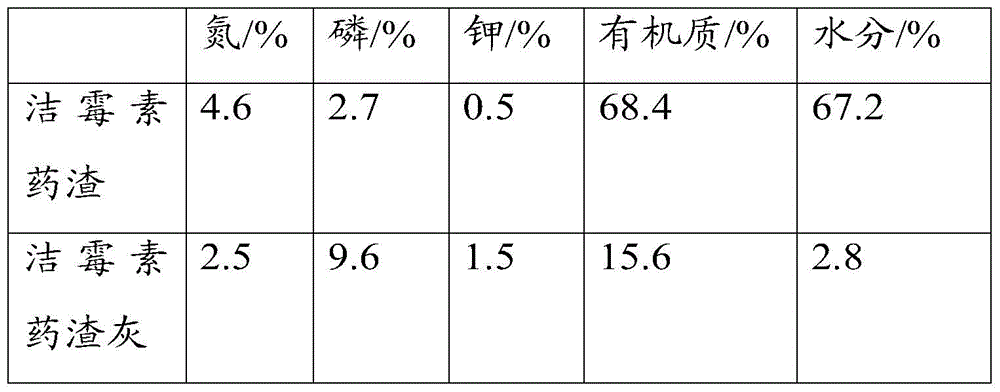

[0035] This embodiment provides an additive for sludge dewatering, and the additive is antibiotic slag ash. In addition, in the antibiotic slag ash used, the percentage of N is 2.5%, the percentage of P is 9%, the percentage of K is 1%, and the percentage of organic matter is 15%.

Embodiment 2

[0037] This embodiment provides an additive for sludge dewatering, and the additive is antibiotic slag ash. In addition, in the antibiotic slag ash used, the percentage of N is 5%, the percentage of P is 15%, the percentage of K is 5%, and the percentage of organic matter is 25%.

Embodiment 3

[0039] This embodiment provides an additive for sludge dewatering. On the basis of Embodiment 1, the particle size of antibiotic residue ash used in this embodiment is 6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com