Method for preparing composite fiber material for visible light photocatalytic degradation of organic pollutants

A visible light and photocatalyst technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of reduced efficiency, refractory degradation, secondary pollution of adsorbents, etc., and achieves reduction in average time and recombination probability. The effect of reducing and improving the photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

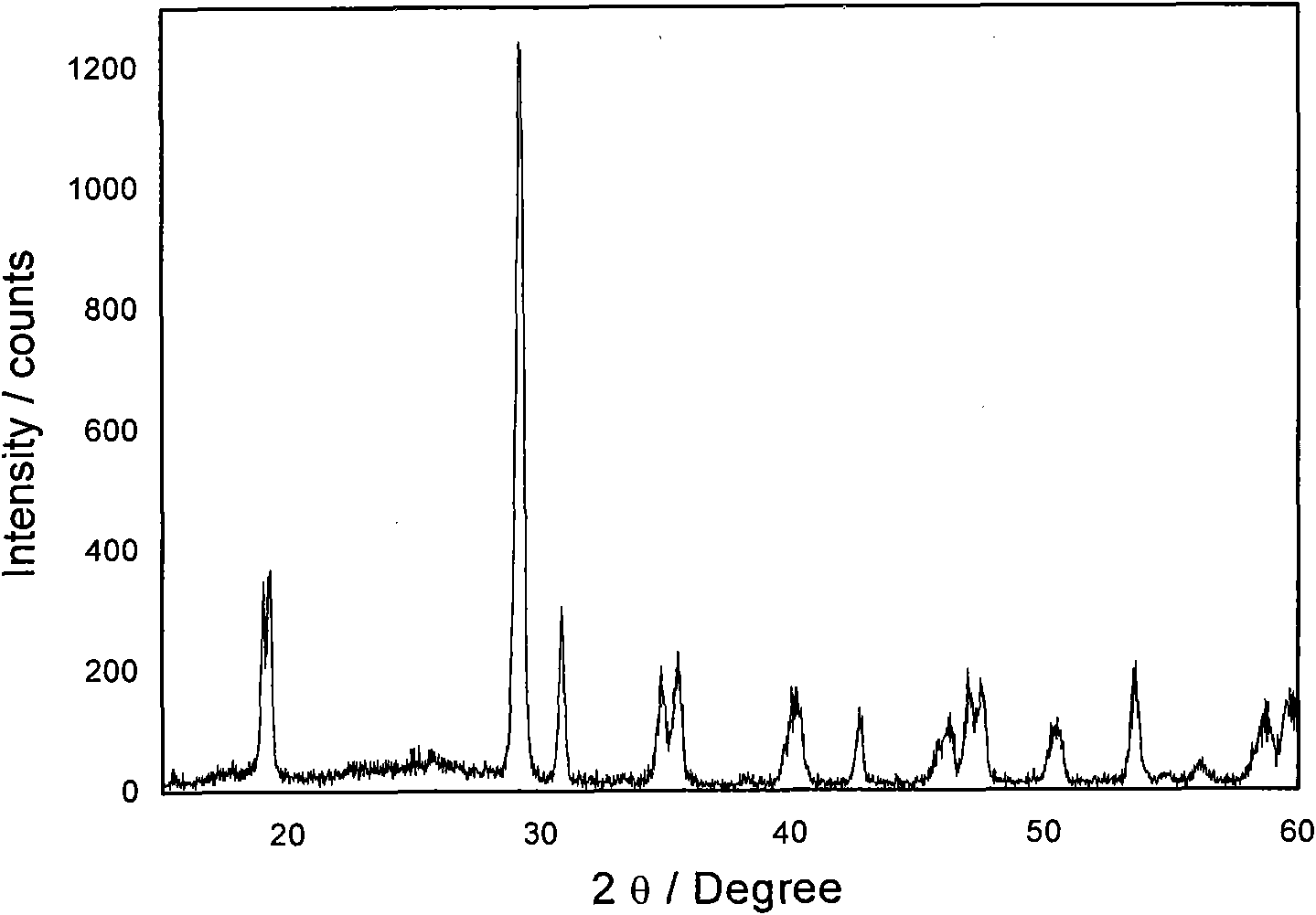

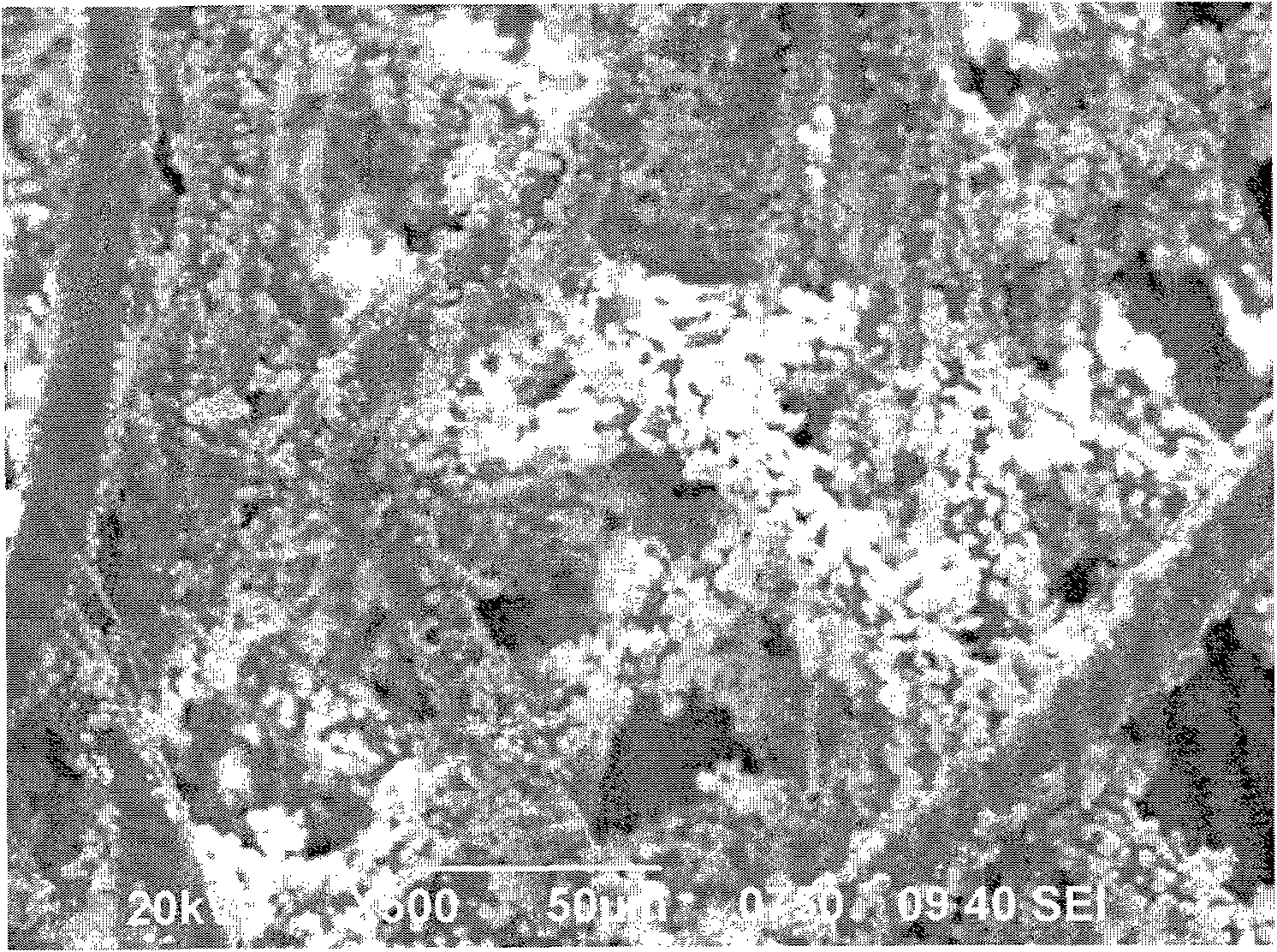

[0016] Dissolve in 2.0M HNO 3 0.12mol / LNH 4 VO 3 and 0.12mol / L Bi(NO 3 ) 3 The solution is used as the mother liquid. After the fiber material is washed and dried with pure water, ethanol, deionized water, etc., it is soaked in the mother liquid, and then a certain amount of urea is added to the mixed solution, and the solution is heated to 60-90°C and kept for 5 ~24 hours, the ammonia produced by the hydrolysis of urea gradually increases the pH value of the solution, thereby making BiVO 4 The crystallization is generated on the fiber material, and then the material is washed and dried to obtain the fiber material loaded nano-BiVO 4 catalyst of light. Its shape and structure are as figure 2 As shown, it can be seen that the diameter of the fiber in the synthesized composite fiber material is about 12-13 μm, and the attached BiVO 4 The particle size is about 1.3-3 μm.

Embodiment approach 2

[0018] Dissolve in 2.0M HNO 3 0.12mol / L NH 4 VO 3 and 0.12mol / L Bi(NO 3 ) 3 The solution is used as the mother liquor. After the fiber material is washed and dried with pure water, ethanol, deionized water, etc., it is immersed in the mother liquor. Crystalline; BiVO 4 Produced on the fiber material, wash and dry it to get BiVO 4 Composite textile fiber materials. Among them, the diameter of the fiber in the composite fiber material is about 12-13 μm, and the attached BiVO 4 The particles are also about 1.3 to 3 μm, but compared with the particles of the sample in Embodiment 1, the surface is smoother.

Embodiment approach 3

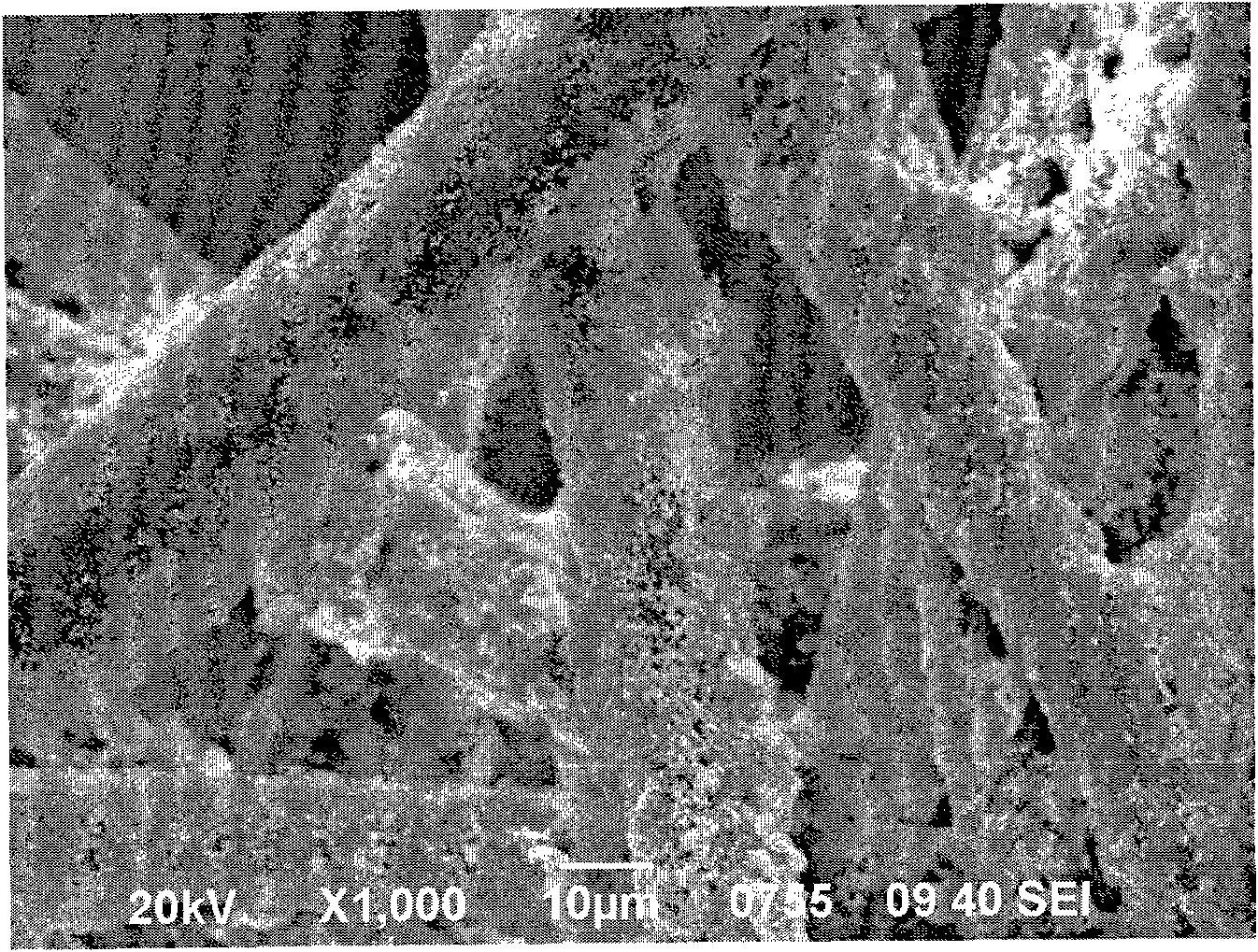

[0020] 0.12mol / L NH dissolved in citric acid 4 VO 3 and 0.12mol / L Bi(NO 3 ) 3 The solution is used as the mother liquor. After the textile fiber material is washed and dried with pure water, ethanol, deionized water, etc., it is immersed in the mother liquor for 8-12 hours, taken out and dried at 30-60°C for 2-8 hours, and then placed in a high-pressure reaction In the kettle, make it hydrothermally crystallized at 100-200°C; BiVO 4 Produced on the fiber material, wash and dry it to get BiVO 4 Composite textile fiber materials. Its shape and structure are as image 3 shown. It can be seen that the fiber size in the obtained fiber composite material is about 12-13 μm, and the attached BiVO4 particles are about 310-690 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com